Low temperature focal surface presetting technology for light and small infrared camera

-

摘要

针对低温红外光学系统对温度敏感、常温装调、低温下离焦和相机常温焦面预置准确度低的问题,提出一种基于光机联合仿真与干涉测量及线性位移测量相结合的低温红外系统离焦测试技术。首先分析引起红外光学系统低温离焦的主要因素,运用光机仿真计算出离焦量数据,再利用Power对焦点位置敏感的特性,建立光学系统低温干涉测试光路,结合高精度位移测量,实现红外光学系统低温离焦量的测试。运用该技术对某181 mm口径的轻小型红外相机由常温到低温的离焦量进行分析与测试,测试结果与仿真计算偏差小于半个系统焦深。在此基础上对相机做常温焦面预置。实验结果表明,焦面预置准确,证明相机低温离焦量测试方法的可行性和准确性。测试方法可用于对温度敏感的轻小型光学相机常温预置定焦。

Abstract

Aiming at the problems of temperature sensitivity, setting at room temperature, defocusing at low temperature, and low accuracy of camera focal surface prefabrication at room temperature, a defocusing test technology of low temperature infrared optical system based on opto-machine co-simulation, interferometry, and linear displacement measurement was proposed. The main factors causing low temperature defocusing are analyzed, and the defocusing data is calculated by optical machine simulation. The low temperature interference test optical path of the optical system is established by using the sensitive characteristic of power to focus position, and the low temperature defocusing of the infrared optical system is tested by combining high precision displacement measurement. This technology is used to analyze and test the defocus of a light and small infrared camera with an 181 mm aperture from normal temperature to low temperature. The deviation between the test results and the simulation calculation is less than half of the system focal depth. On this basis, the camera is preset at a normal temperature focal plane, and the experiment shows that the preset focal plane is accurate, which proves the feasibility and accuracy of the low temperature defocus measurement method. The test method can be used for presetting and focusing light and a small optical camera at normal temperature which is sensitive to temperature.

-

Overview

Overview: This study addresses the challenges of defocusing in lightweight, compact infrared cameras under low-temperature conditions, proposing a novel methodology for accurately presetting the focal plane at room temperature. Traditional solutions, such as mechanical refocusing mechanisms or strict material-based thermalization, often compromise weight constraints or incur high costs, making them unsuitable for miniaturized satellite payloads. The authors introduce a low-cost, high-precision approach combining opto-mechanical co-simulation, low-temperature interferometry, and linear displacement measurement to quantify defocusing effects and enable focal plane presetting.

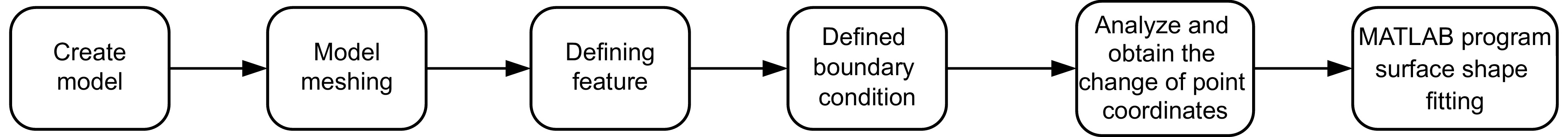

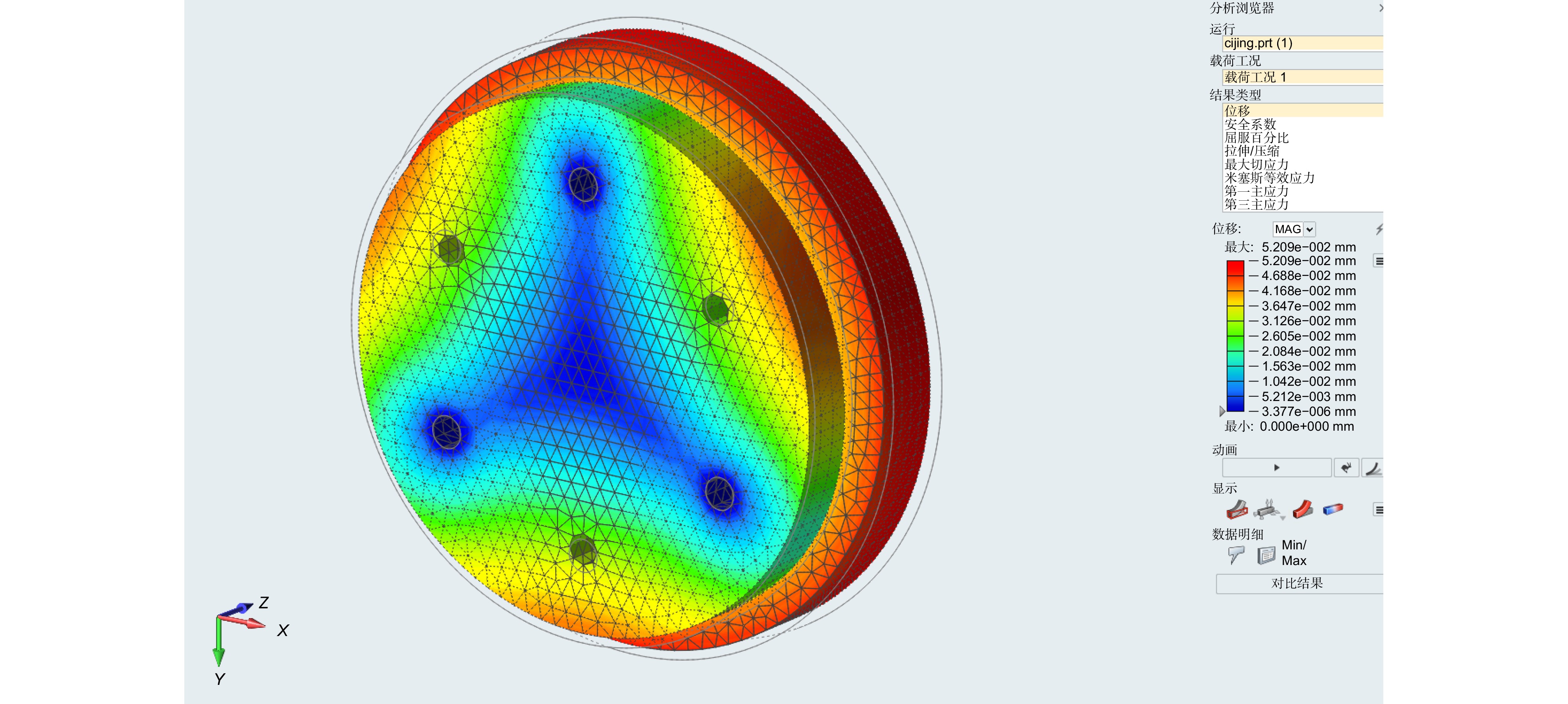

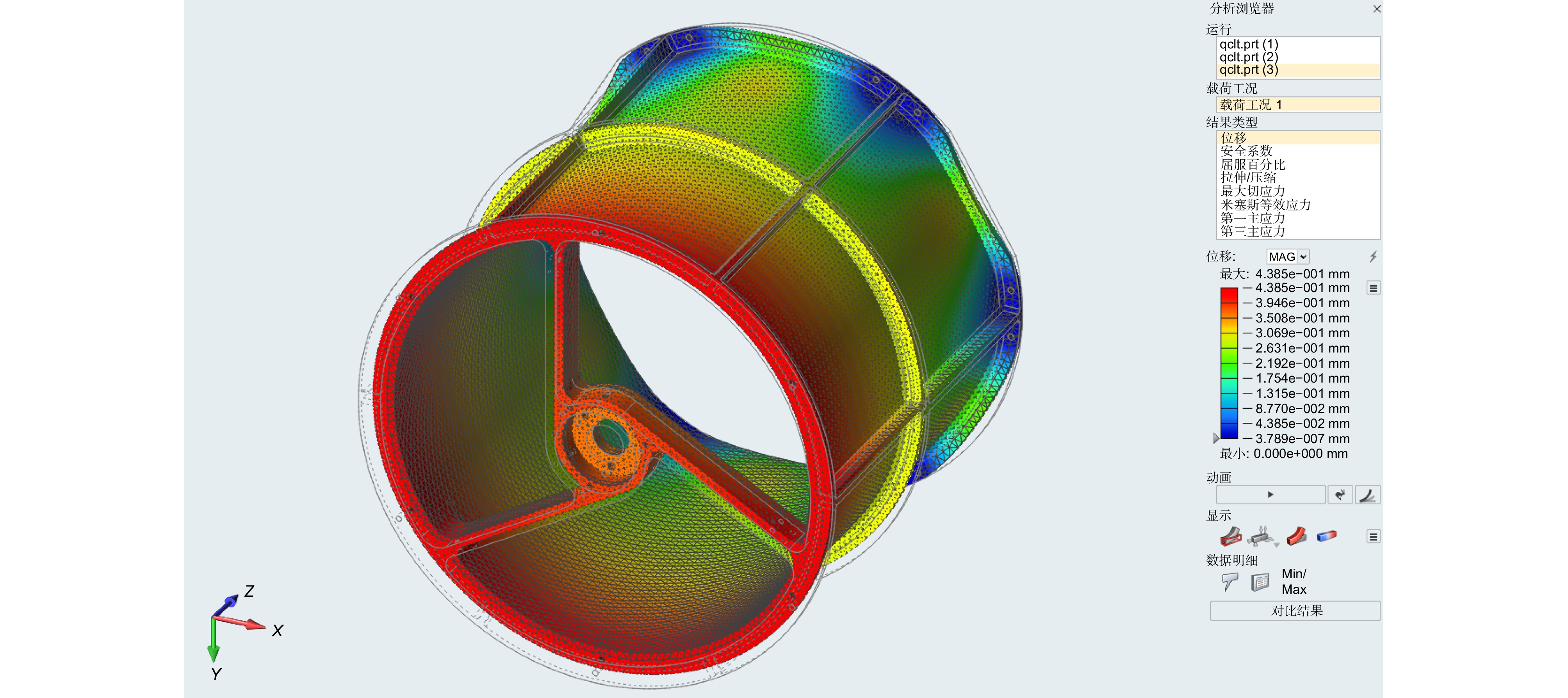

The research focuses on an 181 mm aperture lightweight infrared camera with a 535 mm focal length operating at 220 K (−50 °C). Key factors contributing to low-temperature defocusing are analyzed, including structural contraction of aluminum alloy components (axial shrinkage of 0.23 mm in the front barrel), curvature radius variations in primary/secondary mirrors (ΔR = −0.12 mm and +0.04 mm, respectively), and refractive index changes in Si/Ge corrective lenses. Through finite element analysis and Zernike polynomial surface fitting, these factors are integrated into optical simulations, predicting a 0.38 mm back-focal-length (BFL) shift.

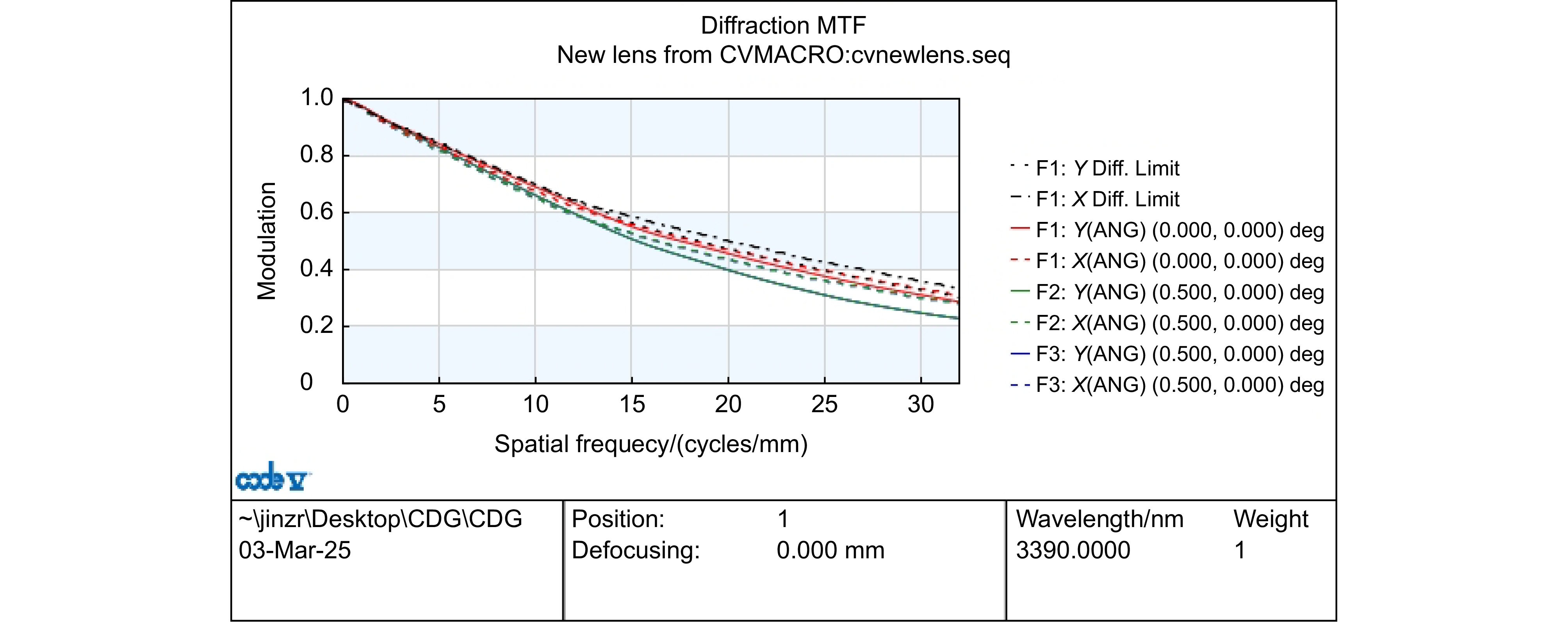

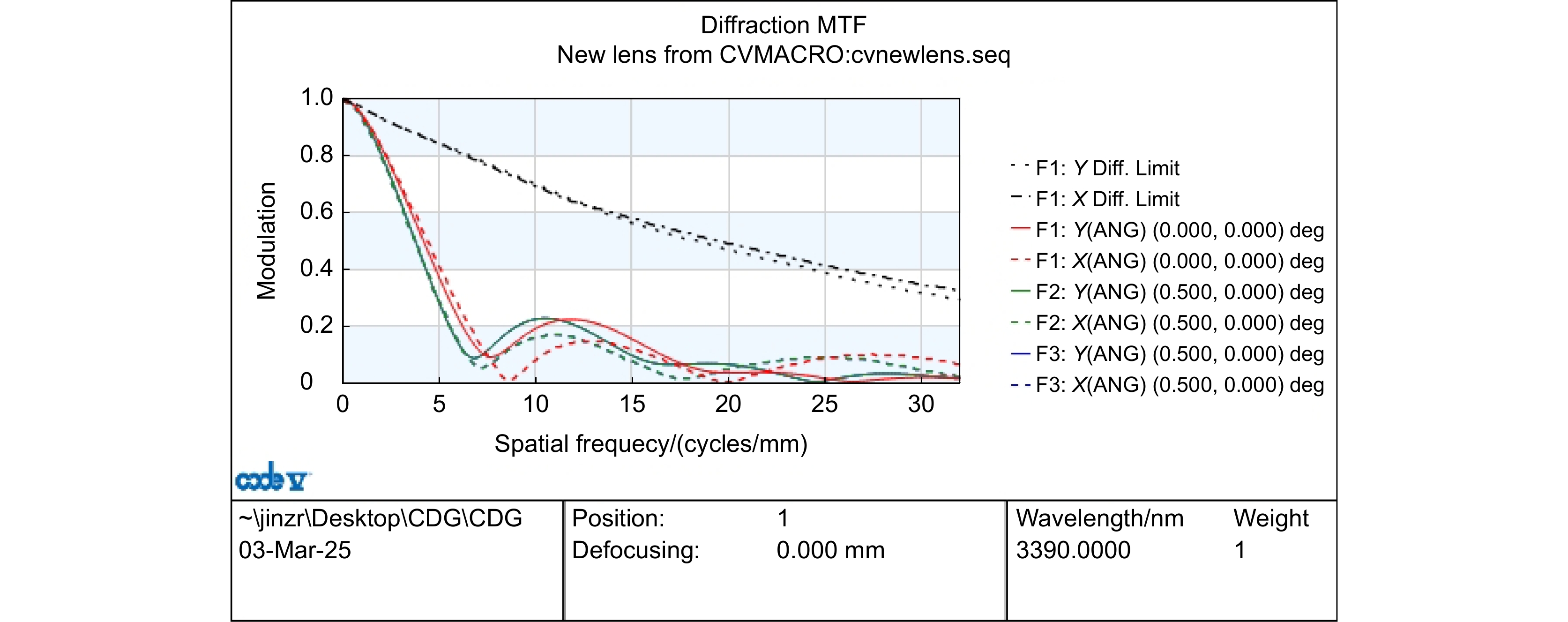

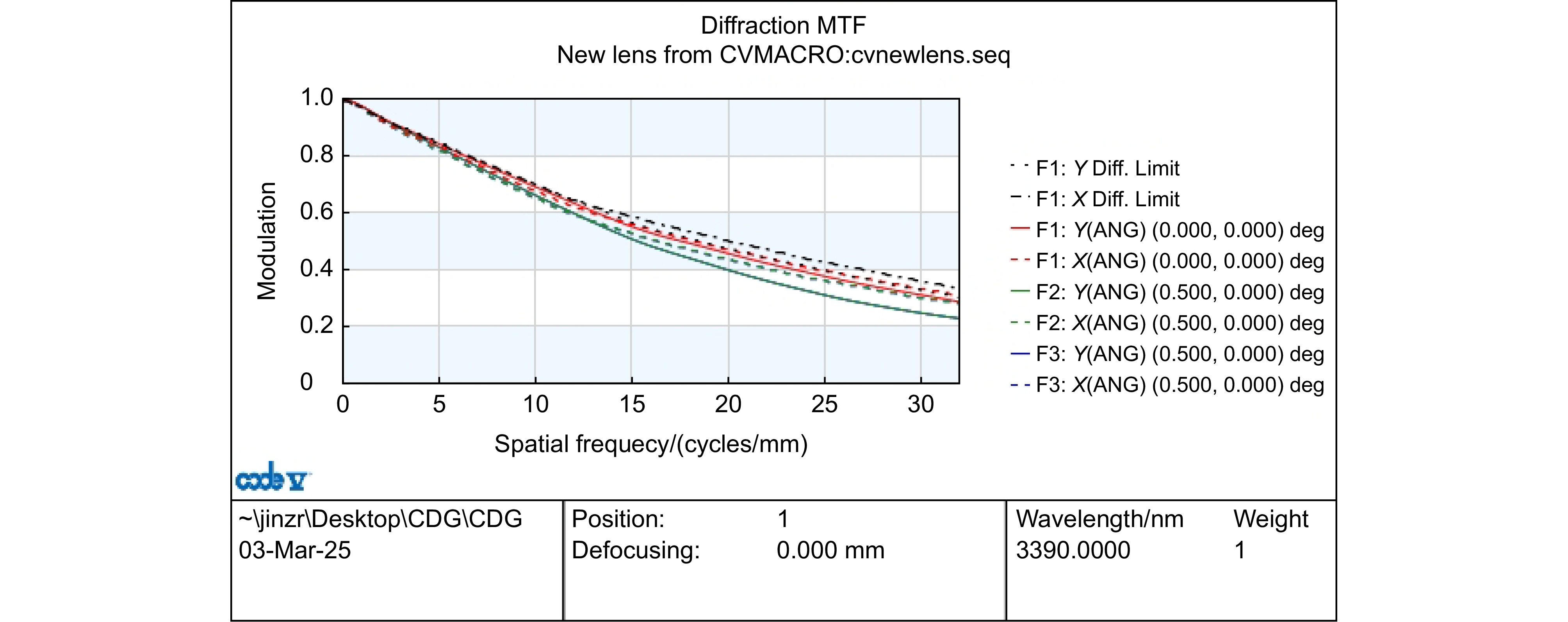

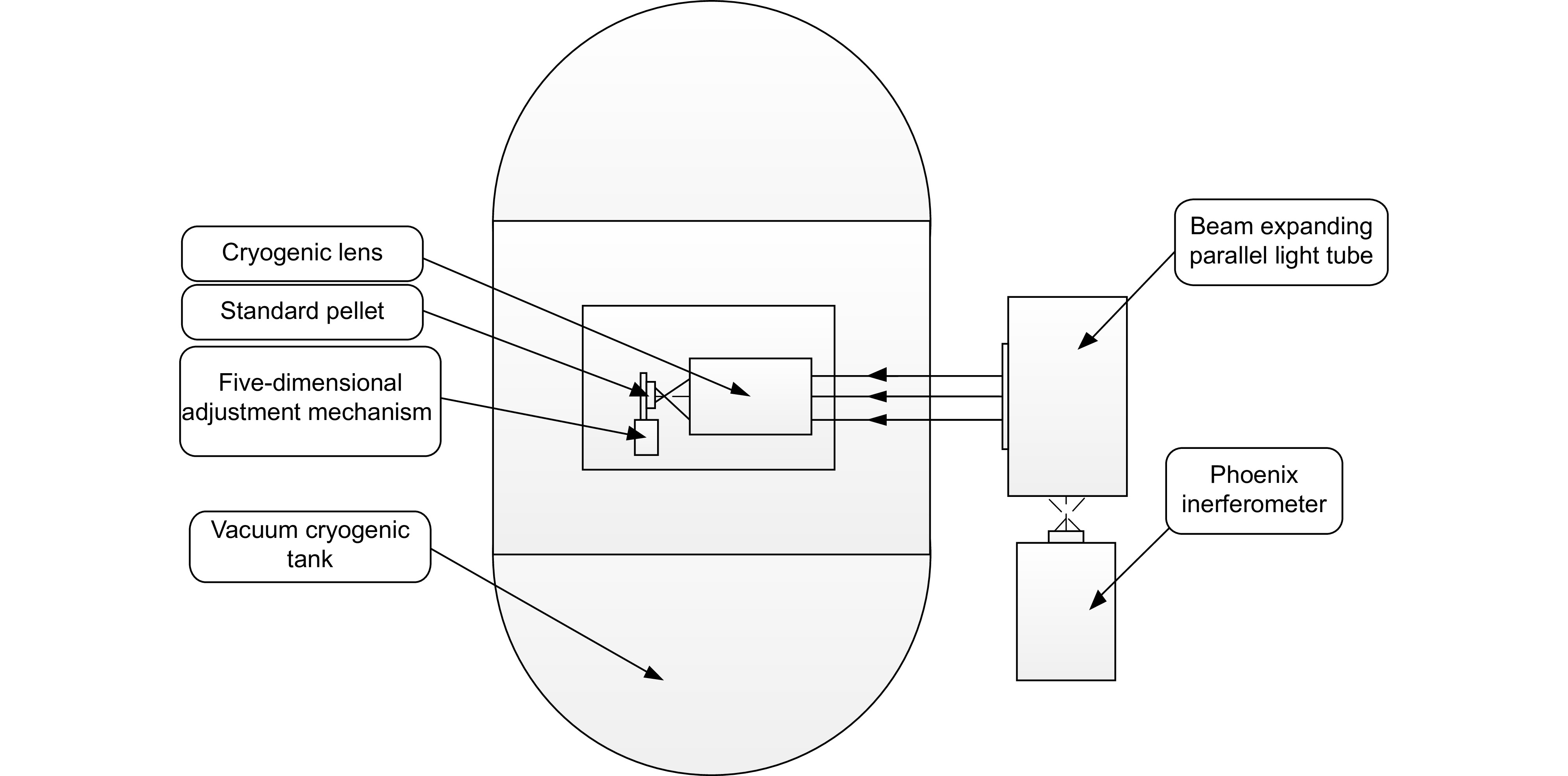

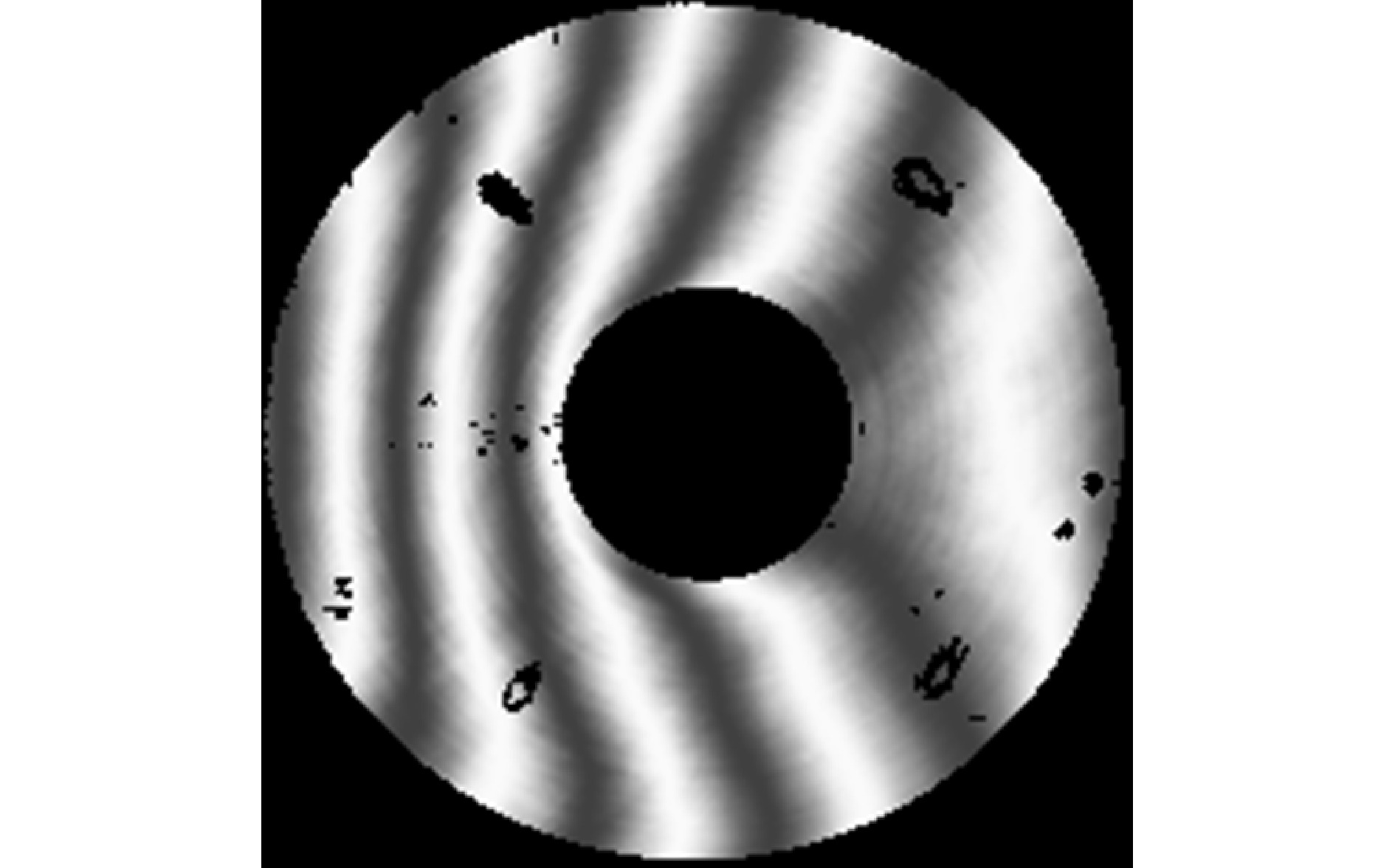

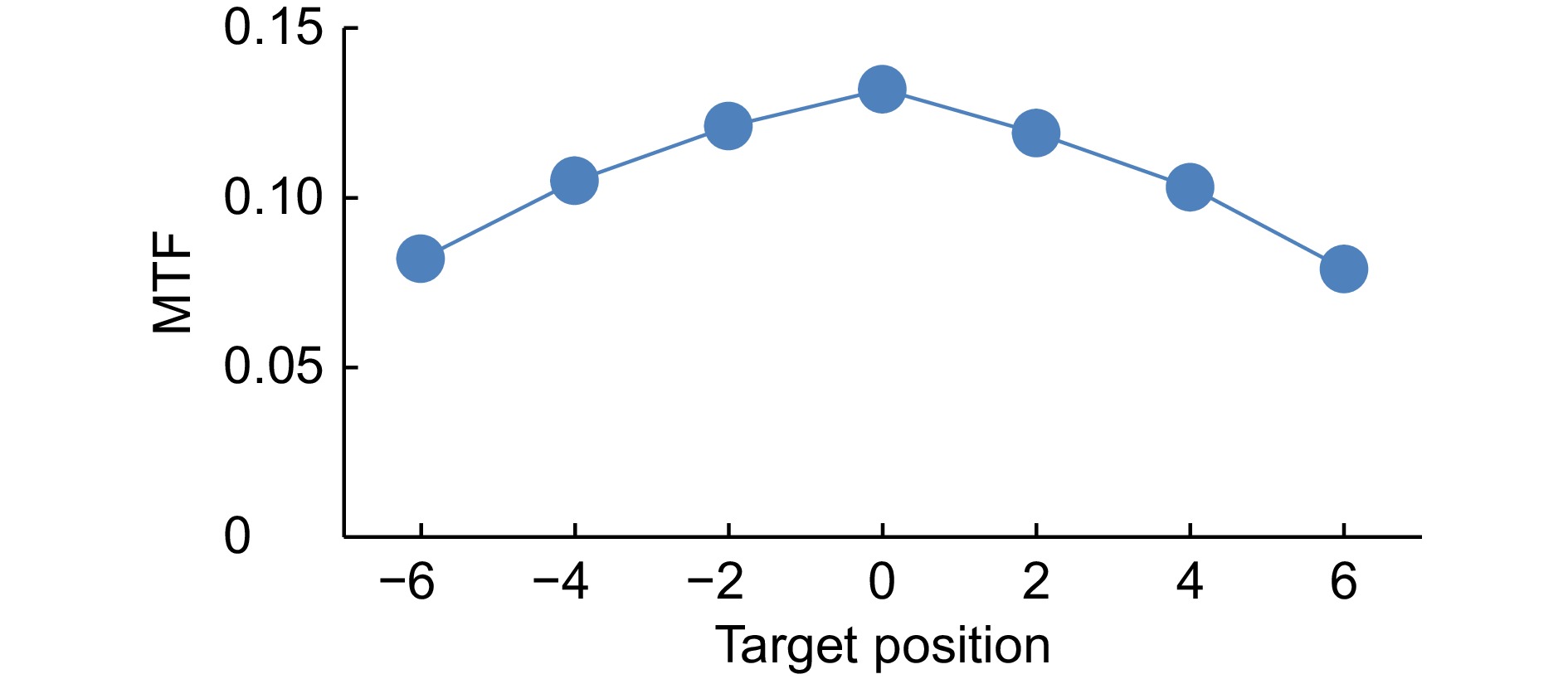

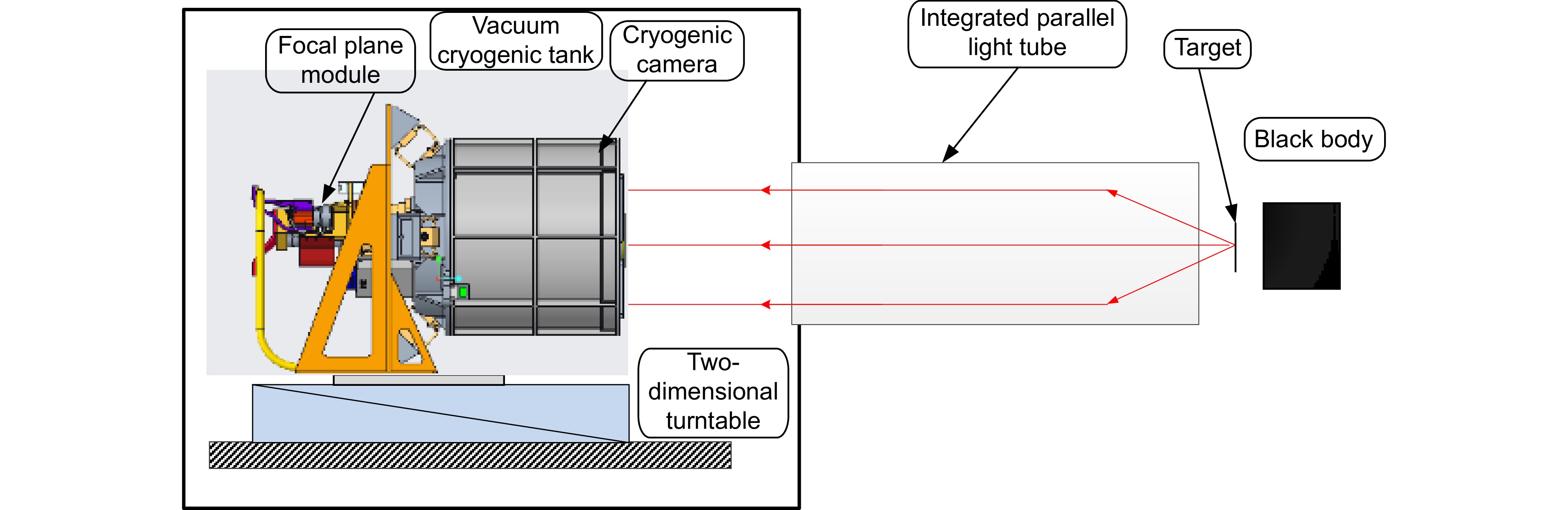

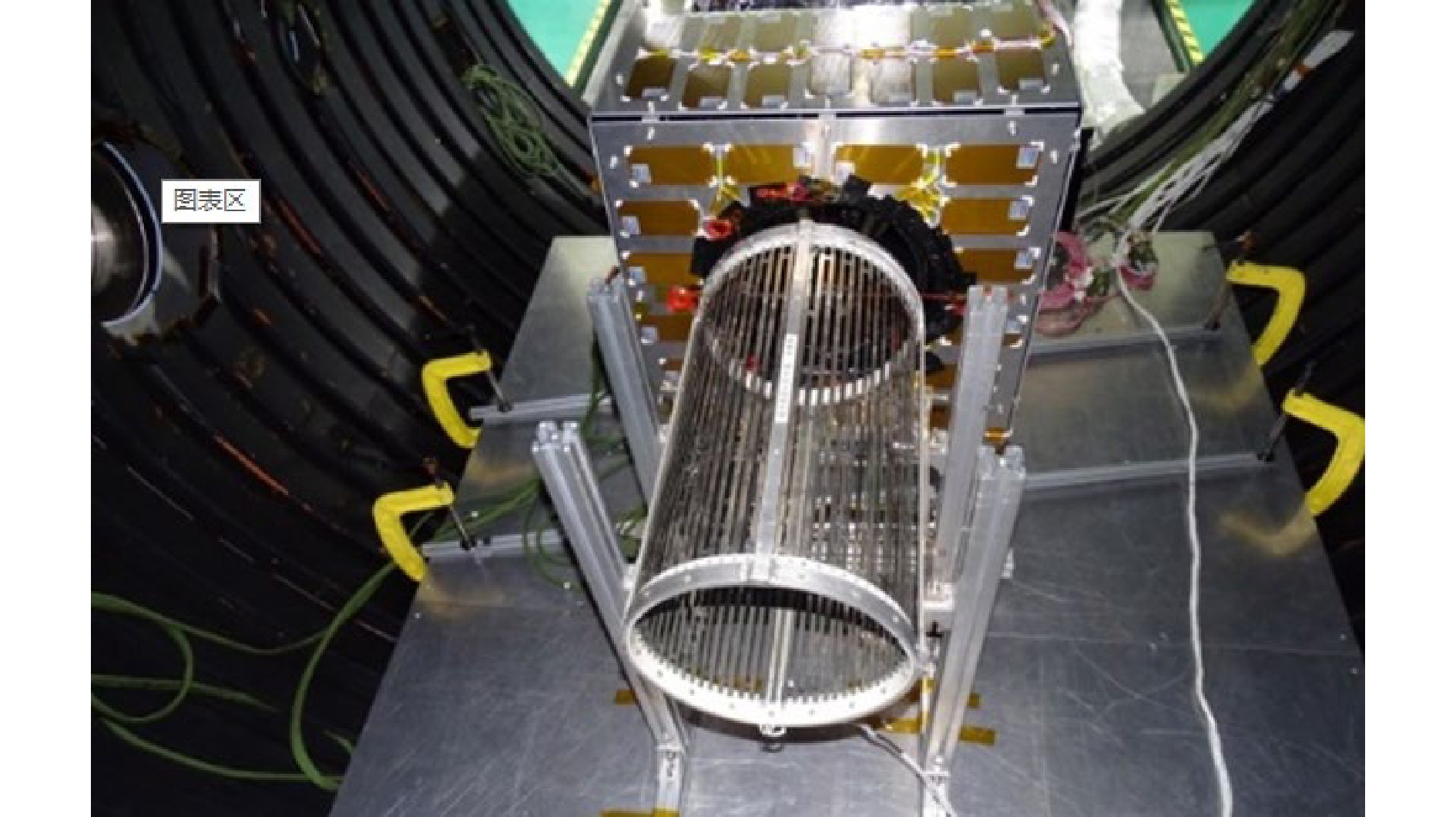

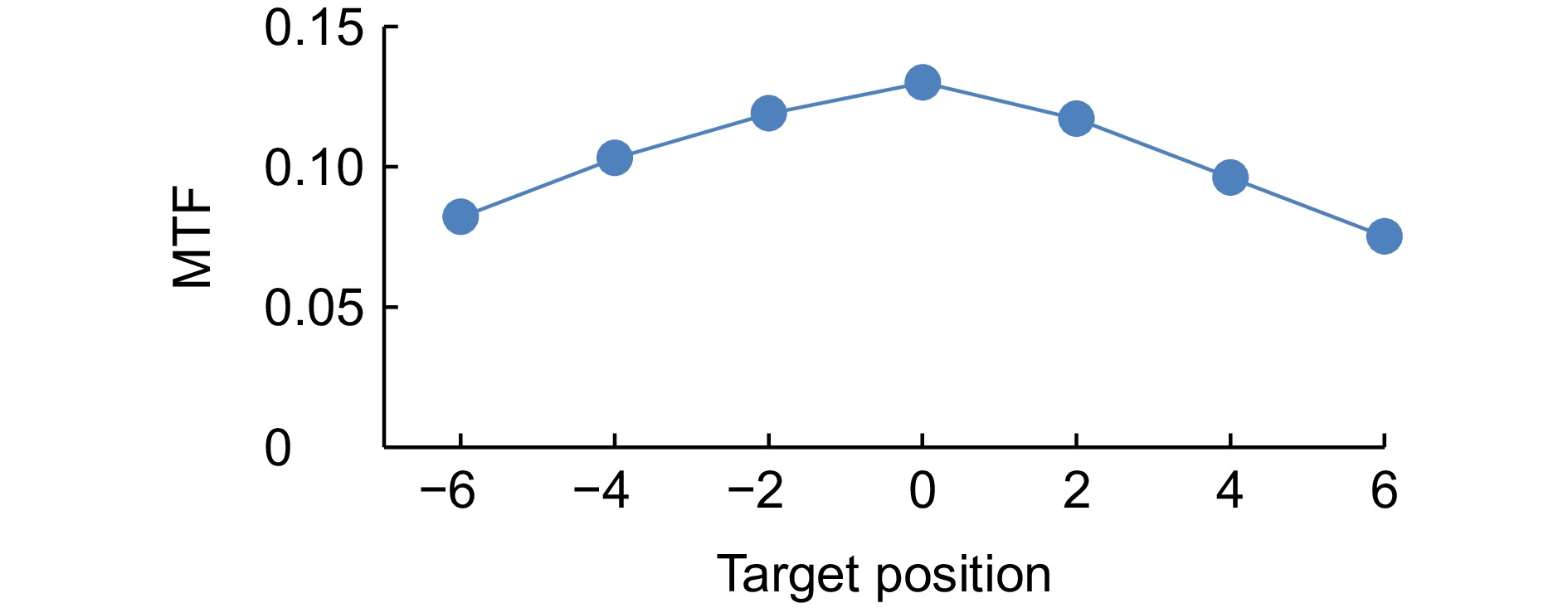

Experimental validation employs a ZYGO interferometer (3.39 μm wavelength) with a customized cryogenic test setup. The system measures wavefront changes under vacuum conditions, utilizing a reference spherical mirror mounted on a high-precision 5-axis stage. Results confirm a 0.396 mm focal shift from room temperature to −50 °C, demonstrating excellent agreement with simulations (deviation: 0.016 mm < half the 0.07 mm focal depth). The methodology achieves micron-level accuracy (<0.03 mm), validated through MTF testing of a pre-focused camera under simulated space conditions.

Two critical innovations are demonstrated. 1) Focal shift measurement: leveraging power term sensitivity in wavefront interferometry to detect defocusing, combined with submicron displacement tracking, enables direct quantification of thermal-induced focal shifts. 2) Presetting protocol: room-temperature focal positioning compensates for predicted low-temperature shifts, achieving MTF equivalence (0.13 at Nyquist frequency) between ambient and cryogenic environments without mechanical refocusing.

The technology successfully resolves the inherent conflict between miniaturization requirements and thermal stability in spaceborne infrared optics. Experimental verification confirms that the focal position preset error remains within one focal depth (±0.07 mm), meeting stringent imaging performance criteria. This approach eliminates complex cryogenic actuators while accommodating material mismatch in compact designs, offering broad applicability for temperature-sensitive optical systems in lightweight satellite platforms. Future work may extend the methodology to multi-spectral systems and optimize parameter weighting algorithms for improved prediction accuracy.

-

-

表 1 光学系统参数

Table 1. Optical system parameter

Parameter Data Operating wavelength/μm 3.6-4.2 Entrance pupil diameter/mm 181 Focal length/mm 535 Back focal length/mm 30.37 Operating temperature/K 220 表 2 反射镜低温曲率半径变化

Table 2. Variation of mirror curvature radius at low temperature

Mirror Radius of vertex curvature (△R)/mm Primary mirror −0.12 Secondary mirror 0.04 表 3 Ge低温折射率

Table 3. The low temperature refractive index of Ge

Temperature/K Refractive index 210.00 3.99290 220.00 3.99656 230.00 4.00027 293.15 4.02500 表 4 Si低温折射率

Table 4. The low temperature refractive index of Si

Temperature/K Refractive index 210.00 3.99290 220.00 3.99656 230.00 4.00027 293.15 4.02500 表 5 低温光学系统常、低温参数

Table 5. Constant and low temperature parameters of low temperature optical system

Temperature MTF Focal length/mm Back intercept/mm PV/RMS (λ=3.39 μm) Wavefront Normal temperature 0.32 535.0 30.37 0.245λ/0.0252λ

Low temperature 0 538.4 30.75 3.166λ/0.4464λ

-

参考文献

[1] 曾勇强, 张凤芹. 空间轻小型相机结构总体技术国内外发展情况研究[C]//中国宇航学会空间遥感专业委员会、中国遥感应用协会红外遥感专业委员会2009年学术交流会, 2009, 341−349.

Zeng Y Q, Zhang F Q. Research on development of domestic and foreign general technology of space lightweight camera structure [C]//Academic Exchange Conference of the Infrared Remote Sensing Committee of the Chinese Society for Remote Sensing Applications and the Space Remote Sensing Committee of the Chinese Society of Astronautics, 2009, 341−349.

[2] 姜海滨, 罗世魁, 曹东晶, 等. “高分二号”卫星轻小型高分辨率相机技术[J]. 航天返回与遥感, 2015, 36(4): 25−33. doi: 10.3969/j.issn.1009-8518.2015.04.004

Jiang H B, Luo S K, Cao D J, et al. Technology of high-density and high-resolution camera of GF-2 satellite[J]. Spacecr Recov Remote Sens, 2015, 36(4): 25−33. doi: 10.3969/j.issn.1009-8518.2015.04.004

[3] 李福东. 小型星载红外相机的研制[J]. 航天返回与遥感, 2004, 25(1): 21−25. doi: 10.3969/j.issn.1009-8518.2004.01.005

Li F D. Research and development of infrared camera onboard minisatellites[J]. Spacecr Recov Remote Sens, 2004, 25(1): 21−25. doi: 10.3969/j.issn.1009-8518.2004.01.005

[4] 洪裕珍, 任国强, 孙健. 离焦模糊图像清晰度评价函数的分析与改进[J]. 光学 精密工程, 2014, 22(12): 3401−3408. doi: 10.3788/OPE.20142212.3401

Hong Y Z, Ren G Q, Sun J. Analysis and improvement on sharpness evaluation function of defocused image[J]. Opt Precis Eng, 2014, 22(12): 3401−3408. doi: 10.3788/OPE.20142212.3401

[5] 原育凯, 程仕东, 裴云天. 光学系统离焦对自动调焦评价函数的影响[J]. 光电工程, 2005, 32(12): 51−54,58. doi: 10.3969/j.issn.1003-501X.2005.12.013

Yuan Y K, Cheng S D, Pei Y T. Influence of defocus on automatic focusing evaluation function[J]. Opto-Electron Eng, 2005, 32(12): 51−54,58. doi: 10.3969/j.issn.1003-501X.2005.12.013

[6] 朱鹤, 梁伟, 高晓东. 航空相机光电自准直检调焦系统[J]. 光电工程, 2011, 38(3): 35−39. doi: 10.3969/j.issn.1003-501X.2011.03.007

Zhu H, Liang W, Gao X D. Autofocusing system with opto-electronic auto-collimation method for aerial camera[J]. Opto-Electron Eng, 2011, 38(3): 35−39. doi: 10.3969/j.issn.1003-501X.2011.03.007

[7] 张发强, 樊祥, 孔辉, 等. 温度对红外光学系统的影响分析及消热差设计[J]. 激光与红外, 2015, 45(7): 854−860. doi: 10.3969/j.issn.1001-5078.2015.07.026

Zhang F Q, Fan X, Kong H, et al. Influence of temperature on infrared optical system and athermal design[J]. Laser Infrared, 2015, 45(7): 854−860. doi: 10.3969/j.issn.1001-5078.2015.07.026

[8] 王远方舟. 温度自适应红外光学系统设计及测试方法研究[D]. 长春: 长春理工大学, 2013.

Wang Y F Z. A study of design and testing method for temperature adaption IR lens[D]. Changchun: Changchun University of Science and Technology, 2013.

[9] Schreibman M, Young P. Design of Infrared Astronomical Satellite (IRAS) primary[J]. Opt Eng, 1981, 20(2): 202190. doi: 10.1117/12.7972689

[10] 沈忙作, 马文礼, 廖胜. 低温红外光学系统: 96233926.1[P]. 1996-10-23. https://cprs.patentstar.com.cn/Search/Detail?ANE=9ECG9HDH9DGCBIHA8BEA9FAF9GED9IBG.

Shen M Z, Ma W L, Liao S. Low-temp. infrared optical system: 96233926.1[P]. 1996-10-23. https://cprs.patentstar.com.cn/Search/Detail?ANE=9ECG9HDH9DGCBIHA8BEA9FAF9GED9IBG.

[11] 杨佳文, 黄巧林, 韩友民. Zernike多项式在拟合光学表面面形中的应用及仿真[J]. 航天返回与遥感, 2010, 31(5): 49−55. doi: 10.3969/j.issn.1009-8518.2010.05.009

Yang J W, Huang Q L, Han Y M. Application and simulation in fitting optical surface with Zernike polynomial[J]. Spacecr Recov Remote Sens, 2010, 31(5): 49−55. doi: 10.3969/j.issn.1009-8518.2010.05.009

[12] 李其锴. Zernike多项式拟合用于低温光学镜头热集成分析[J]. 航天返回与遥感, 2010, 31(4): 45−50. doi: 10.3969/j.issn.1009-8518.2010.04.008

Li Q K. Zernike polynomials fitting in cryogenic optical thermal integration analysis[J]. Spacecr Recov Remote Sens, 2010, 31(4): 45−50. doi: 10.3969/j.issn.1009-8518.2010.04.008

[13] 倪磊, 任栖锋, 廖胜. 红外材料低温折射率测定: 不确定度分析[J]. 光电工程, 2010, 37(10): 77−82. doi: 10.3969/j.issn.1003-501X.2010.10.013

Ni L, Ren Q F, Liao S. Measurement of cryogenic refractive index of IR materials: uncertainty analysis[J]. Opto-Electron Eng, 2010, 37(10): 77−82. doi: 10.3969/j.issn.1003-501X.2010.10.013

[14] 余怀之. 红外光学材料[M]. 2版. 北京: 国防工业出版社, 2015.

Yu H Z. Infrared Optical Material[M]. 2nd ed. Beijing: National Defense Industry Press, 2015.

[15] 王之江. 光学设计理论基础[M]. 2版. 北京: 科学出版社, 1985.

Wang Z J. Theoretical Foundations of Optical Design[M]. 2nd ed. Beijing: Science Press, 1985.

[16] 宋俊儒, 邢辉, 裴景洋, 等. 低温镜头能量集中度测试及其误差分析[J]. 红外与激光工程, 2019, 48(7): 0717007. doi: 10.3788/IRLA201948.0717007

Song J R, Xing H, Pei J Y, et al. Measurement and error analysis of encircled energy of cryogenic lens[J]. Infrared Laser Eng, 2019, 48(7): 0717007. doi: 10.3788/IRLA201948.0717007

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: