-

摘要

由于超疏水表面在防腐、油水分离、流体减阻和液体转移方面的应用潜力,如何制作性能优异的超疏水表面成为研究热点。材料表面的形貌特征是决定其润湿性能的一个重要因素,因此,通常采用表面结构化来获得超疏水性能。在材料表面构织微纳结构方面,基于脉冲激光的微纳加工技术具有得天独厚的优势,尤其是在制作特定图案的复杂结构方面。本文根据激光器的脉冲宽度分类,通过刻蚀后材料表面形貌和润湿性特征对激光制作超疏水表面的基本理论和典型工艺方法进行介绍和总结,并对超疏水表面的发展前景作出展望。

Abstract

Over the past few decades, many methods have been developed to fabricate superhydrophobic surfaces because these surfaces are useful in several important applications such as anti-corrosion, oil-water separation, friction reduction, and liquid transportation. Surface morphology is a key factor to determine the wettability of a solid surface, and patterning is one of the effective ways to change the surface morphology and to improve the wetting properties. Laser patterning using a pulse laser source is a unique technique that can modify the surface morphology with very limited distortion of the bulk material. Moreover, it is a noncontact method, and complex patterns can be created. In this paper, we summarized several typical approaches, theories and relevant applications of laser fabricated superhydrophobic surfaces.

-

Key words:

- superhydrophobic surface /

- laser processing /

- contact angle /

- sliding angle

-

Overview

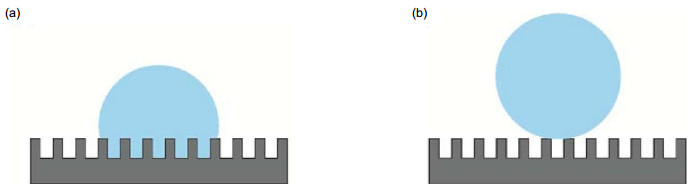

Abstract: Superhydrophobic surfaces, which are defined by the water contact angle higher than 150° and the slide angle lower than 10°, have recently attracted more and more attention due to their important applications in anti-corrosion, oil-water separation, friction reduction, and liquid transportation. Over the past few decades, many methods have been developed to fabricate superhydrophobic surfaces which can usually be achieved by creating a rough surface structure on a hydrophobic material or depositing a layer of chemical molecules with low surface energy onto a rough surface, so surface morphology is a key factor to determine the wettability of a solid surface, and patterning is one of the effective ways to change the surface morphology and to improve the wetting properties. Laser patterning using a pulse laser source is a unique technique that can modify the surface morphology with very limited distortion of the bulk material. Moreover, it is a noncontact method, and complex patterns can be created. The basic wettability theory of solid surface was introduced, such as Young equation, Wenzel model, Cassie-Baxter model, wetting courses and conditions. As the surperhydrophobicity depends on the surface microstructure of materials, and the pulse width is one of the key factors affecting the processing accuracy and quality of laser fabricated microstructure, the research progress in the superhydrophobic surfaces fabricated by laser was classified based on the laser pulse width (nanosecond, picosecond and femtosecond). Several typical approaches of laser fabricated superhydrophobic surfaces were summarized, including the laser texturing and subsequent surface modified technologies, meanwhile the surface morphologies and wetting properties of the surperhydrophobic surfaces fabricated with different laser pulse width were compared, and the relevant applications were also presented. The cost of nanosecond laser is relatively low, but the processing accuracy is restricted by the diffraction theory, and the nanosecond laser is not suitable for fabricating superhydrophobic surface on hard-brittle transparent materials, so as on low-melting materials. The nonlinear absorption effect of femtosecond laser could obtain the processing accuracy which is much smaller than the focal spot, meanwhile depending on this effect, microstructure superhydrophobic surfaces could be fabricated on almost all the solid materials. Although the research in the field of superhydrophobic surfaces has been conducted for over ten years, the fabricating cost and durability still could not meet the requirements of industrial application.

-

-

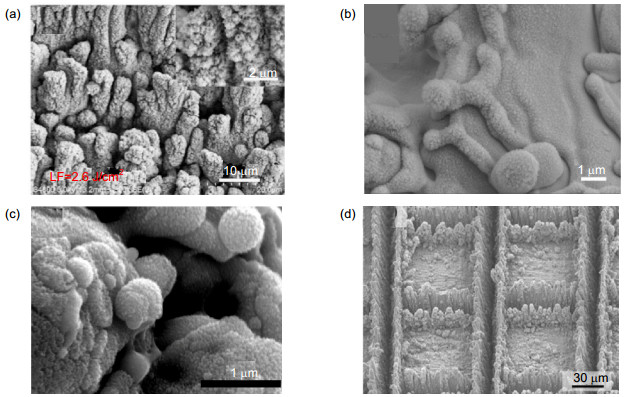

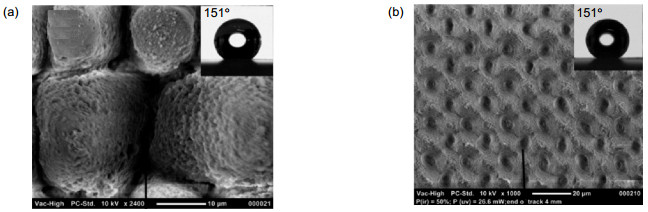

图 3 (a) 纳秒激光在钨表面制备微纳结构[36]. (b)纳秒激光在不锈钢表面制备的超疏水结构[37]. (c)纳秒紫外激光在金属表面制备微纳米复合结构[38]. (d)红外纳秒激光在纯铜表面制作超疏水结构[39].

Figure 3. (a) Micro-nano structures fabricated on tungsten by nanosecond laser[36]. (b) Superhydrophobic structure fabricated on SUS by nanosecond laser[37]. (c) Micro-nano structures fabricated on metal by UV nanosecond laser[38]. (d) Superhydrophobic structure fabricated on copper by IR nanosecond laser[39].

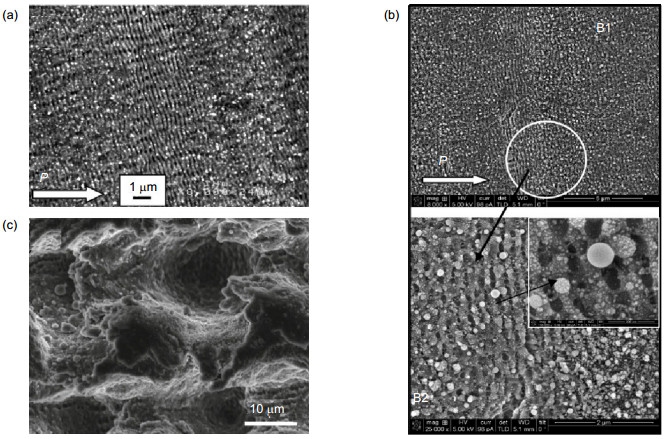

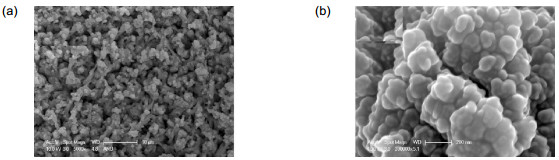

图 4 (a) 皮秒激光作用于不锈钢表面显微形貌[40]. (b)皮秒激光作用于钛合金表面显微形貌[40]. (c)皮秒激光作用于铝合金表面显微形貌[41].

Figure 4. (a) Micro-nano structures fabricated on SUS by picosecond laser[40]. (b) Micro-nano structures fabricated on titanium metal by picosecond laser[40]. (c) Micro-nano structures fabricated on aluminium metal by picosecond laser[41].

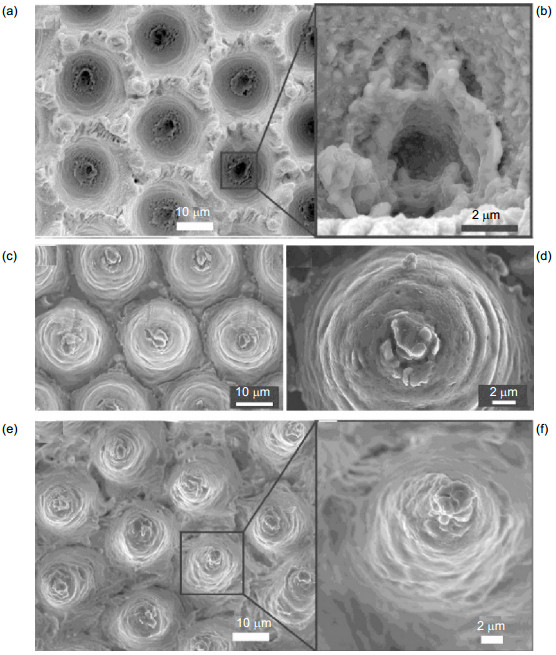

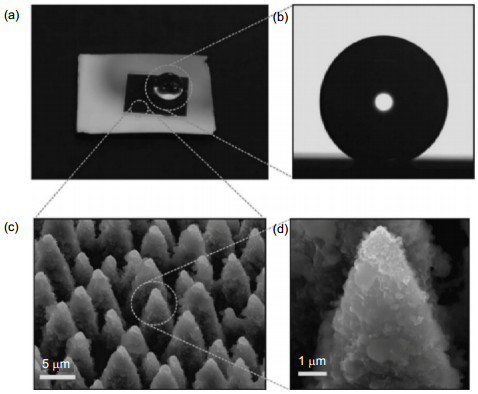

图 5 激光制造磨具钢压印模板及压印铝合金和硅橡胶表面形貌[42]. (a)皮秒激光加工磨具钢后SEM图片. (b)皮秒激光加工磨具钢后单个凹坑显微结构. (c)铝合金压铸后表面凸起结构. (d)铝合金压铸后单个凸起显微. (e)硅橡胶表面凸起结构. (f)单个凸起高倍显微结构.

Figure 5. Surface morphologies of mold surface fabricated by laser and imprinted silicone rubber surfaces[42]. (a) SEM picture of die steel ablated by picosecond. (b) SEM picture of the single concave. (c) Aluminium alloy fabricated by casting. (d) SEM picture of the single convex on the aluminum alloy. (e) Silicone rubber fabricated by casting. (f) SEM picture of the single convex on the silicone rubber.

图 9 飞秒激光在不锈钢表面制备超疏水表面微观结构[49]. (a)激光能量密度和扫描速度对材料表面结构的影响. (b)激光能量密度为77.1 J/cm2时表面形貌及超疏水性能. (c)激光能量密度为184 J/cm2时表面形貌及超疏水性能.

Figure 9. Micro-nano structures fabricated on SUS by femtosecond laser[49]. (a) Effect of the fluence and scanning speed on micro-nano structure. (b) Superhydrophobic surface at the fluence of 77.1 J/cm2. (c) Superhydrophobic surface at the fluence of 184 J/cm2.

-

参考文献

[1] Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in biological surfaces[J]. Planta, 1997, 202(1): 1–8. doi: 10.1007/s004250050096

[2] 周文木. 生物表面海洋防污性能研究[D]. 长沙: 国防科学技术大学, 2010.

Zhou Wenmu. Research on marine antifouling performances of biologic surface[D]. Changsha: National University of Defense Technology, 2010.

http://cdmd.cnki.com.cn/Article/CDMD-90002-1011280029.htm [3] Koch K, Bhushan B, Barthlott W. Diversity of structure, mor-phology and wetting of plant surfaces[J]. Soft Matter, 2008, 4(10): 1943–1963. doi: 10.1039/b804854a

[4] Duparré A, Flemming M, Steinert J, et al. Optical coatings with enhanced roughness for ultrahydrophobic, low-scatter applications[J]. Applied Optics, 2002, 41(16): 3294–3298. doi: 10.1364/AO.41.003294

[5] Zhang H, Lamb R, Lewis J. Engineering nanoscale roughness on hydrophobic surface—preliminary assessment of fouling behaviour[J]. Science and Technology of Advanced Materials, 2005, 6(3-4): 236–239. doi: 10.1016/j.stam.2005.03.003

[6] Li Shenghai, Xie Haibo, Zhang Suobo, et al. Facile transformation of hydrophilic cellulose into superhydrophobic cellulose[J]. Chemical Communications, 2007, 46: 4857–4859. https://www.researchgate.net/publication/5491724_Facile_transformation_of_hydrophilic_cellulose_into_superhydrophobic_cellulose

[7] Onda T, Shibuichi S, Satoh N, et al. Super-water-repellent fractal surfaces[J]. Langmuir, 1996, 12(9): 2125–2127. doi: 10.1021/la950418o

[8] Shibuichi S, Onda N, Satoh N, et al. Super water-repellent surfaces resulting from fractal structure[J]. Journal of Physical Chemistry, 1996, 100(50): 19512–19517. doi: 10.1021/jp9616728

[9] Chen Wei, Fadeev A Y, Hsieh M C, et al. Ultrahydrophobic and ultralyophobic surfaces: some comments and examples[J]. Langmuir, 1999, 15(10): 3395–3399. doi: 10.1021/la990074s

[10] Oner D, McCarthy T J. Ultrahydrophobic surfaces. effects of topography length scales on wettability[J]. Langmuir, 2000, 16(20): 7777–7782. doi: 10.1021/la000598o

[11] Matsumoto Y, Ishida M. The property of plasma-polymerized fluorocarbon film in relation to CH4/C4F8 ratio and substrate temperature[J]. Sensors and Actuators A: Physical, 2000, 83(1–3): 179–185. doi: 10.1016/S0924-4247(99)00396-9

[12] Wu Y, Sugimura H, Inoue Y, et al. Thin films with nanotextures for transparent and ultra water-repellent coatings produced from trimethylmethoxysilane by microwave plasma CVD[J]. Chemical Vapor Deposition, 2002, 8(2): 47–50. doi: 10.1002/(ISSN)1521-3862

[13] Takeda K, Sasaki M, Kieda N, et al. Preparation of transparent super-hydrophobic polymer film with brightness enhancement property[J]. Journal of Materials Science Letters, 2001, 20(23): 2131–2133. doi: 10.1023/A:1013724314507

[14] Shibuichi S, Yamamoto T, Onda T, et al. Super water-and oil-repellent surfaces resulting from fractal structure[J]. Journal of Colloid and Interface Science, 1998, 208(1): 287–294. doi: 10.1006/jcis.1998.5813

[15] Miwa M, Nakajima A, Fujishima A, et al. Effects of the surface roughness on sliding angles of water droplets on superhydrophobic surfaces[J]. Langmuir, 2000, 16(13): 5754–5760. doi: 10.1021/la991660o

[16] Nakajima A, Abe K, Hashimoto K, et al. Preparation of hard super-hydrophobic films with visible light transmission[J]. Thin Solid Films, 2000, 376(1–2): 140–143. doi: 10.1016/S0040-6090(00)01417-6

[17] Tadanaga K, Morinaga J, Minami T. Formation of superhydrophobic-superhydrophilic pattern on flowerlike alumina thin film by the sol-gel method[J]. Journal of Sol-Gel Science and Technology, 2000, 19(1–3): 211–214. https://link.springer.com/article/10.1023/A:1008732204421

[18] Li Shuhong, Li Huanjun, Wang Xianbao, et al. Su-per-hydrophobicity of large-area honeycomb-like aligned carbon nanotubes[J]. Journal of Physical Chemistry B, 2002, 106(36): 9274–9276. doi: 10.1021/jp0209401

[19] Veeramasuneni S, Drelich J, Miller J D, et al. Hydrophobicity of ion-plated PTFE coatings[J]. Progress in Organic Coatings, 1997, 31(3): 265–270. doi: 10.1016/S0300-9440(97)00085-4

[20] Miller J D, Veeramasuneni S, Drelich J, et al. Effect of rough-ness as determined by atomic force microscopy on the wetting properties of PTFE thin films[J]. Polymer Engineering & Sci-ence, 1996, 36(14): 1849–1855. http://www.mse.mtu.edu/~jwdrelic/1996PES.pdf

[21] Genzer J, Efimenko K. Creating long-lived superhydrophobic polymer surfaces through mechanically assembled monolay-ers[J]. Science, 2000, 290(5499): 2130–2133. doi: 10.1126/science.290.5499.2130

[22] Nakajima A, Saiki C, Hashimoto K, et al. Processing of roughened silica film by coagulated colloidal silica for su-per-hydrophobic coating[J]. Journal of Materials Science Letters, 2001, 20(21): 1975–1977. doi: 10.1023/A:1013199105688

[23] Erbil H Y, Demirel A L, Avci Y, et al. Transformation of a simple plastic into a superhydrophobic surface[J]. Science, 2003, 299(5611): 1377–1380. doi: 10.1126/science.1078365

[24] 钱柏太. 金属基体上超疏水表面的制备研究[D]. 大连: 大连理工大学, 2006.

Qian Baitai. Study on fabrication of superhydrophobic sur-faces on metallic substrates[D]. Dalian: Dalian University of Technology, 2006.

http://cdmd.cnki.com.cn/Article/CDMD-10141-2006064917.htm [25] 江雷.从自然到仿生的超疏水纳米界面材料[J].化工进展, 2003, 23(12): 1258–1264. doi: 10.3321/j.issn:1000-6613.2003.12.002

Jiang Lei. Nanostructured materials with superhydrophobic surface——from nature to biomimesis[J]. Chemical Industry and Engineering Progress, 2003, 23(12): 1258–1264. doi: 10.3321/j.issn:1000-6613.2003.12.002

[26] 颜肖慈, 罗明道.界面化学[M].北京:化学工业出版社, 2005.

Yan Xiaoci, Luo Mingdao. Surface Chemistry[M]. Beijing: Chemical Industry Press, 2005.

[27] 滕新荣.表面物理化学[M].北京:化学工业出版社, 2009.

Teng Xinrong. Surface physical chemistry[M]. Beijing: Chemical Technology Press, 2009.

[28] Young T. An essay on the cohesion of fluids[J]. Philosophical Transactions of the Royal Society of London, 1805, 95: 65–87. doi: 10.1098/rstl.1805.0005

[29] Furmidge C G L. Studies at phase interfaces. I. The sliding of liquid drops on solid surfaces and a theory for spray retention [J]. Journal of Colloid and Interface Science, 1962, 17: 309– 324. doi: 10.1016/0095-8522(62)90011-9

[30] Wenzel P N. Resistance of solid surfaces to wetting by wa-ter[J]. Industrial & Engineering Chemistry, 1936, 28(8): 988–994. https://pubs.acs.org/doi/abs/10.1021/ie50320a024

[31] Cassie A B D, Baxter S. Wettability of porous surfaces[J]. Transactions of the Faraday Society, 1944, 40: 546–551. doi: 10.1039/tf9444000546

[32] Quéré D, Lafuma A, Bico J. Slippy and sticky microtextured solids[J]. Nanotechnology, 2003, 14(10): 1109–1112. doi: 10.1088/0957-4484/14/10/307

[33] Peters A M, Pirat C, Sbragaglia M, et al. Cassie-Baxter to Wenzel state wetting transition: Scaling of the front velocity[J]. The European Physical Journal E, 2009, 29(4): 391–397. doi: 10.1140/epje/i2009-10489-3

[34] Nishino T, Meguro M, Nakamae K, et al. The lowest surface free energy based on −CF3 alignment[J]. Langmuir, 1999, 15(13): 4321–4323. doi: 10.1021/la981727s

[35] Blossey R. Self-cleaning surfaces-virtual realities[J]. Nature Materials, 2003, 2(5): 301–306. doi: 10.1038/nmat856

[36] He Haidong, Qu Ningsong, Zeng Yongbin. Lotus-leaf-like microstructures on tungsten surface induced by one-step nanosecond laser irradiation[J]. Surface and Coatings Technology, 2016, 307: 898–907. doi: 10.1016/j.surfcoat.2016.10.033

[37] Emelyanenko A M, Shagieva F M, Domantovsky A G, et al. Nanosecond laser micro-and nanotexturing for the design of a superhydrophobic coating robust against long-term contact with water, cavitation, and abrasion[J]. Applied Surface Science, 2015, 332: 513–517. doi: 10.1016/j.apsusc.2015.01.202

[38] Tang T, Shim V, Pan Z Y, et al. Laser ablation of metal sub-strates for super-hydrophobic effect[J]. Journal of Laser Mi-cro/Nanoengineering, 2011, 6(1): 6–9. doi: 10.2961/jlmn.2011.01.0002

[39] Chun D M, Ngo C V, Lee K M. Fast fabrication of superhydrophobic metallic surface using nanosecond laser texturing and low-temperature annealing[J]. CIRP Annals, 2016, 65(1): 519– 522. doi: 10.1016/j.cirp.2016.04.019

[40] Jagdheesh R, Pathiraj B, Karatay E, et al. Laser-induced nanoscale superhydrophobic structures on metal surfaces[J]. Langmuir, 2011, 27(13): 8464–8469. doi: 10.1021/la2011088

[41] Long Jiangyou, Zhong Minlin, Zhang Hongjun, et al. Superhydrophilicity to superhydrophobicity transition of picosecond laser microstructured aluminum in ambient air[J]. Journal of Colloid and Interface Science, 2015, 441: 1–9. doi: 10.1016/j.jcis.2014.11.015

[42] 林澄. 皮秒激光制备大面积金属类荷叶结构及其超疏水压印研究[D]. 北京: 清华大学, 2014.

Lin Cheng. Large-area Metal lotus-like structures fabricated by picosecond laser for superhydrophobic surface repli-cation[D]. Beijing: Tsinghua University, 2014.

[43] Jagdheesh R. Fabrication of a superhydrophobic Al2O3 surface using picosecond laser pulses[J]. Langmuir, 2014, 30(40): 12067–12073. doi: 10.1021/la5033527

[44] Baldacchini T, Carey J E, Zhou Ming, et al. Superhydrophobic surfaces prepared by microstructuring of silicon using a femtosecond laser[J]. Langmuir, 2006, 22(11): 4917–4919. doi: 10.1021/la053374k

[45] Yong Jiale, Yang Qing, Chen Feng, et al. Stable superhydrophobic surface with hierarchical mesh-porous structure fabricated by a femtosecond laser[J]. Applied Physics A, 2013, 111(1): 243–249. doi: 10.1007/s00339-013-7572-z

[46] Zhang Dongshi, Chen Feng, Fang Guoping, et al. Wetting characteristics on hierarchical structures patterned by a femtosecond laser[J]. Journal of Micromechanics and Micro-engineering, 2010, 20(7): 075029. doi: 10.1088/0960-1317/20/7/075029

[47] Zorba V, Stratakis E, Barberoglou M, et al. Biomimetic artificial surfaces quantitatively reproduce the water repellency of a lotus leaf[J]. Advanced Materials, 2008, 20(21): 4049–4054. doi: 10.1002/adma.v20:21

[48] Yoon T O, Shin H J, Jeoung S C, et al. Formation of superhydrophobic poly(dimethysiloxane) by ultrafast laser-induced surface modification[J]. Optics Express, 2008, 16(17): 12715– 12725. doi: 10.1364/OE.16.012715

[49] Moradi S, Kamal S, Englezos P, et al. Femtosecond laser irradiation of metallic surfaces: effects of laser parameters on superhydrophobicity[J]. Nanotechnology, 2013, 24(41): 415302. doi: 10.1088/0957-4484/24/41/415302

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: