Detection method of obstacle for plant protection UAV based on structured light vision

-

摘要

针对存在障碍物农田区域的植保无人机避障问题,提出了一种基于结构光视觉的植保无人机障碍物检测方法。本文基于激光三角测量原理,通过半导体激光器与CCD传感器间特殊的光路,设计了可探测前方障碍物信息的光学检测系统。激光器发出的线结构光经障碍物表面的反射,成像于CCD靶面上,通过图像采集、处理和计算提取出前方障碍物距离、方位角和宽度等参数信息。实验表明,该方法能够有效检测出未知环境下障碍物的距离、方位角和宽度,并且距离检测误差小于0.06 m。

Abstract

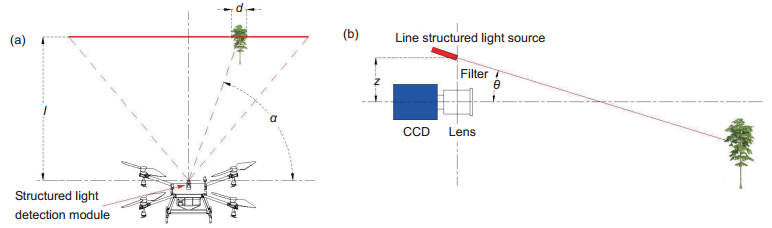

To solve the obstacle avoidance problem in plant protection UAV in operation, especially for farmland areas, a technology based on structured light vision was proposed. Based on the laser triangulation principle, through the special optical path design between the semiconductor laser and CCD sensor, an optical detection system to detect front obstacle information was designed. The line structured light emitted by the laser was reflected by the surface of the obstacle and was imaged on the CCD target surface. Through the image acquisition, processing and calculation, the distance, azimuth, width and other parameter information of front obstacle were extracted. Experiments show that this method can effectively detect the distance, azimuth and width of the obstacle in the unknown environment. The deviation of distance detection is less than 0.06 m.

-

Overview

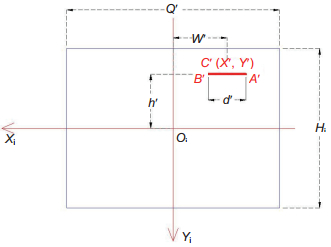

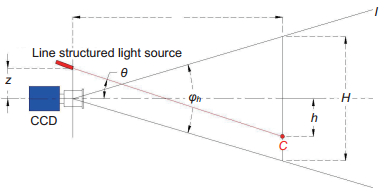

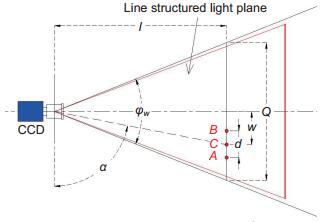

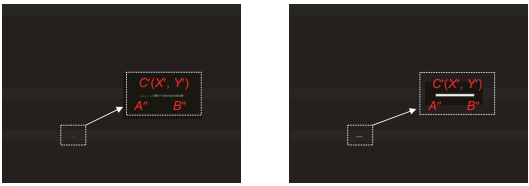

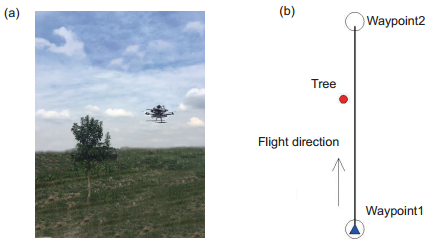

Overview: With the rapid development of UAV technology, the applications of plant protection UAV are more and more common. At present, most of the plant protection UAV is a semi-automatic operation with manual intervention. UAV needs to manually avoid obstacles, when it encounters obstacles during plant protection operations. Developing the automatic plant protection UAV with automatic obstacle avoidance is particularly important. However, the current UAV obstacle avoidance technology is not mature. To solve the obstacle avoidance problem of plant protection UAV in operation, especially for farmland areas, a technology based on structured light vision was proposed as shown in Fig. (a). Based on the laser triangulation principle, through the special optical path design between the semiconductor laser and CCD sensor, an optical detection system to detect front obstacle information was designed. The compositions of this optical detection system were the line structured light source, CCD camera, optical lens and filter device as shown in Fig. (b). They were fixed by specific designed structure. The distance between the line structured light source exit hole and the CCD imaging optical axis was designed as 'z'. The angle between the optical axis of the line structured light source and the CCD imaging optical axis was designed as 'θ'. The parameters 'z' and 'θ' both required to be calibrated before detection. The line structured light emitted by the laser was reflected by the surface of the obstacle and was imaged on the CCD target surface. Because of the narrow bandwidth of the original image obtained by CCD maintained obvious image with line structured light and some optical noises. The processing such as image segmentation, linear image denoise and refinement were needed to extract the clear image of the line structured light. The information of front obstacle was contained by the position of the line structured light image in the whole image and the length of it. Through the image acquisition, processing and calculation, the distance, azimuth, width and other parameter information of front obstacle could be extracted. Experiments show that this method can effectively detect the distance, azimuth and width of the obstacle in the unknown environment. The deviation of distance detection is less than 0.06 m. The deviation of azimuth detection is less than 4°. The deviation of width detection is less than 0.01 m. The study of this method provides a theoretical basis for further realizing the function of automatic obstacle avoidance of plant protection UAV.

-

-

表 1 距离检测实验数据

Table 1. Test data of distance detection

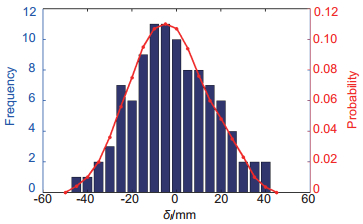

No. l/mm l0/mm δl/mm 1 3000 3012 12 2 3000 2994 -6 3 3000 3015 15 4 3000 3004 4 5 3000 2993 -7 6 3000 2988 -12 7 3000 2994 -6 8 3000 2997 -3 9 3000 3009 9 10 3000 2990 -10 表 2 角度检测实验数据

Table 2. Test data of azimuth detection

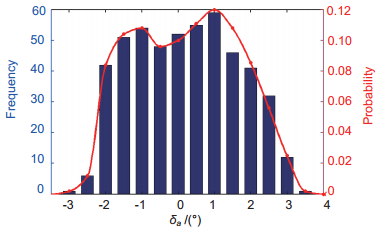

No. α0/(°) α0/(°) δα/(°) 1 70 72.4 2.4 2 80 81.9 1.9 3 90 90.6 0.6 4 100 98.8 -1.2 5 110 107.5 -2.5 表 3 宽度检测实验数据

Table 3. Test data of width detection

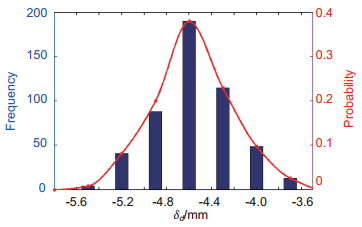

No. d/mm d0/mm δd/mm 1 25 20.1 -4.9 2 40 35.8 -4.2 3 63 58.6 -4.4 4 90 85.1 -4.9 5 125 120.9 -4.1 表 4 树木检测实验数据

Table 4. Test data of tree detection

No. l/mm l0/mm δl/mm α/(°) α0/(°) δα/(°) d/mm d0/mm δd/mm 1 1360 1455 95 111.1 106.9 -4.2 850 651.9 -198.1 2 1106 1488 382 107.4 102.1 -5.3 850 794.2 -55.8 3 1228 1447 219 104.1 107.2 3.1 850 705.4 -144.5 4 1316 1462 146 102.9 106.5 3.6 850 787.1 -62.9 5 1409 1472 63 102.6 104.7 2.1 850 751.7 -98.3 6 1215 1476 261 106.9 102.4 -4.5 850 742.4 -107.6 -

参考文献

[1] 温源, 薛新宇, 邱白晶, 等.中国植保无人机发展技术路线及行业趋势探析[J].中国植保导刊, 2014, 34(S1): 30–32. http://www.doc88.com/p-3149687223812.html

[2] 岳学军, 王健, 兰玉彬, 等.小型无人机振动特性对超声波传感器的影响[J].华南农业大学学报, 2016, 37(6): 10–15. http://d.old.wanfangdata.com.cn/Periodical/hnnydxxb201606003

Yue X J, Wang J, Lan Y B, et al.Impacts of small-size unmanned aerial vehicle vibration characteristics on ultrasonic transducers[J]. Journal of South China Agricultural University, 2016, 37(6): 10–15. http://d.old.wanfangdata.com.cn/Periodical/hnnydxxb201606003

[3] 张明, 唐尧, 景雄.直升机载毫米波雷达高压线防撞处理研究[J].火控雷达技术, 2016, 45(2): 7–11, 30. http://www.cnki.com.cn/Article/CJFDTotal-HKLD201602002.htm

Zhang M, Tang Y, Jing X. Power line detection processing of heliborne millimeter wave radar[J]. Fire Control Radar Technology, 2016, 45(2): 7–11, 30. http://www.cnki.com.cn/Article/CJFDTotal-HKLD201602002.htm

[4] 肖志涛, 张文寅, 耿磊, 等.双目视觉系统测量精度分析[J].光电工程, 2014, 41(2): 6–11. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201402003&dbname=CJFD&dbcode=CJFQ

Xiao Z T, Zhang W Y, Geng L, et al.Accuracy analysis of binocular vision system[J]. Opto-Electronic Engineering, 2014, 41(2): 6–11. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201402003&dbname=CJFD&dbcode=CJFQ

[5] 王宇, 刘泓滨, 李华文.机器视觉的灾后救援机器人越障系统设计[J].传感器与微系统, 2016, 35(4): 79–81, 85. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_cgqjs201604024

Wang Y, Liu H B, Li H W. Design of disaster rescue robot obstacle surmounting system based on machine vision[J]. Transducer and Microsystem Technologies, 2016, 35(4): 79–81, 85. http://industry.wanfangdata.com.cn/dl/Detail/Periodical?id=Periodical_cgqjs201604024

[6] 宋丽梅, 覃名翠, 杨燕罡, 等.激光视觉方法用于检测齿轮加工误差[J].光电工程, 2015, 42(1): 1–5. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201501001&dbname=CJFD&dbcode=CJFQ

Song L M, Qin M C, Yang Y G, et al. Gear machining error detection based on laser vision method[J]. Opto-Electronic Engineering, 2015, 42(1): 1–5. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201501001&dbname=CJFD&dbcode=CJFQ

[7] 张博翰, 蔡志浩, 王英勋.电动VTOL飞行器双目立体视觉导航方法[J].北京航空航天大学学报, 2011, 37(7): 882–887. http://www.cqvip.com/QK/90750X/201107/39043489.html

Zhang B H, Cai Z H, Wang Y X. Binocular stereo vision navigation for electric VTOL aircraft[J]. Journal of Beijing University of Aeronautics and Astronautics, 2011, 37(7): 882–887. http://www.cqvip.com/QK/90750X/201107/39043489.html

[8] 梁春疆, 段发阶, 杨毅, 等.车辆外廓尺寸计算机视觉动态测[J].光电工程, 2016, 43(1): 42–48, 54. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201601009&dbname=CJFD&dbcode=CJFQ

Liang C J, Duan F J, Yang Y, et al.A vehicle outer contour dimension measuring method based on computer vision technology[J]. Opto-Electronic Engineering, 2016, 43(1): 42–48, 54. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201601009&dbname=CJFD&dbcode=CJFQ

[9] 田国会, 王家超, 段朋.病房巡视机器人复杂环境下的避障技术研究[J].华中科技大学学报(自然科学版), 2013, 41(S1): 312–315. http://d.wanfangdata.com.cn/Periodical_hzlgdxxb2013z1079.aspx

Tian G H, Wang J C, Duan P. Research on obstacles avoidance for Ward inspection robot in complex environment[J]. Journal of Huazhong University of Science and Technology (Nature Science Edition), 2013, 41(S1): 312–315. http://d.wanfangdata.com.cn/Periodical_hzlgdxxb2013z1079.aspx

[10] 廖平, 任成, 杨小雨.基于线阵CCD的高精度位移传感器前端设计[J].光电工程, 2017, 44(5): 498–504. http://www.oejournal.org/J/OEE/Article/Details/A170830000013/CN

Liao P, Ren C, Yang X Y. Front-end design of high precision displacement sensor based on linear array CCD[J]. Opto-Electronic Engineering, 2017, 44(5): 498–504. http://www.oejournal.org/J/OEE/Article/Details/A170830000013/CN

[11] 吴开华, 陈康.轮对在线检测中Tsai异面标定算法研究[J].光电工程, 2015, 42(11): 1–7. doi: 10.3969/j.issn.1003-501X.2015.11.001 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201511002&dbname=CJFD&dbcode=CJFQ

Wu K H, Chen K. Tsai non-coplanar calibration algorithm of wheel set online detection[J]. Opto-Electronic Engineering, 2015, 42(11): 1–7. doi: 10.3969/j.issn.1003-501X.2015.11.001 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201511002&dbname=CJFD&dbcode=CJFQ

[12] 何文彦, 曹学东, 匡龙, 等.结构光检测大型止推环止推面平面度探究[J].光电工程, 2016, 43(11): 7–12. doi: 10.3969/j.issn.1003-501X.2016.11.002 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201611002&dbname=CJFD&dbcode=CJFQ

He W Y, Cao X D, Kuang L, et al.A preliminary based on structured-light for flatness measurement of large annular planes[J]. Opto-Electronic Engineering, 2016, 43(11): 7–12. doi: 10.3969/j.issn.1003-501X.2016.11.002 http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201611002&dbname=CJFD&dbcode=CJFQ

[13] 范生宏, 刘昌儒, 亓晓彤, 等.结构光三维测量系统精度分析及验证[J].光电工程, 2014, 41(5): 52–56. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405010&dbname=CJFD&dbcode=CJFQ

Fan S H, Liu C R, Qi X T, et al.Accuracy analysis and verification of structured light 3D measurement system[J]. Opto-Electronic Engineering, 2014, 41(5): 52–56. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405010&dbname=CJFD&dbcode=CJFQ

[14] 张劲峰, 张继业.基于激光三角法的倾斜角测量系统[J].光电工程, 2016, 43(1): 18–23. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201601005&dbname=CJFD&dbcode=CJFQ

Zhang J F, Zhang J Y. Measurement system of inclination angle based on laser triangulation[J]. Opto-Electronic Engineering, 2016, 43(1): 18–23. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201601005&dbname=CJFD&dbcode=CJFQ

[15] 林志强, 王天友, 南刚雷, 等.基于线结构光的柴油机缸盖三维形貌测量[J].光电工程, 2014, 41(5): 46–51. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405009&dbname=CJFD&dbcode=CJFQ

Lin Z Q, Wang T Y, Nan G L, et al.Three-dimensional data measurement of engine cylinder head blank based on line structured light[J]. Opto-Electronic Engineering, 2014, 41(5): 46–51. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405009&dbname=CJFD&dbcode=CJFQ

[16] 许增朴, 许敬华, 王永强, 等.激光传感器扫描边缘系统定位方法研究[J].传感器与微系统, 2016, 35(2): 49–51. http://www.cnki.net/kcms/doi/10.13873/J.1000-9787(2016)02-0049-03.html

Xu Z P, Xu J H, Wang Y Q, et al.Research on system localization method of laser sensor scanning edge[J]. Transducer and Microsystem Technologies, 2016, 35(2): 49–51. http://www.cnki.net/kcms/doi/10.13873/J.1000-9787(2016)02-0049-03.html

[17] 刘宾, 王黎明, 赵霞.基于激光位移传感器的缸套内部形廓尺寸测量系统[J].光电工程, 2014, 41(5): 40–45. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405008&dbname=CJFD&dbcode=CJFQ

Liu B, Wang L M, Zhao X. Cylinder-shaped dimensions measuring system based on laser displacement sensor[J]. Opto-Electronic Engineering, 2014, 41(5): 40–45. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gdgc201405008&dbname=CJFD&dbcode=CJFQ

[18] 行麦玲, 刘贱平, 林家明, 等.大视场短焦距镜头CCD摄像系统的畸变校正[J].光学技术, 2003, 29(3): 377–379. https://www.wenkuxiazai.com/doc/485665f7ba0d4a7302763abc.html

Xing M L, Liu J P, Lin J M, et al. Distortion measurement of CCD camera with a large-field, short focal length lens[J]. Optical Technique, 2003, 29(3): 377–379. https://www.wenkuxiazai.com/doc/485665f7ba0d4a7302763abc.html

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: