-

摘要

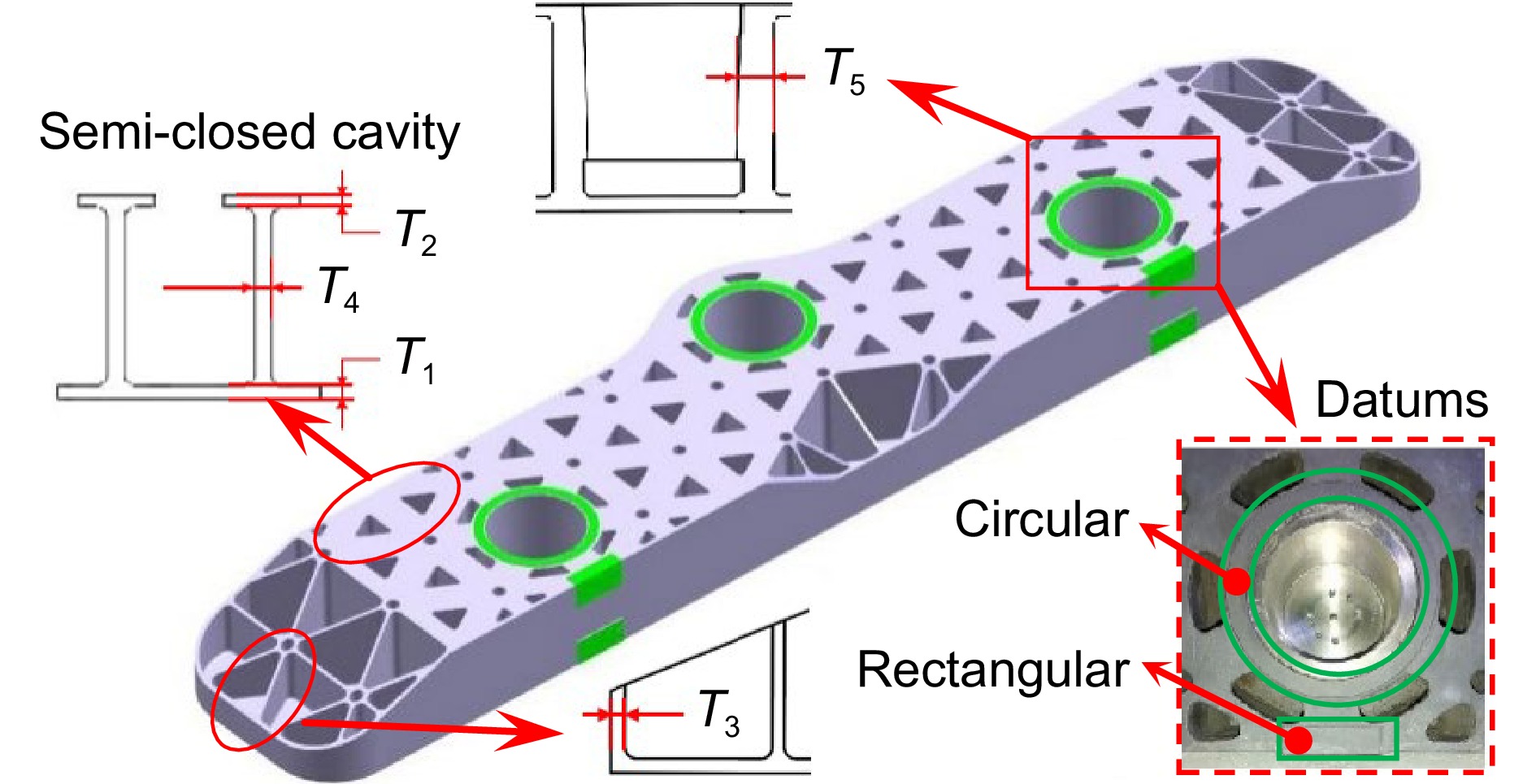

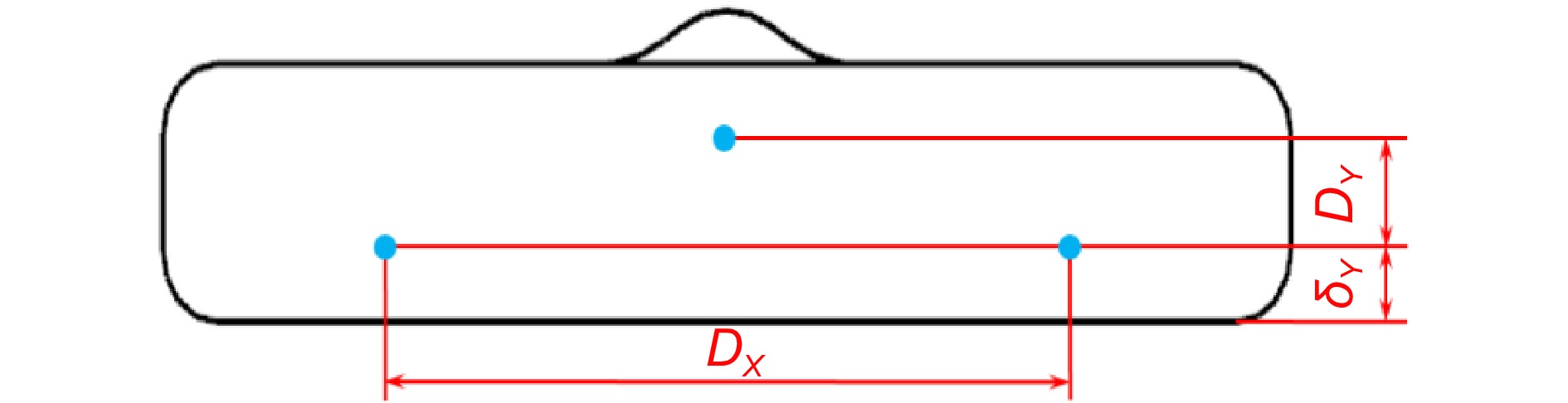

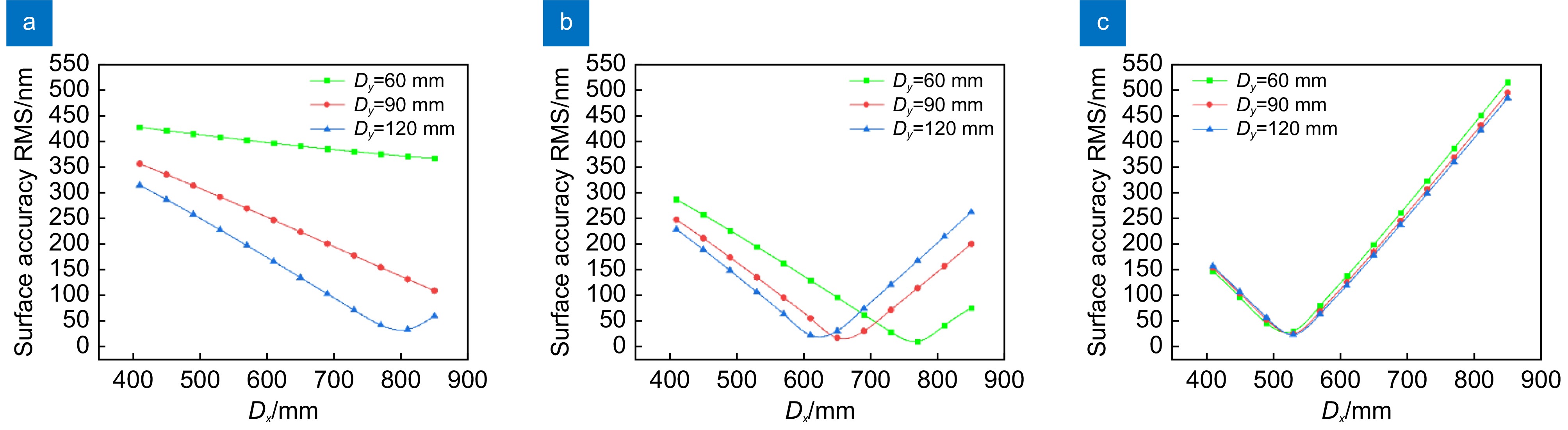

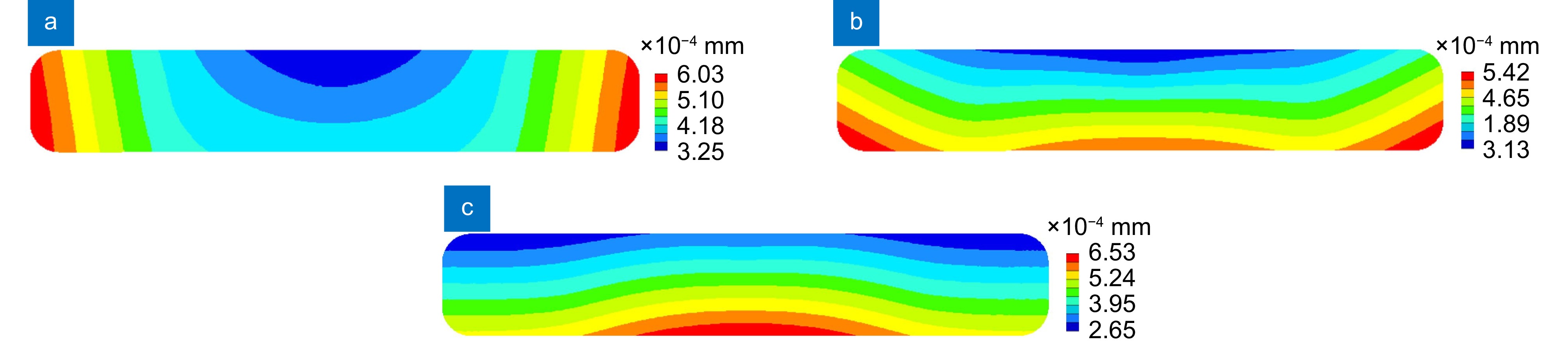

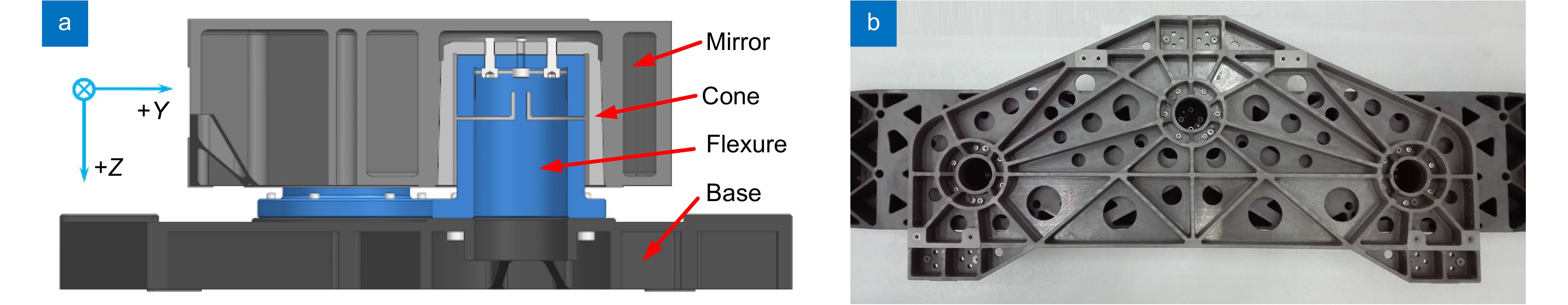

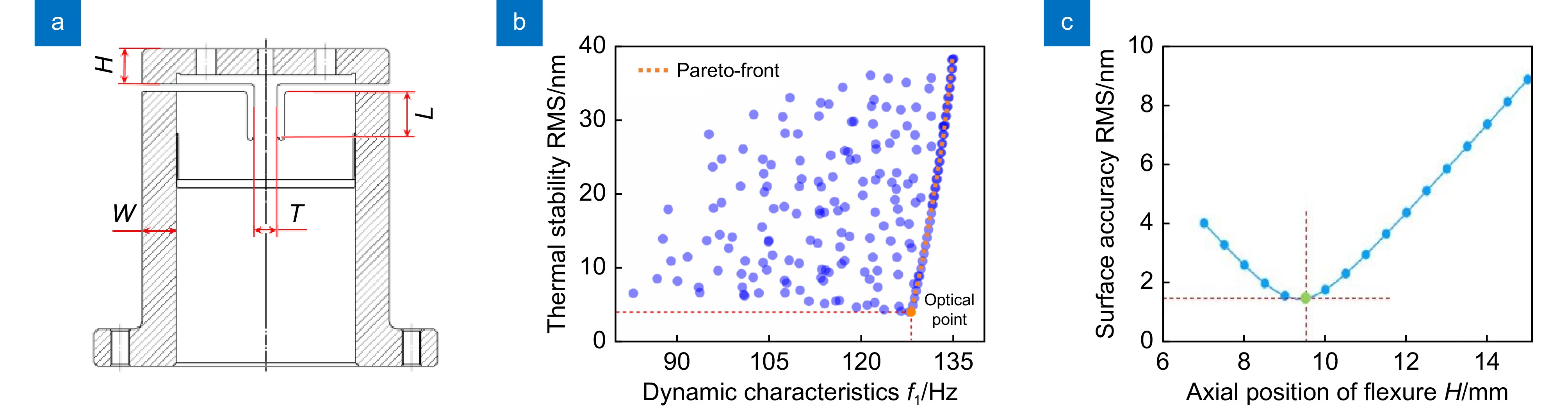

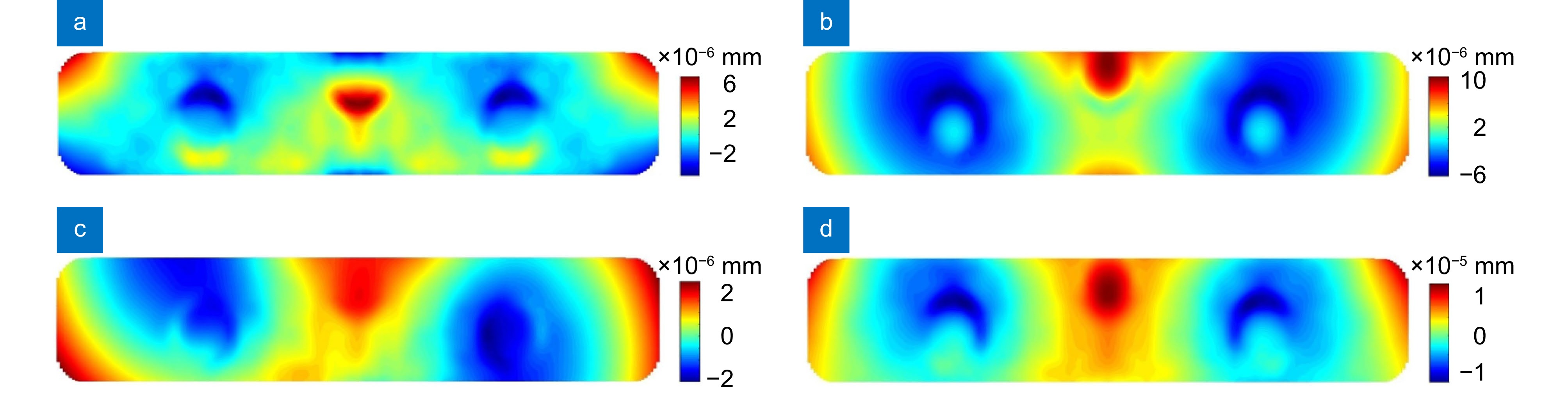

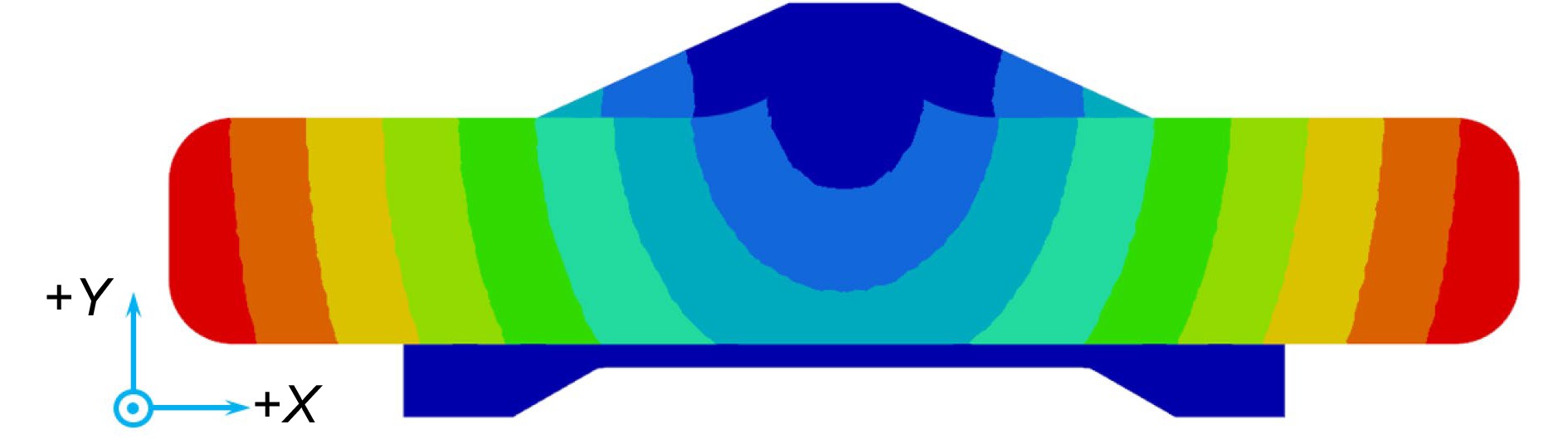

具备大长宽比、高轻量化率特征的平面反射镜是大型离轴三反相机光机结构的研制难点,针对某通光口径为1220 mm×198 mm的平面反射镜,提出一种使用半封闭式碳化硅镜体并配合背部三点支撑形式的组件方案,质量仅为30.5 kg。通过优化支撑点位置,改善镜体支撑效果。调整柔性支撑中铰链的尺寸和位置,兼顾组件的自重变形、热稳定性及动力学特性。仿真分析结果表明,平面反射镜在检测重力工况中的面形精度变化均方根(RMS)为1.812 nm、倾角为3.639″。实测组件基础频率为132.5 Hz,经抛光后,测得平面反射镜左、中、右各子区域的面形精度RMS值分别为0.0203λ、0.0197λ、0.0204λ (λ=632.8 nm),且在环境试验前后保持稳定,可满足高性能空间相机的使用需求。

Abstract

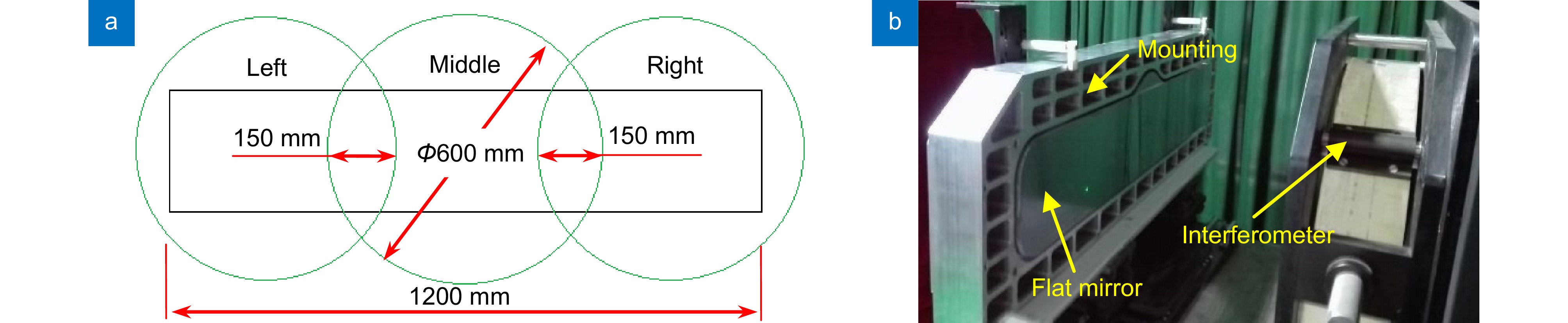

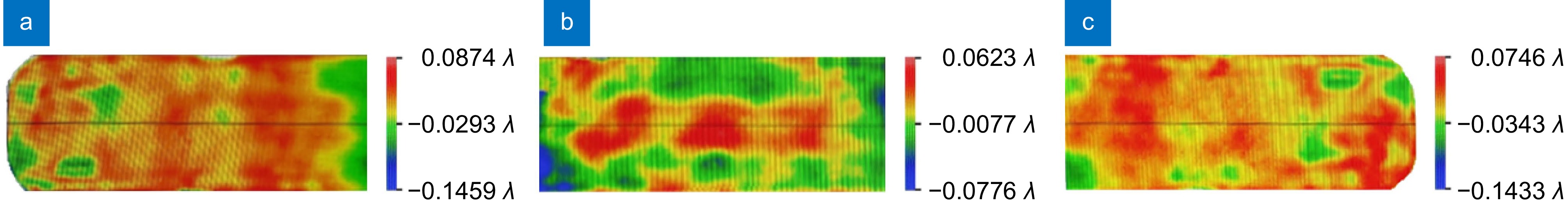

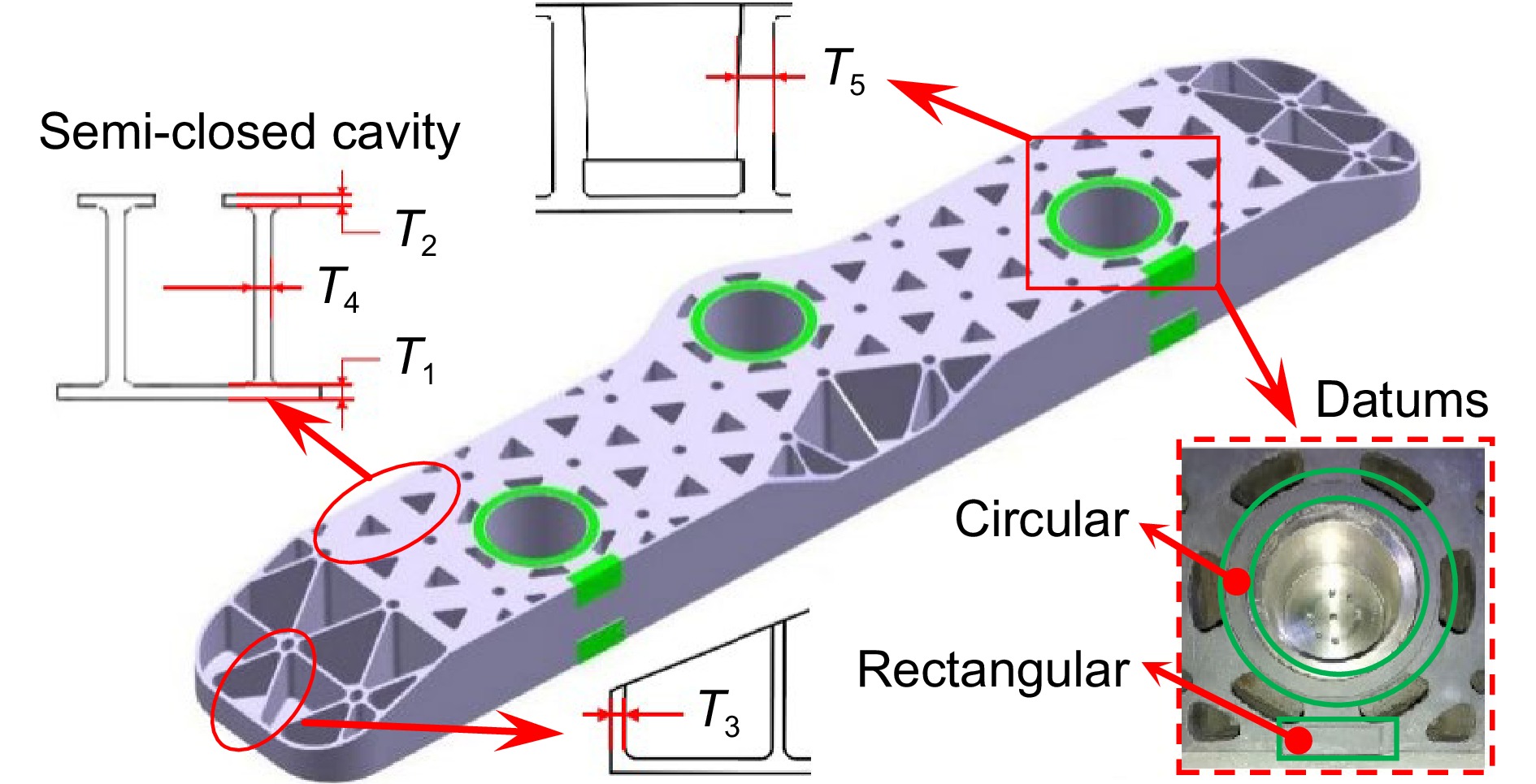

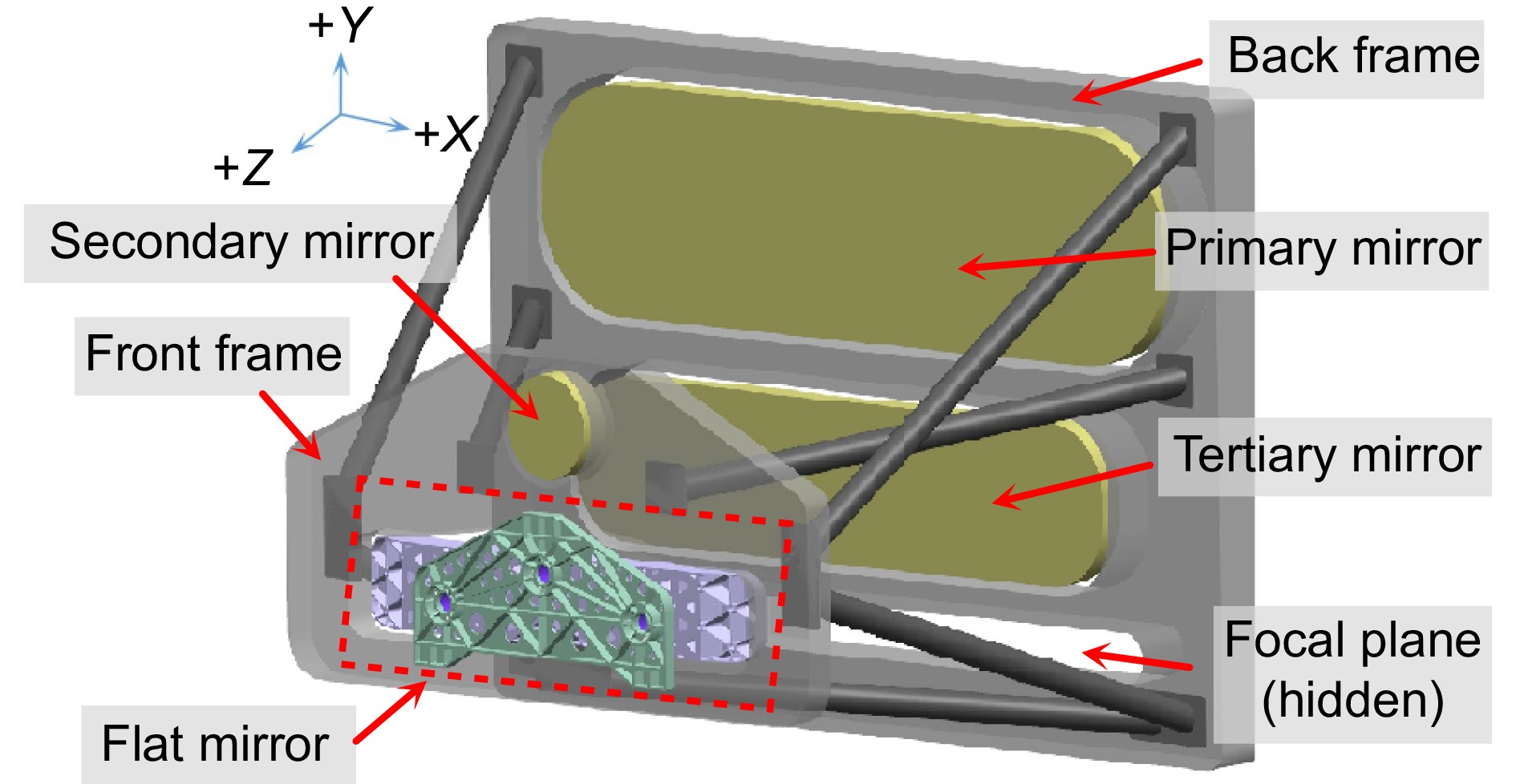

The flat mirror with the characteristics of large aspect ratio and high lightweight rate is one difficulty in the opto-mechanical design of a large off-axis three-mirror anastigmat cameras. For a certain flat mirror with a clear aperture of 1220 mm×198 mm, the assembly structure combining a semi-closed mirror blank made of silicon carbide with the three-point back support scheme was proposed, resulting in a total design weight of 30.5 kg. The supporting effect of the mirror was improved through the optimization of support positions. Both the size and position of hinges in the flexure were adjusted, taking into account gravitational deformation, thermal stability, and dynamic characteristics of the assembly. Simulation reveals that, under the condition of gravity during the test, the root mean square (RMS) of the surface accuracy change of the flat mirror is 1.812 nm, together with the tilt of 3.639" for the mirror blank. The measured fundamental frequency of the assembly is 132.5 Hz. After polishing, the tested RMS values of surface accuracy are 0.0203λ, 0.0197λ, and 0.0204λ (λ=632.8 nm), corresponding to the left, middle, and right sub-zones of the flat mirror respectively. The surface accuracy can remain basically unchanged after environmental tests, which meets the requirements of high-performance space cameras.

-

-

表 1 平面镜组件主要设计指标

Table 1. Main design metrics for flat mirror assembly

No. Item Requirement 1 Clear aperture 1220 mm×198 mm 2 Testing attitude Optical axis horizontal 3 Gravitational deformation Tilt: θM≤10″ 4 Working temperature (20±4) ℃ 5 Surface accuracy RMS≤1/50λ over sub-aperture of φ140 mm (λ=632.8 nm) 6 Mass ≤40 kg 7 Frequency ≥100 Hz 表 2 主要可见光波段空间反射镜材料属性

Table 2. Properties of spatial reflector materials in main visible light band

Property SiC ULE Zerodur Density ρ/(kg·m−3) 3050 2210 2530 Elastic modulus E/Gpa 340 67 91 Specific stiffness E/ρ 111.5 30.3 36 Thermal conductivity λ1/(W·K−1·m−1) 155 1.31 1.64 Thermal expansion coefficient α/(10−6·K−1) 2.50 0.03 0.05 Thermal stability λ1/α 62 43.7 32.8 表 3 主要零件材料及其物理属性

Table 3. Main parts materials and their physical properties

Parameter Main parts material Mirror Cone Flexure Base Material SiC Invar TC4 SiC/Al Density ρ/(kg·m−3) 3050 8100 4400 3000 Elastic modulus E/Gpa 340 141 114 180 Poisson ratio μ 0.27 0.25 0.34 0.18 Thermal expansion coefficient α/(10−6·K−1) 2.5 2.5 9.1 8.4 表 4 典型工况下平面镜组件变形数据

Table 4. Deformation data of the flat mirror assembly under typical conditions

Typical condition RMS/nm θX/″ Condition 1 Gravity/(1 G, −Y) 1.812 3.639 Condition 2 Temperature change/4 ${}^ \circ {\mathrm{C}} $ 3.302 / Condition 3 Forced displacement/0.02 mm 0.948 / Condition 1+2+3 Compound 5.044 / Requirement ≤1/50λ (λ=632.8 nm) ≤10″ 表 5 平面镜组件模态分析结果

Table 5. Modal analysis results of flat mirror assembly

No. Frequency/Hz Vibration mode 1 129.1 Mirror rotation around Y-axis 2 134.6 Mirror rotation around X-axis 3 174.9 Mirror rotation around Z-axis 4 178.5 Mirror translation along Y-axis 5 193.3 Mirror translation along X-axis 6 201.5 Mirror translation along Z-axis 表 6 翻转前后平面镜面形精度数据

Table 6. Surface accuracy data of flat mirror before and after overturn

Zone RMS/λ Left Before 0.0203 After 0.0213 Middle Before 0.0197 After 0.0204 Right Before 0.0204 After 0.0207 -

参考文献

[1] 蒋成斌, 陈智利, 王肖同, 等. 紧凑式离轴三反光学系统设计[J]. 光电工程, 2023, 50(12): 230231. doi: 10.12086/oee.2023.230231

Jiang C B, Chen Z L, Wang X T, et al. Design of compact off-axis triple mirror optical system[J]. Opto-Electron Eng, 2023, 50(12): 230231. doi: 10.12086/oee.2023.230231

[2] 王朋朋, 辛宏伟, 朱俊青, 等. 轻质长条形反射镜结构优化设计[J]. 光电工程, 2020, 47(8): 200109. doi: 10.12086/oee.2020.200109

Wang P P, Xin H W, Zhu J Q, et al. Structural optimization design of lightweight rectangular reflective mirror[J]. Opto-Electron Eng, 2020, 47(8): 200109. doi: 10.12086/oee.2020.200109

[3] 袁健, 张雷. 大型离轴三反相机主镜组件结构设计与验证[J]. 红外与激光工程, 2023, 52(1): 20220363. doi: 10.3788/IRLA20220363

Yuan J, Zhang L. Structure design and verification of primary mirror assembly for large off-axis TMA camera[J]. Infrared Laser Eng, 2023, 52(1): 20220363. doi: 10.3788/IRLA20220363

[4] 武红宇, 白杨, 王灵丽, 等. 吉林一号宽幅01星宽幅相机在轨几何定标及精度验证[J]. 光学 精密工程, 2021, 29(8): 1769−1781. doi: 10.37188/OPE.20212908.1769

Wu H Y, Bai Y, Wang L L, et al. On-orbit geometric calibration and accuracy verification of Jilin1-KF01A WF camera[J]. Opt Precis Eng, 2021, 29(8): 1769−1781. doi: 10.37188/OPE.20212908.1769

[5] 袁健, 张雷. 新型中小口径反射镜消热刚性支撑结构设计[J]. 激光与光电子学进展, 2024, 61(5): 0522005. doi: 10.3788/LOP222590

Yuan J, Zhang L. Novel design of athermal and rigid support structure for small- and medium-aperture mirrors[J]. Laser Optoelectron Prog, 2024, 61(5): 0522005. doi: 10.3788/LOP222590

[6] 宋伟阳, 解鹏, 王循. 大型空间离轴三反相机分体支撑结构设计[J]. 光学 精密工程, 2021, 29(3): 571−581. doi: 10.37188/OPE.20212903.0571

Song W Y, Xie P, Wang X. Design of lightweight split support structure for large space off-axis three mirror camera[J]. Opt Precis Eng, 2021, 29(3): 571−581. doi: 10.37188/OPE.20212903.0571

[7] 李宗轩, 张昌昊, 张德福, 等. 1.8 m空间长条反射镜柔性支撑技术研究[J]. 中国光学, 2022, 15(5): 1079−1091. doi: 10.37188/CO.2022-0131

Li Z X, Zhang C H, Zhang D F, et al. Flexural mounting technology of a 1.8 m space-borne rectangular mirror[J]. Chin Opt, 2022, 15(5): 1079−1091. doi: 10.37188/CO.2022-0131

[8] 曲慧东, 魏加立, 董得义, 等. 长条形空间反射镜组件轻量化结构设计[J]. 红外与激光工程, 2021, 50(6): 20200404. doi: 10.3788/IRLA20200404

Qu H D, Wei J L, Dong D Y, et al. Lightweight structural design of rectangular space mirror assembly[J]. Infrared Laser Eng, 2021, 50(6): 20200404. doi: 10.3788/IRLA20200404

[9] 刘朋朋, 吴俊, 常君磊, 等. 长条镜柔性支撑及点阵结构设计方法[J]. 光学学报, 2024, 44(2): 0222002. doi: 10.3788/AOS231368

Liu P P, Wu J, Chang J L, et al. Design method of flexible support and lattice structure for long strip mirror[J]. Acta Optica Sin, 2024, 44(2): 0222002. doi: 10.3788/AOS231368

[10] 龙荃, 李宗轩, 张德福, 等. 1.8 m长条形轻质SiC反射镜支撑位置设计[J]. 光学学报, 2024, 44(13): 1322004. doi: 10.3788/AOS240445

Long Q, Li Z X, Zhang D F, et al. Support position design of 1.8 m rectangular light-weight SiC mirror[J]. Acta Optica Sin, 2024, 44(13): 1322004. doi: 10.3788/AOS240445

[11] 陈太喜, 伍雁雄, 宋绍漫, 等. 折叠式离轴三反光学系统设计与装调[J]. 激光与光电子学进展, 2021, 58(17): 1722001. doi: 10.3788/LOP202158.1722001

Chen T X, Wu Y X, Song S M, et al. Design and alignment of folded off-axis three-mirror optical system[J]. Laser Optoelectron Prog, 2021, 58(17): 1722001. doi: 10.3788/LOP202158.1722001

[12] Wei L, Zhang L, Gong X X, et al. Design and optimization for main support structure of a large-area off-axis three-mirror space camera[J]. Appl Opt, 2017, 56(4): 1094−1100. doi: 10.1364/AO.56.001094

[13] 袁健, 张雷, 姜启福, 等. 1.2 m高轻量化率主反射镜镜坯结构设计[J]. 光电工程, 2023, 50(4): 220225. doi: 10.12086/oee.2023.220225

Yuan J, Zhang L, Jiang Q F, et al. Structure design of 1.2 m high lightweight primary mirror blank[J]. Opto-Electron Eng, 2023, 50(4): 220225. doi: 10.12086/oee.2023.220225

[14] 朱俊青, 沙巍, 陈长征, 等. 空间长条形反射镜背部三支撑点的设置[J]. 光学 精密工程, 2015, 23(9): 2562−2569. doi: 10.3788/OPE.20152309.2562

Zhu J Q, Sha W, Chen C Z, et al. Position layout of rear three point mounting for space rectangular mirror[J]. Opt Precis Eng, 2015, 23(9): 2562−2569. doi: 10.3788/OPE.20152309.2562

[15] 李延伟, 张景国, 谢新旺, 等. 大口径矩形SiC扫描反射镜组件的设计[J]. 激光与光电子学进展, 2022, 59(5): 0522001. doi: 10.3788/LOP202259.0522001

Li Y W, Zhang J G, Xie X W, et al. Design of large-aperture rectangular SiC scanning mirror assembly[J]. Laser Optoelectron Prog, 2022, 59(5): 0522001. doi: 10.3788/LOP202259.0522001

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: