-

摘要

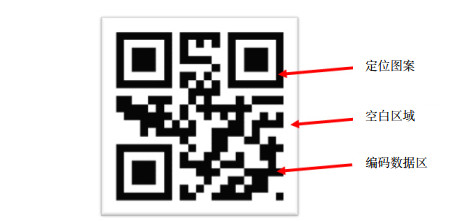

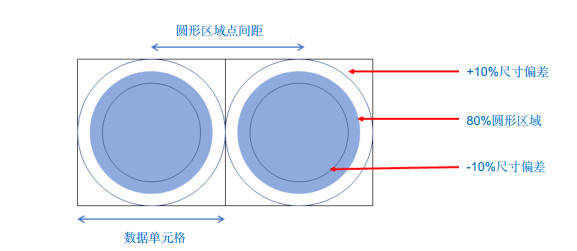

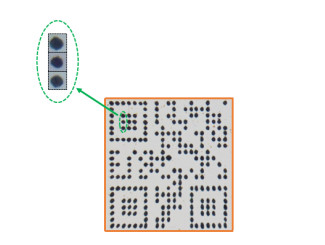

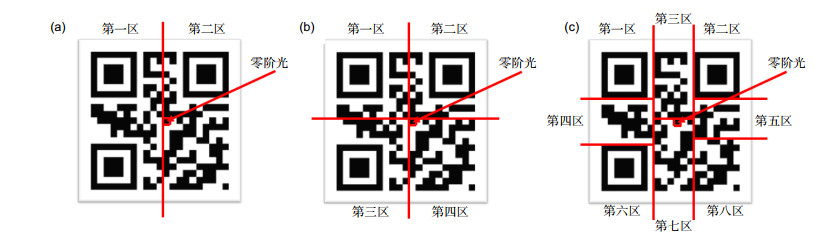

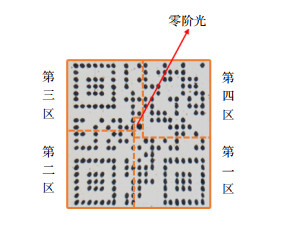

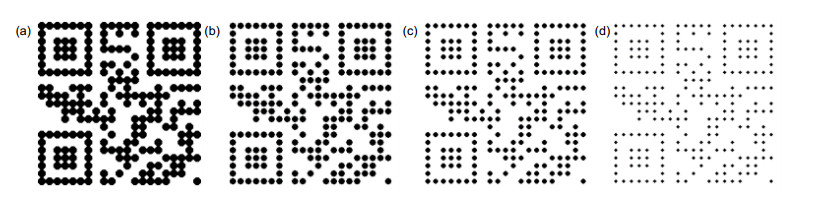

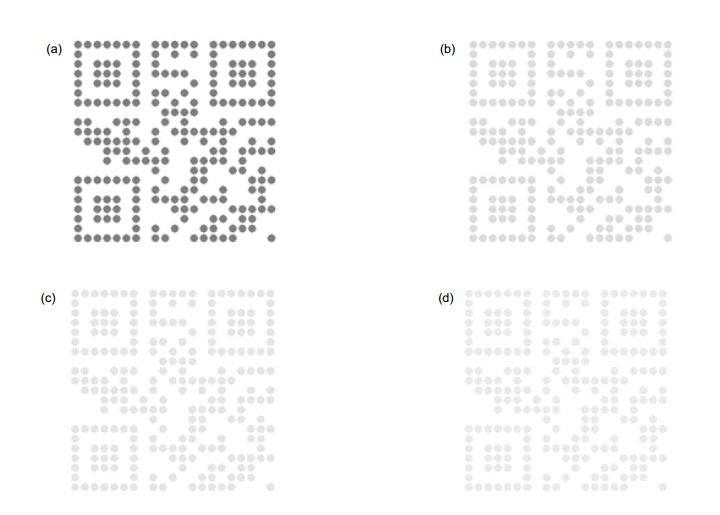

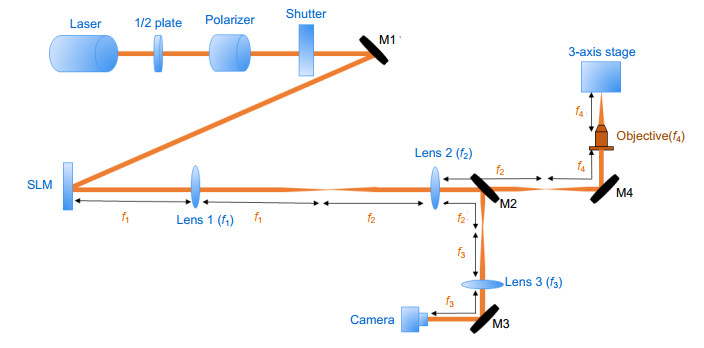

针对激光器单光束加工二维码输出能量大部分被浪费且加工效率低的问题,本文采用了一种多光束并行加工的方法来提高加工效率。仿真研究了QR码加工填充率和对比度对识别率和识别时间的影响,得到了一个二维码可识别范围。然后使用飞秒激光器基于空间光调制器的并行加工技术进行试验,对实验结果的对比度和加工填充率展开分析。分析结果表明,在二维码的识读评价标准范围内,加工填充率越大,识别率越低,识别时间越长;同样,对比度越低,识别率越低,识别时间越长。同时,对单束激光加工二维码进行了实验,分析了并行加工与单光束加工的加工时间等参数的对比,得到并行加工要比单激光束加工提高约10倍的效率。

Abstract

Aiming at the problem that most of the output energy of laser single-beam processing of two-dimensional codes is wasted and the processing efficiency is low, this paper adopts a multi-beam parallel processing method to improve the processing efficiency. The simulation studies the effect of the QR code processing filling rate, and contrast on recognition rate, and recognition time, and obtains a QR code recognizable range. Then use the femtosecond laser based on the parallel processing technology of the spatial light modulator to conduct experiments, and analyze the contrast and processing fill rate of the experimental results. The analysis results show that within the range of the QR code reading evaluation standard, the greater the processing filling rate is, the lower the recognition rate and the longer the recognition time are; similarly, the lower the contrast is, the lower the recognition rate and the longer the recognition time are. At the same time, experiments were performed on the single-beam laser processing of two-dimensional codes. The comparison of processing time and other parameters of the parallel processing and single-beam processing was analyzed, and the efficiency of the parallel processing was about 10 times higher than that of the single-beam processing.

-

Key words:

- QR code /

- laser marking /

- parallel processing /

- spatial light modulator

-

Overview

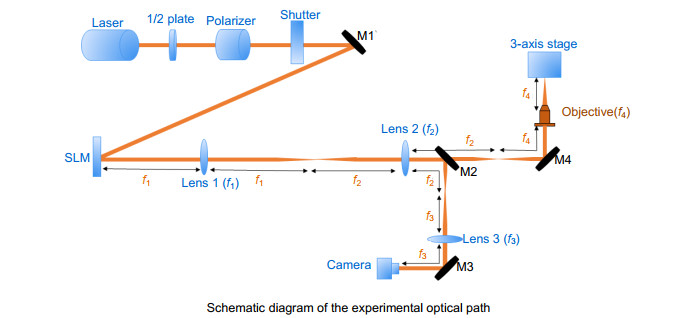

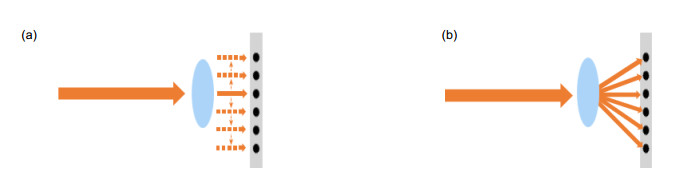

Overview: Laser processing is a non-contact processing method, which has the advantages of high energy density, good directionality, high coherence, and small heat-affected zone. It is favored in the field of industrial processing. Traditional laser processing is mainly focused on the single-beam laser marking method using a scanning galvanometer. This marking method has a clear and high-precision pattern and can be processed at any position. This method has low processing efficiency and long marking production time. In addition, the laser output single pulse energy is much higher than the required energy during processing. If single beam processing is used, most of the laser output energy is wasted and the energy utilization rate is low. Parallel processing technology can divide a single beam into multiple beams, and can improve processing efficiency, laser energy utilization. Also, the above problems can effectively solved. Aiming at the problem of low energy utilization and processing efficiency in femtosecond laser micro-machining, this paper adopts the femtosecond parallel processing method based on the spatial light modulator.

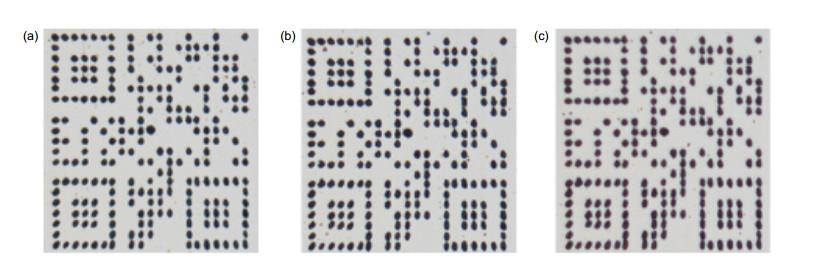

Nowadays, there are many researches on the laser marking two-dimensional codes, but there are few researches on the relationship between the reading quality of two-dimensional codes and its filling rate or contrast. Most of them focus on finding suitable processing parameters. Therefore, this article first simulates the processing filling rate and different contrasts of the two-dimensional code. The simulation method is as follows: first, to gradually increase the radius on a fixed circle center until it is tangent, and change the gray scale of the data circular area; second, use the WeChat scan code function to count the recognition time and calculate the recognition rate; finally, based on the basis of the parallel processing of the spatial light modulator, using femtosecond laser to process the two-dimensional code. It can be obtained that the larger the processing filling rate is, the smaller the gap is, the easier it is to be recognized within the range of the two-dimensional code reading evaluation standard. The observation of the contrast is verified by different processing times, and the result obtained has little change in contrast. Because the contrast meets the simulation upon request, the results can be scanned. At the same time, we conducted a single-beam laser processing experiment on the two-dimensional code, and compared the important parameters such as processing time of single-beam laser processing and parallel processing. The parallel processing efficiency of multiple light beams obtained by splitting 60 beams at the same time is about ten times higher than the processing efficiency under the galvanometer.

-

-

表 1 不同加工填充率下的识别率

Table 1. Recognition rate for different filling rate of processing

Filling rate of processing P/% Recognition rate/% 80.2 100 50.4 100 30.6 60 10.7 0 表 2 不同对比度下的识别率

Table 2. Recognition rate for different contrasts

Contrast C Recognition rate/% 127 100 35 80 25 20 20 0 表 3 飞秒激光器的主要参数

Table 3. The main parameters of the femtosecond laser

Parameter Scope Average output power/W 0~4 Maximum single pulse energy/mJ 0.4 Repetition frequency/kHz 10 Pulse width/fs 100 Beam quality factor (M2) < 1.3 Spot diameter/mm 9 Wavelength/nm 800 表 4 单束激光加工和并行加工对比实验

Table 4. Contrast experiment of the single-beam laser processing and parallel processing

Processing methods Processing filling rate P/% Processing time t/s 25.6 32.5 48.5 Parallel processing

0.4 Single beam laser processing

4.1 -

参考文献

[1] Vedel-Smith N K, Lenau T A. Casting traceability with direct part marking using reconfigurable pin-type tooling based on paraffin-graphite actuators[J]. J Manuf Syst, 2012, 31(2): 113-120. doi: 10.1016/j.jmsy.2011.12.001

[2] Moss C, Chakrabarti S, Scott D W. Parts quality management: Direct part marking of data matrix symbol for mission assurance[C]//2013 IEEE Aerospace Conference, Big Sky, MT, USA. 2013: 1-12.

[3] Noor Y M, Tam S C, Lim L E N, et al. A review of the Nd: YAG laser marking of plastic and ceramic IC packages[J]. J Mater Process Technol, 1994, 42(1): 95-133. doi: 10.1016/0924-0136(94)90078-7

[4] Chitu L, Cernat R, Bucatica I, et al. Improved technologies for marking of different materials[J]. Laser Phys, 2003, 13(8): 1108-1111. https://www.mendeley.com/catalogue/d61fb461-36eb-3e7d-b860-172ac5037275/

[5] Dumont T, Lippert T, Wokaun A, et al. Laser writing of 2D data matrices in glass[J]. Thin Solid Films, 2004, 453-454: 42-45. doi: 10.1016/j.tsf.2003.11.148

[6] Jangsombatsiri W, Porter J D. Laser direct-part marking of data matrix symbols on carbon steel substrates[J]. J Manuf Sci Eng, 2007, 129(3): 583-591. doi: 10.1115/1.2716704

[7] 张菲, 曾晓雁, 李祥友, 等. 355 nm和1064 nm全固态激光器刻蚀印刷线路板[J]. 中国激光, 2008, 35(10): 1637-1643. doi: 10.3321/j.issn:0258-7025.2008.10.040

Zhang F, Zeng X Y, Li X Y, et al. Laser etching and cutting printed circuit board by 355 nm and 1064 nm diode pumped solid state lasers[J]. Chin J Lasers, 2008, 35(10): 1637-1643. doi: 10.3321/j.issn:0258-7025.2008.10.040

[8] 温殿忠. 激光刻蚀硅磁敏三极管发射区引线槽的研究[J]. 中国激光, 2003, 30(5): 454-456. doi: 10.3321/j.issn:0258-7025.2003.05.018

Wen D Z. Study on laser etching emitter region-groove approach of magnetic-sensitive silicon transistor[J]. Chin J Lasers, 2003, 30(5): 454-456. doi: 10.3321/j.issn:0258-7025.2003.05.018

[9] 张恒, 周云, 方宗豹, 等. 用纳秒激光在镜面不锈钢表面刻蚀微光栅结构[J]. 中国激光, 2008, 35(3): 448-451. doi: 10.3321/j.issn:0258-7025.2008.03.028

Zhang H, Zhou Y, Fang Z B, et al. Fabrication of micro-grating structure on glazed stainless-steel by nanosecond laser[J]. Chin J Lasers, 2008, 35(3): 448-451. doi: 10.3321/j.issn:0258-7025.2008.03.028

[10] Leone C, Genna S, Caprino G, et al. AISI 304 stainless steel marking by a Q-switched diode pumped Nd: YAG laser[J]. J Mater Process Technol, 2010, 210(10): 1297-1303. doi: 10.1016/j.jmatprotec.2010.03.018

[11] Hayakawa H. Laser method for marking bar codes on glass substrates[J]. Proc SPIE, 2000, 4088: 363-366. doi: 10.1117/12.405680

[12] Connolly C. Part-tracking labelling and machine vision[J]. Assembly Autom, 2005, 25(3): 182-187. doi: 10.1108/01445150510610881

[13] 王苏安, 何卫平, 张维, 等. 刀具直接标刻与识别技术研究[J]. 计算机集成制造系统, 2007, 13(6): 1169-1174. doi: 10.3969/j.issn.1006-5911.2007.06.023

Wang S A, He W P, Zhang W, et al. Direct tool marking & identification method[J]. Comput Integr Manuf Syst, 2007, 13(6): 1169-1174. doi: 10.3969/j.issn.1006-5911.2007.06.023

[14] Costa L, Lansford K, Rajput D, et al. Unique corrosion and wear resistant identification tags via LISITM laser marking[J]. Surf Coat Technol, 2009, 203(14): 1984-1990. doi: 10.1016/j.surfcoat.2009.01.028

[15] Leone C, Lopresto V, De Iorio I. Wood engraving by Q-switched diode-pumped frequency-doubled Nd: YAG green laser[J]. Opt Laser Eng, 2009, 47(1): 161-168. doi: 10.1016/j.optlaseng.2008.06.019

[16] 董楠. 铸锻物料激光标刻系统设计及关键技术研究[D]. 兰州: 兰州理工大学, 2019.

Dong N. Research on the key technology of laser marking system design for casting and forging materials[D]. Lanzhou: Lanzhou University of Technology, 2019.

[17] 伍珊红, 齐军, 虞孝舜, 等. Nd: YAG激光打标工艺试验研究[J]. 激光与红外, 1999, 29(2): 92-95. https://www.cnki.com.cn/Article/CJFDTOTAL-JGHW902.007.htm

Wu S H, Qi J, Yu X S, et al. Study of technological experiments of the Nd: YAG laser marking[J]. Laser Infrared, 1999, 29(2): 92-95. https://www.cnki.com.cn/Article/CJFDTOTAL-JGHW902.007.htm

[18] 孔猛. QR二维码设计的基本原则及要点分析[J]. 今日印刷, 2017(1): 69-71. https://www.cnki.com.cn/Article/CJFDTOTAL-JRYS201701028.htm

Kong M. Basic principles and key points analysis of QR code design[J]. Print Today, 2017(1): 69-71. https://www.cnki.com.cn/Article/CJFDTOTAL-JRYS201701028.htm

[19] 汪金礼. 飞秒激光全息并行加工中若干关键问题研究[D]. 合肥: 安徽大学, 2013.

Wang J L. Research on key technologies of holographic femtosecond laser parallel processing[D]. Hefei: Anhui University, 2013.

[20] 余本海. 飞秒激光对透明电介质材料的烧蚀与微加工研究[D]. 武汉: 华中科技大学, 2008.

Yu B H. Ablation and micromachining of dielectris with a femtosecond laser[D]. Wuhan: Huazhong University of Science and Technology, 2008.

[21] Li Y, Hong M H. Parallel laser micro/nano-processing for functional device fabrication[J]. Laser Photon Rev, 2020, 14(3): 1900062. doi: 10.1002/lpor.201900062

[22] Kuang Z, Perrie W, Liu D, et al. Ultrafast laser parallel microprocessing using high uniformity binary Dammann grating generated beam array[J]. Appl Surf Sci, 2013, 273: 101-106. doi: 10.1016/j.apsusc.2013.01.195

[23] 杨秋英. 二维条码—QR Code研究及应用[D]. 太原: 华北工学院, 2003.

Yang Q Y. Research and Application of QR Code[D]. Taiyuan: North China Institute of Technology, 2003.

[24] Li Y, Liu H G, Hong M H. High-quality sapphire microprocessing by dual-beam laser induced plasma assisted ablation[J]. Opt Express, 2020, 28(5): 6242-6250. doi: 10.1364/OE.381268

[25] 季凌飞, Amina, 燕天阳, 等. 基于成丝效应的超快激光加工技术工业化应用研究之探析[J]. 光电工程, 2017, 44(9): 851-861. doi: 10.3969/j.issn.1003-501X.2017.09.001

Ji L F, Amina, Yan T Y, et al. Research progress of ultrafast laser industrial applications based on filamentation[J]. Opto-Elec Eng, 2017, 44(9): 851-861. doi: 10.3969/j.issn.1003-501X.2017.09.001

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: