Construction of convolutional neural network model for micro-scale bump on metal pipe fittings

-

摘要

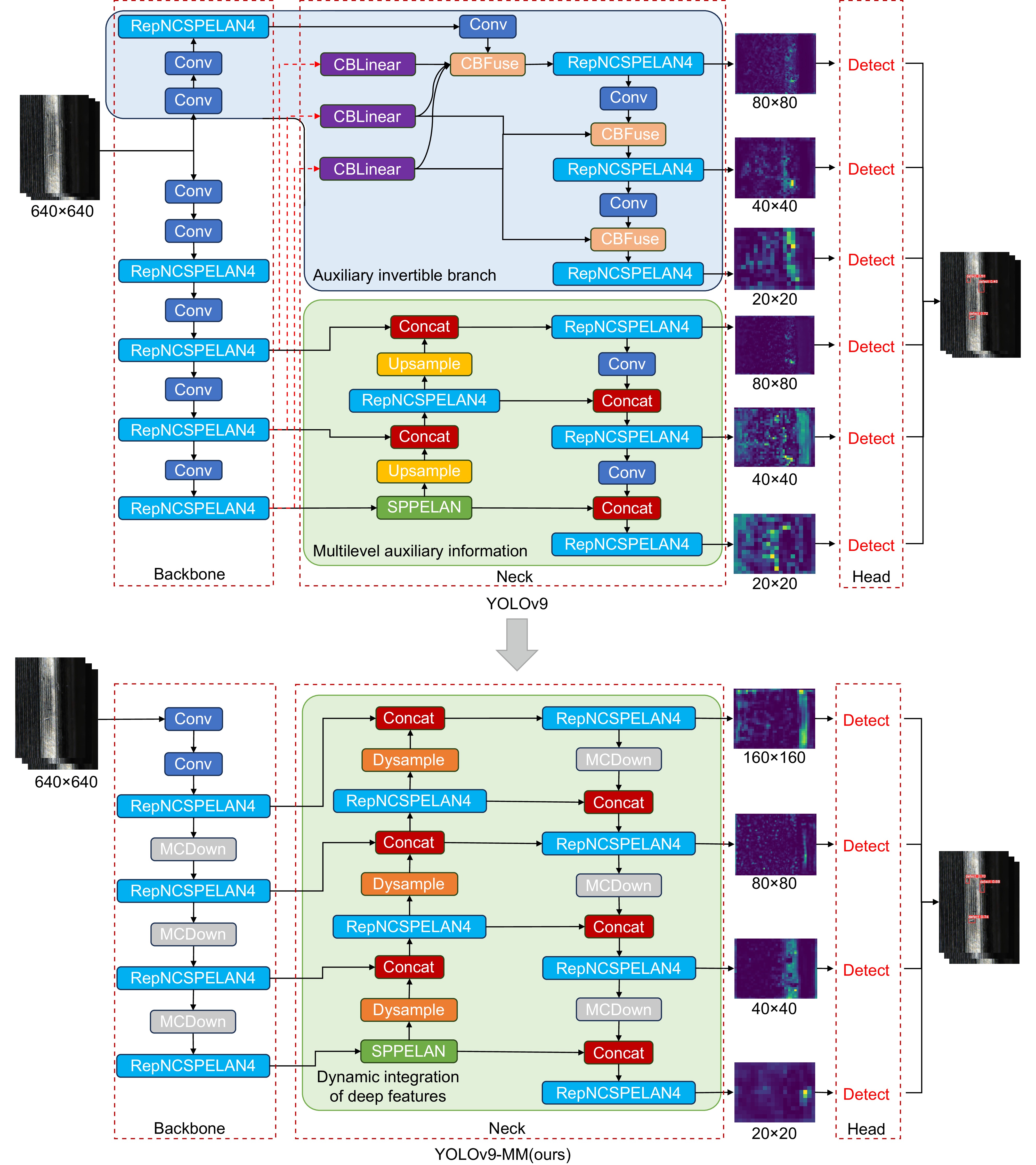

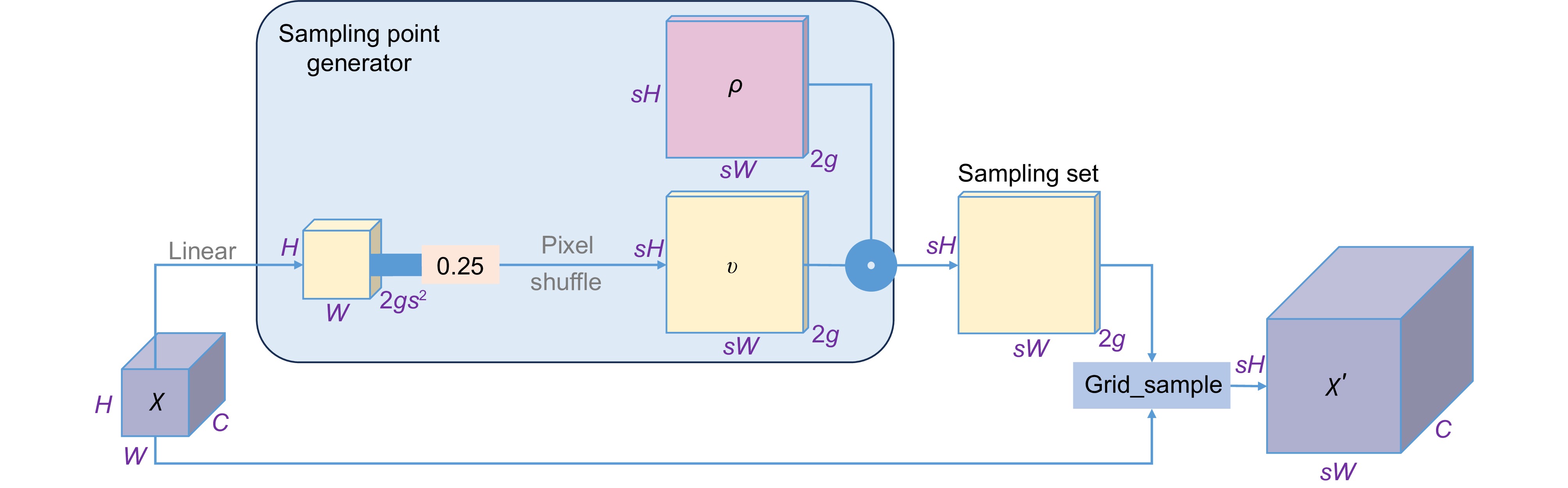

金属管件表面微小缺陷低检出率是工业零部件检测中面临的关键问题。针对此问题,本文构造一种改进YOLOv9-MM模型,以提高小目标检测的准确性。设计了一种针对精密金属管件的图像实时采集系统,采用环形光源结合远心镜头,可实现管件表面的全角度覆盖,消除缺失区域导致的漏检问题;引入浅层网络的特征图,结合Dysample上采样模块,实现深度特征的动态融合;通过改进损失函数,提高小目标检测的准确率。结果表明,所提方法平均检测精度达到70.2%,检测速度达到90 f/s。所提方法在应用中展现出一定的可行性。

Abstract

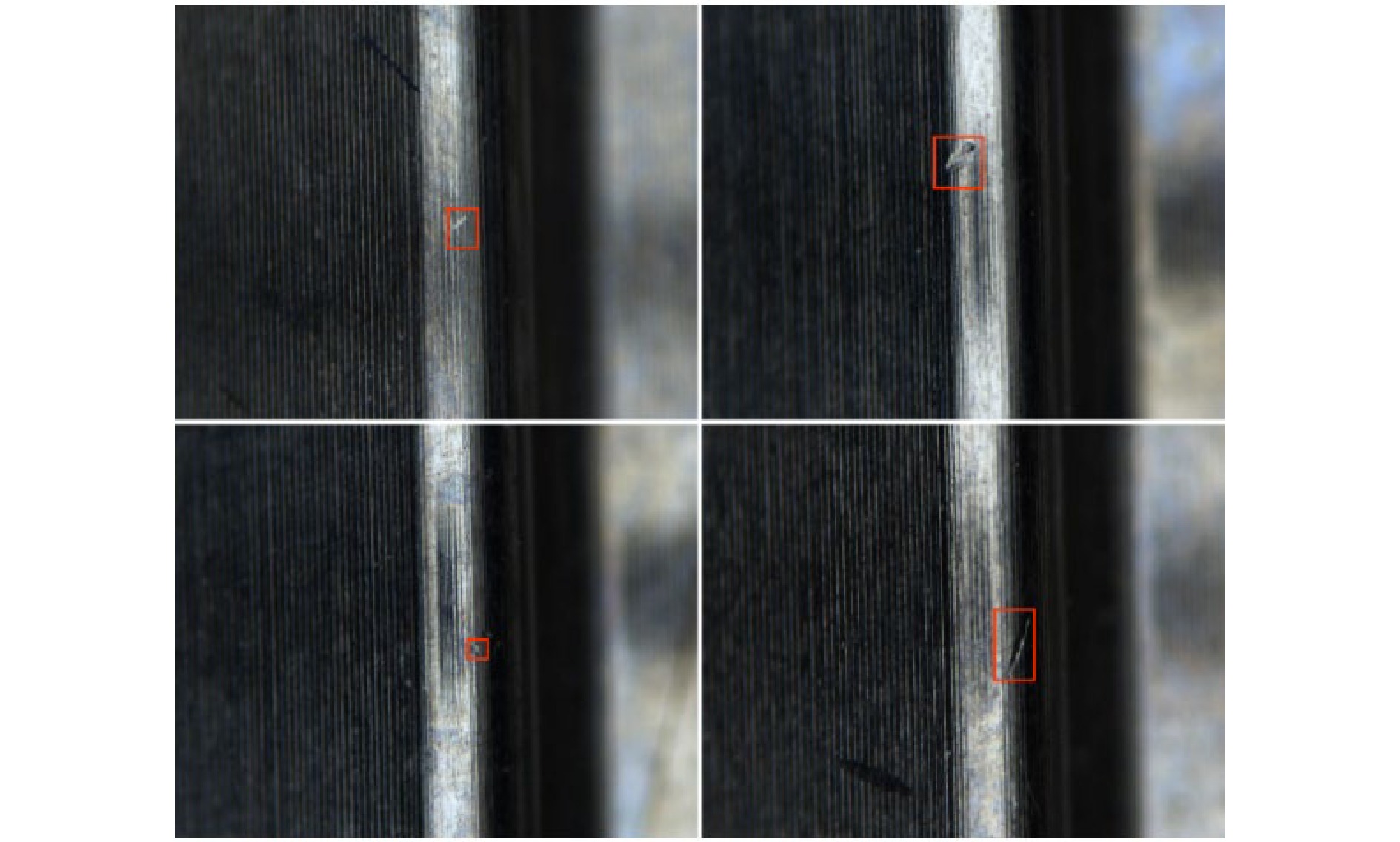

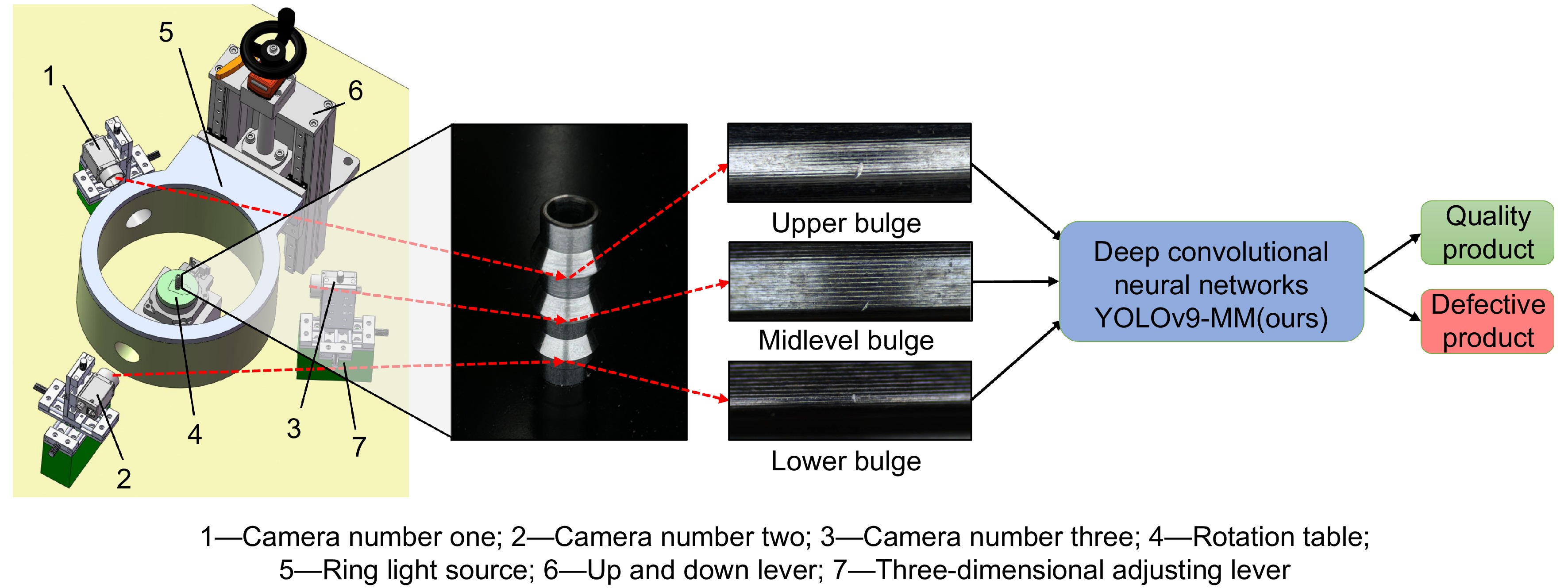

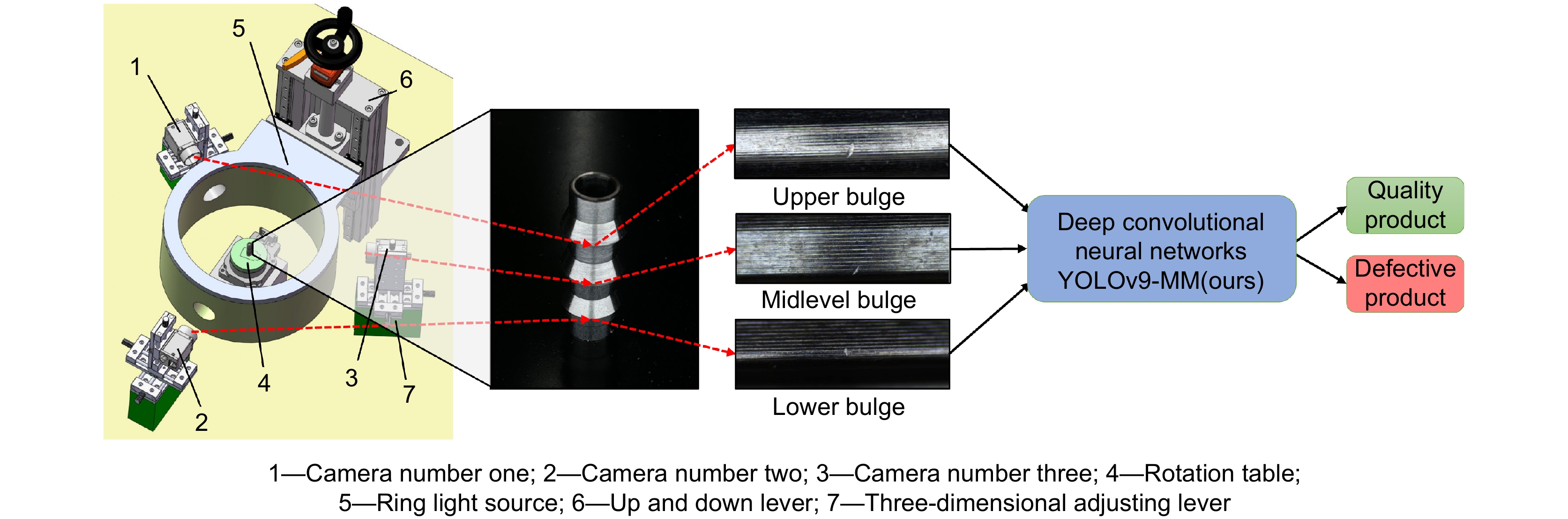

The low detection rate of tiny defects on the surface of metal pipe fittings is a key issue confronting industrial component inspection. In aiming at this problem, an improved YOLOv9-MM model was constructed to improve the accuracy of small target detection. A real-time image acquisition system for precision metal pipe fittings was designed. By using an annular light source combined with a telecentric lens, the surface of pipe fittings can be snapped by the CCD camera and covered at all angles to eliminate the problem of missing areas. The feature map extracted methods of shallow network were introduced, and the upper sampling module of Dysample was combined to realize the dynamic fusion of depth features. By improving the loss function, the precision of small target detection is greatly improved. The results show that the proposed method has an average detection accuracy of 70.2% and a detection speed of 90 f/s. The proposed method shows some feasibility in the actual application.

-

Key words:

- metal fittings /

- small defect detection /

- deep learning /

- YOLOv9 /

- detection system

-

Overview

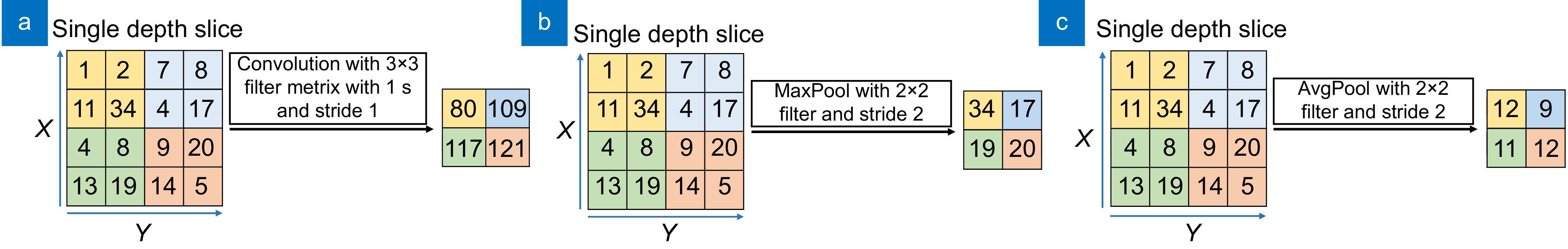

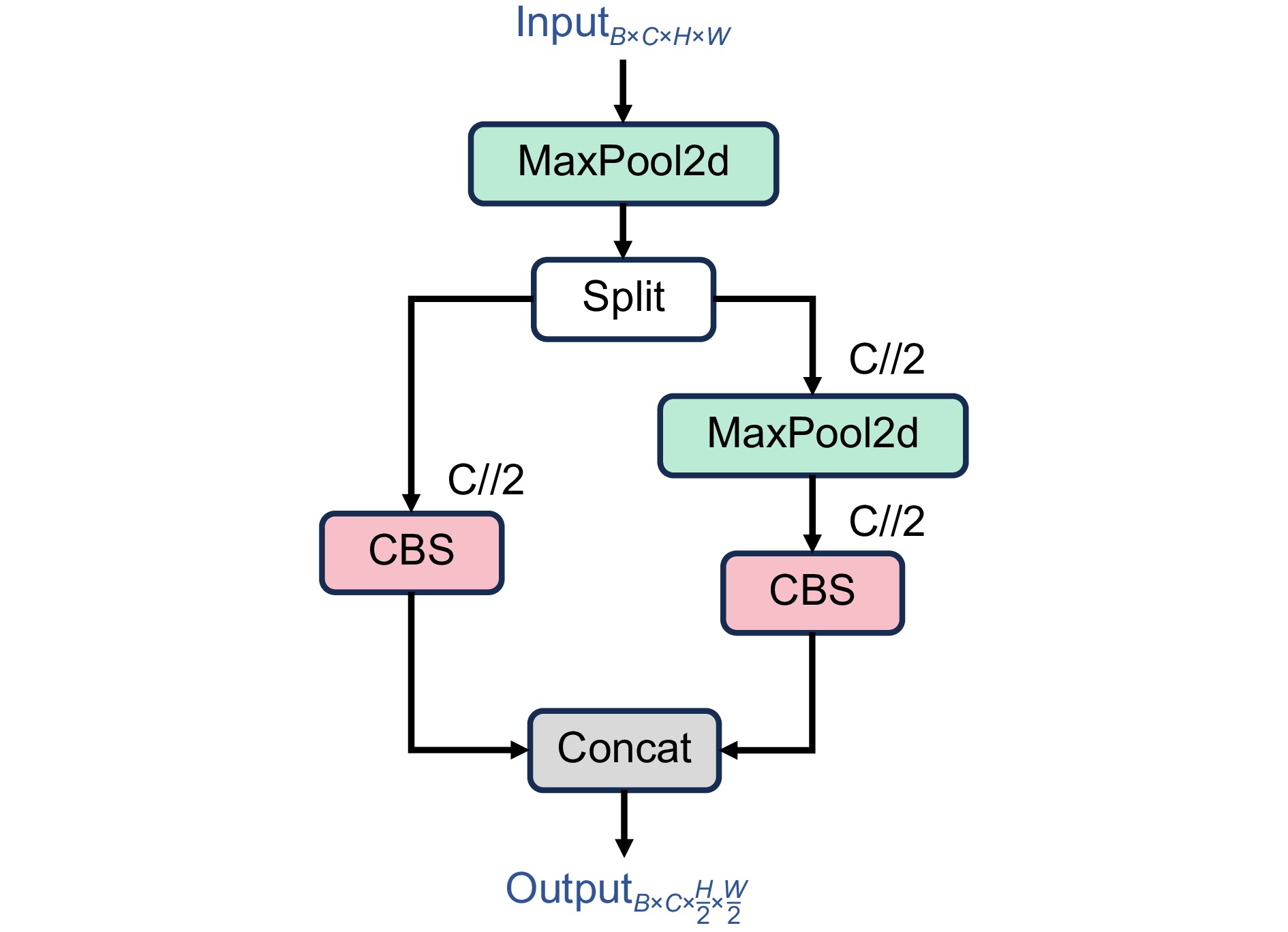

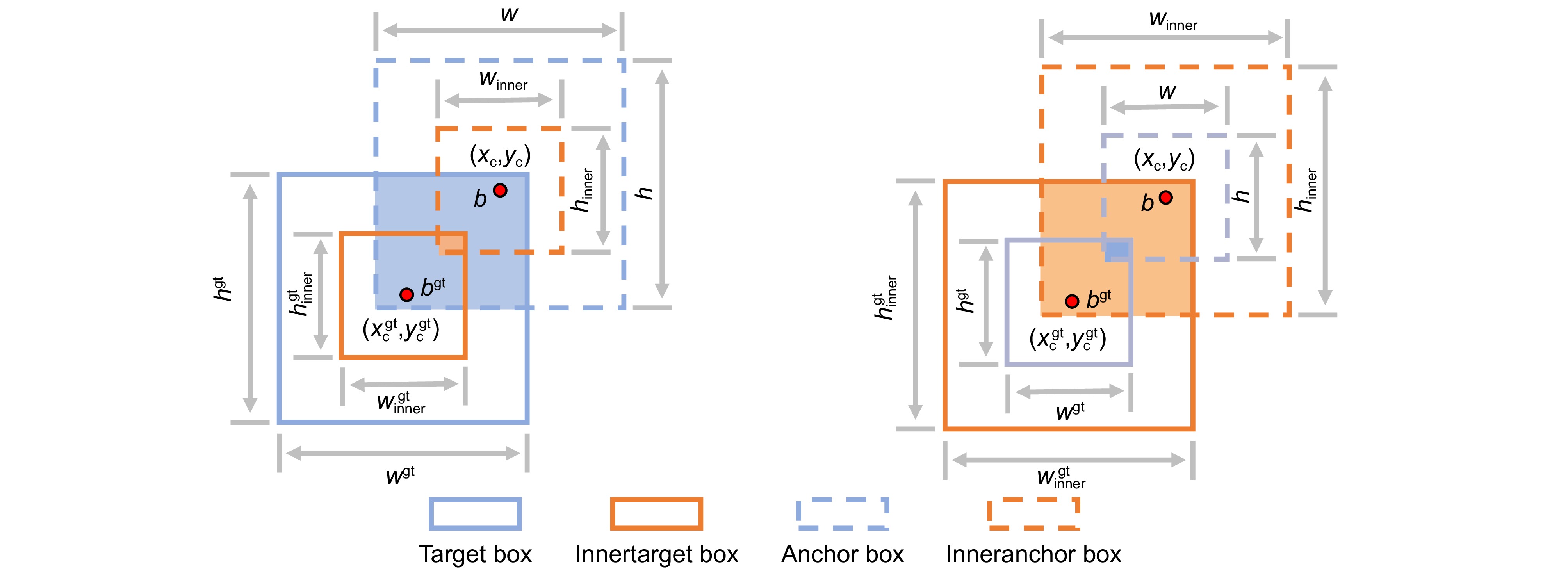

Overview: Metal pipe fittings are also known as "industrial food". The type of metal connection component plays an extremely important role in key national military equipment, such as spacecraft and nuclear industry. Tiny surface defects existing on the surface of these metal pipe fittings can directly affect the safety and quality of the target. Currently, supercomputers are widely used in scientific computation, climate simulation, artificial intelligence, nuclear bomb explosions, aerospace, and other fields and have huge requirements for safety and reliability. The study objective of this paper-metal pipe fittings are mainly applied in the liquid cooling plates of GPU clusters in the supercomputers. Introducing fluorine-containing cooling liquid into the interior of the fittings can quickly cool the high-temperature and high-heat integrated boards. If there are defects such as knocks, or scratches, cracks on the surface of the metal fittings, due to the pressure difference inside and outside, the liquid will be leaked out, causing tremendous economic losses upon the GPU chips. Therefore, to investigate the impact of surface defects on metal fittings, which can significantly affect the safety and stability of electro-mechanical equipment assembly, an improved detection algorithm called YOLOv9-MM is proposed. Firstly, a real-time image acquisition system for precision metal pipe fittings was designed. The ring light source combined with a telecentric lens can achieve full angle coverage of the surface of pipe fittings and eliminate the problem of missing areas. Secondly, based on deep convolutional neural network construction theory, a module called MCDown was constructed to combine max pooling and segmentation-connection strategy, thereby enhancing feature extraction capability and effectively reducing spatial dimensions. Additionally, shallow network feature maps were incorporated to enrich the feature information of small targets, and a dysample upsampling module was utilized to achieve the dynamic fusion of deep features. Finally, the combination of MDPIoU (mean distance of prediction intersection over union) and InnerIoU regression loss optimization strategies can accelerate model convergence and improve small target detection accuracy. Experimental results indicate that the average detection accuracy reaches 69.7%, a 3.9% improvement over the baseline model, with a detection speed of 90 f/s. Compared to other mainstream object detection algorithms, the proposed method demonstrates a better balance between precision and detection speed, showing its feasibility and value in practical applications. Furthermore, the model's performance in different environments and datasets also shows good robustness and generalization ability. Future work will expand upon other metal surface micro-defect image datasets and continuously optimize the algorithm to further improve its detection accuracy and generalization ability.

-

-

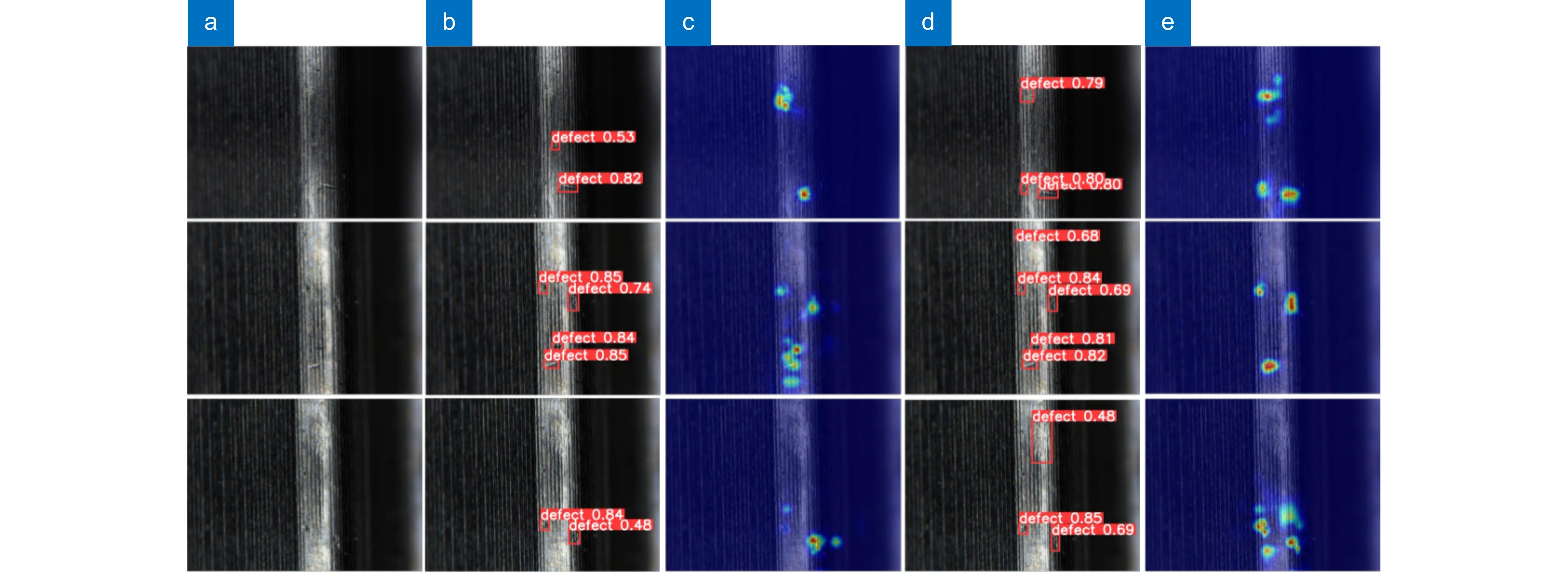

图 10 金属表面微尺度磕碰伤检测的热力图和结果可视化。(a)原始图像;(b) YOLOv9检测结果;(c) YOLOv9检测热力图;(d) YOLOv9-MM检测结果;(e) YOLOv9-MM检测热力图

Figure 10. Thermal maps and visualization of the results of micro-scale bump detection on metal surfaces. (a) Original images; (b) The detection results of YOLOv9; (c) Thermal maps for YOLOv9 detection; (d) The detection results of YOLOv9-MM; (e) Thermal maps for YOLOv9-MM detection

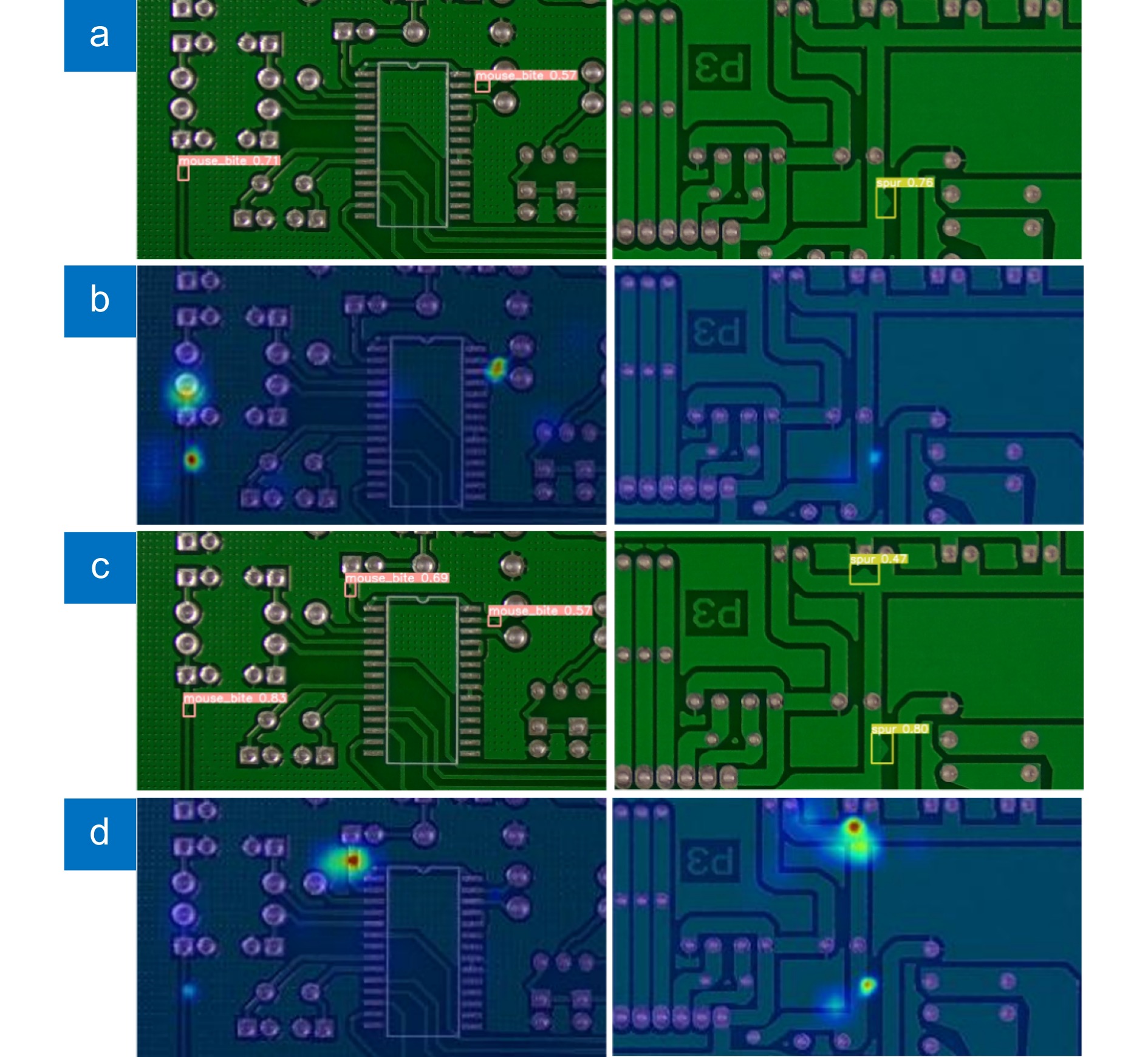

图 12 PCB缺陷检测的热力图和结果可视化。(a) YOLOv9检测结果;(b) YOLOv9检测热力图;(c) YOLOv9-MM检测结果;(d) YOLOv9-MM检测热力图

Figure 12. Thermal map and result visualization of PCB defect detection. (a) The test result of YOLOv9; (b) Thermal map for YOLOv9 detection; (c) Detection result of YOLOv9-MM; (d) Thermal map of YOLOv9-MM detection

表 1 图像采集系统中各个组件的型号和参数

Table 1. Models and specifications of components in the image acquisition system

Instrument indicators

and parametersAn experimental instrument is needed to construct a micro-scale bump detection system for metal pipe fittings Industrial CCD

cameraLens Ring light source Move the lever

up and down3D adjustment

leverFitting

typeRotation

tableInstrument type MV-CS016-10UC WT-G0745 PRC-200360X-B1 LZ-500 HTZ120 KCM82-4NC 16 CM/5-100S/15 KG Parameter name Resolution/pixel Magnification/X Luminous

power/WRange of

movement/mmStretch

range/mmWidth×

Height/mmRotational

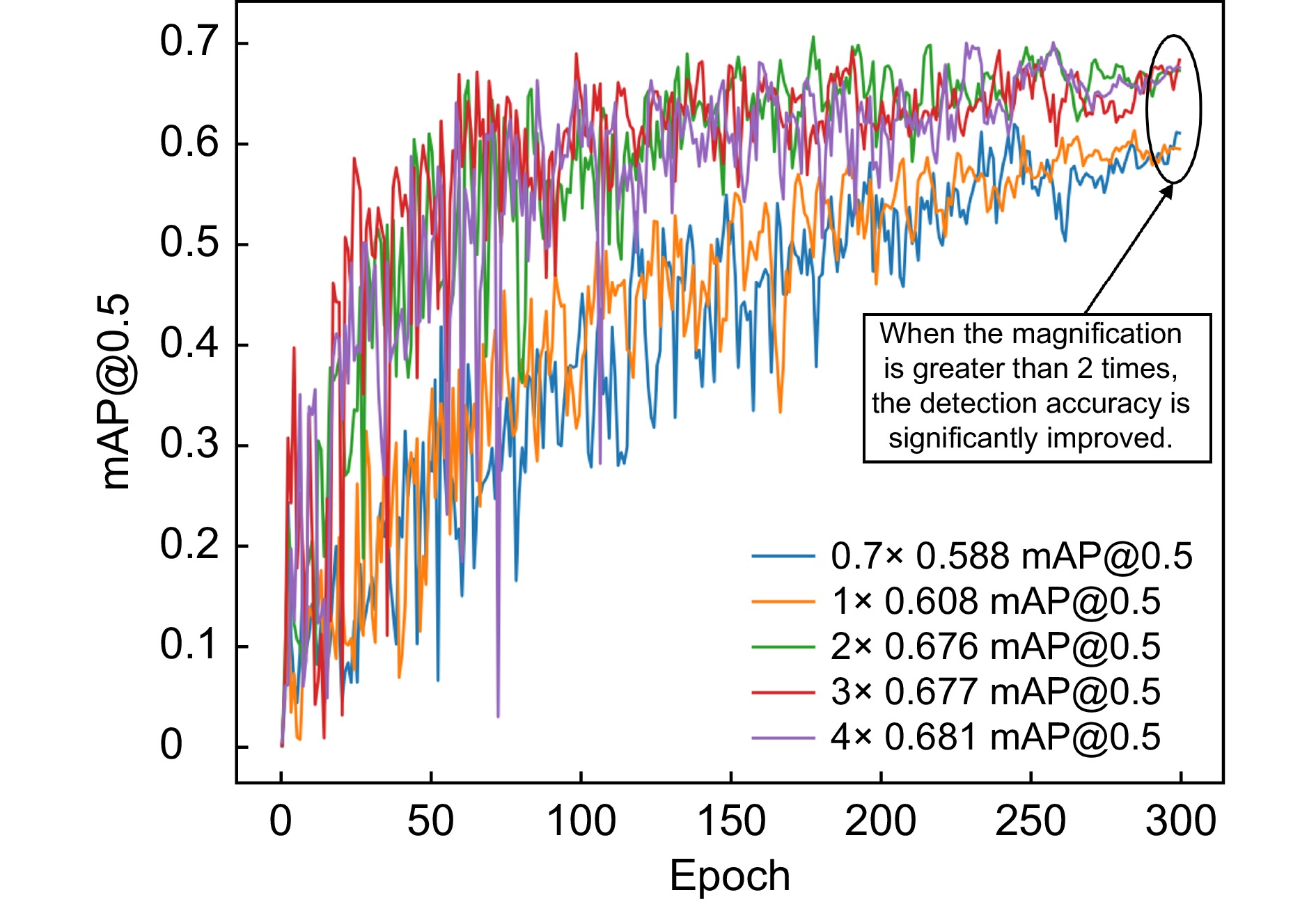

speed/rpmParameter value 1440×1080 [0.7,4] [2.8,12.1] [0,461] [-10,100] 8.8$ \times $24 [0,1.54] 表 2 多倍率实验参数

Table 2. Multi-magnification experimental parameters

Magnification 0.7× 1.0× 2.0× 3.0× 4.0× Exposure time/ms 10 15 20 25 30 Depth of field/mm 1.40 1.30 0.96 0.62 0.28 Field of view/mm

(1/3CCD diagonal)8.6 8.0 6.1 4.2 2.3 表 3 去除辅助可逆分支实验结果

Table 3. Removal of auxiliary reversible branch experimental results

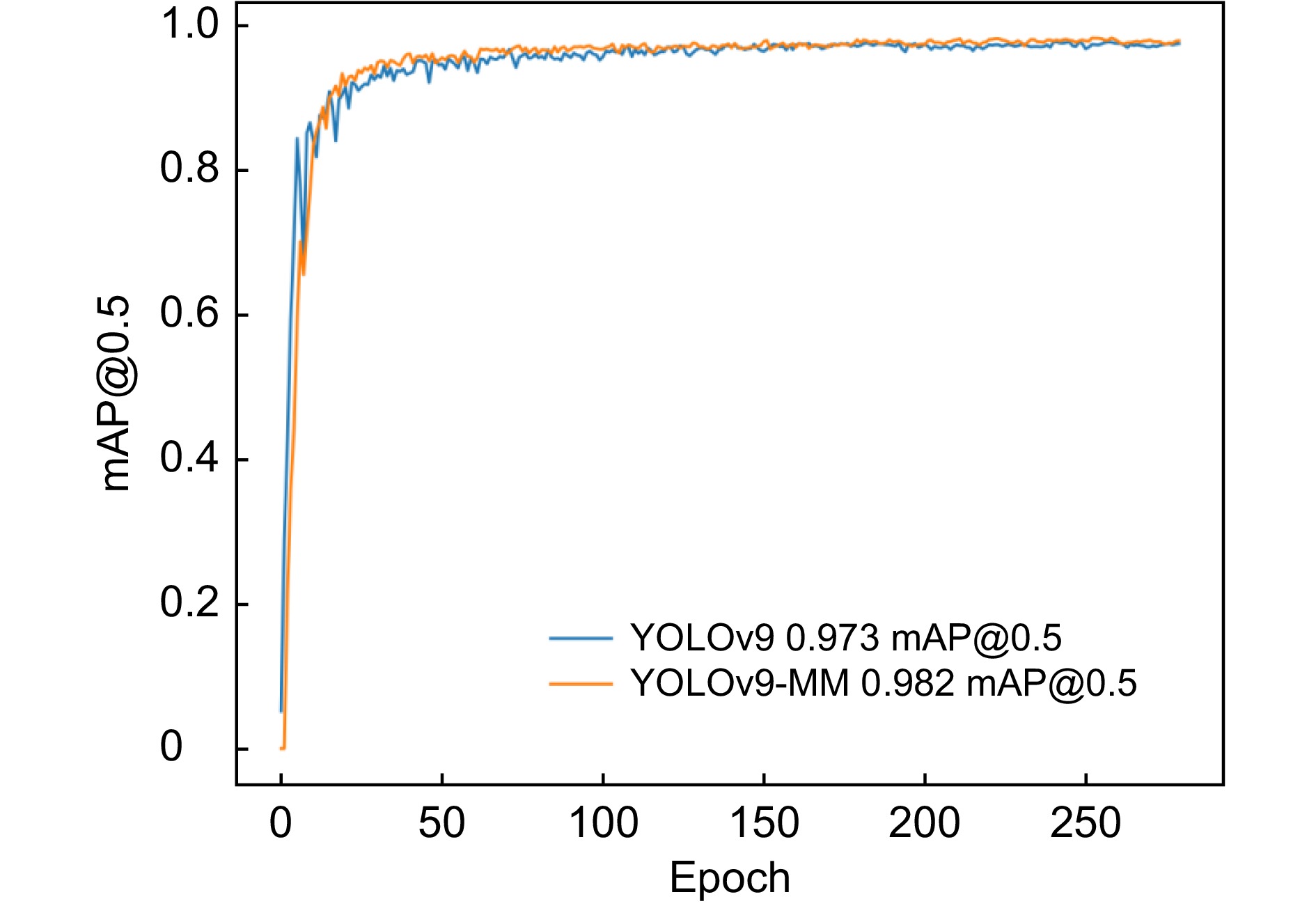

Network structure mAP@0.5/% Param/M FLOPs/G YOLOv9s 65.2 48.6 238.9 - Auxiliary invertible branch 66.9 30.0 118.5 表 4 消融实验结果

Table 4. Ablation experimental results

Number MCDown Dynamic integration of deep features Inner_MDPIoU P/% R/% mAP@0.5/% FLOPs/G FPS/(f/s) Ⅰ 66.2 57.1 66.9 118.5 133 Ⅱ √ 70.1 61.7 68.7 101.8 108 Ⅲ √ 72.0 63.9 69.4 145.7 83 Ⅳ √ 74.3 57.7 69.1 116.8 138 Ⅴ √ √ 76.4 58.5 69.8 130.3 88 Ⅵ √ √ 69.9 57.9 69.3 144.6 92 Ⅶ √ √ 77.2 60.8 68.3 101.8 130 Ⅷ √ √ √ 71.1 61.5 70.2 129.3 90 表 5 对比实验结果

Table 5. Comparative experimental results

Method mAP@0.5/% FLOPs/G FPS/(f/s) Param/M Faster RCNN 56.9 36.4 18 24.1 YOLOv5s 62.1 15.9 131 13.7 YOLOv7 65.5 104.7 161 18.1 YOLOv8s 64.7 28.4 303 21.5 FCOS 59.7 33.5 25 53.0 YOLOv10s 65.8 24.8 45.9 8.2 YOLOv11s 65.3 21.3 53.2 9.4 YOLOv9s 65.2 238.9 87 48.6 YOLOv9-MM(ours) 70.2 129.3 90 22.7 -

参考文献

[1] 伍麟, 郝鸿宇, 宋友. 基于计算机视觉的工业金属表面缺陷检测综述[J]. 自动化学报, 2024, 50(7): 1261−1283. doi: 10.16383/j.aas.c230039

Wu L, Hao H Y, Song Y. A review of metal surface defect detection based on computer vision[J]. Acta Autom Sin, 2024, 50(7): 1261−1283. doi: 10.16383/j.aas.c230039

[2] 高亦沁, 罗智宇, 王一超, 等. 面向国产超算的操作系统评测与优化[J/OL]. 计算机科学, 2024.http://kns.cnki.net/kcms/detail/50.1075.tp.20240925.1330.007.html

Gao Y Q, Luo Z Y, Wang Y C, et al. Evaluation and optimization of operating system for domestic supercomputer[J/OL]. Comput Sci, 2024.http://kns.cnki.net/kcms/detail/50.1075.tp.20240925.1330.007.html

[3] Rajitha B, Tiwari A, Agarwal S. A new local homogeneity analysis method based on pixel intensities for image defect detection[C]//2015 IEEE 2nd International Conference on Recent Trends in Information Systems (ReTIS), Kolkata, India, 2015: 200–206. https://doi.org/10.1109/ReTIS.2015.7232878.

[4] Chen W, Zou B, Yang J Z, et al. The machined surface defect detection of improved superpixel segmentation and two-level region aggregation based on machine vision[J]. J Manuf Process, 2022, 80: 287−301. doi: 10.1016/j.jmapro.2022.05.038

[5] Huang Z R. Fusion of complex networks-based global and local features for feature representation[C]//2021 International Conference on Machine Learning and Cybernetics (ICMLC), Adelaide, Australia, 2021: 1–6. https://doi.org/10.1109/ICMLC54886.2021.9737154.

[6] Sun Z J, Wang X H, Luo F, et al. Scale adaptive attention network for accurate defect detection from metal parts[J]. IEEE Access, 2024, 12: 131035−131043. doi: 10.1109/ACCESS.2024.3432660

[7] Zhu X F, Wang Q M, Zhang B F, et al. An improved feature enhancement CenterNet model for small object defect detection on metal surfaces[J]. Adv Theory Simul, 2024, 7(8): 2301230. doi: 10.1002/adts.202301230

[8] Dong H W, Song K C, He Y, et al. PGA-Net: pyramid feature fusion and global context attention network for automated surface defect detection[J]. IEEE Trans Industr Inform, 2020, 16(12): 7448−7458. doi: 10.1109/TII.2019.2958826

[9] Peng T, Zheng Y, Zhao L, et al. Industrial product surface anomaly detection with realistic synthetic anomalies based on defect map prediction[J]. Sensors, 2024, 24(1): 264. doi: 10.3390/s24010264

[10] Xie X, Xu L, Li X L, et al. A high-effective multitask surface defect detection method based on CBAM and atrous convolution[J]. J Adv Mech Des Syst Manuf, 2022, 16(6): JAMDSM0063. doi: 10.1299/jamdsm.2022jamdsm0063

[11] Xue P, Jiang C H, Pang H L. Detection of various types of metal surface defects based on image processing[J]. Trait Signal, 2021, 38(4): 1071−1078. doi: 10.18280/ts.380417

[12] Chen T, Saxena S, Li L L, et al. Pix2seq: a language modeling framework for object detection[C]//The Tenth International Conference on Learning Representations, 2021.

[13] Wang C Y, Yeh I H, Liao H Y M. YOLOv9: learning what you want to learn using programmable gradient information[C]//18th European Conference on Computer Vision, Milan, Italy, 2024: 1–21. https://doi.org/10.1007/978-3-031-72751-1_1.

[14] Lin T Y, Dollár P, Girshick R, et al. Feature pyramid networks for object detection[C]//2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 2017: 936–944. https://doi.org/10.1109/CVPR.2017.106.

[15] Li S, Wang Z C, Zhang X D, et al. Robust image steganography against general downsampling operations with lossless secret recovery[J]. IEEE Trans Dependable Secure Comput, 2024, 21(1): 340−352. doi: 10.1109/TDSC.2023.3253691

[16] Liu S, Qi L, Qin H F, et al. Path aggregation network for instance segmentation[C]//2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 2018: 8759–8768. https://doi.org/10.1109/CVPR.2018.00913.

[17] Lin Y, Tu Y, Dou Z. An improved neural network pruning technology for automatic modulation classification in edge devices[J]. IEEE Trans Veh Technol, 2020, 69(5): 5703−5706. doi: 10.1109/TVT.2020.2983143

[18] Liu W Z, Lu H, Fu H T, et al. Learning to upsample by learning to sample[C]//2023 IEEE/CVF International Conference on Computer Vision (ICCV), Paris, France, 2023: 6004–6014. https://doi.org/10.1109/ICCV51070.2023.00554.

[19] Ma S L, Xu Y. MPDIoU: a loss for efficient and accurate bounding box regression[Z]. arXiv: 2307.07662, 2023. https://arxiv.org/abs/2307.07662.

[20] Zhang H, Xu C, Zhang S J. Inner-IoU: more effective intersection over union loss with auxiliary bounding box[Z]. arXiv: 2311.02877, 2023. https://arxiv.org/abs/2311.02877.

[21] 郭从洲, 李可, 李贺, 等. 遥感图像质量等级分类的深度卷积神经网络方法[J]. 武汉大学学报(信息科学版), 2022, 47(8): 1279−1286. doi: 10.13203/j.whugis20200292

Guo C Z, Li K, Li H, et al. Deep convolution neural network method for remote sensing image quality level classification[J]. Geomatics Inf Sci Wuhan Univ, 2022, 47(8): 1279−1286. doi: 10.13203/j.whugis20200292

[22] 陶国好, 刘子豪, 徐晓萌, 等. 圆柱金属管件外表面图像在线采集装置构建及关键参数控制优化[J]. 计量学报, 2024, 45(10): 1494−1501. doi: 10.3969/j.issn.1000-1158.2024.10.09

Tao G H, Liu Z H, Xu X M, et al. Construction of on-line image acquisition device for cylindrical metal pipe fittings and control optimization of key parameters[J]. J Metrol, 2024, 45(10): 1494−1501. doi: 10.3969/j.issn.1000-1158.2024.10.09

[23] Ren S Q, He K M, Sun R J. Faster R-CNN: towards real-time object detection with region proposal networks[J]. IEEE Trans Pattern Anal Mach Intell, 2017, 39(6): 1137−1149. doi: 10.1109/TPAMI.2016.2577031

[24] Wang C Y, Bochkovskiy A, Liao H Y M. YOLOv7: trainable bag-of-freebies sets new state-of-the-art for real-time object detectors[C]//2023 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Vancouver, BC, Canada, 2023: 7464–7475. https://doi.org/10.1109/CVPR52729.2023.00721.

[25] Varghese R, M S. YOLOv8: a novel object detection algorithm with enhanced performance and robustness[C]//2024 International Conference on Advances in Data Engineering and Intelligent Computing Systems (ADICS), Chennai, India, 2024: 1–6. https://doi.org/10.1109/ADICS58448.2024.10533619.

[26] Wang A, Chen H, Liu L H, et al. YOLOv10: real-time end-to-end object detection[C]//Proceedings of the 38th International Conference on Neural Information Processing Systems, Vancouver, BC, Canada, 2024.

[27] Tian Z, Shen C H, Chen H, et al. FCOS: fully convolutional one-stage object detection[C]//2019 IEEE/CVF International Conference on Computer Vision (ICCV), Seoul, Korea (South), 2019: 9626–9635. https://doi.org/10.1109/ICCV.2019.00972.

[28] Feng B X, Cai J P. PCB defect detection via local detail and global dependency information[J]. Sensors, 2023, 23(18): 7755. doi: 10.3390/s23187755

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: