-

摘要

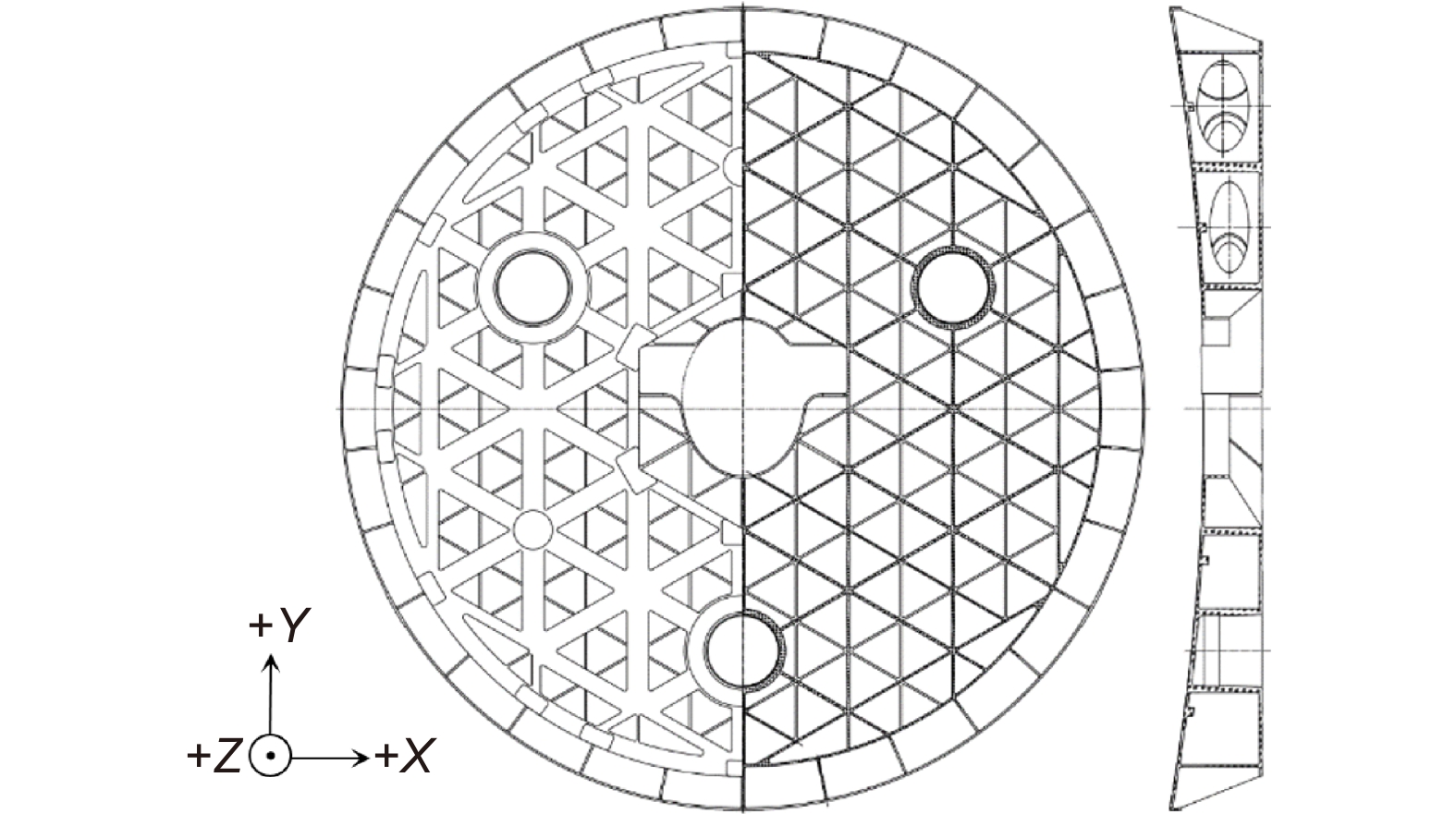

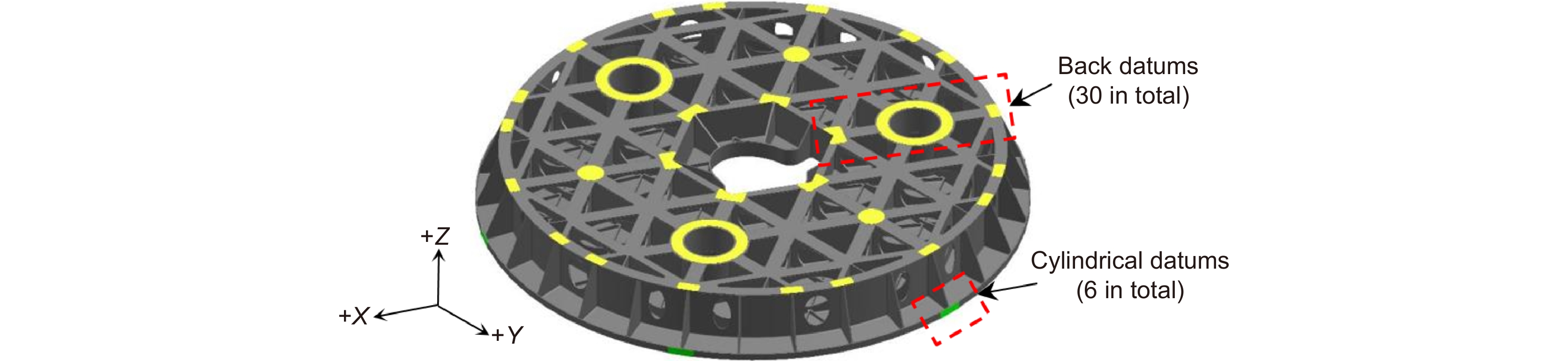

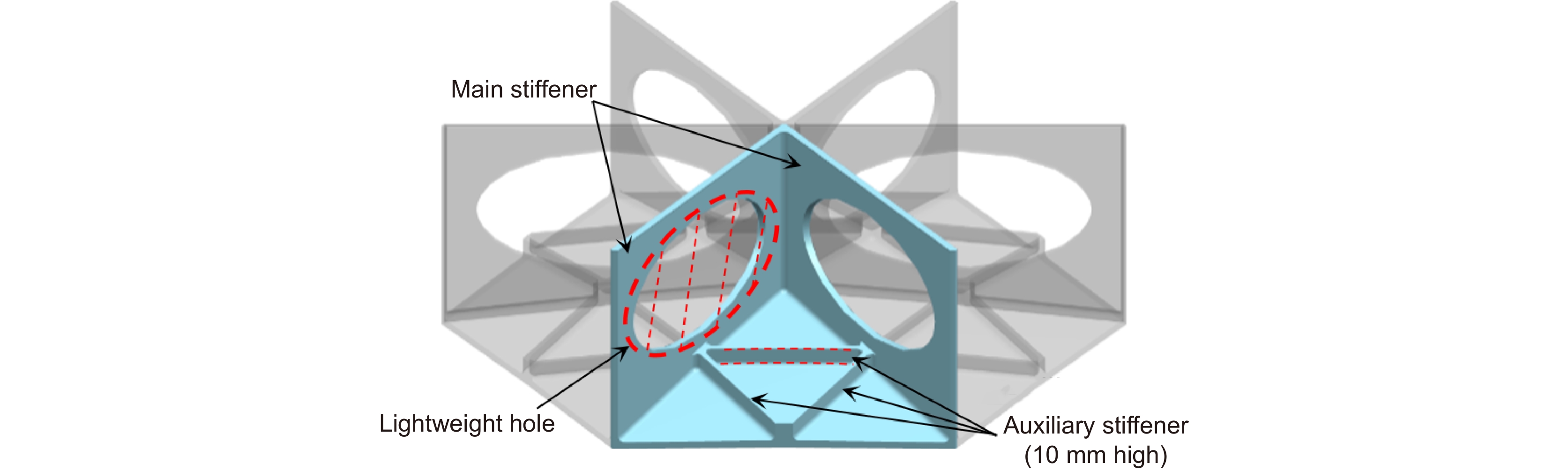

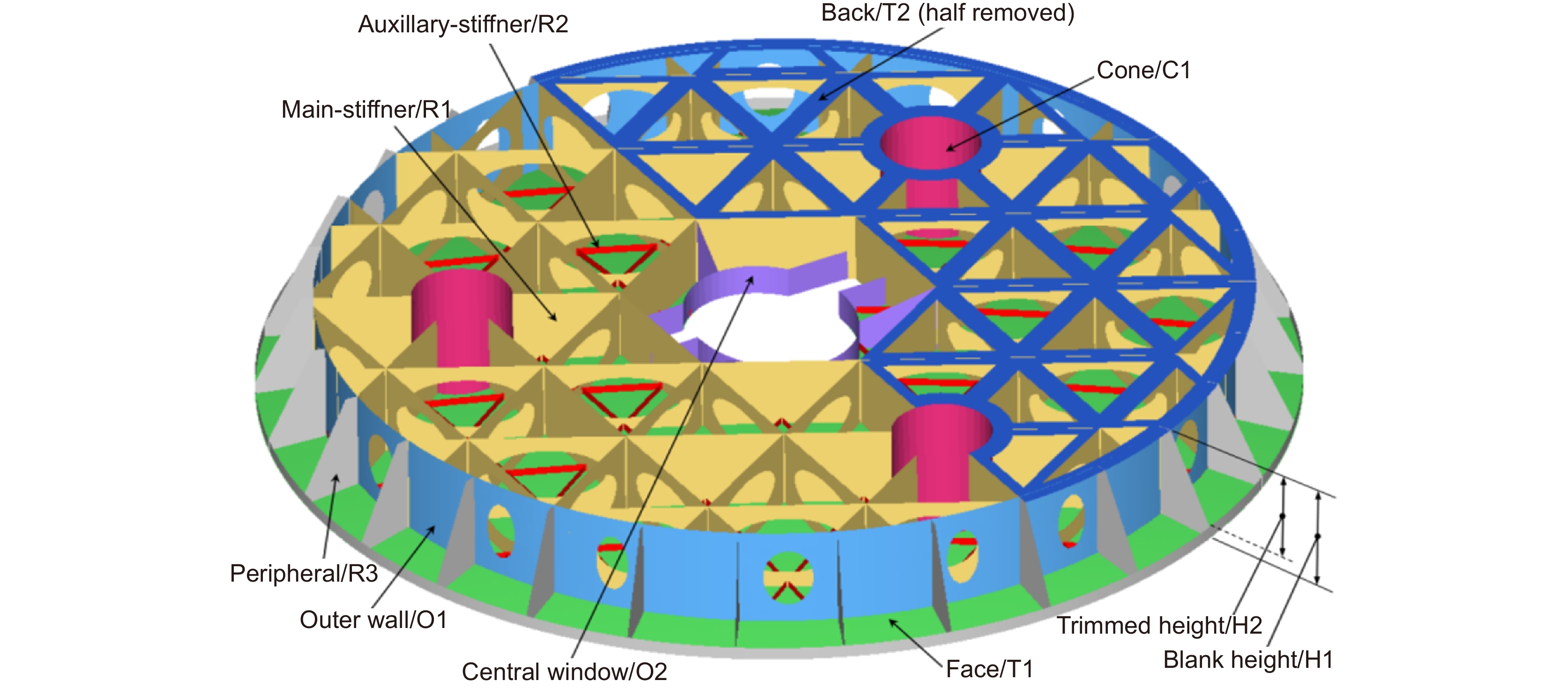

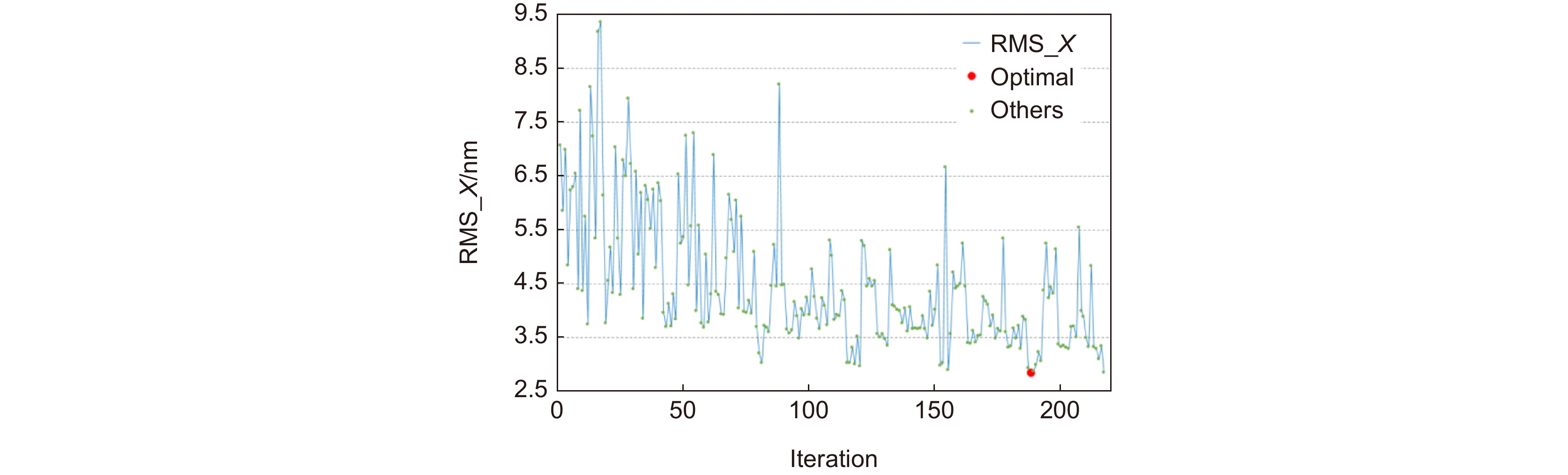

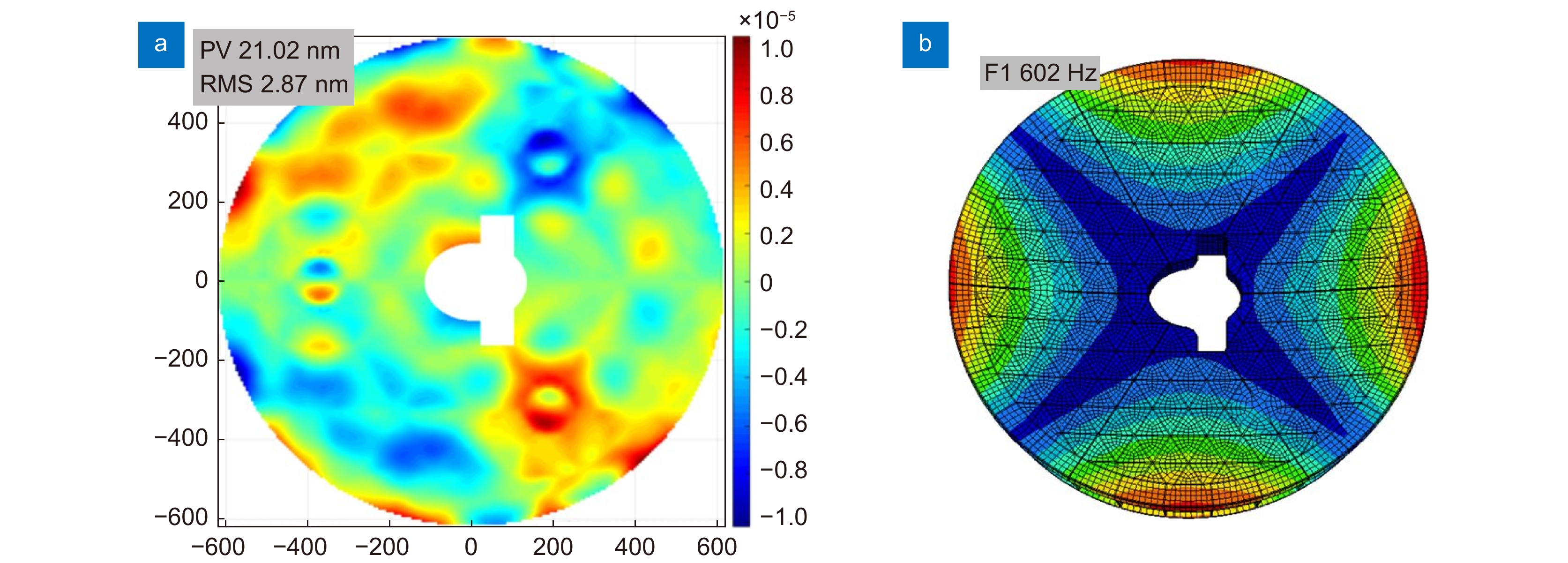

如何进一步提升高性能米级空间反射镜轻量化率是大口径光机结构研制领域内的核心问题之一。本文为某高分辨率空间相机研制了通光口径Φ1200 mm的主反射镜,实现了面密度40 kg/m2的设计目标。碳化硅镜体采用凝胶注模成型及反应烧结工艺制备,将光轴水平状态作为检测状态以简化支撑结构,在半封闭式镜体内使用了主副筋交叉布置、立壁增加减重孔等轻量化手段,用分布式基准面取代传统基准设置,将基准面加工面积减少80%以上、提高了加工效率。通过参数化建模与集成优化,确定了镜体最优结构参数组合,最终镜体设计重量为46.9 kg。光轴水平时主镜自重变形RMS值仅2.87 nm,镜体自由基频为602 Hz,主镜具有良好的动、静力学特性。镜坯经机械加工后实测重量为51.3 kg、超重约9.4%,镜面厚度不均匀性小于1 mm,当前镜面已抛光至面形精度RMS

λ /8λ =632.8 nm),未见印透效应。Abstract

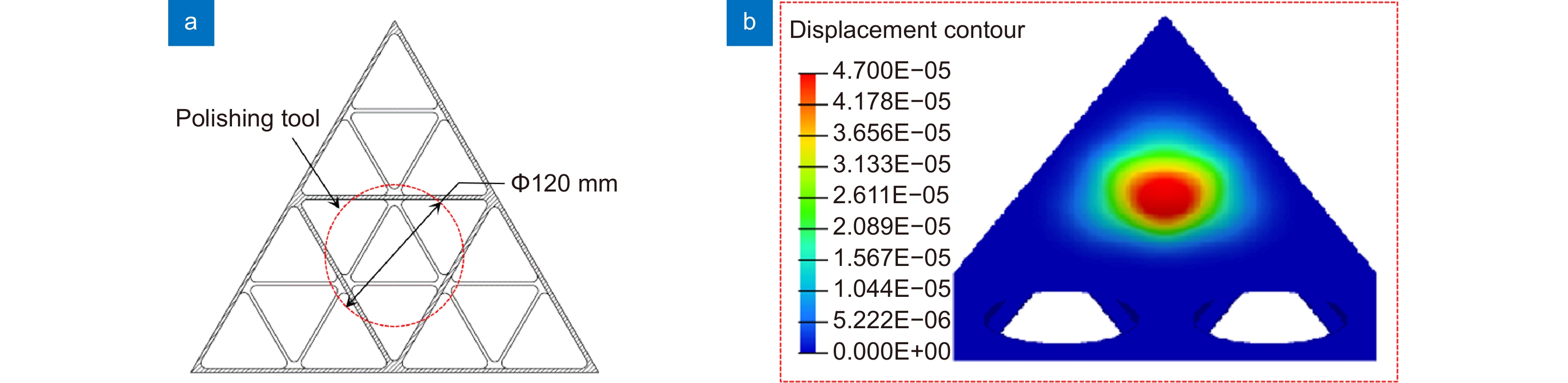

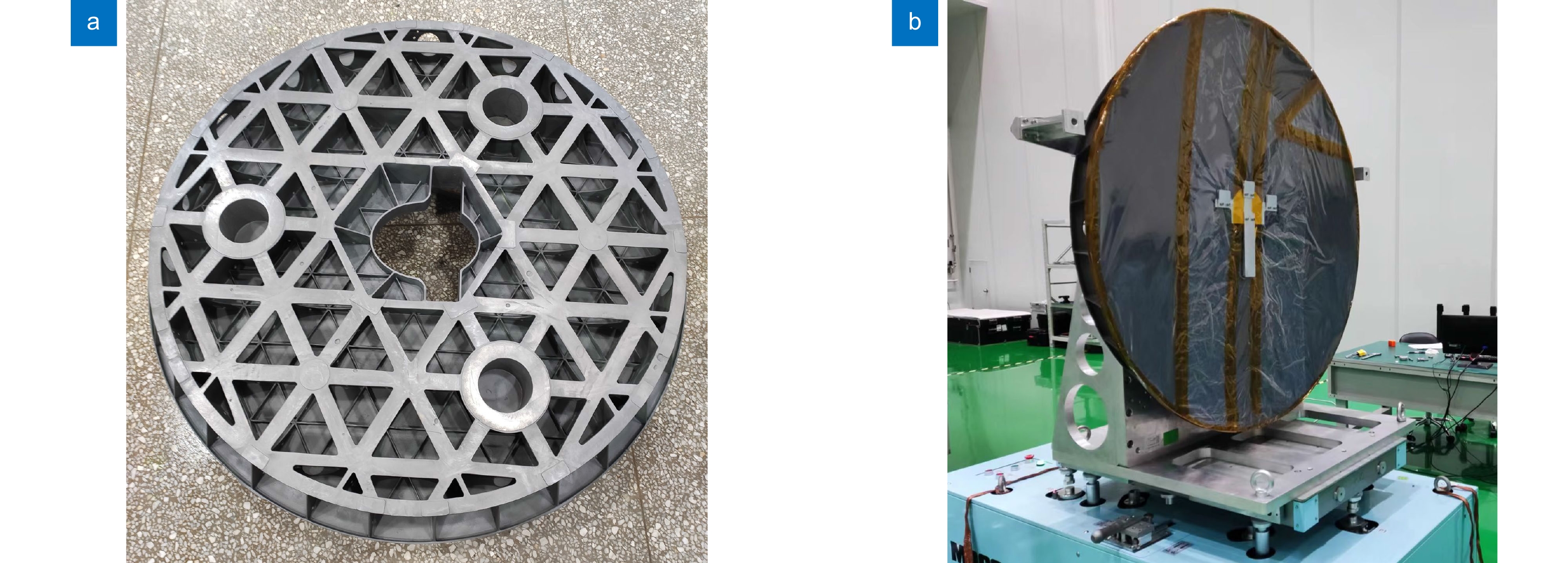

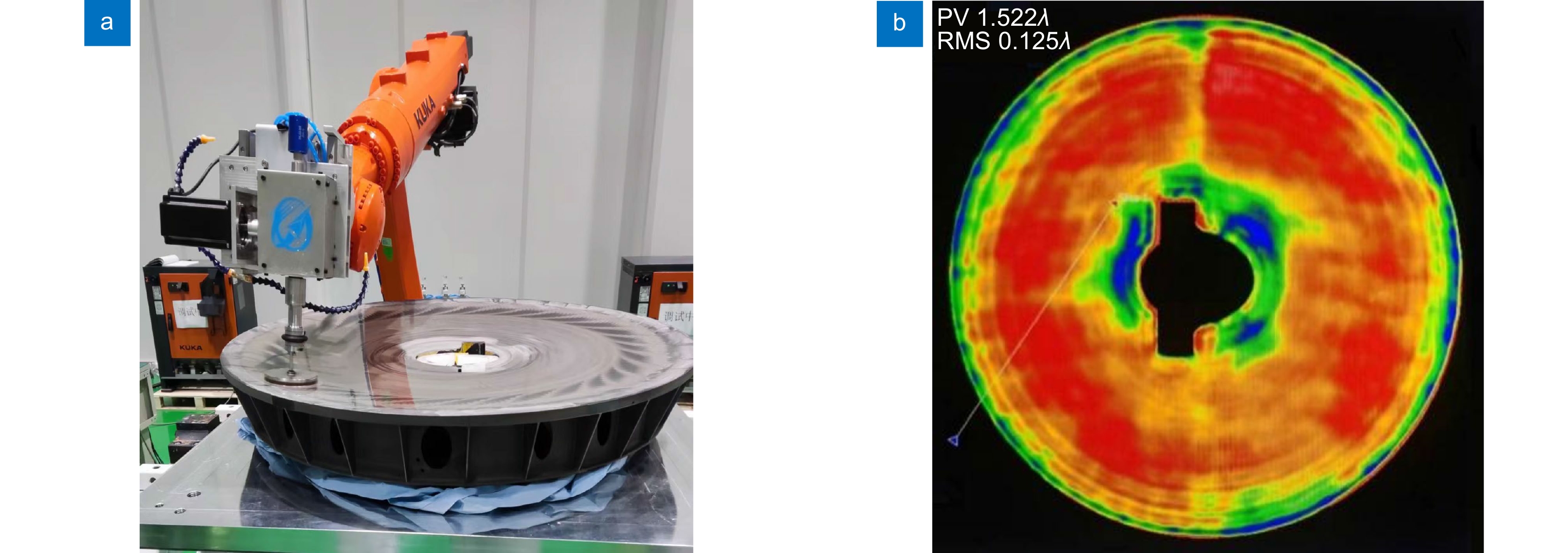

How to further improve the lightweight ratio of high-performance meter-level space mirrors is one of the core issues in the field of large aperture optomechanical structure design. In this paper, a primary mirror with a clear aperture of Φ1200 mm was developed for a high-resolution space camera, which achieves the goal of designing area density below 40 kg/m2. The SiC mirror blank was prepared by gel injection molding and reaction sintering process. The state of the optical axis being horizontal was taken as the testing state to simplify the supporting structure. Novel lightweight measures such as an alternate arrangement of main and auxiliary stiffeners and the addition of lightweight holes on vertical walls were used inside the semi-closed mirror blank. The distributed datums were used to replace traditional datum settings, which reduces the machining area of datums by more than 80% and improves machining efficiency. Through parametric modeling and integrated optimization, the optimal structural parameter combination of the mirror blank was determined, with the final design weight of 46.9 kg. The RMS value of self-weight deformation of the mirror blank is only 2.87 nm under the state of the optical axis being horizontal, and its free fundamental frequency is 602 Hz, indicating that the primary mirror proposed in this paper has good dynamic and static characteristics. After machining, the measured weight of the mirror blank is 51.3 kg, about 9.4% overweight, and the facesheet is about 1-mm thicker than the design. At present, the mirror has already been polished to RMS λ/8 (

λ =632.8 nm) of surface shape accuracy, with no obvious print-through effect observed.-

Key words:

- space optics /

- mirror /

- lightweight /

- large aperture /

- reaction bonded silicon carbide

-

Overview

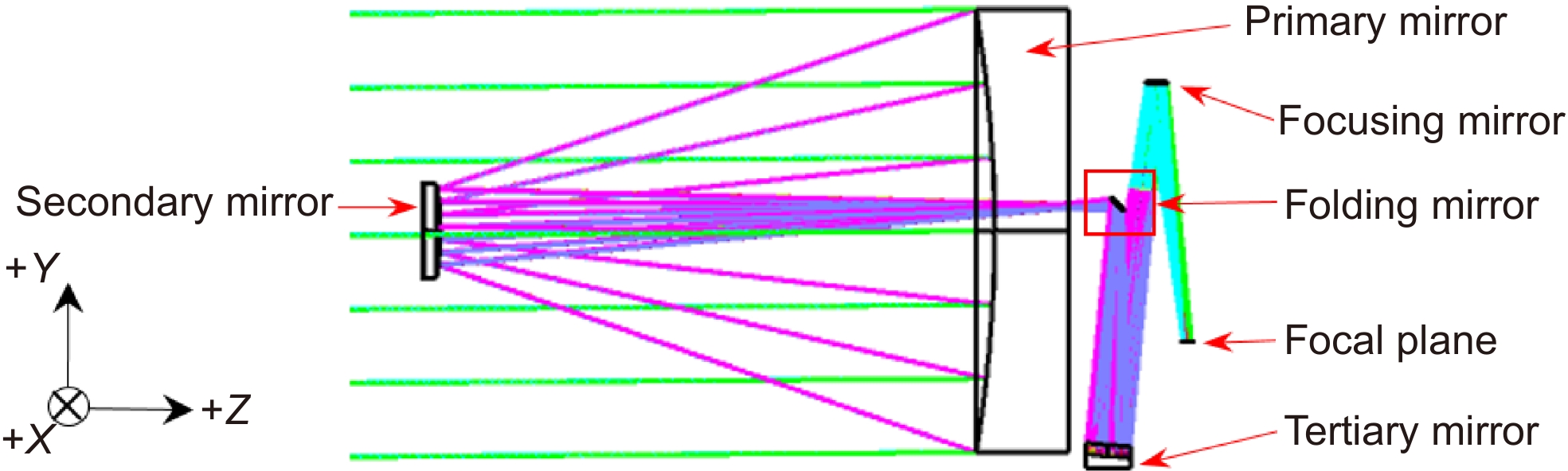

Overview: How to further improve the lightweight ratio of high-performance meter-level space mirrors is one of the core issues in the field of large aperture optomechanical structure design. In this paper, a primary mirror blank with a clear aperture of Φ1200 mm was developed for a high-resolution space camera, which achieves the goal of designing area density below 40 kg/m2. The SiC mirror blank was manufactured by gel injection molding and reaction sintering process, with the classical back three-point support scheme together with the testing state of the optical axis being horizontally adopted to simplify the supporting structure. Novel lightweight measures such as an alternate arrangement of main and auxiliary stiffeners and the addition of lightweight holes to vertical walls were used inside the semi-closed blank, which further improves the lightweight ratio of space mirrors with the sandwich structure. Distributed datums were proposed to replace the traditional datum setting, which reduces the machining area of datums by more than 80% and improves machining efficiency significantly. A robot arm is used for polishing in optical processing, and the local surface deformation is 47 nm in PV value under the typical polishing pressure of 1.77 kPa, with the mirror surface of 4 mm thick and the spacing between stiffener ribs of 81 mm. A parametric model of the mirror blank was built with shell elements, which contains ten variables including stiffener thickness and blank height, and integrated optimization was carried out so as to determine the optimal combination of structural parameters, using the multi-island genetic algorithm. The final design weight of the mirror blank is 46.9 kg, with corresponding area density of 38.8 kg/m2. The RMS value of self-weight deformation of the mirror blank is only 2.87 nm with its optical axis being horizontal, and the free fundamental frequency is 602 Hz, indicating that the mirror blank has good dynamic and static characteristics, which satisfies the design requirements of space cameras. After machining, the measured weight of the mirror blank is 51.3 kg, about 9.4% overweight than the design, and the facesheet is about 1 mm thicker, mainly caused by the inhomogeneity of the molding process. During the centroid position test of the primary mirror blank, the deviation between the measured and theoretical centroid position is about 3.7 mm in the axial direction and 2.0 mm in the radial direction, which can be compensated through adjustment of the supporting structure and has limited influence on the optical performance of mirror assembly. At present, the primary mirror blank has already been polished to RMS λ/8 (λ=632.8 nm) of surface shape accuracy, with no obvious print-through effect observed. The lightweight structure scheme and optimization method of the mirror blank proposed in this paper can provide an important reference for the design of similar space mirrors with the characteristics of large aperture and low areal density.

-

-

表 1 主要大口径空间反射镜材料物理属性

Table 1. Physical properties of main materials for the large aperture mirror

Property RB-SiC Beryllium ULE Zerodur Density ρ/(kg·m−3) 3050 1850 2210 2530 Elastic modulus E/GPa 340 287 67 91 Poisson ratio μ 0.2 0.08 0.17 0.24 Thermal conductivity λ/(W·K−1·m−1) 155 216 1.31 1.64 Thermal expansion coefficient α/(10−6·K−1) 2.50 11.4 0.03 0.05 Specific stiffness E/ρ 111.5 155 30.3 36 Thermal stability λ/α 62 18.9 43.7 32.8 Comprehensive performance (E/ρ)·(λ/α) 6913 2939 1324 1180 表 2 参数取值范围及优化结果(单位:mm)

Table 2. Parameter ranges and optimization results (unit: mm)

No. Parameter Limits Original Optimal Ultimate 1 Face thickness/T1 [4, 8] 6 4.282 4 2 Bottom thickness/T2 [3, 6] 5 4.419 4 3 Cone thickness/C1 [6, 12] 10 8.154 10 4 Main-stiffener thickness/R1 [3, 6] 5 4.143 4 5 Sub-stiffener thickness/R2 [3, 6] 5 3.246 3 6 Outer wall thickness/O1 [3, 6] 5 3.440 3 7 Central window thickness/O2 [3, 6] 5 3.222 3 8 Peripheral thickness/R3 [3, 6] 5 3.203 3 9 Blank height/H1 [125, 150] 130 146.660 142.5 10 Trimmed height/H2 [100, 125] 100 115.325 125 -

参考文献

[1] 张超杰, 习兴华, 王永宪, 等. 空间遥感相机大口径反射镜结构优化设计[J]. 红外与激光工程, 2020, 49(2): 0214002. doi: 10.3788/IRLA202049.0214002

Zhang C J, Xi X H, Wang Y X, et al. Structural optimization design of large-aperture mirror for space remote sensing camera[J]. Infrared Laser Eng, 2020, 49(2): 0214002. doi: 10.3788/IRLA202049.0214002

[2] 张博文, 王小勇, 赵野, 等. 天基大口径反射镜支撑技术的发展[J]. 红外与激光工程, 2018, 47(11): 1113001. doi: 10.3788/IRLA201847.1113001

Zhang B W, Wang X Y, Zhao Y, et al. Progress of support technique of space-based large aperture mirror[J]. Infrared Laser Eng, 2018, 47(11): 1113001. doi: 10.3788/IRLA201847.1113001

[3] 胡瑞, 陈志强, 张媛媛, 等. Ф1.05 m轻量化反射镜设计与制造[J]. 光电工程, 2020, 47(10): 200317. doi: 10.12086/oee.2020.200317

Hu R, Chen Z Q, Zhang Y Y, et al. Design and manufacture of Ф1.05 m lightweight mirror[J]. Opto-Electron Eng, 2020, 47(10): 200317. doi: 10.12086/oee.2020.200317

[4] 袁健, 任建岳. 碳化硅反射镜轻量化结构的改进与优化[J]. 光子学报, 2015, 44(8): 0812004. doi: 10.3788/gzxb20154408.0812004

Yuan J, Ren J Y. Improvement and optimization of lightweight structure for SiC reflective mirror[J]. Acta Photonica Sinica, 2015, 44(8): 0812004. doi: 10.3788/gzxb20154408.0812004

[5] 刘贝. 空间大口径反射镜组件优化设计及可调节支撑技术研究[D]. 西安: 中国科学院大学(中国科学院西安光学精密机械研究所), 2019: 7–14. https://doi.org/10.27605/d.cnki.gkxgs.2019.000061.

Liu B. Research on optimization design for large-aperture mirror assembly and adjustable support technique[D]. Xi’an: Xi’an Institute of Optics & Precision Mechanics, Chinese Academy of Sciences, 2019: 7–14. https://doi.org/10.27605/d.cnki.gkxgs.2019.000061.

[6] Lightsey P A, Atkinson C, Clampin M, et al. James Webb Space Telescope: large deployable cryogenic telescope in space[J]. Opt Eng, 2012, 51(1): 011003. doi: 10.1117/1.OE.51.1.011003

[7] Toulemont Y, Passvogel T, Pilbratt G, et al. The 3, 5m all SiC Telescope for Herschel[J]. Proc SPIE, 2004, 10568: 105682F. doi: 10.1117/12.2500110

[8] Lampton M L, Sholl M J, Krim M H, et al. SNAP Telescope: an update[J]. Proc SPIE, 2004, 5166: 113−123. doi: 10.1117/12.502333

[9] 王克军, 董吉洪, 宣明, 等. 空间遥感器大口径反射镜的复合支撑结构[J]. 光学 精密工程, 2016, 24(7): 1719−1730. doi: 10.3788/OPE.20162407.1719

Wang K J, Dong J H, Xuan M, et al. Compound support structure for large aperture mirror of space remote sensor[J]. Opt Precis Eng, 2016, 24(7): 1719−1730. doi: 10.3788/OPE.20162407.1719

[10] Wang K J, Dong J H, Zhao Y, et al. Research on high performance support technology of space-based large aperture mirror[J]. Optik, 2021, 226: 165929. doi: 10.1016/j.ijleo.2020.165929

[11] 刘岩, 张辉, 刘雷敏, 等. 大尺寸拼接式碳化硅反射镜的研制及环境模拟试验[J]. 光电工程, 2020, 47(8): 200088. doi: 10.12086/oee.2020.200088

Liu Y, Zhang H, Liu L M, et al. Preparation and environmental simulation tests of large-size silicon carbide brazed reflection mirrors[J]. Opto-Electron Eng, 2020, 47(8): 200088. doi: 10.12086/oee.2020.200088

[12] 王克军, 董吉洪. 空间遥感器Ф2 m量级大口径SiC反射镜镜坯结构设计[J]. 红外与激光工程, 2017, 46(7): 0718005. doi: 10.3788/IRLA201746.0718005

Wang K J, Dong J H. Structural design of Ф2m-level large-diameter SiC reflector used in space remote sensor[J]. Infrared Laser Eng, 2017, 46(7): 0718005. doi: 10.3788/IRLA201746.0718005

[13] 郭疆, 朱磊, 赵继, 等. 大口径空间反射镜大容差支撑结构设计与优化[J]. 光学 精密工程, 2019, 27(5): 1138−1147. doi: 10.3788/OPE.20192705.1138

Guo J, Zhu L, Zhao J, et al. Design and optimize of high tolerance support structure for large aperture space mirror[J]. Opt Precis Eng, 2019, 27(5): 1138−1147. doi: 10.3788/OPE.20192705.1138

[14] 李劲东. 卫星遥感技术(上册)[M]. 北京: 北京理工大学出版社, 2018: 77–79.

Li J D. Satellite Remote Sensing Technology[M]. Beijing: Beijing Institute of Technology Press, 2018: 77–79.

[15] 王升, 丛杉珊, 薛志鹏, 等. 一体式碳纤维次镜支撑结构设计[J]. 光学学报, 2022, 42(5): 0522001. doi: 10.3788/AOS202242.0522001

Wang S, Cong S S, Xue Z P, et al. Design of integrated carbon fiber secondary mirror supporting structure[J]. Acta Opt Sin, 2022, 42(5): 0522001. doi: 10.3788/AOS202242.0522001

[16] 张景贤, 江东亮, 林庆玲, 等. 通过凝胶注模成型和无压烧结制备碳化硅陶瓷[J]. 硅酸盐学报, 2012, 40(8): 1154−1157. doi: 10.14062/j.issn.0454-5648.2012.08.016

Zhang J X, Jiang D L, Lin Q L, et al. Preparation of silicon carbide ceramics by aqueous gelcasting and pressureless sintering[J]. J Chin Ceram Soc, 2012, 40(8): 1154−1157. doi: 10.14062/j.issn.0454-5648.2012.08.016

[17] 杨金华, 刘虎, 焦春荣, 等. 层压成型工艺制备近净成型反应烧结碳化硅材料的研究[J]. 中国陶瓷, 2018, 54(4): 57−61. doi: 10.16521/j.cnki.issn.1001-9642.2018.04.011

Yang J H, Liu H, Jiao C R, et al. Research on reaction-bonded silicon carbide with near-net-shape prepared by lamination process[J]. China Ceram, 2018, 54(4): 57−61. doi: 10.16521/j.cnki.issn.1001-9642.2018.04.011

[18] 保罗•约德尔. 光机系统设计[M]. 周海宪, 程云芳, 译. 3版. 北京: 机械工业出版社, 2008: 471–474.

Yoder Jr P R. Opto-Mechanical Systems Design[M]. Zhou H X, Cheng Y F, trans. 3rd ed. Beijing: China Machine Press, 2008: 471–474.

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: