-

摘要:

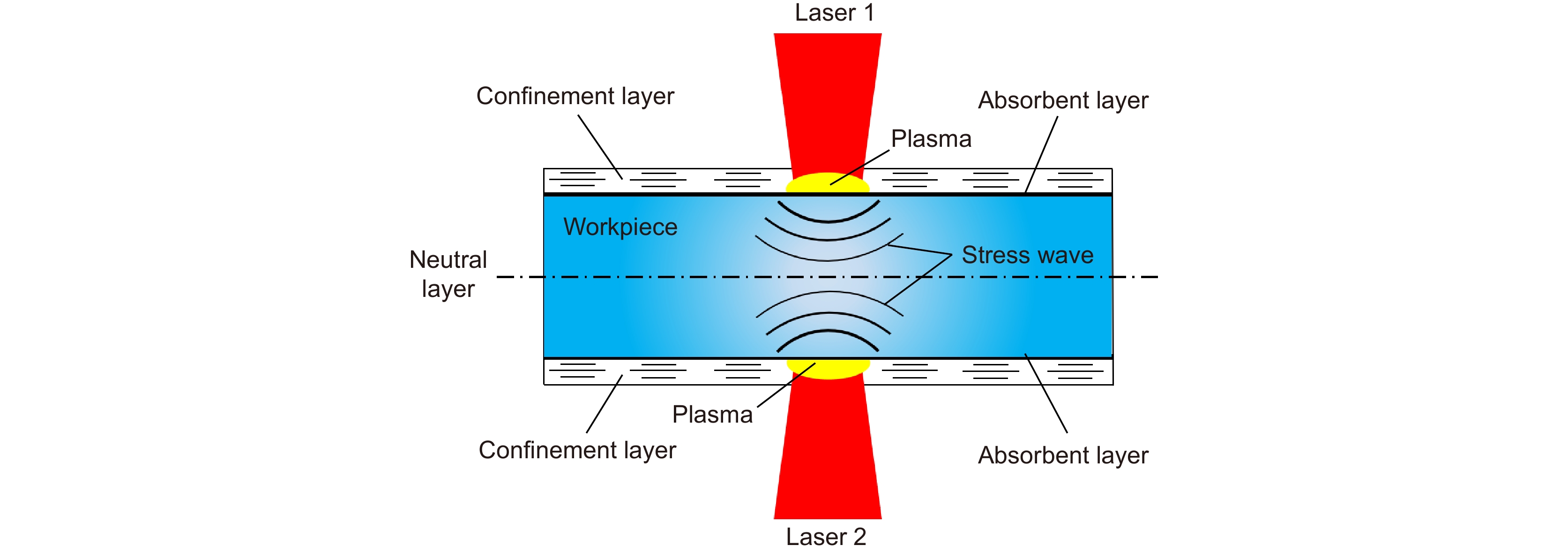

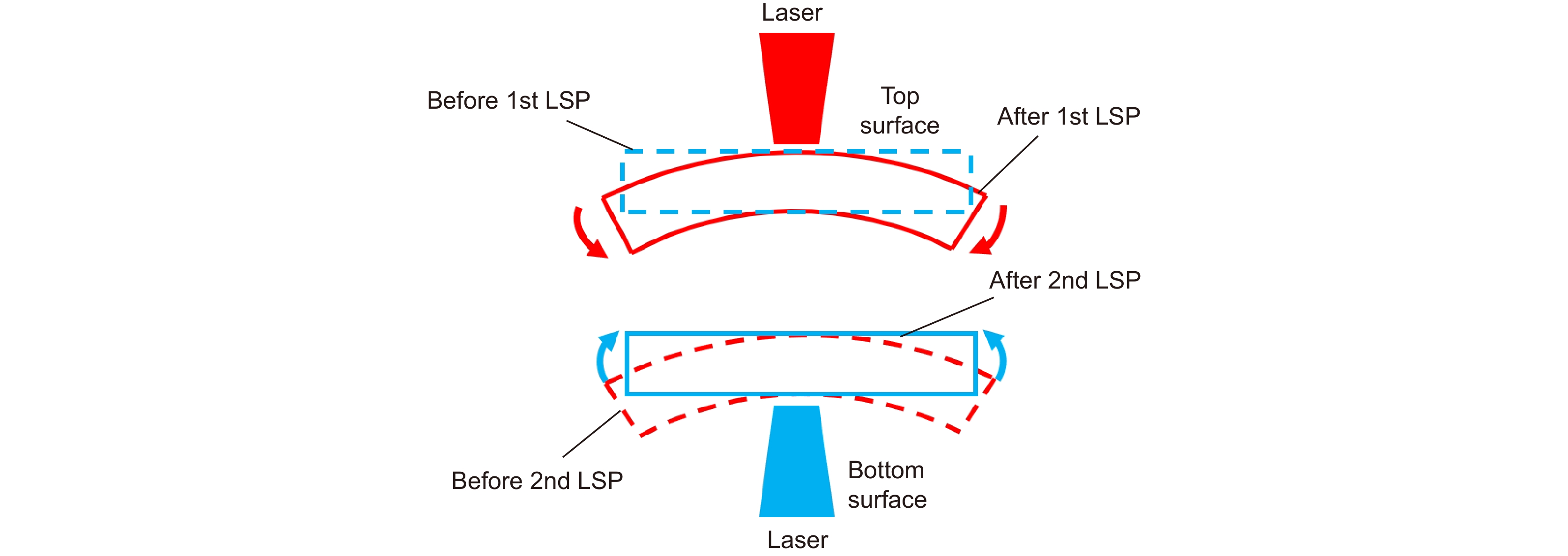

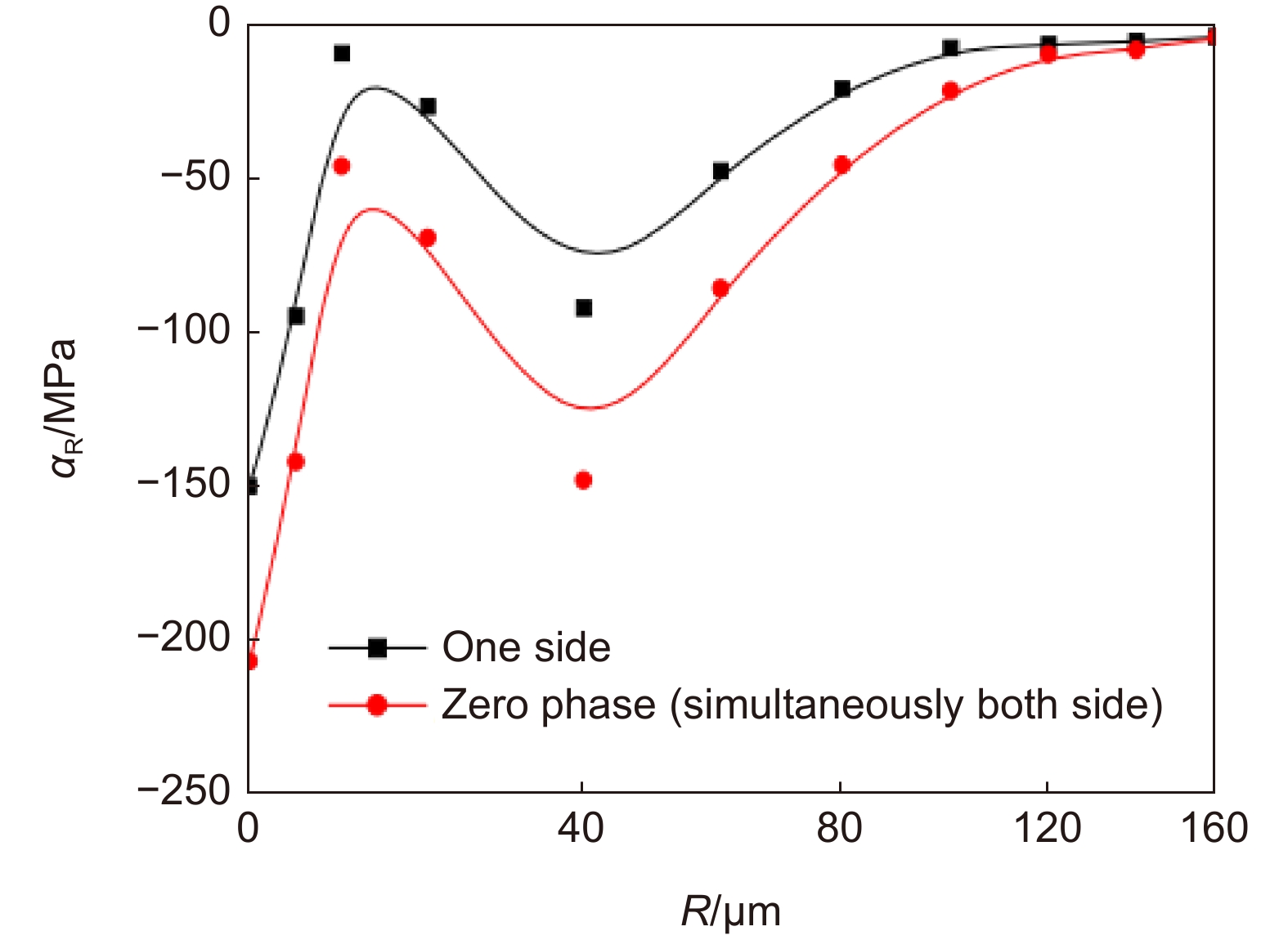

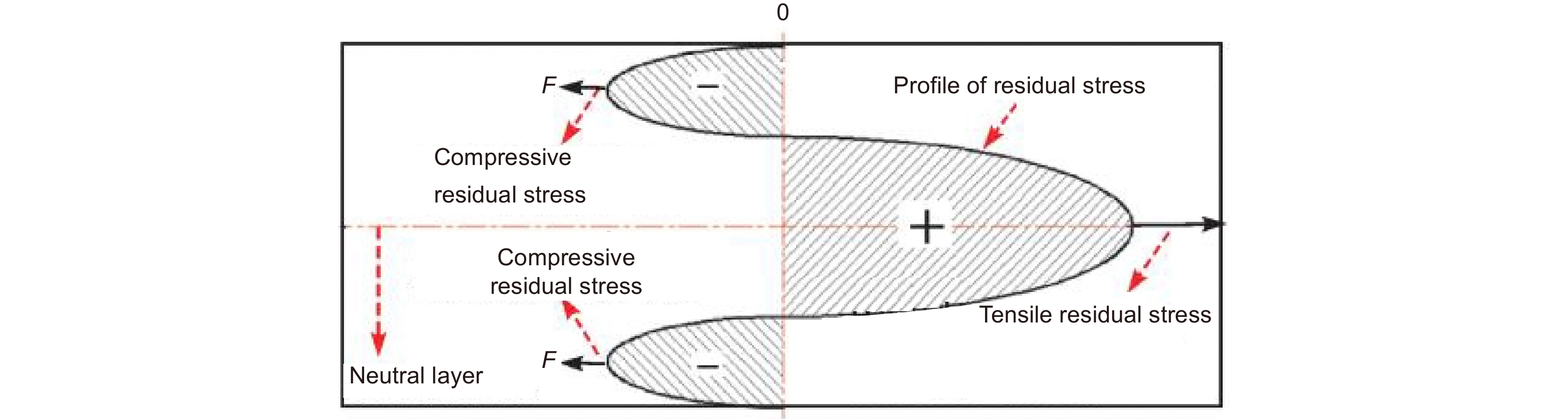

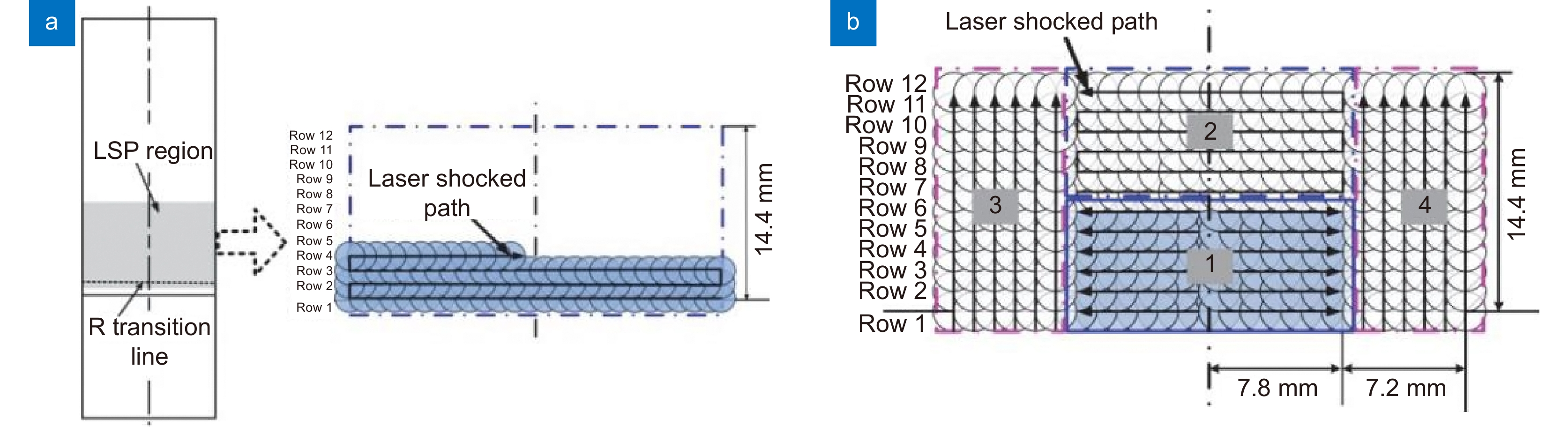

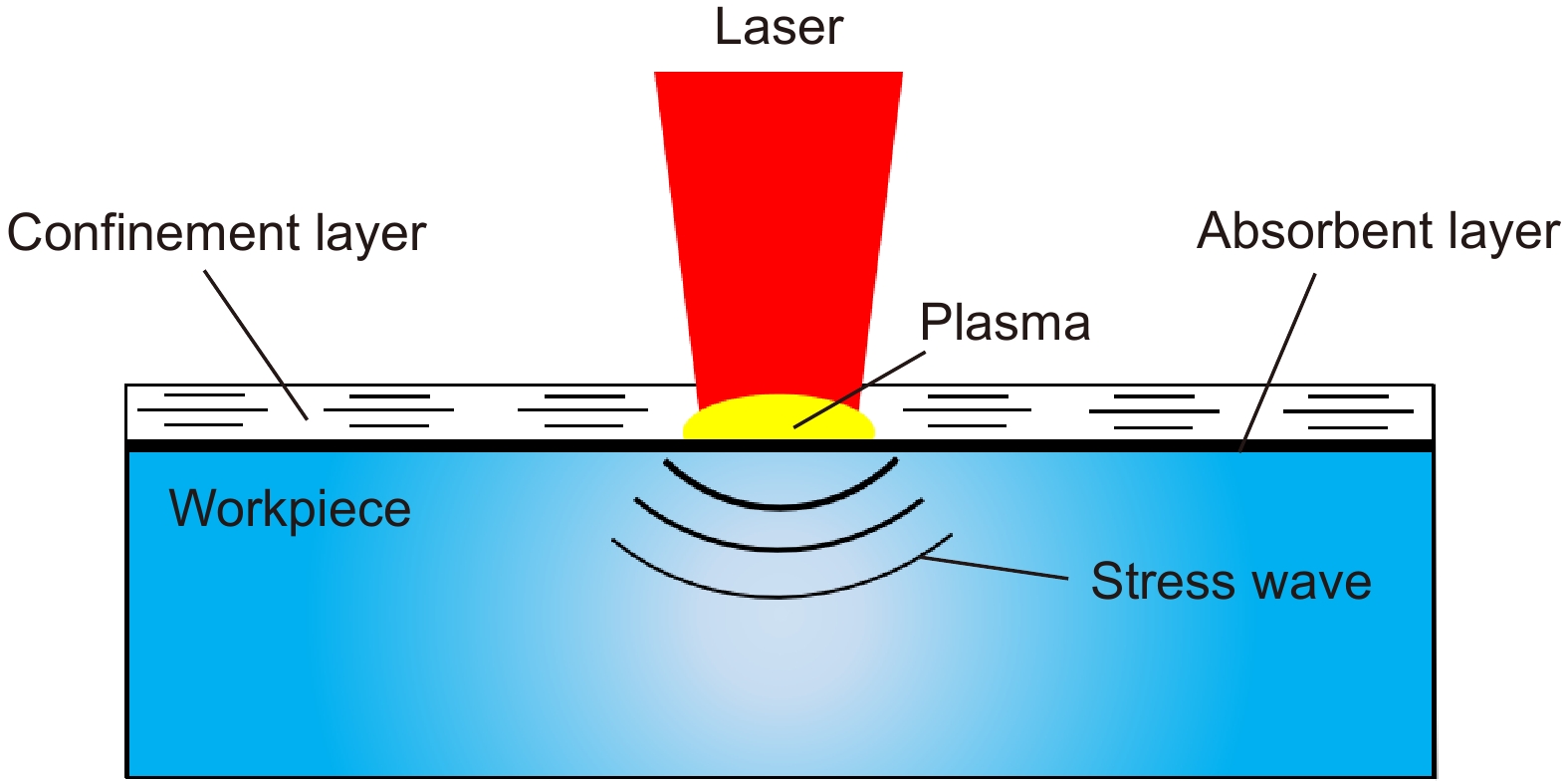

激光冲击强化利用激光的力效应进行表面强化,传统的激光冲击强化技术为单面冲击,强化复杂型面薄壁件时,难以同时实现形状控制(控形)和疲劳性能控制(控性)。新型的双面激光冲击强化技术是解决复杂型面薄壁件表面强化难题的理想选择。介绍了两种双面激光冲击强化技术的原理和技术特点,对双面激光冲击强化的应力波传播、应力场分布等过程进行了分析,介绍了双面激光冲击强化在控形和控性方面的应用,并对双面激光冲击强化未来的发展进行了展望。

Abstract:Laser shock peening uses the force effect of the laser to strengthen the surface. The traditional laser shock peening technology is a single-sided shock. When applied to thin-walled parts with complex profiles, it is difficult to achieve shape control and fatigue performance control coordination. The new double-sided laser shock peening technology is ideal for solving the surface strengthening challenges of thin-walled parts with complex profiles. On the basis of introducing the characteristics and deficiencies of single-sided laser shock peening technology, the principle and technical characteristics of two double-sided laser shock peening technologies are summarized. The application of simulation research in analyzing the physical mechanism of stress wave propagation and stress field distribution of double-sided laser shock peening is expounded. The mechanism and application of double-sided laser shock peening in the application of shape control and fatigue performance control are introduced, and the future development of double-sided laser shock peening is prospected.

-

-

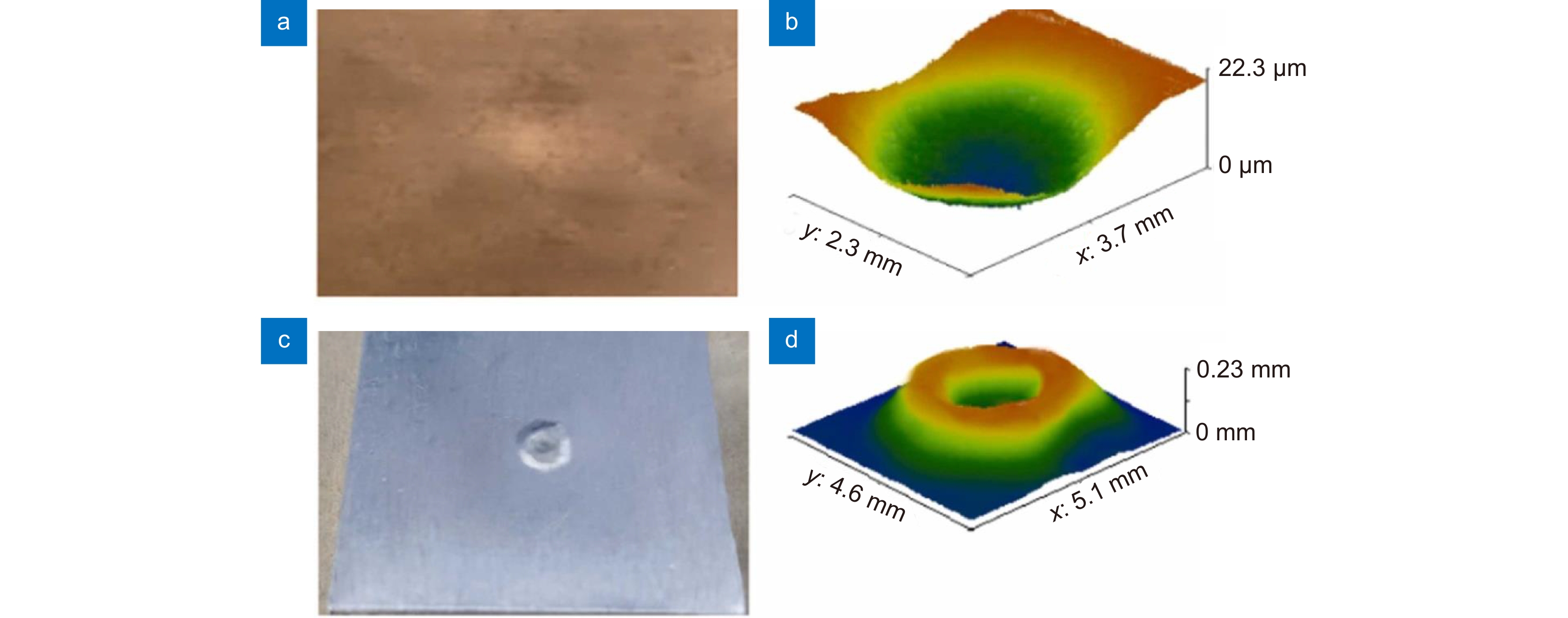

图 5 工件和吸收层形貌[29]。(a) 工件表面形貌;(b) 工件3D形貌;(c) 吸收层表面形貌;(d) 吸收层3D形貌

Figure 5. The topography of the workpiece and the absorption film[29]. (a) The surface morphology of the workpiece; (b) 3D morphology of the workpiece; (c) Surface morphology of the absorption layer; (d) 3D morphology of the absorption layer

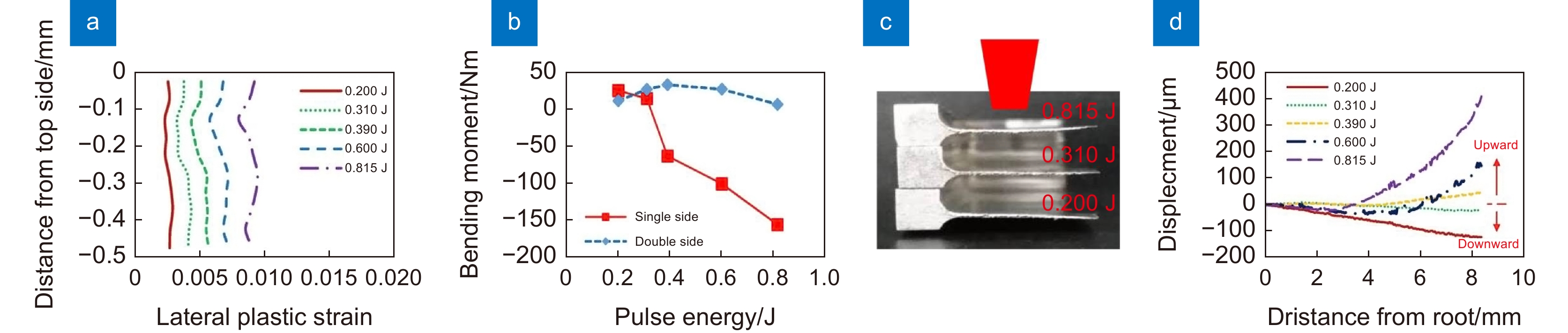

图 10 双面异步激光冲击强化钛合金薄壁件[22]。(a) 厚度方向横向塑性应变分布;(b) 不同能量下单面冲击和双面冲击的等效弯矩;(c) 冲击强化后的零件;(d) 轮廓曲线图

Figure 10. Titanium alloy sheet subject to DNLSP[22]. (a) Transverse plastic strain distribution in the thickness direction; (b) Equivalent bending moment of SLSP and DLSP under different energy; (c) Parts after laser shock peening; (d) Contour graph

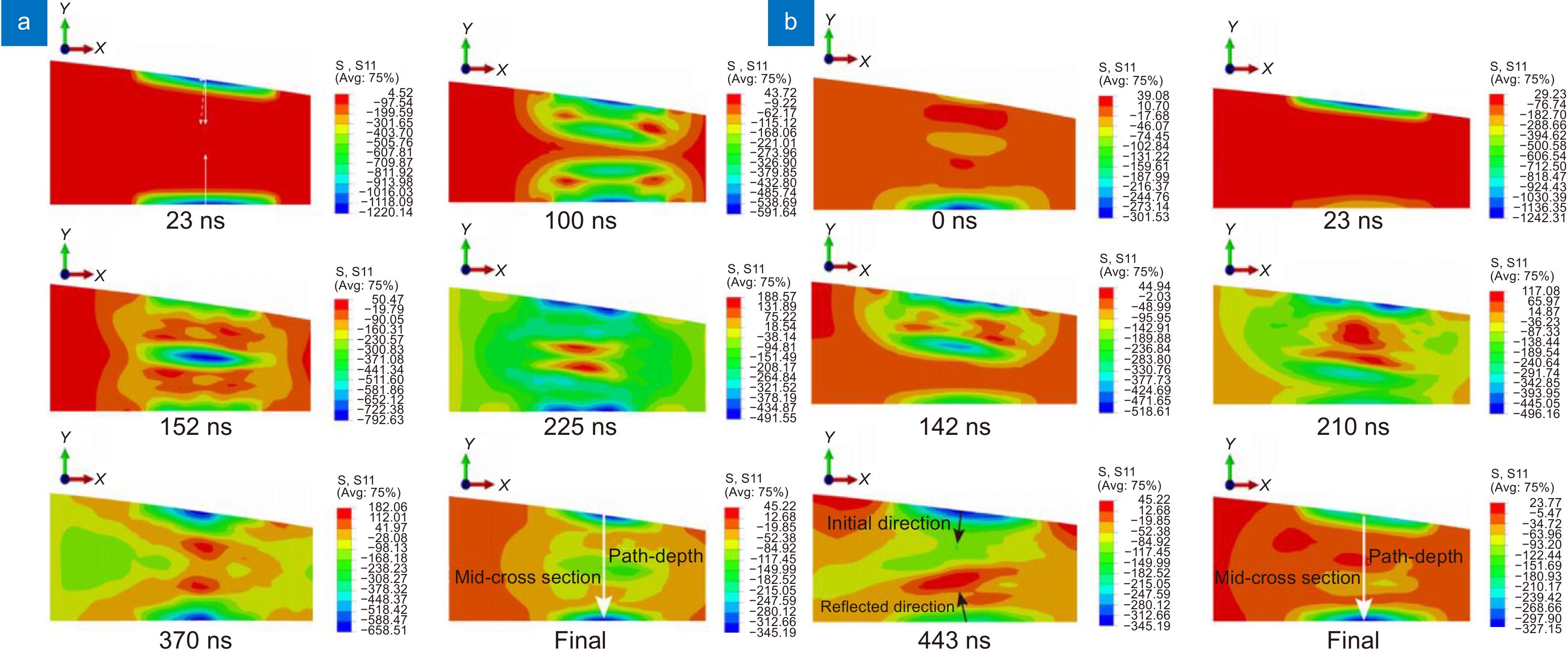

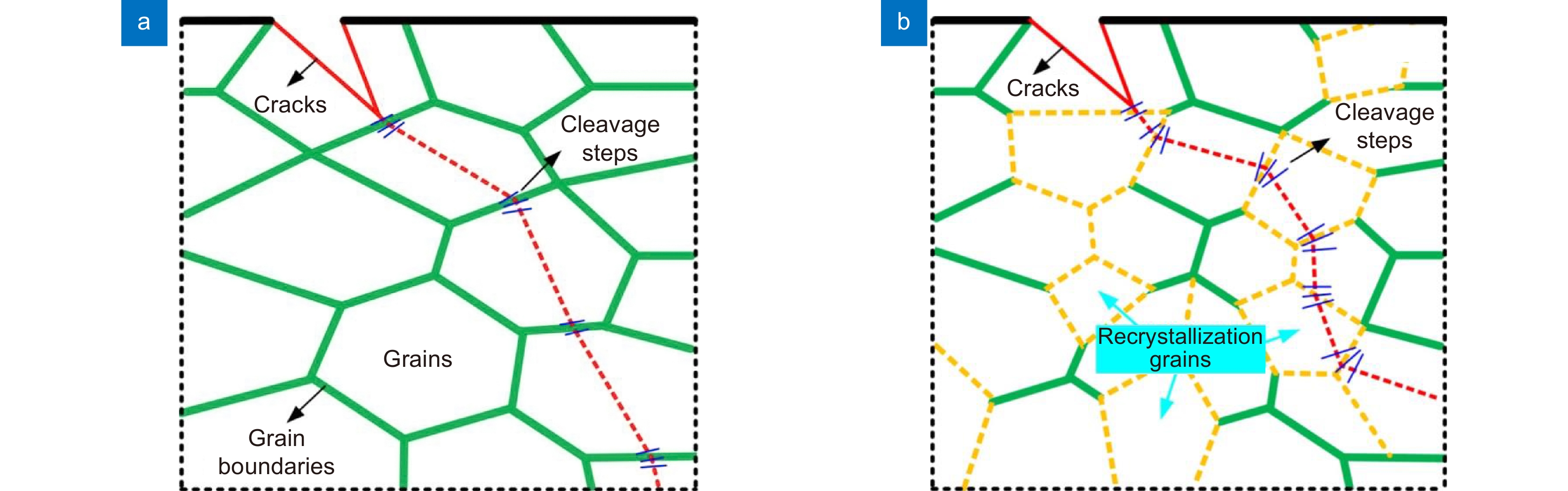

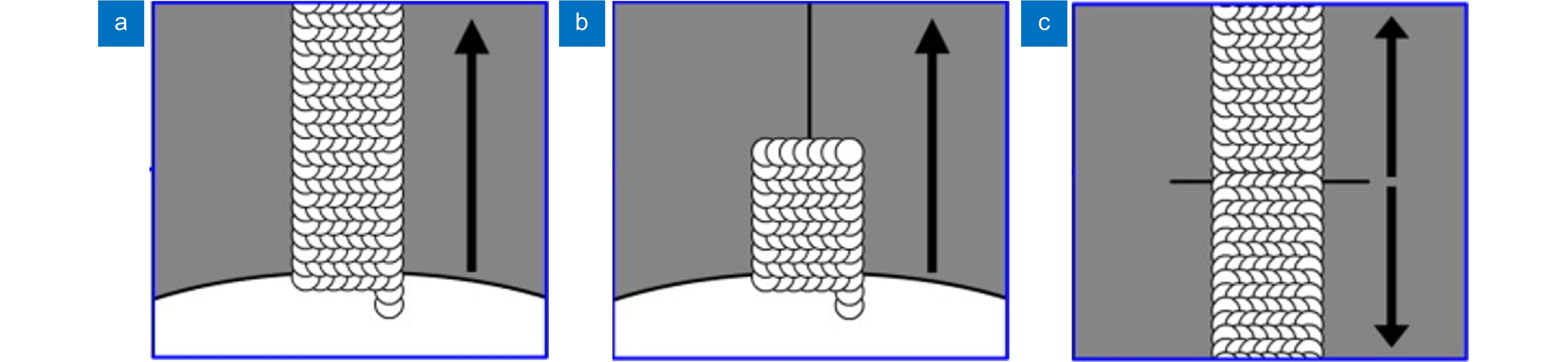

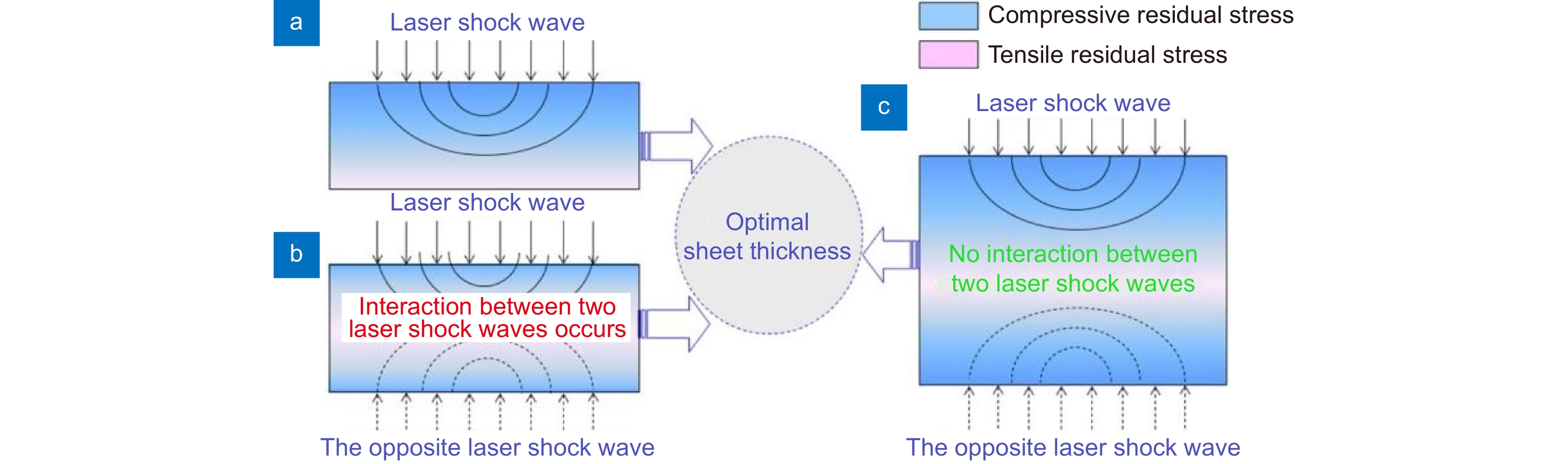

图 19 Mg-Al-Mn合金在DSLSP下的冲击波相互作用[49]。(a) 单面激光冲击强化影响;(b) 薄板双面同步激光冲击强化;(c)薄板双面异步激光冲击强化。

Figure 19. Schematic illustrations of laser shock wave interaction on Mg-Al-Mn alloy sheet subjected to DSLSP[49]. (a) One-sided LSP impacts; (b) Two-sided and simultaneous LSP impacts for the thin sheet; (c) Two-sided and simultaneous LSP impacts for the thin sheet

表 1 双面激光冲击强化技术对比总结

Table 1. Comparison and summary of DSLSP

DNLSP DSLSP 技术原理 双光束上下入射 双光束同步入射 优点 控性强化 控形强化 缺点 冲击低刚度件产生大变形或断裂 中性层附近可能存在高幅值残余拉应力或层裂 物理机制 诱导近似对称分布的塑性应变 诱导完全对称分布的塑性应变 应用领域 一定刚度的薄壁件 低刚度的薄壁件 表 2 冲击方式和厚度对应力波传播和应力场分布的影响

Table 2. Effects of impact mode and thickness on stress wave propagation and stress field distribution

双面同步冲击 双面异步冲击 薄壁件 (应力波相互作用强) (应力波无相互作用) CRS-TRS-CRS-TRS-CRS对称分布 CRS-TRS-CRS非对称分布 厚壁件 (应力波相互作用弱) (应力波无相互作用) CRS-TRS-0-TRS-CRS对称分布 CRS-TRS-0-TRS-CRS对称分布 CRS: compressive residual stress; TRS: tensile residual stresses; 0: no residual stress 表 3 不同扫描路径下单面、双面同步和双面异步冲击下强化件的最大变形

Table 3. Maximum deformation of the model in single-sided, double-sided simultaneous (DSLSP) and double-sided non-simultaneous(DNLSP) shock under different scan paths

扫描路径1/mm 扫描路径2/mm 扫描路径3/mm 单面 −1.091 −1.070 −1.098 双面同步 −0.00409 −0.00415 −0.00427 双面异步 −0.1164 −0.1327 −0.1122 -

[1] 吴嘉俊, 赵吉宾, 乔红超, 等. 激光冲击强化技术的应用现状与发展[J]. 光电工程, 2018, 45(2): 170690. doi: 10.12086/oee.2018.170690

Wu J J, Zhao J B, Qiao H C, et al. The application status and development of laser shock processing[J]. Opto-Electron Eng, 2018, 45(2): 170690. doi: 10.12086/oee.2018.170690

[2] 朱有利, 王燕礼, 边飞龙, 等. 金属材料超声表面强化技术的研究与应用进展[J]. 机械工程学报, 2014, 50(20): 35−45. doi: 10.3901/JME.2014.20.035

Zhu Y L, Wang Y L, Bian F L, et al. Progresses on research and application of metal ultrasonic surface enhancement technologies[J]. J Mech Eng, 2014, 50(20): 35−45. doi: 10.3901/JME.2014.20.035

[3] 丛家慧, 王磊. 超声喷丸表面强化技术的研究现状与应用进展[J]. 机械工程材料, 2019, 43(5): 1−5. doi: 10.11973/jxgccl201905001

Cong J H, Wang L. Research status and application progress of ultrasonic shot peening surface strengthening technology[J]. Mater Mech Eng, 2019, 43(5): 1−5. doi: 10.11973/jxgccl201905001

[4] Tang C B, Liu D X, Tang B, et al. Influence of plasma molybdenizing and shot-peening on fretting damage behavior of titanium alloy[J]. Appl Surf Sci, 2016, 390: 946−958. doi: 10.1016/j.apsusc.2016.08.146

[5] 黄潇, 曹子文, 常明, 等. 激光冲击强化对TC4钛合金单面修饰激光焊接接头疲劳性能的影响[J]. 中国机械工程, 2018, 29(1): 104−109. doi: 10.3969/j.issn.1004-132X.2018.01.016

Huang X, Cao Z W, Chang M, et al. Effects of laser shock processing on fatigue performances of TC4 titanium alloy single-side laser modification welding joints[J]. China Mech Eng, 2018, 29(1): 104−109. doi: 10.3969/j.issn.1004-132X.2018.01.016

[6] Li J, Feng A X, Zhou J Z, et al. Enhancement of fatigue properties of 2024-T351 aluminum alloy processed by cryogenic laser peening[J]. Vacuum, 2019, 164: 41−45. doi: 10.1016/j.vacuum.2019.02.030

[7] Siddaiah A, Mao B, Kasar A K, et al. Influence of laser shock peening on the surface energy and tribocorrosion properties of an AZ31B Mg alloy[J]. Wear, 2020, 462–463: 203490. doi: 10.1016/j.wear.2020.203490

[8] King A, Evans A D, Preuss M, et, al. Study of residual stresses introduced by laser shock peening in wide chord fan blades by neutron and synchrotron diffraction[J]. J Neutron Res, 2004, 12(1–3): 207−211. doi: 10.1080/10238160410001734694

[9] Mannava S R, Risbeck J D, Jacobs L G. Distortion control for laser shock peened gas turbine engine compressor blade edges: US5531570A[P]. 1996-07-02

[10] Ding K. FEM simulation of two sided laser shock peening of thin sections of Ti-6Al-4V alloy[J]. Surf Eng, 2003, 19(2): 127−133. doi: 10.1179/026708403225002568

[11] Fang Y W, Li Y H, He W F, et al. Effects of laser shock processing with different parameters and ways on residual stresses fields of a TC4 alloy blade[J]. Mater Sci Eng A, 2013, 559: 683−692. doi: 10.1016/j.msea.2012.09.009

[12] Ren X D, Yang X Q, Zhou W F, et al. Thermal stability of surface nano-crystallization layer in AZ91D magnesium alloy induced by laser shock peening[J]. Surf Coat Technol, 2018, 334: 182−188. doi: 10.1016/j.surfcoat.2017.09.037

[13] Wu J J, Zhao J B, Qiao H C, et al. Evaluating methods for quality of laser shock processing[J]. Optik, 2020, 200: 162940. doi: 10.1016/j.ijleo.2019.162940

[14] Peyre P, Fabbro R, Merrien P, et al. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour[J]. Mater Sci Eng A, 1996, 210(1–2): 102–113. doi: 10.1016/0921-5093(95)10084-9.

[15] Peyre P, Berthe L, Fabbro R, et al. Corrosion reactivity of laser-peened steel surfaces[J]. J Mater Eng Perform, 2000, 9(6): 656−662. doi: 10.1361/105994900770345520

[16] Sánchez-Santana U, Rubio-González C, Gomez-Rosas G, et al. Wear and friction of 6061-T6 aluminum alloy treated by laser shock processing[J]. Wear, 2006, 260(7–8): 847–854. doi: 10.1016/j.wear.2005.04.014.

[17] Hu Y X, Xu X X, Yao Z Q, et al. Laser peen forming induced two way bending of thin sheet metals and its mechanisms[J]. J Appl Phys, 2010, 108(7): 073117. doi: 10.1063/1.3486218

[18] Graham M E, Jackson J D. Dual laser shock peening: 6479790[P]. 2002-11-12.

[19] Mannava S, Wright III P K, Azad F H, et al. Single sided laser shock peening: 6559415[P]. 2003-05-06.

[20] Ge M Z, Xiang J Y, Yang L, et al. Effect of laser shock peening on the stress corrosion cracking of AZ31B magnesium alloy in a simulated body fluid[J]. Surf Coat Technol, 2017, 310: 157−165. doi: 10.1016/j.surfcoat.2016.12.093

[21] Luo M S, Hu Y X, Hu L, et al. Efficient process planning of laser peen forming for complex shaping with distributed Eigen-moment[J]. J Mater Process Technol, 2020, 279: 116588. doi: 10.1016/j.jmatprotec.2020.116588

[22] Hu Y X, Yang R Y, Wang D Y, et al. Geometry distortion and residual stress of alternate double-sided laser peening of thin section component[J]. J Mater Process Technol, 2018, 251: 197−204. doi: 10.1016/j.jmatprotec.2017.08.033

[23] Ivetic G. Three-dimensional FEM analysis of laser shock peening of aluminium alloy 2024-T351 thin sheets[J]. Surf Eng, 2011, 27(6): 445−453. doi: 10.1179/026708409X12490360425846

[24] Hu Y X, Xie Y F, Wu D, et al. Quantitative evaluation of specimen geometry effect on bending deformation of laser peen forming[J]. Int J Mech Sci, 2019, 150: 404−410. doi: 10.1016/j.ijmecsci.2018.10.040

[25] Braisted W, Brockman R. Finite element simulation of laser shock peening[J]. Int J Fatigue, 1999, 21(7): 719−724. doi: 10.1016/S0142-1123(99)00035-3

[26] Fan Y J, Wang Y N, Vukelic S, et al. Numerical Investigation of opposing dual sided micro scale laser shock peening[J]. J Manuf Sci Eng, 2007, 129(2): 256−264. doi: 10.1115/1.2540771

[27] Zhang X Q, Li H, Duan S W, et al. Modeling of residual stress field induced in Ti-6Al-4V alloy plate by two sided laser shock processing[J]. Surf Coat Technol, 2015, 280: 163−173. doi: 10.1016/j.surfcoat.2015.09.004

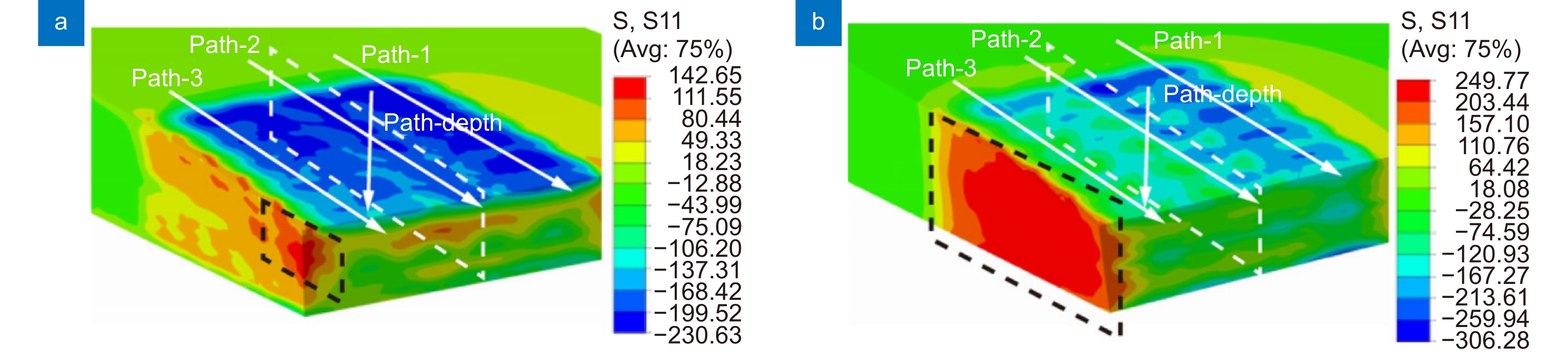

[28] Ouyang P X, He L J, Li P J, et al. Effect of dual-sided laser peening modes on residual stress distribution of aero-engine titanium blades[M]//Han Y F. Advances in Materials Processing. Singapore: Springer, 2017: 29–45. https://doi.org/10.1007/978-981-13-0107-0_4.

[29] Zhang X Q, Chen T, Zhang Y, et al. Investigation on failure mechanism of the absorption film subjected to double-sided laser shock processing[J]. Optik, 2022, 251: 168363. doi: 10.1016/j.ijleo.2021.168363

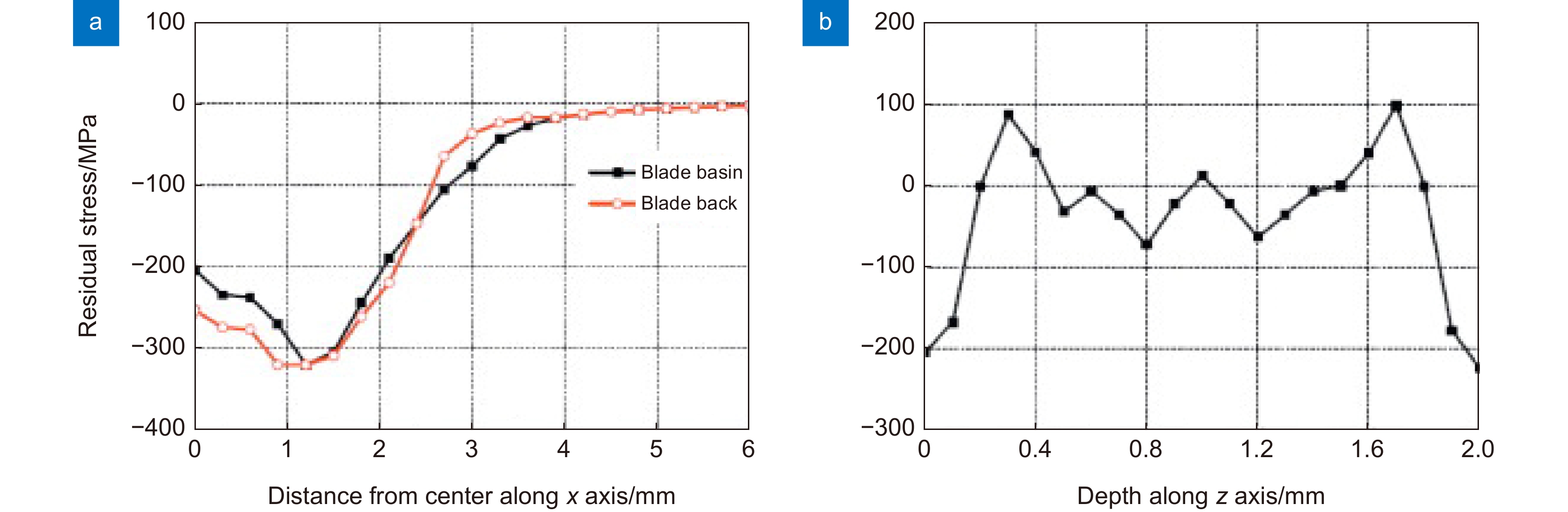

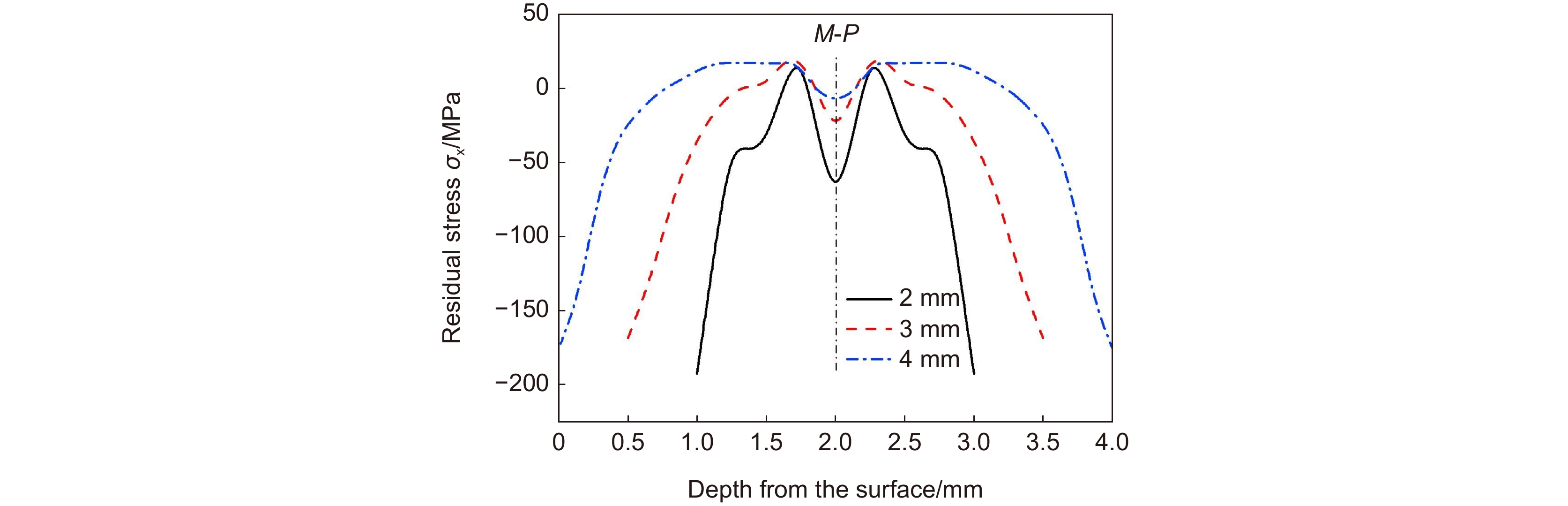

[30] Xiang Y F, Mei R L, Zhao L Z, et al. Effects of processing parameters on residual stress fields of 2024-T351 alloy blade subjected to massive double-sided laser peening treatment[J]. J Laser Appl, 2022, 34(2): 022015. doi: 10.2351/7.0000672

[31] Nam T. Finite element analysis of residual stress field induced by laser shock peening[D]. Columbus: The Ohio State University, 2002.

[32] Ayeb M, Frija M, Fathallah R. Influence of multiple laser impacts on thin leading edges of turbine blade[J]. Proc Inst Mech Eng L J Mater Des Appl, 2020, 234(1): 130−143. doi: 10.1177/1464420719873936

[33] Ling X, Peng W W, Ma G. Influence of laser peening parameters on residual stress field of 304 stainless steel[J]. J Pressure Vessel Technol, 2008, 130(2): 1030−1036. doi: 10.1115/1.2891914

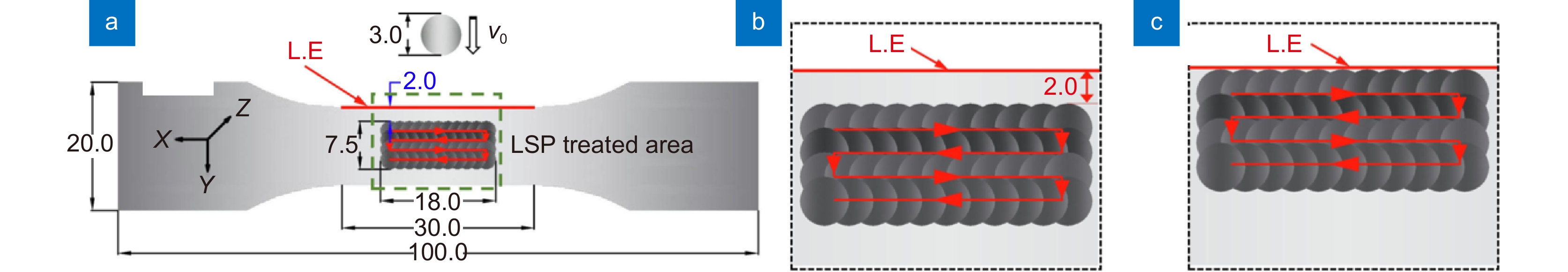

[34] Correa C, De Lara L R, Díaz M, et al. Effect of advancing direction on fatigue life of 316L stainless steel specimens treated by double-sided laser shock peening[J]. Int J Fatigue, 2015, 79: 1−9. doi: 10.1016/j.ijfatigue.2015.04.018

[35] Zhao M H, Duan C H, Li J Y, et al. Deformation and residual stress characteristics of TC17 alloy subjected to laser shock peening with single and double sides[J]. IOP Conf Ser Mater Sci Eng, 2019, 493: 012001. doi: 10.1088/1757-899X/493/1/012001

[36] Trdan U, Skarba M, Grum J. Laser shock peening effect on the dislocation transitions and grain refinement of Al-Mg-Si alloy[J]. Mater Charact, 2014, 97: 57−68. doi: 10.1016/j.matchar.2014.08.020

[37] Chen L, Ren X D, Zhou W F, et al. Evolution of microstructure and grain refinement mechanism of pure nickel induced by laser shock peening[J]. Mater Sci Eng A, 2018, 728: 20−29. doi: 10.1016/j.msea.2018.04.105

[38] Meng X K, Wang H, Tan W S, et al. Gradient microstructure and vibration fatigue properties of 2024-T351 aluminium alloy treated by laser shock peening[J]. Surf Coat Technol, 2020, 391: 125698. doi: 10.1016/j.surfcoat.2020.125698

[39] Pantelakis S G, Petroyiannis P V, Bouzakis K D, et al. Surface hardness increase of 2024 aluminum alloy subjected to cyclic loading[J]. Theor Appl Fract Mech, 2007, 48(1): 68−81. doi: 10.1016/j.tafmec.2007.04.002

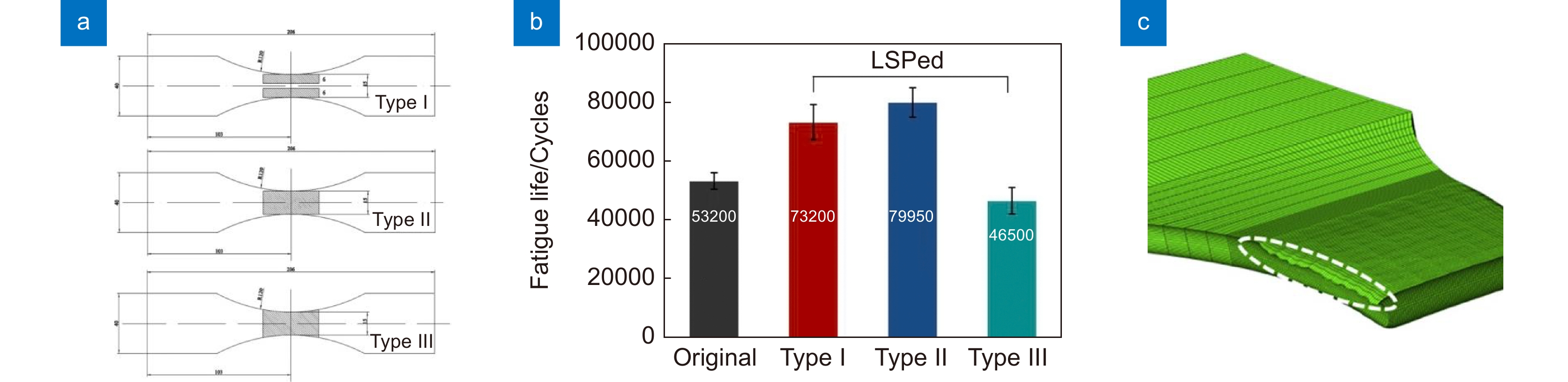

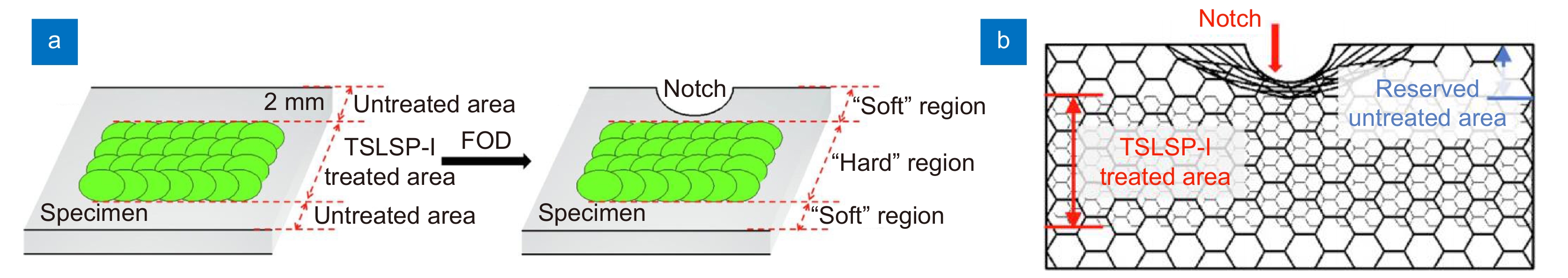

[40] Ren X D, Chen B Q, Jiao J F, et al. Fatigue behavior of double-sided laser shock peened Ti-6Al-4V thin blade subjected to foreign object damage[J]. Opt Laser Technol, 2020, 121: 105784. doi: 10.1016/j.optlastec.2019.105784

[41] Zhang L, Lu J Z, Zhang Y K, et al. Effects of processing parameters on fatigue properties of LY2 Al alloy subjected to laser shock processing[J]. Chin Opt Lett, 2011, 9(6): 061406. doi: 10.3788/COL201109.061406

[42] Bhamare S, Ramakrishnan G, Mannava S R, et al. Simulation-based optimization of laser shock peening process for improved bending fatigue life of Ti-6Al-2Sn-4Zr-2Mo alloy[J]. Surf Coat Technol, 2013, 232: 464−474. doi: 10.1016/j.surfcoat.2013.06.003

[43] Nie X, Li Y, He W, et al. Optimization and fracture mechanism analysis of TC17 titanium alloy simulated-blade with two-sided laser shock processing[M]//Ye L. Recent Advances in Structural Integrity Analysis-Proceedings of the International Congress. Amsterdam: Elsevier, 2014: 2–6. https://doi.org/10.1533/9780081002254.2.

[44] 王长雨, 罗开玉, 鲁金忠. 双面激光喷丸条件下冲击前进方向对AM50镁合金试样残余应力场的影响[J]. 中国激光, 2016, 43(3): 0303002. doi: 10.3788/CJL201643.0303002

Wang C Y, Luo K Y, Lu J Z. Effect of advancing direction on residual stress fields of AM50 Mg alloy specimens treated by double-sided laser shock peening[J]. Chin J Lasers, 2016, 43(3): 0303002. doi: 10.3788/CJL201643.0303002

[45] Zhang L, Lu J Z, Zhang Y K, et al. Effects of different shocked paths on fatigue property of 7050-T7451 aluminum alloy during two-sided laser shock processing[J]. Mater Des, 2011, 32(2): 480−486. doi: 10.1016/j.matdes.2010.08.039

[46] Correa C, Ruiz de Lara L, Díaz M, et al. Influence of pulse sequence and edge material effect on fatigue life of Al2024-T351 specimens treated by laser shock processing[J]. Int J Fatigue, 2015, 70: 196−204. doi: 10.1016/j.ijfatigue.2014.09.015

[47] Sun R J, Che Z G, Cao Z W, et al. Fatigue behavior of Ti-17 titanium alloy subjected to different laser shock peened regions and its microstructural response[J]. Surf Coat Technol, 2020, 383: 125284. doi: 10.1016/j.surfcoat.2019.125284

[48] Yang Y, Zhou W F, Chen B Q, et al. Fatigue behaviors of foreign object damaged Ti-6Al-4V alloys under laser shock peening[J]. Int J Fatigue, 2020, 136: 105596. doi: 10.1016/j.ijfatigue.2020.105596

[49] Luo K Y, Liu B, Wu L J, et al. Tensile properties, residual stress distribution and grain arrangement as a function of sheet thickness of Mg-Al-Mn alloy subjected to two-sided and simultaneous LSP impacts[J]. Appl Surf Sci, 2016, 369: 366−376. doi: 10.1016/j.apsusc.2016.02.045

[50] Correa C, Peral D, Porro J A, et al. Random-type scanning patterns in laser shock peening without absorbing coating in 2024-T351 Al alloy: a solution to reduce residual stress anisotropy[J]. Opt Laser Technol, 2015, 73: 179−187. doi: 10.1016/j.optlastec.2015.04.027

[51] Jiménez C A V, Rosas G G, González C R, et al. Effect of laser shock processing on fatigue life of 2205 duplex stainless steel notched specimens[J]. Opt Laser Technol, 2017, 97: 308−315. doi: 10.1016/j.optlastec.2017.07.020

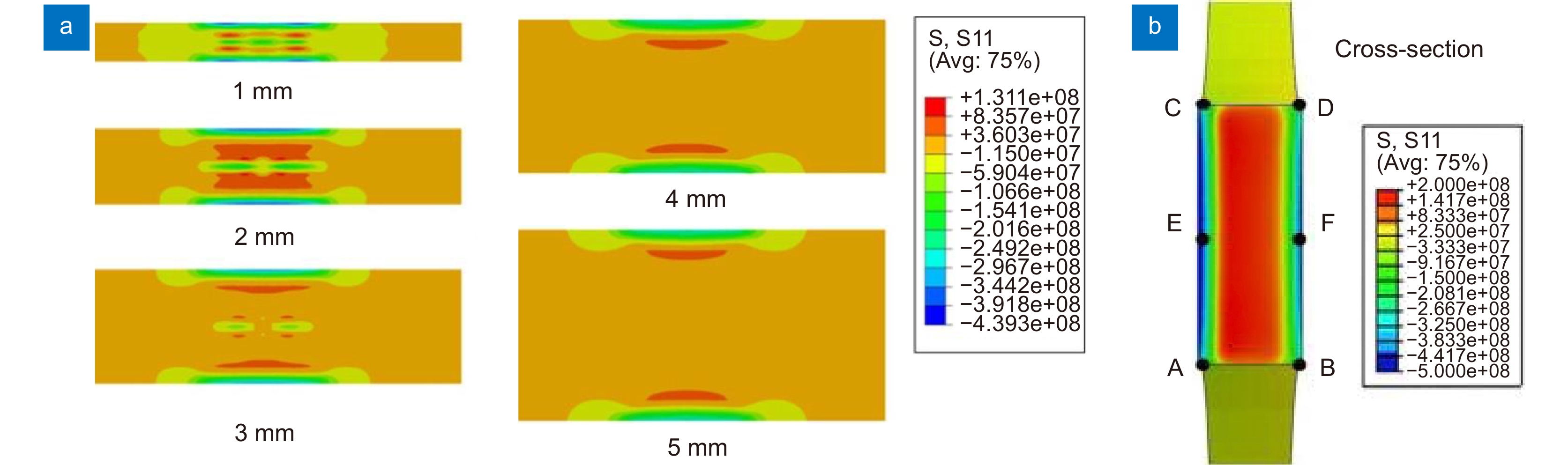

[52] Zhang X Q, Huang Z W, Chen B, et al. Investigation on residual stress distribution in thin plate subjected to two sided laser shock processing[J]. Opt Laser Technol, 2019, 111: 146−155. doi: 10.1016/j.optlastec.2018.09.035

[53] 罗开玉, 陈起, 吕刺, 等. 双面激光同时冲击AM50镁合金板料的厚度分析[J]. 中国激光, 2014, 41(1): 0103003. doi: 10.3788/cjl201441.0103003

Luo K Y, Chen Q, Lv C, et al. Thickness analysis of two-sided simultaneous laser shock processing on AM50 Mg alloy[J]. Chin J Lasers, 2014, 41(1): 0103003. doi: 10.3788/cjl201441.0103003

[54] Zhang Z F, Qin R, Li G, et al. Deep learning-based monitoring of surface residual stress and efficient sensing of AE for laser shock peening[J]. J Mater Process Technol, 2022, 303: 117515. doi: 10.1016/j.jmatprotec.2022.117515

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: