-

摘要:

紫外激光以其波长短、加工精度高、冷加工等特性,在微细制造中具有独特优势,能够有效提高制造品质。近年来,随着现代电子产业的快速发展,其对生产制造的要求不断提高,紫外激光的应用和发展也受到人们的广泛关注。紫外激光在微加工过程中对材料尺寸形状要求小,加工过程灵活可变,产生的热影响区小,能够实现精密复杂结构的加工。本文介绍了紫外激光器的发展过程,并对目前主要用于微加工的两类紫外激光器:准分子激光器和全固态激光器的工作原理和技术特点进行了简要的概述。重点讨论紫外激光在半导体、光学元件和聚合物等领域的技术发展和应用现状,并进一步对未来研究方向进行预测和展望。

Abstract:Ultraviolet (UV) laser has unique advantages in micromachining due to short wavelength, high machining accuracy and cold processing property, leading to improve manufacturing quality effectively. In recent years, electronic industry has been developed rapidly and needs high fabrication requirements. Progress of UV laser has attracted much attention in applications of electronic industry because it can produce complex structures on almost any materials with flexible process and small heat-affected zone. In this review, we summarize the history of UV laser development and fundamental principles as well as characteristics of excimer laser and diode pumped solid state laser, which are two major UV lasers used for micromachining. Moreover, we analyze the development and applications of UV laser in micromachining of semiconductor, optical element and polymer. Finally, we propose some prospects for further research and development in UV laser and its applications.

-

Key words:

- UV laser /

- laser micromachining /

- semiconductor /

- micro-optical element /

- polymer

-

Ultraviolet(UV) laser with its short wavelength, high machining accuracy and cold processing property, has unique advantages in micromachining, and can effectively improve the manufacturing quality. Modern electronic industry has achieved a rapid development in recent years, and sets higher demands in fabricating. UV laser’s progress and applications in electronic industry attracts are attracting broad attention. UV laser can process complex structures on almost any materials with flexible process and small heat-affected zone. It summarizes the development of UV laser. The fundamental principles and characteristics of excimer laser and diode pumped solid state laser are given, which are two major UV lasers used for micromachining. The development and applications of UV laser in the micromachining of semiconductor, optical element and polymer are introduced. It gives some prospects and forecasts about research in the further development.

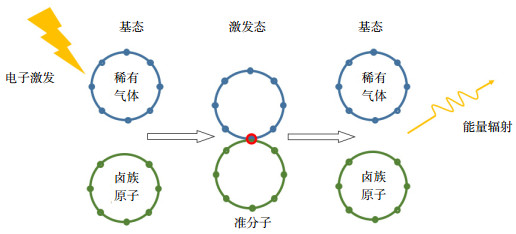

According to different actuating mediums, UV lasers used for micro-machining are majorly classified into two categories, excimer laser and diode pumped solid state laser. The noble gases and halogen elements work as actuating medium in excimer laser. Under the excitation of high-energy electrons, the noble gas atom and halogen element atom combine into excimer. When these excited atoms return to the ground state, it emits energy of a characteristic wavelength. The wavelengths of excimer laser can vary from 126 nm (Ar2) to 650 nm (Xe2F). While in the diode pumped solid state laser, the photons generate from the diode. The origin photons are transmitted into the photonic crystal, where photons excite more photons of fundamental wavelength, which compose fundamental light. Then fundamental light penetrates into the nonlinear frequency doubling crystal, and changes into the second harmonic light with wavelength halved. After several frequency transformations, the origin light finally becomes the expected light of an ultraviolet wavelength.

During the process of laser machining, UV laser carries on processing to materials using the photochemical effects. When UV laser irradiates on the surface of materials, part of photons are absorbed by the electrons of surface. Owing to UV laser’s single photon energy higher than that of chemical bonds between material atoms, the chemical bonds can be directly broken in irradiated area. The materials can be stripped from the surface in the form of gaseous atom or particle, to compete presupposed micro-machining. UV laser has been widely used in the fields of semiconductor, optical element and polymer, for its small heat-affected zone and high machining precision. Application status and developing prospects of UV laser are discussed in this review.

-

1. 引言

随着现代化电子产业的快速发展,产业需求转为尺寸小型化、重量轻型化和功能多样化,要求同时实现小尺寸、高精度和高质量等高品质制造。传统制造方法存在工艺复杂、成本高、加工形状、尺寸、材料受限等问题,容易导致加工精度低、效率低、副产品污染严重、加工刀具磨损严重、成品率较低等问题。与传统加工方法相比,激光微细加工具有相干性高、热影响小、加工效率、精度和重复率高、对材料无选择性、加工方式灵活多样、成本低等优点,因此得到实际应用并快速发展。紫外激光波长短,单光子能量高,能够直接打断物质原子/分子间连接的化学键加工物质,导致被照射区域材料直接形成气态粒子或微粒并发生光化学剥离过程,不对周围物质造成明显影响,几乎不产生热影响区,进而获得高的尺寸精度和边缘质量,因此从而在半导体材料加工、微光学元件制作和印刷电路板等领域。

紫外激光器起源于上世纪六十年代[1]。世界上第一台紫外激光器来自苏联,Basov等[2]利用Xe2首次获得波长172 nm的准分子激光。随后相继出现XeF、KrF、ArF等准分子激光器[3-5]。由于准分子激光器需要持续使用腐蚀性卤族气体,因此在实际使用中受到诸多限制,使得人们开始同时关注固体激光器的研发。1989年,浙江大学尤晨华教授[6]利用非线性晶体BBO制得216 nm的深紫外激光。2000年,日本Kojima等人[7]利用非线性晶体CLBO输出20 W、266 nm脉冲紫外激光输出,取得突破性进展。随着光学元器件加工技术的日益成熟,紫外激光的谱线不再局限于355 nm、266 nm和213 nm。2006年,Johansson等人[8]使用周期极化KTP晶体(PPKTP)和BBO晶体对调Q 946 nm激光器进行四倍频处理,制得20 mW的236 nm紫外激光输出。2008年,Kimmelma等人[9]研制新型调Q Nd:YAG脉冲激光器,输出波长为237 nm,输出脉宽为1.9 ns,平均功率为7.6 mW。2014年,Deyra等人[10]对调Q Nd:YAG脉冲激光器进行进一步优化,得到600 mW的237 nm激光输出,这是当时237 nm紫外波段上获得的最高平均功率。

目前,光谱物理、相干、通快等外国公司占有着紫外激光的高端市场。光谱物理公司新款Quasar高功率紫外激光器具有高脉冲频率、高功率紫外输出等特点,该产品不但能够调节脉冲宽度,还可实现对波形进行编程,为产品提供了高度工艺灵活性和可控性,大幅提升了加工产能与效率。此外,Quasar稳定性高,使用寿命长,能确保24/7长期连续运行。同时,国内品牌也得到长足发展,华日、英谷、瑞丰恒等企业得到了良好的增长。2009年,华日激光开始发展纳秒级的紫外激光器,经过8年发展,华日公司纳秒级紫外激光器月产量可达到600台。2015年,华日成功收购加拿大超快激光器公司Attodyne,同时在多伦多建立了全球领先的超快激光器研发中心。

近年来,紫外激光器是工业激光市场增长最快的一部分,紫外激光器尤其是准分子激光器和全固态紫外激光器成为新的研究热点。本文在介绍这两种紫外激光器的工作原理和近年来国内外研究进展的基础上, 重点介绍紫外激光器在激光微细加工中的应用,并对紫外激光微加工未来的研究方向进行了预测和展望。

2. 紫外激光器

紫外激光产生介质主要分为气体和固体两种。气体介质产生方式通过电子束或脉冲放电,利用电子碰撞激发,将气体粒子激发至某高能级上,从而产生受激跃迁向外辐射紫外激光。固体介质是通过将红外光或近红外光透过非线性倍频晶体的方式进行一次或多次的频率转换后得到紫外激光。用于激光微细加工的激光器主要有准分子激光器和全固态激光器等。

2.1 准分子激光器

准分子激光器是以准分子作为工作介质的一类气体激光器,工作介质主要为稀有气体(Ar, Kr, Xe等)和卤族元素(F, Cl, Br等),常采用电子束或脉冲放电的形式实现泵浦(如图 1所示)。处于基态的稀有气体原子受到激发后,核外电子跃迁到更高能级的轨道从而改变原有最外层电子充满的结构,并与其他原子结合形成分子,当激发态的分子跃迁回到基态时,又离解成原来分立的原子,能量以光子的形式放出,经谐振腔放大后,变为具有高能量的紫外激光。准分子激光器通过使用不同工作介质实现输出不同激光波长,比如Xe2F激光器可输出最长的波长(610±65) nm,Ar2激光可输出最短的波长126 nm。常见准分子激光器还包括ArF激光器(193 nm),KrF激光器(248 nm)和XeCl激光(308 nm)等。

2.2 全固态激光器

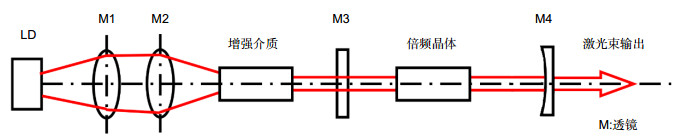

全固态激光器具有峰值功率高、稳定性好、光束质量高、体积小等优点,具有更广的应用前景。固体激光器的紫外激光产生过程主要分为以下两个步骤:1)泵浦光源经激光器内光路照射到增强介质上,实现粒子数反转,在谐振腔内形成红外光,作为基波;2)基波在谐振腔内振荡,经过一次或多次非线性晶体腔内倍频,得到所需的紫外谱线后经镜片透射、反射从谐振腔输出。紫外固体激光器采用的泵浦方式主要分为灯泵浦和激光二极管(LD)泵浦,其中LD泵浦的紫外固体激光器又被称为全固态激光器,其光路原理如图 2所示。

目前全固态激光器使用较为广泛的增强介质有Nd:YAG(掺钕钇铝石榴石)和Nd:YVO4(掺钕钒酸钇),两者的主要物理性质如表 1所示。Nd:YAG晶体具有良好的热导率和较长的荧光寿命,对激光器系统硬件的散热要求不高,能够适应脉冲激光器和大功率激光器的工作使用需求。同时,Nd:YAG晶体具有较高的机械强度,对激光波长范围的光线具有高的透过率,能够获得较好的光束质量。因此,Nd:YAG晶体已经成为了目前LD泵浦紫外固体激光器的首选增强介质。相比于Nd:YAG,Nd:YVO4是单轴晶体,在使用过程中具有吸收带宽高,并且输出偏振光,但受其自身物理及机械性能的限制,无法制备大尺寸的高质量晶体,并且晶体热导率偏小,在小功率激光以及薄片激光器中拥有部分应用。

表 1. Nd:YAG和Nd:YVO4的主要物理性质.Table 1. The main physical properties of Nd:YAG and Nd:YVO4晶体 Nd:YAG Nd:YVO4 受激发射截面/(10-20·cm2) 4.3 4.8(∥C), 4.3(⊥C) 荧光寿命/μs 230 97 吸收截面/(10-20·cm2) 7.9 60.1(∥C), 12.0(⊥C) 热导率/(W·m-1·K-1) 11 5.23(∥C), 5.10(⊥C) 紫外激光所采用的频率转换方式主要包括:1)利用非线性晶体对红外激光进行直接三倍频、四倍频或五倍频处理,得到三次、四次或五次谐波;2)先利用倍频处理制得二次谐波,再利用和频技术将二次谐波与基波混合制得三倍频紫外激光。其中后者因为利用二次非线性极化,转换效率要高于前者。实现对激光基波频率转换的关键部件为非线性晶体,它直接影响到输出功率的大小和光束的质量。紫外激光器中常见的非线性晶体主要有LBO(三硼酸锂,LiB3O5)和KTP(磷酸钛氧钾,KTiOPO4)。两者的部分物理性质如表 2。LBO拥有较高的倍频系数,很宽的透光波段,高的光学均匀性。LBO相位匹配的接收角度范围宽,离散角小,能实现非临界相位匹配,通过温度调谐或者角度调谐能够实现相位匹配的折返。同时激光损伤阈值高,在高平均功率的二阶谐波、三阶谐波、四阶谐波等的产生以及其和频、差频处理等领域被广泛使用。KTP晶体的光学透过波长范围为350 nm~4500 nm,硬度高、不易潮解、化学性能稳定。最大的优点是非线性系数高,光损伤阈值也高,目前主要应用于Nd:YAG激光器的内腔倍频处理。

表 2. LBO和KTP的部分物理性质.Table 2. Partial physical properties of LBO and KTP.晶体 LBO KTP 光学透过波长范围/nm 160~2600 350~3500 非线性系数/(pm/V) d31=1.05 d33=13.7 激光损伤阈值/(GW/cm2) 18.9 4.6 在深紫外激光器研究领域,中国已成为当今世界上唯一掌握深紫外全固态激光技术并且实用化的国家。中国科学院的研究人员通过研究非线性光学晶体氟硼铍酸钾晶体(KBBF),在国际上率先制得大尺寸KBBF晶体,并且针对KBBF晶体发明特殊棱镜耦合器件[12],能够无需按照匹配角直接实现激光的倍频输出,发展出实用化的深紫外固态激光源[13](如图 3所示)。此外,中国科学院成功研制出深紫外拉曼光谱仪、深紫外光电子发射显微镜等8种国际首创深紫外前沿装备,将拉曼光谱仪、光致发光谱仪、光耦合扫描隧道显微镜延伸扩展到深紫外激光波段,光电子能谱仪的主要技术指标(能量分辨率、动量分辨率和自旋分辨率)和光发射电子显微镜的测量精度成量级提高,对科学仪器行业起了积极的推动作用。

3. 紫外激光在微细制造领域中的典型应用

在激光加工过程中,红外和可见光激光与材料相互作用的过程主要为光热效应,即红外和可见光激光束照射到材料表面时,一部分光子能量被材料表面的电子吸收,使得材料中的电子动能增大,通过热弛豫和热传递等过程使得材料被照射区域温度上升,发生熔化和汽化等物态变化从而实现所需的加工。而紫外激光具有很高的单光子能量,以248 nm激光为例,其单光子能量为5.01 eV,高于常态下的C-C键能(3.49 eV),C-O键能(3.69 eV),Si-O键能(4.67 eV)等,因此在照射过程中,紫外激光能够直接打断材料间连接的化学键,材料以气态或微粒的形式被剥离表面。光化学剥离过程中,电子吸收的激光能量几乎全部用于打断化学键,极少转化为热能,因此加工过程中产生的热影响区小。目前,紫外激光主要用于加工对紫外波段具有良好吸收率并且加工过程对控制热影响要求较高的材料,如Si、GaN等半导体材料,石英、蓝宝石等光学晶体,以及聚酰亚胺(PI)、聚碳酸酯(PC)等高聚物材料。

3.1 半导体材料加工

紫外激光有利于实现集成电路中硅晶衬底上成千上万电路元件高密集高品质加工,同时能够通过改变硅表面的微结构,如二维微光栅等,增强硅材料对光能的利用率,对太阳能电池研发具有重要价值。

紫外激光加工硅基等半导体材料源自1997年德国的Simon和Ihlemann[14]首次利用KrF脉冲紫外激光(波长248 nm)在硅片的表面消融得到了孔和光栅等微结构,并在报道中指出微结构的几何精度和表面质量受到入射紫外激光的功率和脉宽影响,首次证明了采用脉冲紫外激光能够有效地在硅材料表面进行微结构加工。1998年,日本中部大学的Chen等[15]利用四倍频Nd:YAG紫外激光(波长266 nm)逐点加工的方法,在硅表面烧蚀加工出立体的微结构,并且在深度方向上的加工精度能够达到纳米级别。同年,台湾有研究人员同样利用四倍频Nd:YAG激光(波长266 nm)逐点加工,在烧蚀区域边缘得到了周期的波纹结构,并且在控制单脉冲能量条件下,进一步提高了深度方向上的加工精度[16]。

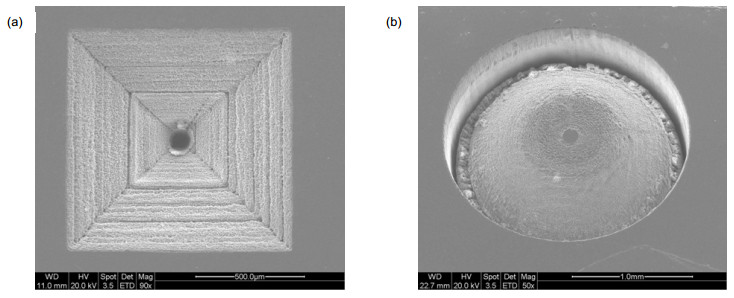

2000年,马炳和等[17]利用KrF准分子激光(波长248 nm)直接照射消融单晶硅,针对消融微结构的几何形状及照射加工中的热效应等方面,研究了准分子激光直接照射单晶硅消融的加工特性。结果表明,紫外激光在照射消融硅材料的过程中仍有热效应作用,并非完全基于非热效应,并针对研究中的热效应提出了紫外激光加工的“热影响区”的概念,借以评定紫外激光的“冷加工”性能。2006年,日本的Furukawa等[18]采用波长355 nm的紫外激光对SiC进行了消融加工,对紫外激光加工刻槽过程中的主要影响因素进行了研究和分析,并在此基础上建立了紫外激光的消融加工模型。同年,英国的Gu[19]利用高峰值功率的紫外激光(波长266 nm)在氮化镓上加工刻蚀出了微槽结构,结果表明氮化镓的缺陷密度越低时,获得的加工质量越高。朱冀梁[20]使用波长351 nm的全固态脉冲激光器经过位相光栅分束,在硅表面直接刻蚀微结构,制作了周期间距0.55 μm、深度55 nm的一维微光栅和周期间距1.25 μm、深度45 nm的正交微光栅结构。该研究提出了一种新改变硅表面微结构,优化硅材料性能的方法,扩展了大功率激光刻蚀在表面微加工领域的应用。杨雄[21]在Si表面先进行了平面结构刻蚀,在使用分层法刻蚀出了图 4所示的四棱台和半球体等三维结构,证明了355 nm紫外脉冲激光对Si具有良好的三维微加工能力。齐立涛等[22]采用紫外固体激光静态照射SiC晶片表面,得到266 nm紫外激光烧蚀SiC晶片的烧蚀阈值,并在SiC晶片上加工出多种典型的微细结构,加工结构如图 5所示。

随着紫外激光器的发展和功率提升,利用紫外激光器对硅基材料进行刻划切割开始获得研究人员的关注。2002年,楼祺洪等[23]利用柱透镜光学系统和准分子激光器(波长193 nm),在硅上获得了宽度约为15 μm的切缝,切面不平整度约为5 μm。为了提升切割速度,研究提出了一种“热劈裂法”,即激光在硅片表面刻上一个细槽,细槽的内部应力发生变化,在外力作用下很容易在劈裂处发生断裂,并且研究表明采用“热劈裂法”切割细槽后掰断的断面表面质量高于直接切断的断面。2003年,Chen和Darling[24]研究表明紫外激光进行切割加工时,其切割质量和加工效率受到紫外激光器的多种参数直接影响,如激光功率、脉冲频率、扫描速度以及焦距距离等。Tom等[25]研究发现功率15 W的紫外激光器能够实现对厚度200 μm的硅片刻划的有效加工,实验中切割速度最高可达到20 mm/s以上,并且研究中还发现在提高切割的加工速度方面,提高脉冲频率相比于提高单脉冲能量更加快速有效。2004年,Gu等[26]利用铜蒸汽紫外激光(波长255 nm)在蓝宝石和氮化镓上进行微结构加工,获得了边缘均匀宽约50 μm的微槽以及高长径比的通孔,并对微型LED器件430 μm厚度的蓝宝石基成功进行切割,紫外激光加工对LED器件的性能并未产生明显影响。Baird等[27]利用紫外激光器在300 μm厚太阳能级多晶硅上加工出半径100 μm的圆角结构,并且未造成基体材料的损伤,展示出紫外激光在薄脆材料上精确加工的巨大优势。针对半导体材料加工需求,牛津激光有限公司研制的355 nm Nd: YAG激光器,其功率密度最高可以达到19 GW/cm2以上,能满足加工过程对快速去除材料的效率要求,同时加工过程中对加工区域边缘几乎不产生损伤,没有明显的热效应影响,能够获得极高的几何精度和边缘质量。

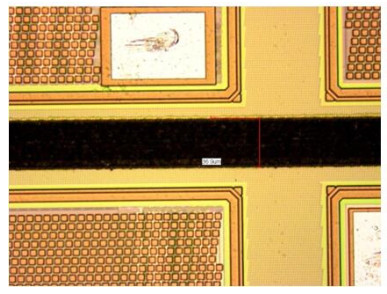

随着半导体芯片集成度不断提高,线宽越来越小,RC时延、串扰噪声和功耗等成为严重问题。在这样的背景下,low-k(低介电常数)层被引入到了集成电路领域,在集成电路内部,由于层间电介质的存在,导线之间不可避免地存在寄生电容。寄生电容不仅影响芯片的速度,也对工作可靠性构成严重威胁。在结构不变的情况下,减少电介质的k值,可以减小电容的容量。因此,使用low-k电介质作为层间电介质,可以有效地降低互连线之间的寄生电容。由于半导体工艺线宽不断减小,low-k晶圆激光开槽设备逐步进入了很多晶圆封装厂以满足先进封装的需求。紫外激光开槽设备采用业内最新“π”型分光加工方式,使用激光在开槽区域两侧划线,再利用激光线间刻蚀出“U”型槽,以此将传统刀轮难以处理的low-k层去除,实现切割深度和宽度可调,以确保较优的开槽工艺效果,如图 6所示。

3.2 微光学元件制备

借助微光学元件,人们可以在微米、纳米尺度上对光线的物理特性进行调控和利用,实现传统光学元件难以完成的光学变换功能,具有重大的前沿科学意义与应用前景。微光学元件以石英玻璃为主要材料。石英玻璃属于硬脆性材料,断裂韧性低,加工过程容易产生裂纹和凹坑,严重影响光学元件的表面质量和性能。因此,光学元件的制造对加工精度和表面质量提出严格要求。基于激光直写技术的紫外激光加工方法,能够实现高效率的冷加工,迅速完成光学元件的高精度微细结构制备,可满足大批量生产或者小批量试制的不同加工需要。

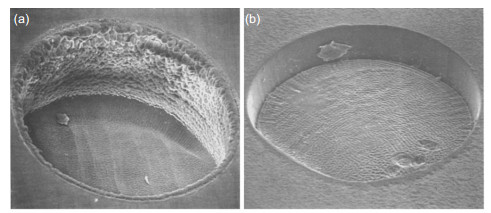

1992年,德国哥廷根激光研究院的Ihlemann等[28]介绍了其在石英玻璃上利用纳秒准分子激光器(波长为193 nm、248 nm、308 nm,脉冲宽度为20 ns~30 ns)和波长248 nm的飞秒激光器(脉冲宽度500 fs)进行的激光刻蚀实验。实验结果表明,激光刻蚀石英的加工效果不仅和激光的波长、脉冲宽度等参数有关,同时还受到石英原始表面质量的影响。实验中利用波长193 nm的准分子纳秒激光器,在厚为1 mm的石英上分别从反面和正面进行刻蚀加工圆槽,加工刻槽的结构如图 7所示。

2000年,日本理化研究所的Zhang等[29]首次利用双光束的方法对石英玻璃进行了刻蚀加工实验。实验采用波长248 nm的KrF准分子激光器和波长157 nm的F2激光器,并在氮气保护下通过调整两束激光的出光延时,完成预设的刻蚀加工,刻蚀的结果边缘平整无裂纹,同时明显提高了刻蚀底面的加工质量。Herman等[30]于2000年利用深紫外超快激光(脉宽1.2 ps)在透明玻璃上加工180 μm×125 μm深度6 μm的微图案。Sugiok[31]等2002年利用深紫外-紫外混合波长激光器石英玻璃上加工矩形截面坑,尺寸为30 μm×30 μm,深度为2 μm,过程几乎没有碎屑沉积和热损伤。王汕2012年[32]利用紫外激光器,采用激光诱导等离子体刻蚀方法在石英玻璃表面获得无脆裂崩边、整齐的刻蚀边缘,刻蚀底部粗糙度可达1 μm以下,且具有很好的重复性、一致性和稳定性。实验中的激光诱导等离子体刻蚀方法最大刻蚀深度达到22 μm。

陈涛等[33]利用248 nm纳秒准分子激光,通过掩模投影和直写刻蚀两种不同的方法在石英玻璃表面上实现了直线型(深度不超过50 μm)和圆弧形(深度不超过28.5 μm)微通道结构的无裂损加工,并对裂损的主要成因进行了分析研究,得出了石英玻璃无裂损加工的能量阈值区间。孙树峰等[34]利用铜膜作吸收层通过紫外激光诱导等离子体对Pyrex7740玻璃进行刻蚀加工,实验得出了刻蚀深度与激光能量密度的对应关系,并对刻蚀次数和刻蚀速度对刻蚀效果的影响进行了分析和总结。

3.3 聚合物加工

利用激光器在聚合物表面直接烧蚀出微结构,是激光加工在聚合物表面处理领域应用的重要研究方向之一。聚合物受温度的影响大,容易发生变形流动,影响加工效果和质量。由于红外或可见光波段激光热效应大,不具备高精度微细加工能力。紫外激光通过直接破坏连接物质原子组分的化学键,不对外围产生光热效应。因此,紫外激光器是加工薄橡胶和塑料制品等聚合物的理想工具[35]。

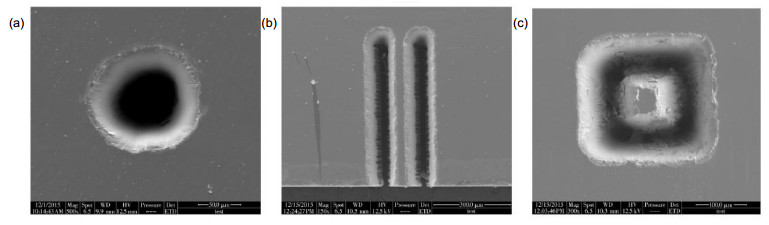

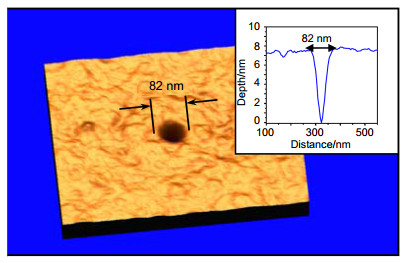

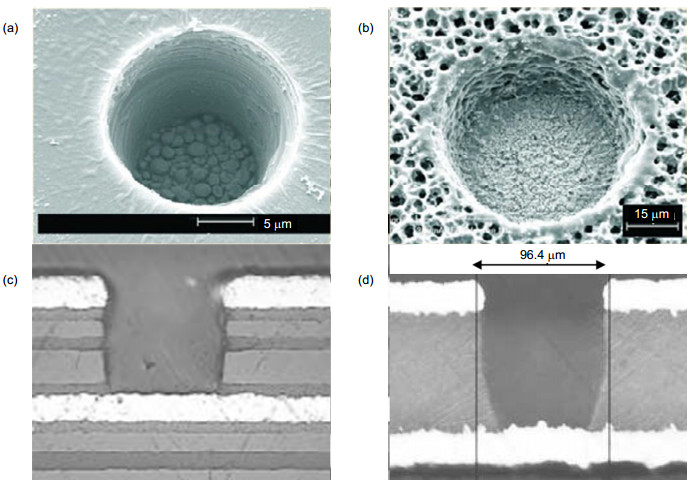

赵泽宇等[36]于2004年利用KrF准分子激光器对PC材料进行烧蚀加工,计算得出了PC材料在空气中对于248 nm激光的能量阈值,同时结果表明烧蚀的深度与脉冲次数保持着良好的线性关系。Aguilar等[37]于2005年使用ArF准分子激光在可生物降解的聚合物材料PCL薄膜上成功制备出193 nm的微孔图案。Menoni等[38]于2007年利用极紫外激光器在PMMA上加工出图 8所示的直径82 nm,深度7 nm的孔,孔内壁干净光洁且加工重复率高。Tiaw等[39]在2008年利用固态激光器在PCL薄膜进行了微孔织构化,孔直径4 μm,深度2 μm微孔,实现了薄聚合物膜的高质量精密加工。刘建国等[40]利用355 nm全固态激光器在PC材料进行刻蚀改性,获得多种亲水性和疏水性表面。Chan Park[41]等2015年通过使用355 nm UV脉冲激光,在厚度为0.1 mm的多孔PP(聚丙烯)片材上通过改变激光参数,制备出孔径可控的多孔图案。

随着电子技术的发展,印制电路板(PCB)生产制造技术也向着小型化、高密度、多层化方向发展,利用激光实现对PCB板的微加工也成为PCB生产领域的重要研究方向之一。PCB板主要由聚合物基板和铜箔导线等组成。紫外激光器在PCB加工中的应用主要为在基板上钻细孔、切割电路以及修复电路板。目前,紫外激光器可以在PCB电路板直接加工出孔径15 μm以下的孔,精度高且不易错位[42],图 9列出了紫外激光在聚酰亚胺(PI)上钻的直径15 μm微孔和环氧树脂上直径50 μm的微孔。红外或可见光激光能够较容易对PI膜实现加工,但是加工用于粘结膜与铜箔的粘结剂非常困难,如丙烯酸粘结剂对热非常敏感,很难通过加工彻底去除而不留任何残余物。从图 9可看到[42],利用紫外激光烧蚀能够彻底除去盲孔中的粘结剂,底部干净平整,被烧蚀的区域内没有留下任何残余物。

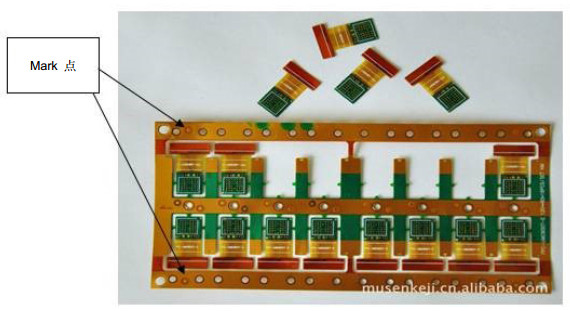

柔性电路板是目前印刷电路板行业增长最快的子行业之一。柔性PCB具有配线密度高、重量轻、厚度薄、弯折性好的特点,主要应用于小型、便携、可穿戴设备上。段军等[43]在2009年利用355 nm全固态紫外激光器在柔性电路板上通过分次加工得到了7 μm深的平整盲孔,并对不同加工方式得到的加工效果综合对比得到了一种优化的加工方法,能够解决传统同心圆扫描或螺旋线扫描钻孔法中微孔中心处过深的问题。国内的木森科技针对柔性PCB加工,利用机器视觉自动定位,打破了夹具加工精度和安装方式等限制条件,基于每一个电路单元的mark点确定柔性PCB板的实际变形情况,并有根据地选择mark点来进行紫外激光定位切割,有效解决了由于材质变形所产生的误差,其精度均控制在±0.05 mm以内,切割效果如图 10所示。

此外,紫外激光器可直接用于PCB电路板的制作以及缺陷修补。日本富士通研究所研制的高分辨紫外激光扫描装置,利用激光直写技术,能够直接在PCB上绘制复杂、精细的电路图[44]。传统的PCB电路板修复方法通常采用对故障发生位置进行微钻头钻孔的方式, 一旦故障出现在多层电路板的夹层中时, 传统的修复方法很难实现精确定位,同时钻孔工艺的难度提升,电路板的废品率也随之提高。而采用紫外激光加工,可以通过使用低功率、低脉冲频率进行预加工完成精确定位,再确定常规参数完成正常加工工作,减小出错的几率[45]。美国机器公司S.E休斯等[45]人利用脉冲紫外激光在有故障缺陷的PCB电路板上直接照射加工,在故障处形成通路连接,成功修复PCB板。

4. 结束语

经过几十年的研究和发展,紫外激光微加工技术已经在多个制造行业获得了应用,在半导体行业、光电行业、生物医疗等领域实现了多种材料的微加工,发展出了紫外激光钻孔、刻蚀、切割等多种精细加工工艺。

近年来,随着科技的进步和发展,加工设备的自动化和高度集成化发展推动着制造过程智能化。紫外激光微加工领域的进一步发展方向也将包含智能制造和柔性加工要求。紫外激光微加工技术由于其独特优势,对于精细制造工艺升级换代具有重要推进作用。目前,紫外激光技术化和产品化仍面临着许多难题:1)全固态激光器倍频晶体单一,转换效率低,输出功率较低;2)输出激光的线宽较宽,限制了窄线宽激光的实现;3)随着功率和峰值功率的提高,倍频晶体的光学损伤程度也随之加剧。具有高效率、高重复率、小型化、高功率稳定性等特点的全固态紫外激光器仍将成为未来紫外激光开发的主趋势之一,从技术上突破现有非线性晶体的局限性和开发新的晶体系列将是一项至关重要的工作。

-

表 1 Nd:YAG和Nd:YVO4的主要物理性质.

Table 1. The main physical properties of Nd:YAG and Nd:YVO4

晶体 Nd:YAG Nd:YVO4 受激发射截面/(10-20·cm2) 4.3 4.8(∥C), 4.3(⊥C) 荧光寿命/μs 230 97 吸收截面/(10-20·cm2) 7.9 60.1(∥C), 12.0(⊥C) 热导率/(W·m-1·K-1) 11 5.23(∥C), 5.10(⊥C) 表 2 LBO和KTP的部分物理性质.

Table 2. Partial physical properties of LBO and KTP.

晶体 LBO KTP 光学透过波长范围/nm 160~2600 350~3500 非线性系数/(pm/V) d31=1.05 d33=13.7 激光损伤阈值/(GW/cm2) 18.9 4.6 -

[1] 楼祺洪.准分子激光器的发展和应用[J].中国激光, 1994, 21(5): 361–364. http://www.opticsjournal.net/abstract.htm?id=OJ100819000037NjPmSp

Lou Qihong. Progress of excimer lasers and its applications[J]. Chinese Journal of Lasers, 1994, 21(5): 361–364. http://www.opticsjournal.net/abstract.htm?id=OJ100819000037NjPmSp

[2] Basov N G, Danilychev V A, Popov Y M, et al. Laser operating in vacuum region of spectrum by excitation of liquid xenon with an electron beam[J]. JETP Letters, 1970, 12(10): 329–331. http://adsabs.harvard.edu/abs/1970ZhPmR..12..473B

[3] Velazco J E, Setser D W. Bound-free emission spectra of diatomic xenon halides[J]. Journal of Chemical Physics, 1975, 62(5): 1990–1991. doi: 10.1063/1.430664

[4] Searles S K, Hart G A. Stimulated emission at 281.8 nm from XeBr[J]. Applied Physics Letters, 1975, 27(4): 243. doi: 10.1063/1.88409

[5] Makarov M K. Once upon a time: a hearty glance over the 30-year history of excimer lasers[J]. Proceedings of SPIE, 2005, 5777: 542–547. doi: 10.1117/12.611113

[6] 尤晨华, 陆祖康, 范琦康, 等.用BBO晶体获得200至218nm的紫外可调谐辐射[J].中国激光, 1989, 16(6): 327–329.

You Chenhua, Lu Zukang, Fan Qikang, et al. Generation of continuosly tunable UV radiation from 200 to 218nm using a BBO crystal[J]. Chinese Journal of Lasers, 1989, 16(6): 327–329.

[7] Kojima T, Konno S, Fujikawa S, et al. 20-W ultraviolet-beam generation by fourth-harmonic generation of an all-solid-state laser[J]. Optics Letters, 2000, 25(1): 58–60. doi: 10.1364/OL.25.000058

[8] Johansson S, Bjurshagen S, Canalias C, et al. An all solid-state UV source based on a frequency quadrupled, passively Q-switched 946 nm laser[J]. Optics Express, 2007, 15(2): 449–458. doi: 10.1364/OE.15.000449

[9] Kimmelma O P, Tittonen I, Buchter S C. Short pulse, diode pumped, passively Q-switched Nd: YAG laser at 946 nm quadrupled for UV production[J]. Journal of the European Optical Society-Rapid Publications, 2008, 3: 08008. doi: 10.2971/jeos.2008.08008

[10] Deyra L, Martial I, Didierjean J, et al. Deep-UV 236.5 nm laser by fourth-harmonic generation of a single-crystal fiber Nd: YAG oscillator[J]. Optics Letters, 2014, 39(8): 2236–2239. doi: 10.1364/OL.39.002236

[11] 许祖彦.深紫外全固态激光源[J].中国激光, 2009, 36(7): 1619–1624. http://www.opticsjournal.net/abstract.htm?aid=OJ090716000003B8EaGd

Xu Zuyan. Deep-ultraviolet diode-pumped solid-state laser[J]. Chinese Journal of Lasers, 2009, 36(7): 1619–1624. http://www.opticsjournal.net/abstract.htm?aid=OJ090716000003B8EaGd

[12] 陈创天, 许祖彦, 吕军华, 等. 一种非线性光学晶体激光变频耦合器: CN1172411C[P]. 2004-10-20.

Chen Chuangtian, Xu Zuyan, Lü Junhua, et al. Variable-frequency laser coupler with non-linear optical crystal: CN1172411C[P]. 2004-10-20.

[13] 许祖彦, 王保山, 宗楠, 等. 直接倍频实现波长160~170nm全固态深紫外激光的装置: CN102957083B[P]. 2014-09-03.

Xu Zuyan, Wang Baoshan, Zong Nan, et al. Device for implementing all-solid-state deep ultraviolet laser with wavelength of 160-170 nm through direct frequency doubling: CN102957083B [P]. 2014-09-03.

[14] Simon P, Ihlemann J. Ablation of submicron structures on metals and semiconductors by femtosecond UV-laser pulses[J].Applied Surface Science, 1997, 109–110: 25–29. doi: 10.1016/S0169-4332(96)00615-0

[15] Chen Chengyan, Chao C Y, Wu Z K, et al. Semiconductor material process with UV laser irradiation[C]//Proceedings of Summaries of Papers Presented at the Lasers and Electro-Optics, San Francisco, CA, USA, 1998: 153–154.

[16] He Liming. An investigation of three-dimensional construction methods in the micromachining of silicon surfaces with an ultraviolet laser[J]. Chinese Journal of Lasers, 1998, 7(5): 339–444. http://www.cnki.com.cn/Article/CJFDTotal-ZGJY805.009.htm

[17] 马炳和, 苑伟政, 李铁军, 等.准分子激光直接刻蚀单晶硅研究[J].西北工业大学学报, 2000, 18(3): 491–495. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xbgydxxb200003037

Ma Binghe, Yuan Weizheng, Li Tiejun, et al. Micromachining of monocrystal silicon by excimer laser direct etching[J]. Journal of Northwestern Polytechnical University, 2000, 18(3): 491–495. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xbgydxxb200003037

[18] Furukawa Y, Sasahara H, Kakuta A, et al. Principal factors affecting the sub-micrometer grooving mechanism of SiC thin layers by a 355 nm UV laser[J]. CIRP Annals, 2006, 55(1): 573–576. doi: 10.1016/S0007-8506(07)60485-5

[19] Gu E, Howard H, Conneely A, et al. Microfabrication in free-standing gallium nitride using UV laser micromachining[J]. Applied Surface Science, 2006, 252(13): 4897–4901. doi: 10.1016/j.apsusc.2005.07.117

[20] 朱冀梁, 张恒, 陈林森, 等.多光束纳秒紫外激光制作硅表面微结构[J].光子学报, 2009, 38(10): 2463–2467. https://www.wenkuxiazai.com/doc/0cc91ed433d4b14e8524684d.html

Zhu Jiliang, Zhang Heng, Chen Linsen, et al. Fabricating microstructure on the surface of silicon using multiple beam of nanosecond UV laser[J]. Acta Photonica Sinica, 2009, 38(10): 2463–2467. https://www.wenkuxiazai.com/doc/0cc91ed433d4b14e8524684d.html

[21] 杨雄. 单晶硅紫外激光微加工工艺研究[D]. 武汉: 华中科技大学, 2011.

Yang Xiong. A study on UV laser micro-machining single-crystal silicon[D]. Wuhan: Huazhong University of Science and Technology, 2011.

[22] 齐立涛, 刘文海. 266 nm紫外固体激光在碳化硅晶片上的微结构加工[J].黑龙江科技大学学报, 2017, 27(2): 176–180. http://www.opticsjournal.net/Journals/zgjg.htm?action=down

Qi Litao, Liu Wenhai. Experimental investigation on 266 nm UV solid-state laser micromachining of microstructures on SiC wafer[J].Journal of Heilongjiang University of Science and Technology, 2017, 27(2): 176–180. http://www.opticsjournal.net/Journals/zgjg.htm?action=down

[23] 楼祺洪, 章琳, 叶震寰, 等.紫外激光切割Si片的实验研究[J].激光技术, 2002, 26(4): 250–251, 254. http://www.cqvip.com/QK/92283X/200204/6674260.html

Lou Qihong, Zhang Lin, Ye Zhenhuan, et al. Experimental research on Si cutting by using UV excimer laser[J]. Laser Technology, 2002, 26(4): 250–251, 254. http://www.cqvip.com/QK/92283X/200204/6674260.html

[24] Chen Taichen, Robert B D. Parametric studies on pulsed near ultraviolet frequency tripled Nd: YAG laser micromachining of sapphire and silicon[J]. Journal of Materials Processing Technology, 2005, 169(2): 214–218. doi: 10.1016/j.jmatprotec.2005.03.023

[25] Tom C, Edward C R, Corey D. High-power UV laser machining of silicon wafers[J]. Proceedings of SPIE, 2003, 5063: 495–500. doi: 10.1117/12.540931

[26] Gu E, Jeon C W, Choi H W, et al. Micromachining and dicing of sapphire, gallium nitride and micro LED devices with UV copper vapour laser[J]. Thin Solid Films, 2004, 453–454: 462–466. https://www.sciencedirect.com/science/article/pii/S0040609003017383

[27] Baird B W, Hainsey R F, Peng X, et al. Advances in laser processing of microelectronics[J]. Proceedings of SPIE, 2007, 6451: 64511K. doi: 10.1117/12.713213

[28] Ihlemann J, Wolff B, Simon P. Nanosecond and femtosecond excimer laser ablation of fused silica[J]. Applied Physics A, 1992, 54(4): 363–368. doi: 10.1007/BF00324203

[29] Zhang J, Sugioka K, Takahashi T, et al. Dual-beam ablation of fused silica by multiwavelength excitation process using KrF excimer and F2 lasers[J]. Applied Physics A, 2000, 71(1): 23–26. https://link.springer.com/content/pdf/10.1007/PL00021086.pdf

[30] Herman P R, Marjoribanks R S, Oettl A, et al. Laser shaping of photonic materials: deep-ultraviolet and ultrafast lasers[J]. Applied Surface Science, 2000, 154–155: 577–586. doi: 10.1016/S0169-4332(99)00463-8

[31] Sugioka K, Akane T, Obata K, et al. Multiwavelength excitation processing using F2 and KrF excimer lasers for precision microfabrication of hard materials[J]. Applied Surface Science, 2002, 197–198: 814–821. doi: 10.1016/S0169-4332(02)00465-8

[32] 王汕. 激光刻蚀抛光石英玻璃工艺研究[D]. 武汉: 华中科技大学, 2012.

Wang Shan. A study on laser etching and polishing quartz glasses technology[D]. Wuhan: Huazhong University of Science and Technology, 2012.

[33] 杨桂栓, 陈涛, 陈虹. 248 nm准分子激光刻蚀的无裂损石英玻璃表面微通道[J].中国激光, 2017, 44(9): 0902004. http://www.opticsjournal.net/Articles/abstract?aid=OJ171012000156JfMiOl

Yang Guishuan, Chen Tao, Chen Hong. Crack-free silica glass surface micro-grooves etched by 248 nm excimer lasers[J]. Chinese Journal of Lasers, 2017, 44(9): 0902004. http://www.opticsjournal.net/Articles/abstract?aid=OJ171012000156JfMiOl

[34] 邵勇, 孙树峰, 廖慧鹏, 等.激光诱导等离子体刻蚀Pyrex7740玻璃工艺研究[J].应用激光, 2017, 37(5): 704–708.

Shao Yong, Sun Shufeng, Liao Huipeng, et al. Process study on laser induced plasma etching of pyrex7740 glass[J]. Applied Laser, 2017, 37(5): 704–708.

[35] Delmdahl R, Pätzel R. Pulsed laser deposition—UV laser sources and applications[J]. Applied Physics A, 2008, 93(3): 611–615. doi: 10.1007/s00339-008-4716-7

[36] 赵泽宇, 侯德胜, 董小春, 等.准分子激光刻蚀聚碳酸酯材料研究[J].光电工程, 2004, 31(2): 4–7. https://www.wenkuxiazai.com/doc/5a7353868762caaedd33d4f9.html

Zhao Zeyu, Hou Desheng, Dong Xiaochun, et al. Research on etching properties of polycarbonate by KrF excimer laser[J]. Opto-Electronic Engineering, 2004, 31(2): 4–7. https://www.wenkuxiazai.com/doc/5a7353868762caaedd33d4f9.html

[37] Aguilar C A, Lu Yi, Mao S, et al. Direct micro-patterning of biodegradable polymers using ultraviolet and femtosecond lasers[J]. Biomaterials, 2005, 26(36): 7642–7649. doi: 10.1016/j.biomaterials.2005.04.053

[38] Menoni C S, Brizuela F, Brewer C, et al. Nanoscale resolution microscopy and ablation with extreme ultraviolet lasers[C]//Proceedings of the 20th Annual Meeting of the IEEE Lasers and Electro-Optics Society, Lake Buena Vista, FL, UAS, 2007: 488–489.

[39] Tiaw K S, Hong M H, Teoh S H. Precision laser micro-processing of polymers[J]. Journal of Alloys and Compounds, 2008, 449(1–2): 228–231. doi: 10.1016/j.jallcom.2006.01.145

[40] 王素焕, 刘建国, 吕铭, 等.脉冲紫外激光改性对聚碳酸酯表面润湿性能的影响[J].光电工程, 2013, 40(7): 77–82. http://doi.wanfangdata.com.cn/10.3969/j.issn.1003-501X.2013.07.013

Wang Suhuan, Liu Jianguo, Lü Ming, et al. The effect of pulse ultraviolet laser modification on the surface wetting property of polycarbonate[J]. Opto-Electronic Engineering, 2013, 40(7): 77–82. http://doi.wanfangdata.com.cn/10.3969/j.issn.1003-501X.2013.07.013

[41] Park C, Shin B S, Kang M S, et al. Experimental study on micro-porous patterning using UV pulse laser hybrid process with chemical foaming agent[J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(7): 1385–1390. doi: 10.1007/s12541-015-0182-2

[42] Lei Weisheng, Davignon J. Solid state UV laser technology for electronic packaging applications[J].Proceedings of SPIE, 2005, 5629: 314–326. doi: 10.1117/12.571520

[43] 张菲, 段军, 曾晓雁, 等. 355 nm紫外激光加工柔性线路板盲孔的研究[J].中国激光, 2009, 36(12): 3143–3148. http://www.cqvip.com/QK/95389X/200912/32405575.html

Zhang Fei, Duan Jun, Zeng Xiaoyan, et al. Study of blind holes drilling on flexible circuit board using 355nm UV laser[J].Chinese Journal of Lasers, 2009, 36(12): 3143–3148. http://www.cqvip.com/QK/95389X/200912/32405575.html

[44] 张林华, 杨永强, 来克娴.激光技术在大规模集成电路中的应用及展望[J].激光与光电子学进展, 2005, 42(6): 48–55. http://www.cqvip.com/QK/92536A/200506/15785885.html

Zhang Linhua, Yang Yongqiang, Lai Kexian. Laser in large-scale integrated circuit: application and prospects[J]. Laser & Optoelectronics Progress, 2005, 42(6): 48–55. http://www.cqvip.com/QK/92536A/200506/15785885.html

[45] 凌磊, 楼祺洪, 叶震寰, 等.紫外激光刻蚀多层线路板初步研究[J].中国激光, 2003, 30(10): 953–955. doi: 10.3321/j.issn:0258-7025.2003.10.021

Ling Lei, Lou Qihong, Ye Zhenhuan, et al. Ablation of circuit board by pulsed UV laser[J]. Chinese Journal of Lasers, 2003, 30(10): 953–955. doi: 10.3321/j.issn:0258-7025.2003.10.021

期刊类型引用(19)

1. 杨晰雅,魏嘉丽,吕毅,吴荣谦,宋承华. UVC波段光源设备的发展现状及医用前景分析. 中国医疗设备. 2024(02): 1-9 .  百度学术

百度学术

2. 杨旭,杨博义,刘学胜. 低损耗紫外空芯反谐振光纤的设计与研究. 光电技术应用. 2024(02): 27-30 .  百度学术

百度学术

3. 齐立涛,陈金鑫,田振. 不同环境中纳秒激光烧蚀单晶硅的物质抛出机理. 激光技术. 2023(06): 824-830 .  百度学术

百度学术

4. 李奇,王金艳,季鑫,王斌,陈曦,郑权. 371~385 nm可调谐翠绿宝石连续激光器. 红外与激光工程. 2023(11): 32-37 .  百度学术

百度学术

5. 张怀智,徐家明,张兰天,秦应雄. 硅晶圆多焦点激光隐切算法与实验. 中国激光. 2022(02): 200-206 .  百度学术

百度学术

6. 矫知真,韩星尘,周昊,韩冬冬. 光/电响应型超滑表面的激光加工制备. 光电工程. 2022(02): 79-88 .  本站查看

本站查看

7. 齐立涛,刘凤聪,张耀东. 266nm紫外固体激光切割碳纤维复合材料的实验研究. 激光技术. 2022(03): 402-407 .  百度学术

百度学术

8. 陆慧娟,欧卓东,黄兵,黄欣,王成勇,郑李娟. 飞秒激光加工高频挠性板基材微孔研究. 机械科学与技术. 2022(08): 1224-1230 .  百度学术

百度学术

9. 程立,吴超,陈燕,熊政军. LCP挠性覆铜板紫外激光去膜工艺分析. 激光与光电子学进展. 2022(17): 253-261 .  百度学术

百度学术

10. 孙浩,田文龙,王博文,于兆磊,朱江峰,魏志义. 全固态飞秒激光高光束质量三倍频研究(特邀). 光子学报. 2021(10): 181-187 .  百度学术

百度学术

11. 熊伟国,朱元成. 基于微型压缩机的高精度紫外激光器温控研究. 激光与红外. 2021(10): 1321-1326 .  百度学术

百度学术

12. 高永强,史兴隆. 紫外激光刻蚀单晶硅片工艺的试验研究. 应用激光. 2021(05): 974-978 .  百度学术

百度学术

13. 詹蕊绮,李宏韬,张玮,萧俊龙. 巨量转移-激光转移及激光对AlGaInP芯片影响的研究. 微纳电子与智能制造. 2021(04): 15-23 .  百度学术

百度学术

14. 孙瑞琦. 聚甲醛材料在光学冷加工中的应用. 科学技术创新. 2020(23): 157-158 .  百度学术

百度学术

15. 王梦玲,高寿飞,汪滢莹,王璞. 紫外空芯反谐振光纤的研制. 中国激光. 2020(08): 221-227 .  百度学术

百度学术

16. 王金艳,李奇,陈曦,郑权,李世杰,陈磊. 全固态高重复频率244 nm紫外激光器. 中国激光. 2019(09): 72-75 .  百度学术

百度学术

17. 张诗梦,崔源,贾真,王浩,岱钦. LD端面泵浦Nd: YVO_4高重频紫外激光器. 沈阳理工大学学报. 2019(05): 81-84 .  百度学术

百度学术

18. 李奇思,梁庭,雷程,李旺旺,林立娜,杨娇燕,熊继军. 355 nm全固态紫外激光直写刻蚀硼硅玻璃微通道. 中国激光. 2018(08): 79-86 .  百度学术

百度学术

19. 李旦,李其亮. 基于超短激光微加工的数控人机交互界面设计. 激光杂志. 2018(12): 93-97 .  百度学术

百度学术

其他类型引用(28)

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: