-

摘要:

基于飞秒激光的双光子聚合(two-photon polymerization, TPP)加工技术一直是三维微纳加工技术中的研究热点。随着生命科学、材料工程、微纳光学等领域对复杂、大面积微型三维器件制备需求的提升,TPP加工效率不足的问题日益严重,加工时间过长不仅造成加工结构的不稳定,更是严重阻碍这些重要三维器件的进一步推广应用。本文以TPP加工效率提升方面的研究工作为主线,分别从单光束刻写、并行多光束刻写、面曝光和体曝光四个方式进行总结与对比,阐述相应的光学系统设计、刻写策略、刻写精度与通量等方面的研究情况,总结各种技术的优势与劣势,同时展望未来发展趋势。

Abstract:Two-photon polymerization (TPP) based on femtosecond laser has been a research hotspot in 3D micro/nano writing technology. With the increasing demand for processing complex and large-scale miniaturized 3D devices in the fields of life science, material engineering, micro and nano optics, and etc., the issue of low processing efficiency of TPP is becoming increasingly serious. During the long fabrication period, many disturbances can be introduced in the processing, causing the quality deterioration of the structure and seriously hindering the further popularization and application of these crucial 3D devices. This paper respectively compares the four approaches of single-beam writing, parallel multi-beam writing, pattern projection, and 3D projection exposure based on the TPP lithography efficiency. Moreover, the researches on the optical design of system, the writing accuracy, the fabrication throughput, the writing strategy, and etc. of each approach are also described. And the advantages and disadvantages of these four methods are summerized simultaneously. Finally, we also made a brief prospect to the developing trend of TPL efficiency improvement in the future.

-

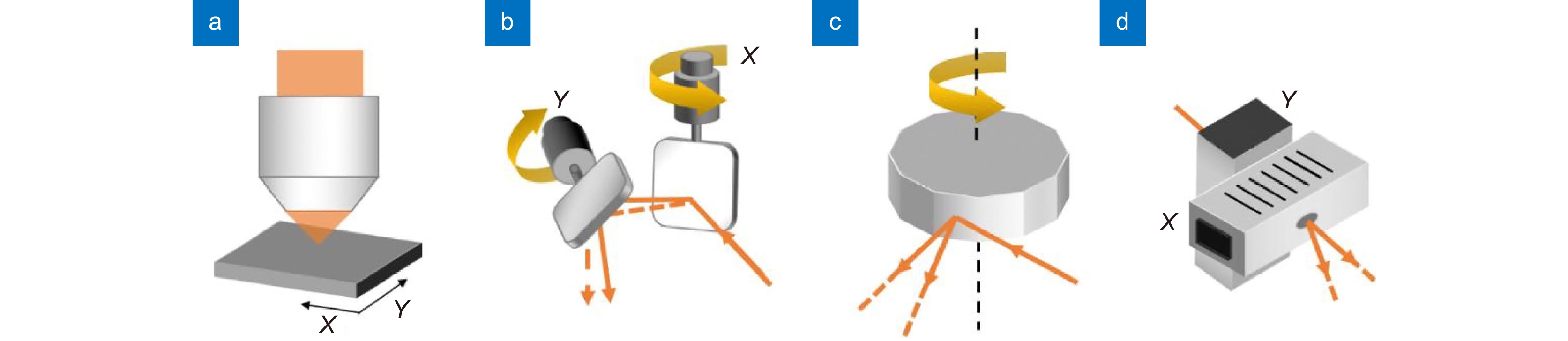

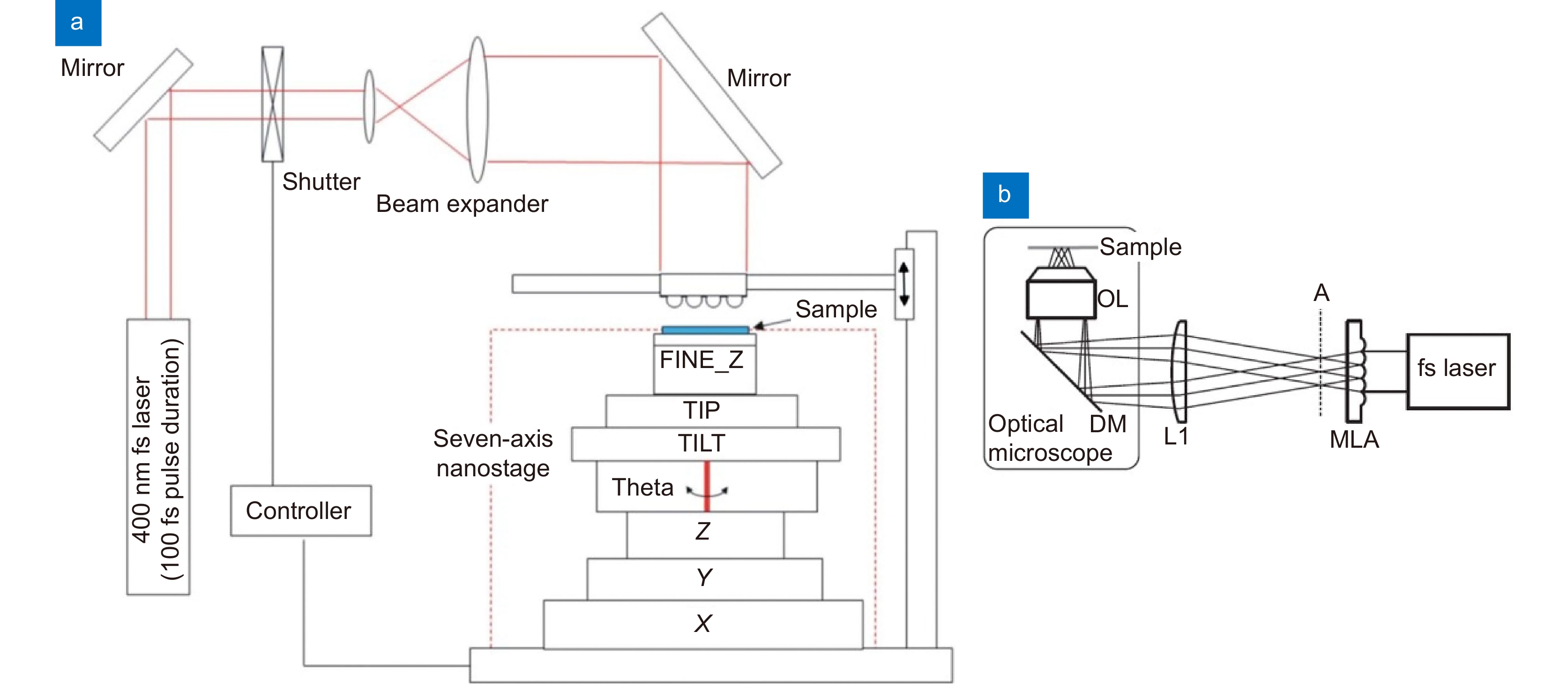

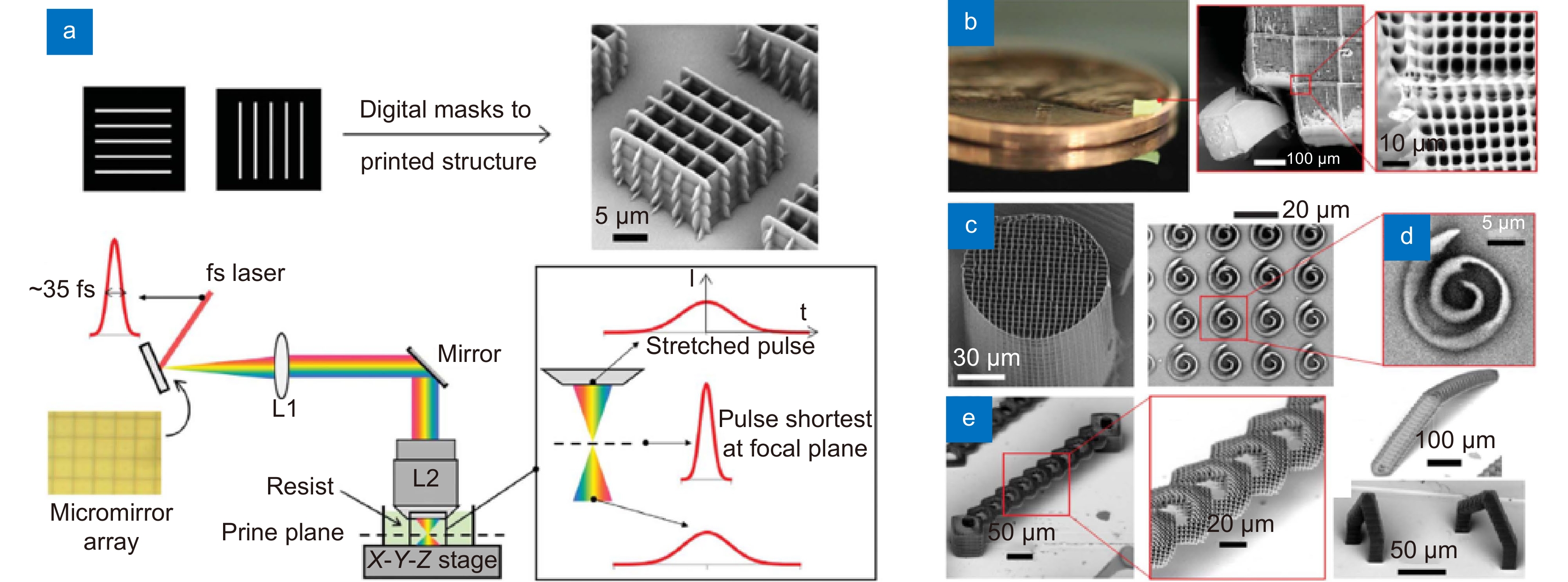

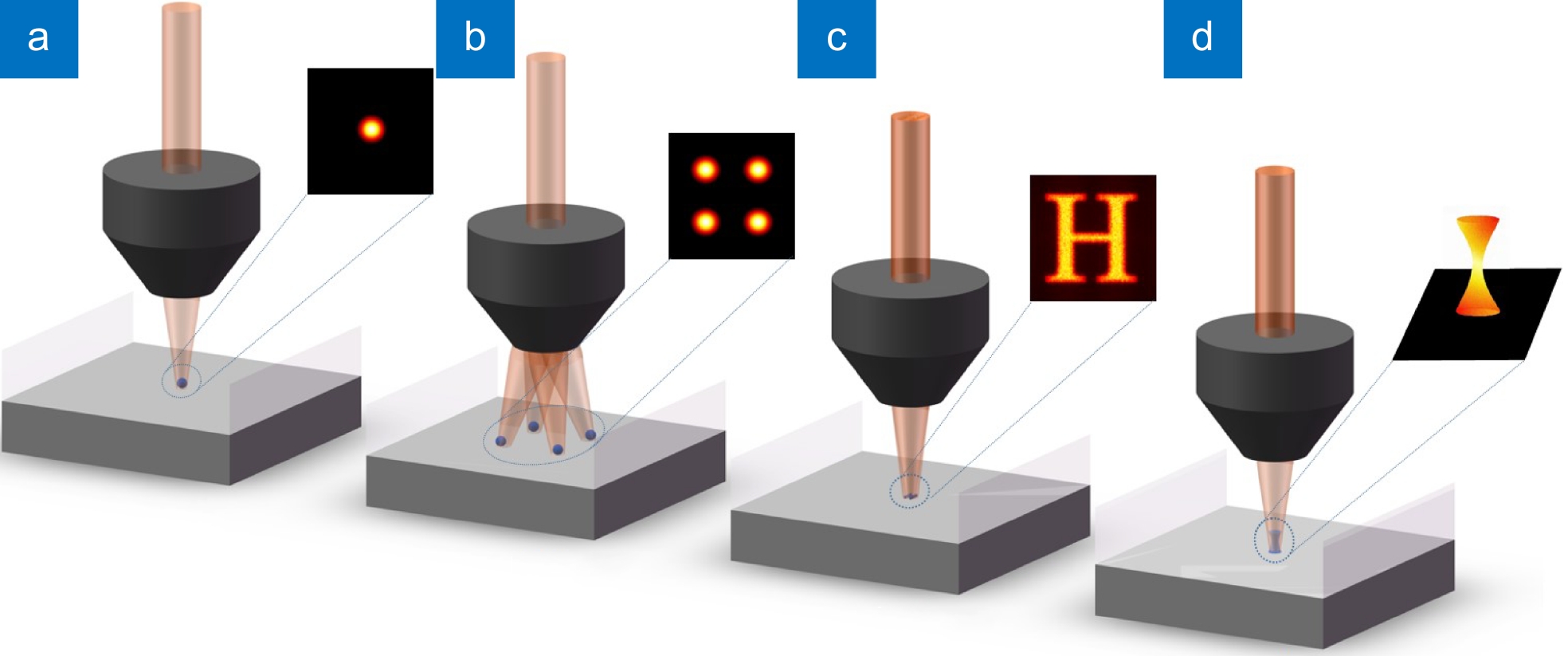

Overview: Two-photon lithography (TPL) has been a research hotspot in 3D micro/nano writing technology due to its characteristics of high resolution, low thermal influence, a wide range of processed materials, low environmental requirements, and 3D processing capability. It has shown unique advantages in the fields of life science, material engineering, micro/nano optics, microfluidic, micro machinery, and so on. This paper summarizes the research works done by researchers on different writing methods to improve TPL processing efficiency. Single-beam writing is the main method for TPL, which mainly depends on the speed of the scanning device. Single-beam writing has the advantages of simple system and high-quality beam, and it is easy to combine various effects to improve writing results. It mainly includes scanning modes based on the translation stage, galvo, polygon laser scanner, and acousto-optic deflector (AOD) (Fig. 2). All these modes have advantages and disadvantages. As for the scanning speed comparison, polygon laser scanner and AOD have relatively faster writing rates (faster than m/s). Multi-foci parallel lithography can obviously promote efficiency, elevating the speed by dozens or even hundreds of thousands of times, mainly based on spatial light modulator (SLM), digital micromirror device (DMD), microlens array (MLA), diffractive optical elements (DOE), multi-beam interference, and so on (Figs. 3-15). Multi-foci parallel lithography based on SLM is most widely used owing to its high efficiency and ability to flexible and independent control of each single beam, but the refresh rate is still insufficient. DMD has a higher refreshing rate (32 kHz), but the state-of-the-art beam parallelism realized by DMD is severely limited. More parallel beams are further required for improving the processing efficiency. The 2D pattern exposure method based on SLM or DMD can further improve the TPL efficiency with the superiority of generating flexibly designed pattern (Figs. 16-18). However, the 2D projection exposure technology is still difficult to achieve high writing precision, especially the axial resolution. An available method to improve the axial precision is spatially and temporally focusing an ultrafast laser to implement a strong intensity gradient at the spatial focal plane that restricts polymerization within a thin layer. The 3D projection method will be the most efficient writing method in the future, especially in 3D device processing (Figs. 19-20). Researchers used this technique to make hollow tubular and conical helices structures, increasing the processing speed by 600 times. However, the research results show that the current 3D projection can only process simple 3D structures. Further researches on 3D exposure processing of complex structures are expected, which will effectively expand its application in various fields. Authors believe that with the effort of researchers on efficiency improvement gradually, TPL can further highlight its advantages to promote the development of life science, materials engineering, micro-nano optics, and many other fields.

-

-

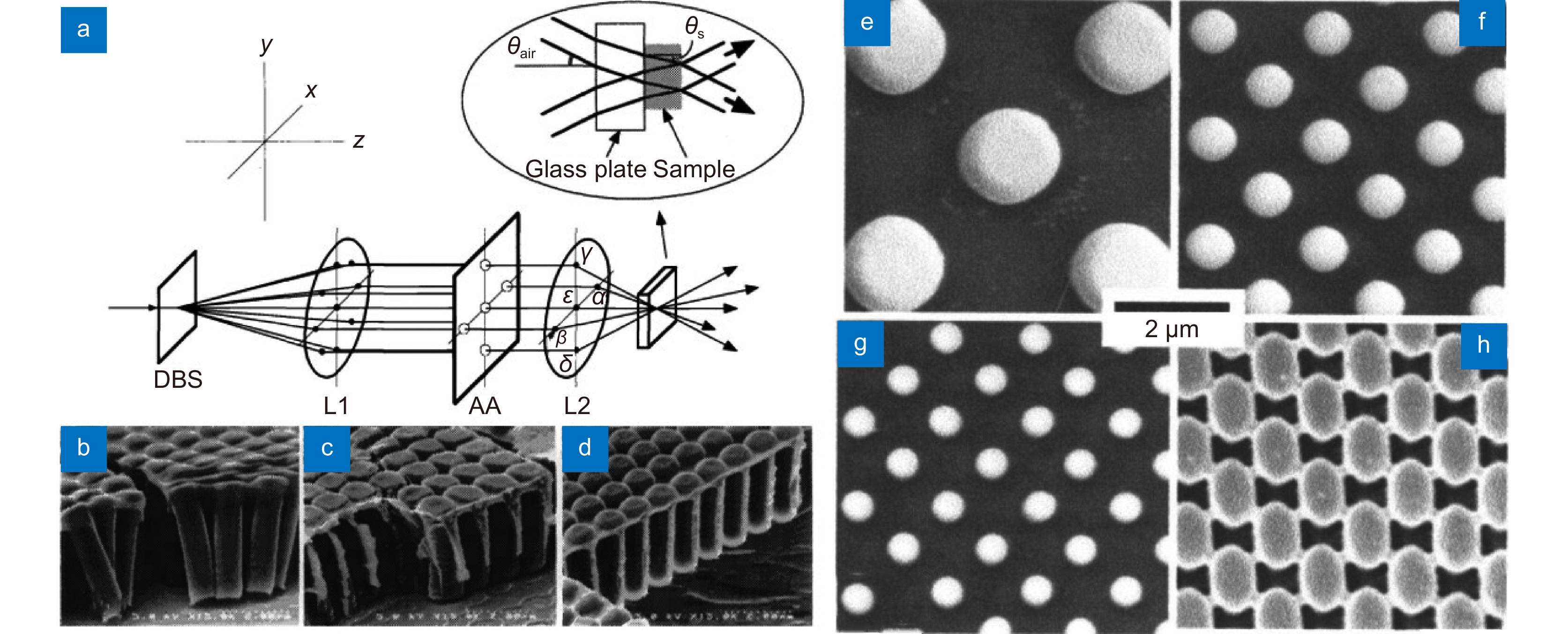

图 3 (a) 基于DBS分束进行多光束干涉的并行刻写系统结构;(b)~(d) 通过四束800 nm/1 kHz飞秒激光干涉形成点阵进行刻写的周期性结构,曝光时间分别为30 s、80 s和120 s;(e)~(g) 四光束在不同干涉角下所制备的结构,干涉角分别为10.8°、21.9°和33.6°;(h) 三光束干涉点阵刻写阵列结构[53-55]

Figure 3. (a) Configuration of the parallel writing system based on diffractive beam splitter (DBS) and multi-beam interference; (b)~(d) The periodic structures written by the foci array generated via the interference of four femtosecond laser beams (800 nm/1 kHz). The exposure time is 30 s, 80 s, and 120 s, respectively; (e)~(g) The dot array structures fabricated by the foci lattice generated via four-beam interference with different interference angles of 10.8°, 21.9°, and 33.6°, respectively; (h) The periodic lattice structure written by the foci array generated via three-beam interference[53-55]

图 4 (a) 基于四光束干涉的多光子聚合刻写系统;(b) 单次曝光(1 s)加工的支柱阵列,周期7.5 μm,高度20 μm,支柱直径3 μm;(c) 连续单次曝光加工的大面积周期性结构,其中单次曝光的激光焦点阵列直径为~80 μm[56]

Figure 4. (a) Configuration of the multi-photon writing system based on four-beam interference; (b) Pillar array fabricated by once laser exposure (1 s), period 7.5 μm, height 20 μm, and diameter 3 μm; (c) Large-scale periodic structure fabricated by continuously shifting the once-exposure position of foci array with diameter of ~80 μm[56]

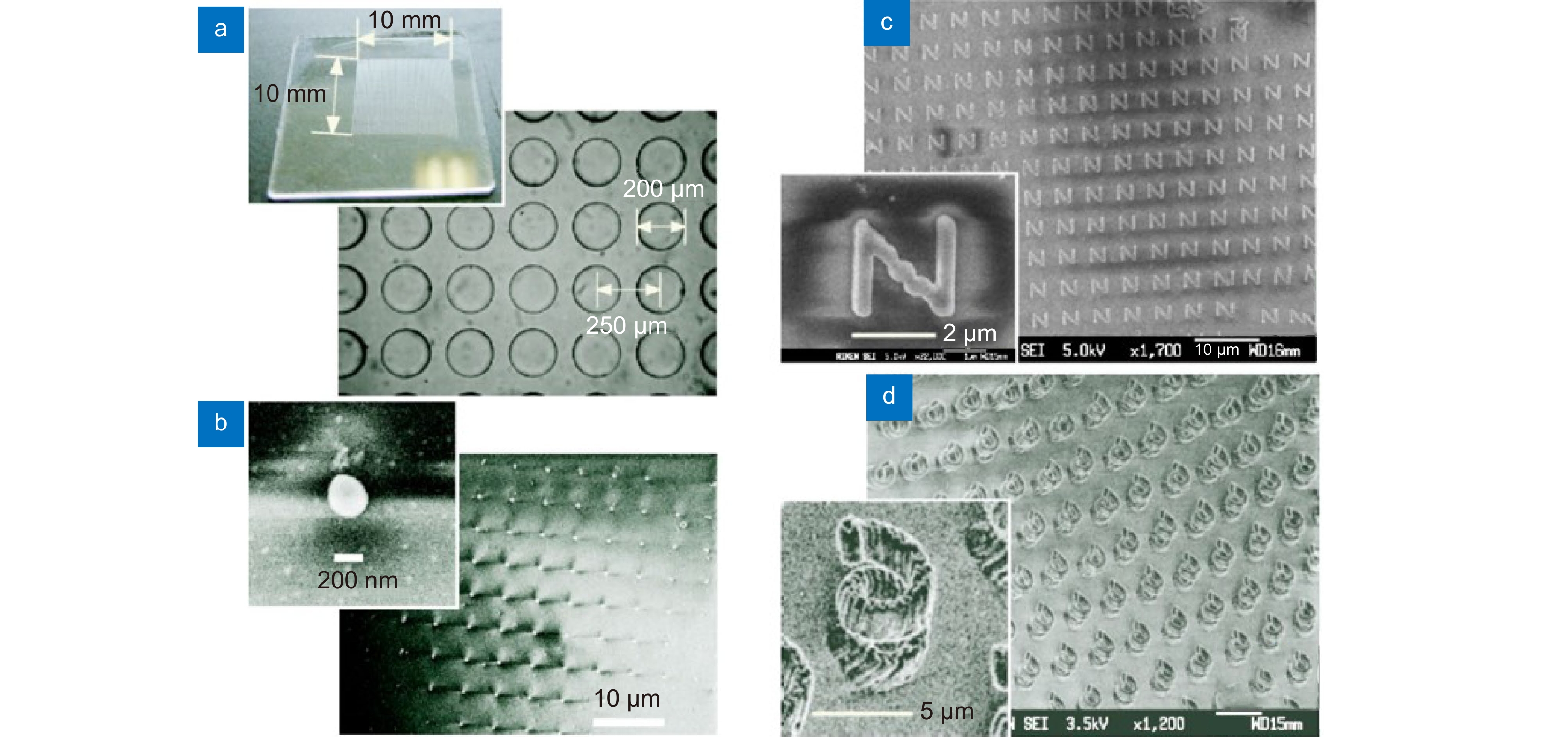

图 6 (a) 所采用MLA外观及其光学显微图像;(b) 在玻璃基板上产生的光聚合树脂体素扫描电子显微镜SEM图像;(c) 采用28个曝光点制作的227个二维“N”字母阵列;(d) 三维加工微弹簧阵列[65]

Figure 6. (a) The overall appearance and optical microscopic image of MLA; (b) SEM of the photopolymerized resin voxels on glass substrate; (c) The 2D array structure of 277 ‘N’ microletters fabricated by 28 foci;(d) The fabricated 3D microspring array[65]

图 7 (a) 在疏水镀膜玻璃表面制备三维周期性镀银结构的电子显微图;(b) 由一个立方体支撑一个线圈组成的单个未镀层聚合物结构的近景;(c) 化学镀银后单个结构的近景[66]

Figure 7. (a) SEM of 3D periodic structures coated with silver fabricated on a hydrophobic coated glass surface; (b) Enlarged view of a single uncoated polymerized structure composed of a spring on top of a cube; (c) The polymerized structure of (b) with coated silver[66]

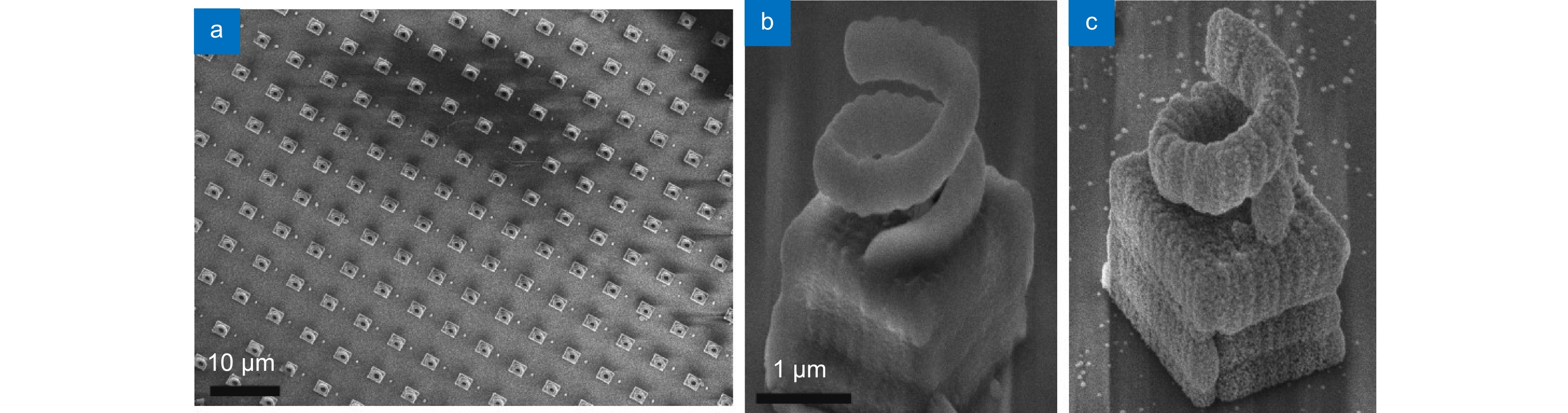

图 8 (a) 基于DBS的多光束并行飞秒多光子加工系统;(b) 利用DBS产生的多光束结构;(c)~(f) 通过图(a)装置并行加工得到的Logo标志、集成齿轮(直径22 μm)、微风扇及六边形结构光子晶体[72]

Figure 8. (a) DBS-based multi-photon processing system with multiple femtosecond laser beams; (b) Multi-foci pattern generated by DBS; (c)~(f) The structures of designed Logo, assembled microgear set (diameter 22 μm), 3D microfans, and assembled microgear set fabricated with the optical setup of (a)[72]

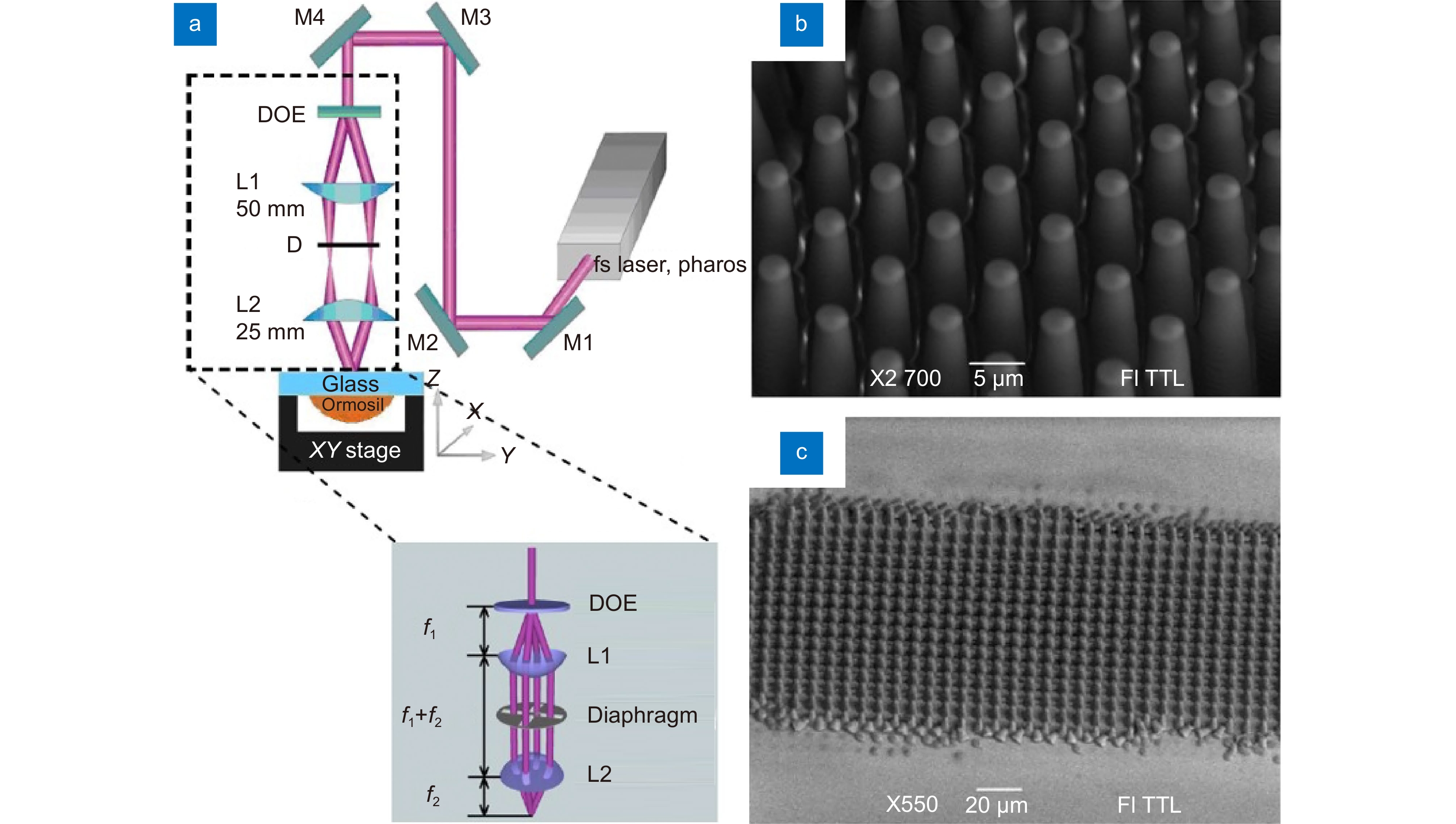

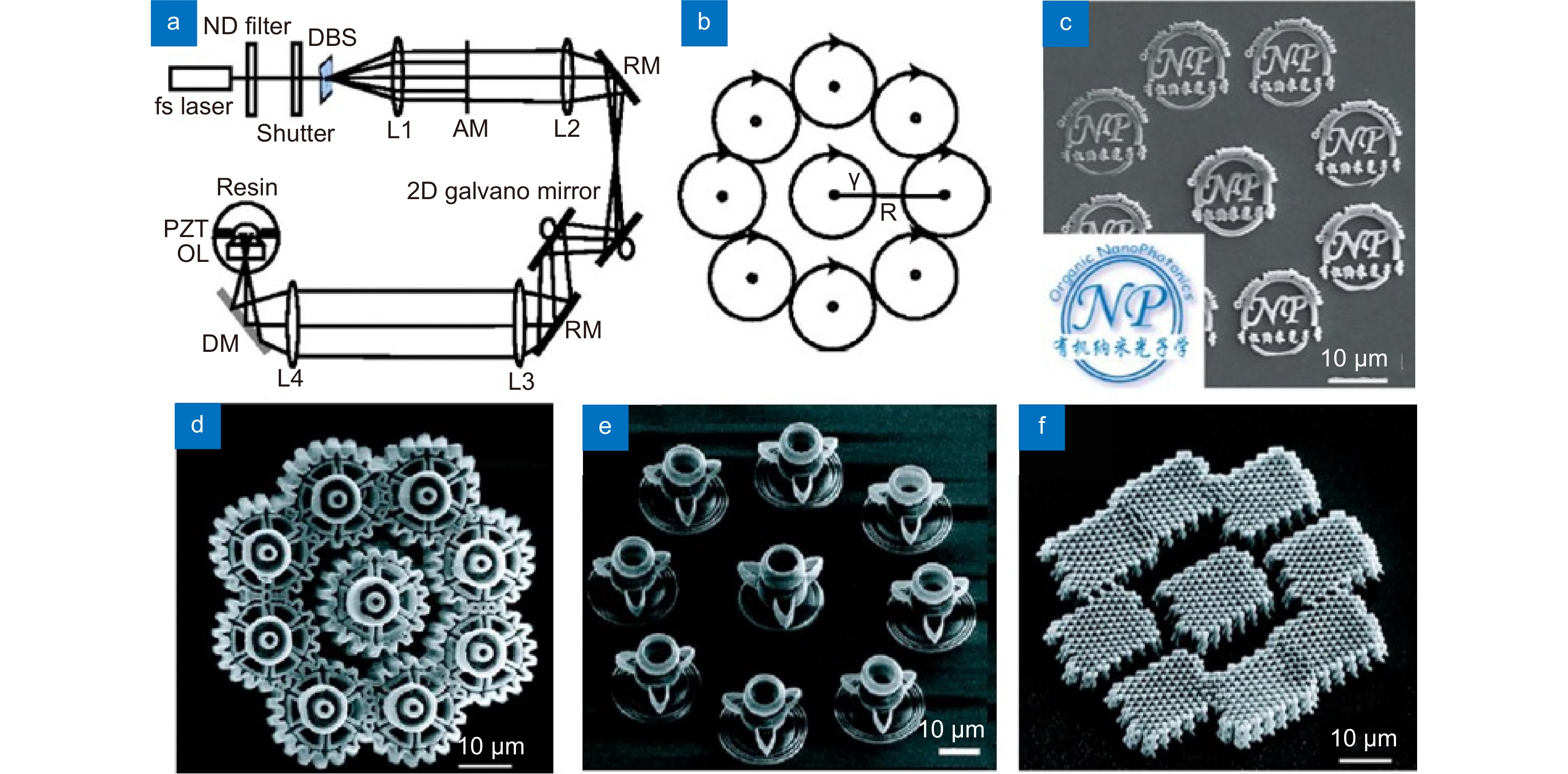

图 9 基于DOE分束的飞秒激光并行刻写。(a) DOE扫描电镜图;(b) DOE表面浮雕结构特写镜头;(c) DOE拍摄实物图;(d) CMOS相机对DOE进行归一化伪色强度测量;(e) 基于DOE生成的3×3焦点阵列的并行三维双光子打印装置方案;(f) 手性三维超材料立方体单元结构设计模型,尺寸a为80 μm;(g) 由30×30×120=108000个(f)所示的单元结构组成的2.4 mm×2.4 mm×9.6 mm手性超材料加工结构;(h) 图(g)手性机械超材料斜侧面的扫描电子显微镜图[73]

Figure 9. DOE-based mluti-beam parallel femtosecond laser writing. (a) SEM of the DOE surface; (b) Enlarged view of (a); (c) Overall appearance of the DOE; (d) Normalized false-color intensity measurement of the DOE using a CMOS-camera; (e) Parallel 3D two-photon fabricating system based on 3×3 foci generated by DOE; (f) Designed model of the chiral 3D metamaterial cubic cell, a=80 μm; (g) 2.4 mm×2.4 mm×9.6 mm chiral metamaterial structure consisting of 30×30×120=108000 3D cubic cells of (f); (h) Oblique side-view SEM of the structure in (g)73]

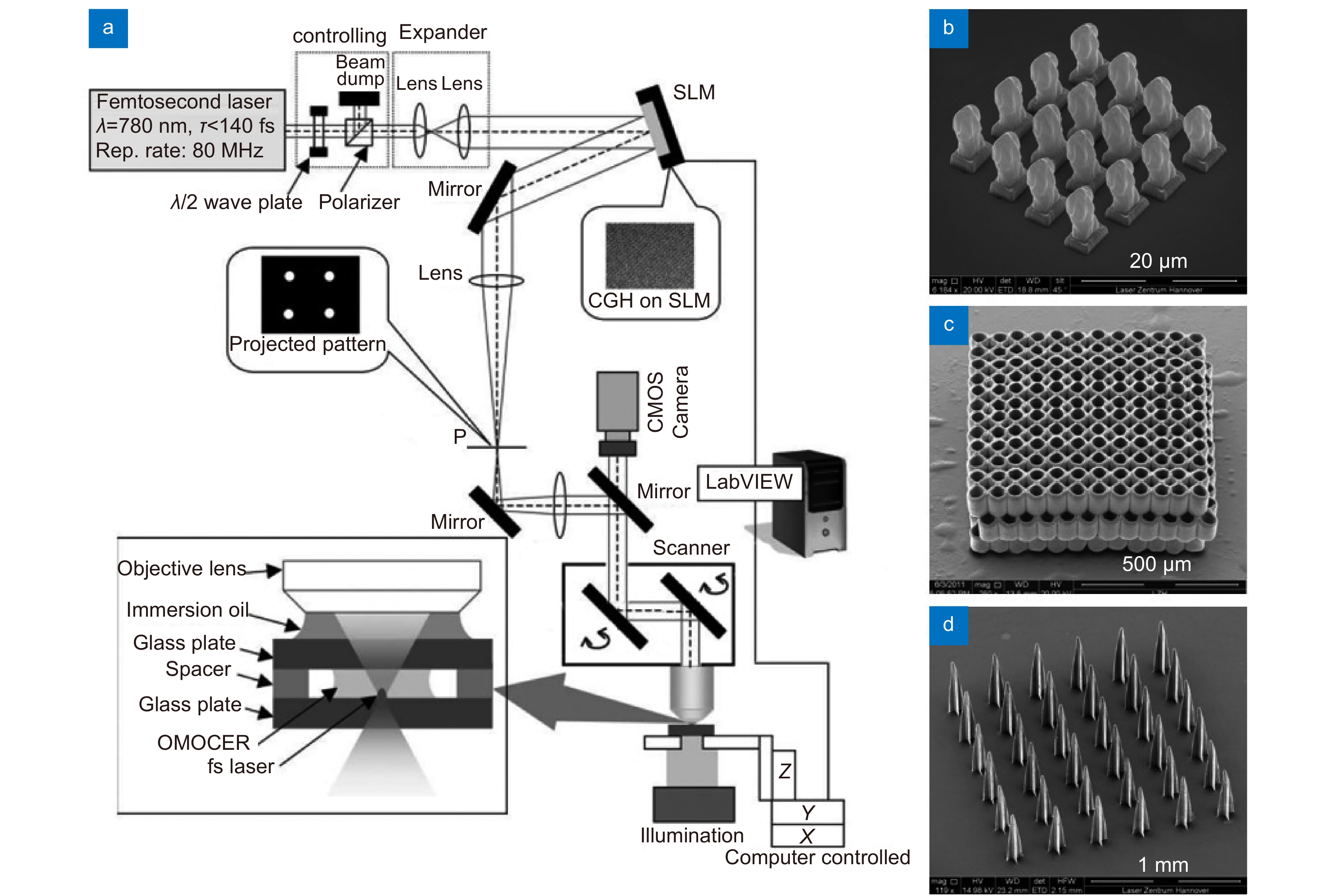

图 10 (a) 基于SLM产生多焦点阵列进行飞秒双光子刻写的装置结构;(b) 产生4×4焦点同时进行刻写生成的“维纳斯雕塑”;(c) 4焦点并行刻写而成的细胞培养组织支架;(d) 4焦点同时刻写产生的36个微针[74]

Figure 10. (a) The SLM-based multi-foci femtosecond two-photon lithography system; (b) The Venus sculptures fabricated by 4×4 foci; (c) The scaffold for cell cultivation fabricated by 4 foci; (d) 36 microneedles processed by 4 foci[74]

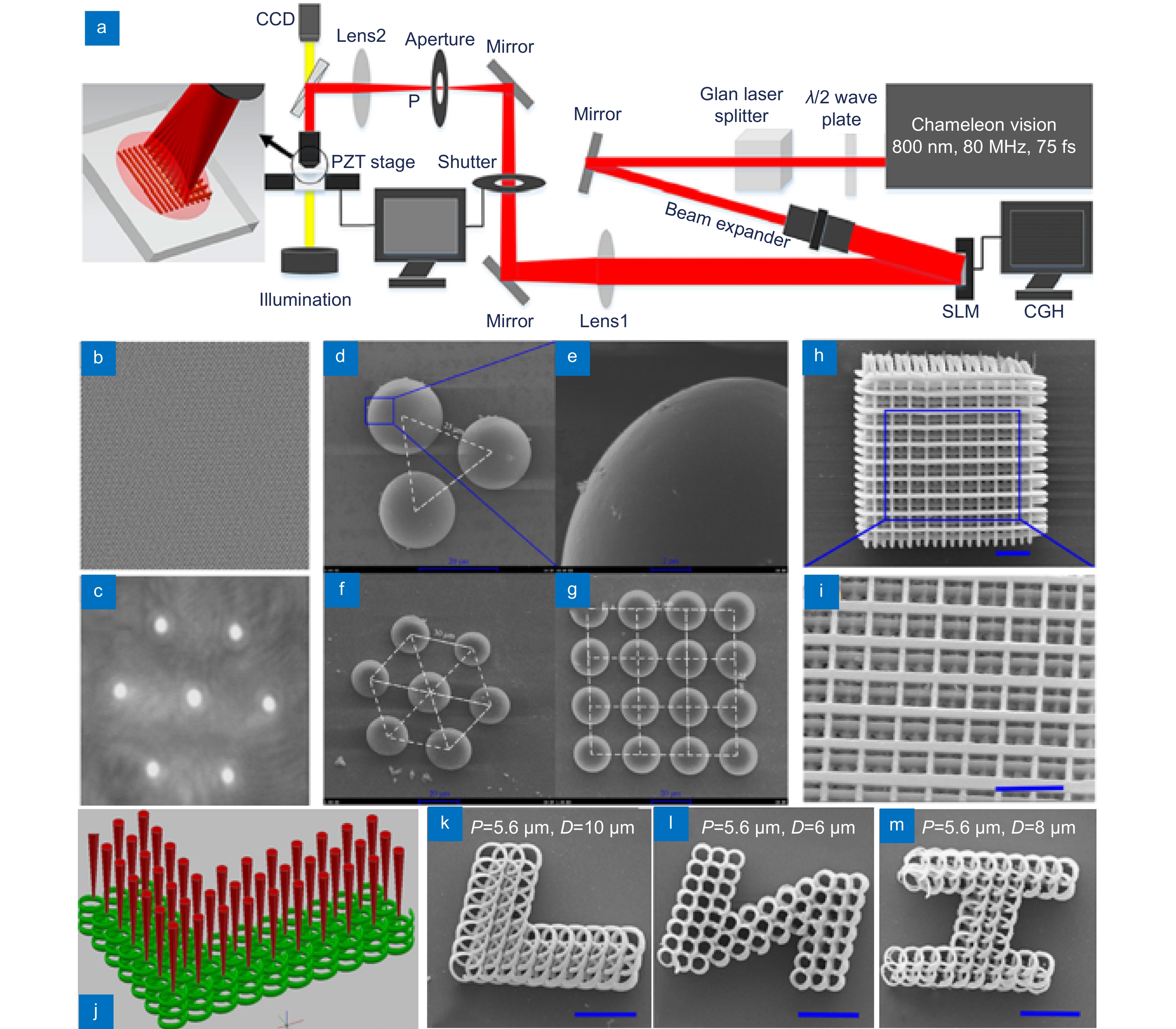

图 11 (a) 通过SLM将飞秒激光调制成多光束进行并行刻写的装置示意图;(b)~(c) SLM加载全息图及生成的7焦点阵列;(d)~(g) 通过SLM产生3焦点、7焦点及4×4焦点分别制备的微透镜阵列;(h)~(i) 利用10焦点并行加工木柴堆结构及其放大图;(j) 多焦点并行螺旋型扫描方式加工示意图;(k)~(m) 通过(j)方法加工三维螺旋型光子晶体“L”、“Z”、“H”,其中激光焦点间距P=5.6 μm,螺旋扫描直径分别为10 μm、6 μm和8 μm[75]

Figure 11. (a) The SLM-based multi-foci femtosecond laser parallel writing system; (b)~(c) The hologram loaded in SLM and the generated 7 foci pattern, respectively; (d)~(g) Microlens arrays fabricated by SLM with 3 foci, 7 foci, and 4×4 foci respectively; (h)~(i) The overall image and enlarged view of the 3D woodpile photonic structure fabricated by 10 foci; (j) Illustration of the multi-foci parallel fabrication process with the spiral scanning strategy; (k)~(m) 3D spiral photonic structures of ‘L’, ‘Z’, and ‘H’ fabricated by the multi-beam scanning way of (j). The foci pitch is 5.6 μm and the diameters of scanning spiral are 10 μm, 6 μm, and 8 μm, respectively[75]

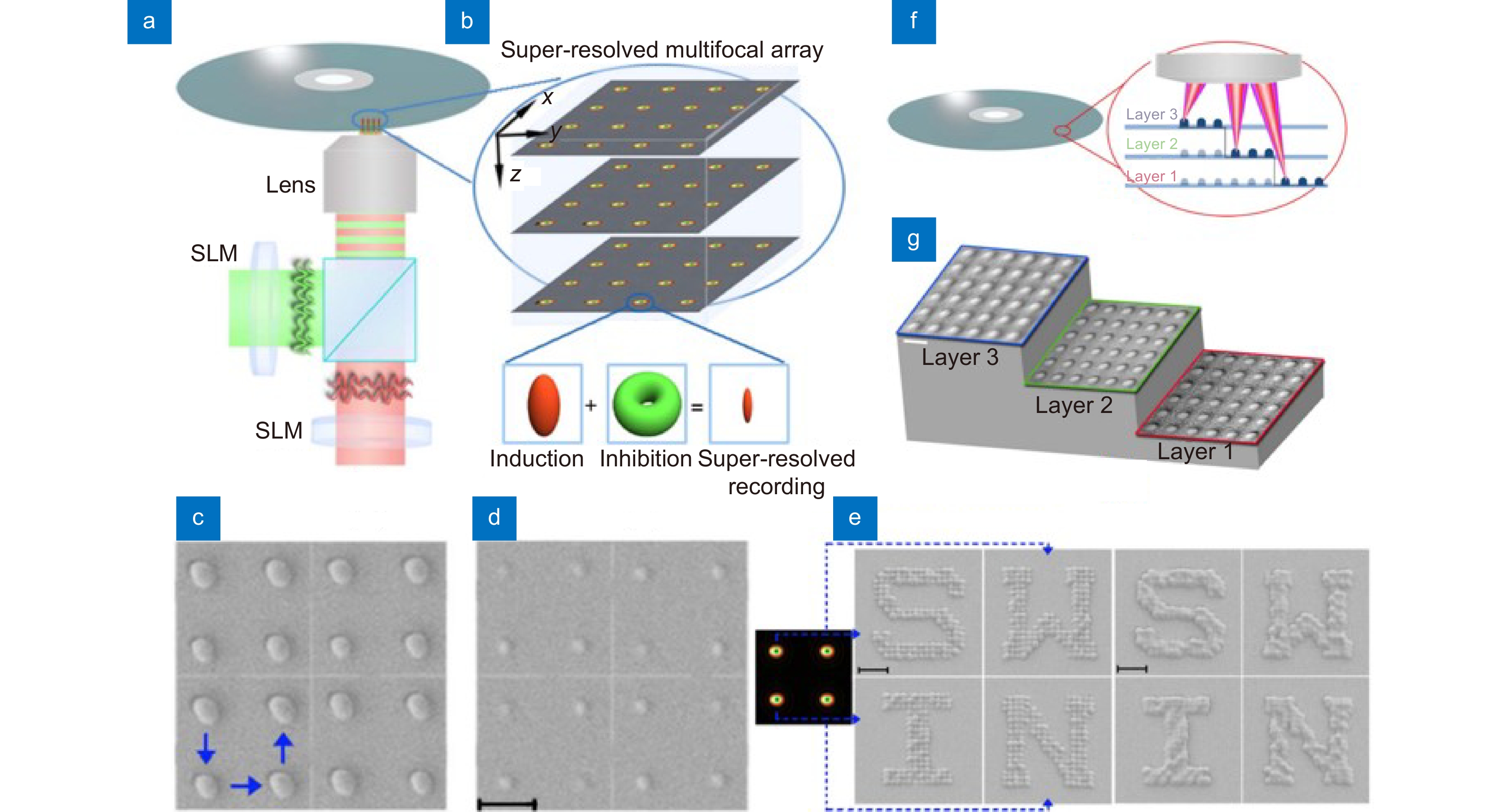

图 12 (a) 基于两同步SLM的相位调制方案;(b) 通过复制2×2并行PPI焦斑形成三维PPI焦点阵列示意图;(c) 无抑制光飞秒激光焦点刻写的点阵结构,蓝色箭头指示刻写路径;(d) 叠加抑制光后PPI焦斑刻写的点阵结构,抑制光功率为210 mW。比例尺为500 nm; (e) 通过PPI焦点阵列(左)和激发光点阵(右)刻写的字母结构,各字母分别由2×2焦点阵列中的一个焦点完成刻写,比例尺为1 μm;(f) PPI焦斑分布在不同刻写层的三维并行刻写方案,层间距为1.5 μm;(g) 通过PPI阵列三维刻写的三层点阵结构,点间距为200 nm,单点尺寸为80 nm[76]

Figure 12. (a) Phase modulation scheme based on two synchronized SLMs; (b) Illustration of the 3D PPI array through duplicating the 2×2 parallel PPI foci; (c) The dot array fabricated with femtosecond foci. The blue arrows indicate the scanning route; (d) The dot array fabricated by PPI foci with inhibition power of 210 mW. Scale bar: 500 nm; (e) SEM of the fabricated letters by 2 × 2 PPI foci (left) and the femtosecond multifocal array (right). Each letter is processed respectively by one focus of the 2×2 multifocal array. Scale bars: 1 μm; (f) The scheme for parallelized PPI 3D writing on different layers with interval of 1.5 μm; (g) 3D dots with interval of 200 nm and size of 80 nm on three different layers which are fabricated by the PPI multifocal array [76]

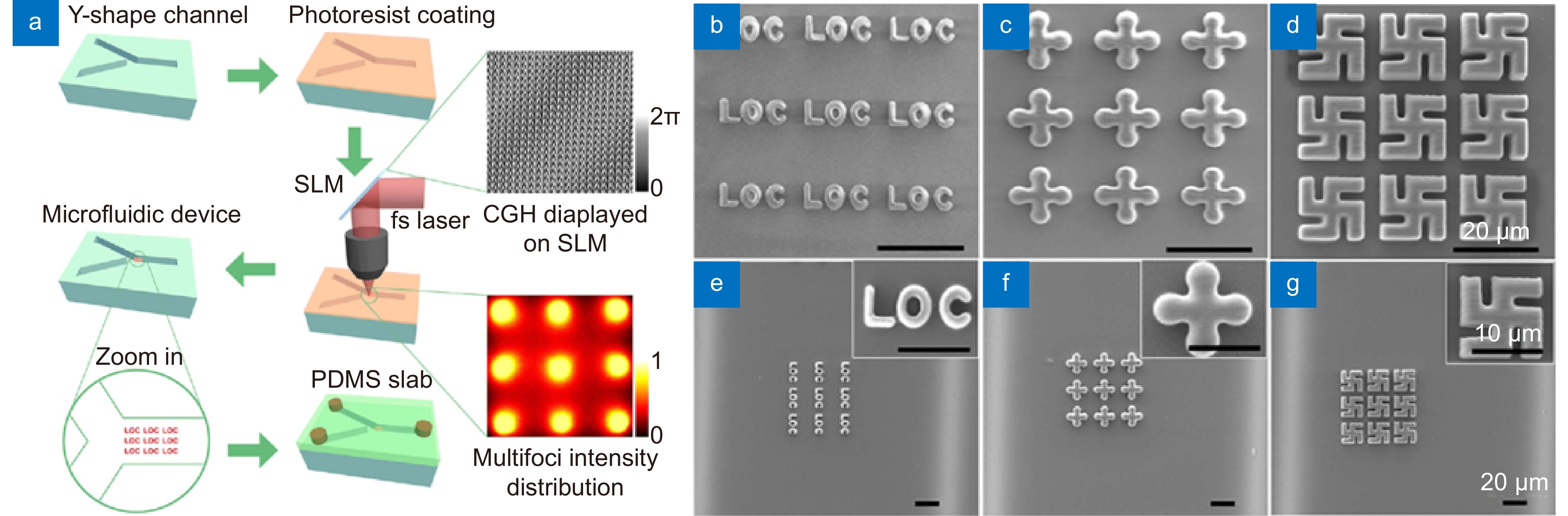

图 13 (a) “Y”形微通道内飞秒激光多焦点并行加工集成微结构示意图;(b)~(g) 在表面(b)~(d)及通道内(e)~(g)刻写“LOC”、“十字”、“万字符”结构[77]

Figure 13. (a) Illustration of fabricating integrated miniaturized structure inside a ‘Y’ shape microchannel by parallel femtosecond multiple foci; (b)~(g) the structures with patterns of ‘LOC’ characters, ‘Cross’ and ‘Svastika’ fabricated on the substrate surface (b)~(d) and in the channel (e)~(g) respectively [77]

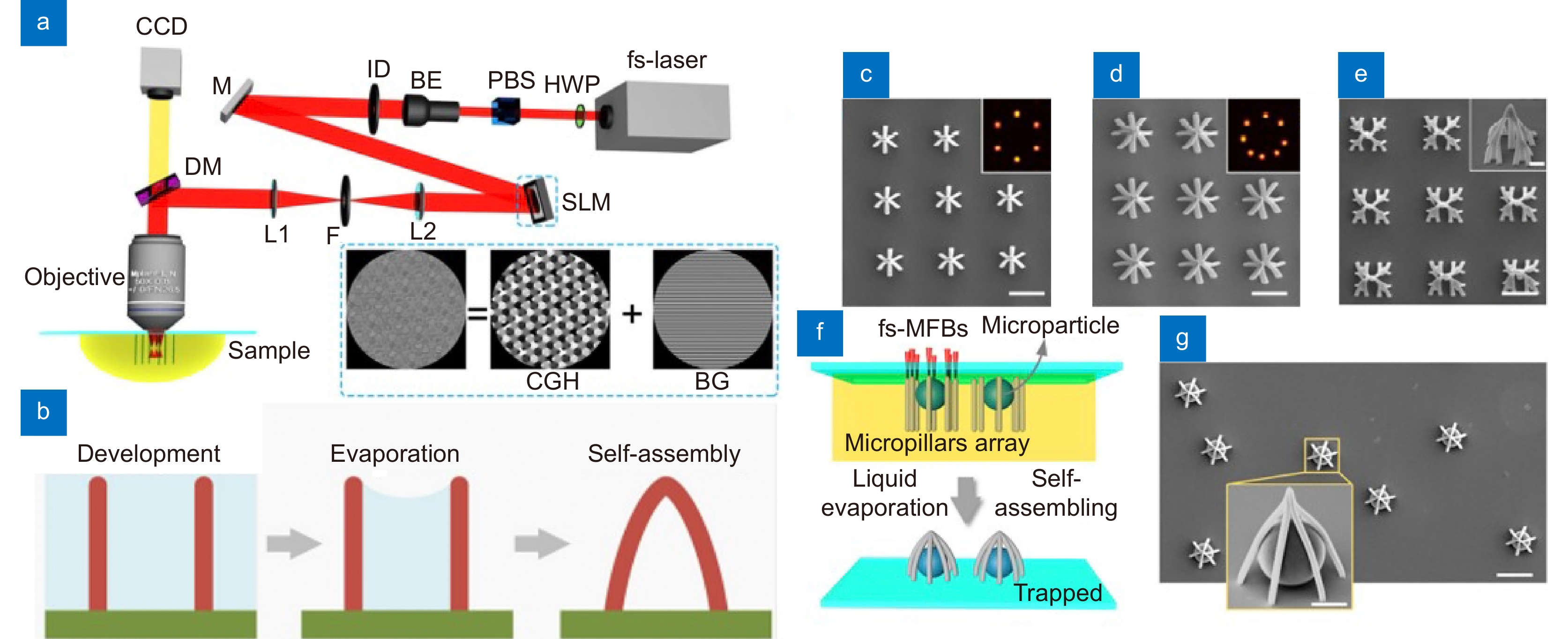

图 14 (a) 基于SLM产生多焦点进行微米柱加工的实验光路图,子图为CGH设计图;(b) 微米柱在蒸发所引起的毛细作用力下所形成自组装结构的原理示意图;(c)~(e) 利用不同焦点数量和空间分布的激光焦点阵列加工不同的微米柱集成结构,每个集成微结构分别包含6、8、12个微米柱,比例尺:2 μm;(f)~(g) 通过6焦点加工的微米柱自组装结构用于原位捕捉微球[78]

Figure 14. (a) The configuration of SLM-based multi-foci parallel writing system for micropillar fabrication. The inset illustrates the design of CGH; (b) The schematic diagram of self-assembly structure formation by capillary force on micropillars; (c)~(e) Diverse micro-assemblies with 6, 8, and 12 micropillars respectively fabricated by foci array with different beam quantity and distribution.Scale bar: 2 μm; (f)~(g) In-situ trapping of microparticles by the micro-assemblies fabricated with six-foci beams[78]

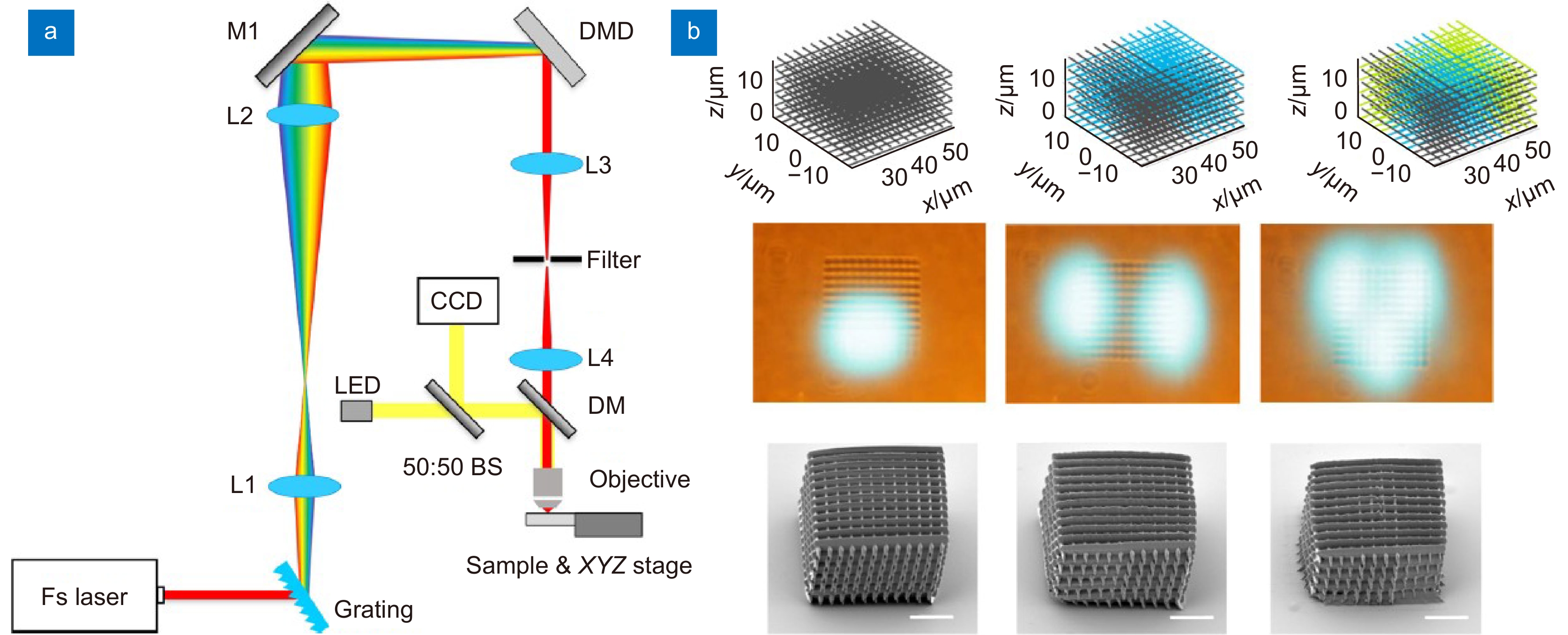

图 15 (a) 基于DMD的飞秒激光多焦点并行直写系统;(b) 单焦点、双焦点、三焦点的激光扫描路径、刻写过程图及加工木柴堆结构,比例尺:10 μm[79]

Figure 15. (a) Optical configuration of DMD-based multi-foci femtosecond laser parallel writing system; (b) Designed laser scanning trajectories, laser writing process, and SEMs of the fabricated woodpile structures with single-focus, two-foci, and three-foci writing respectively. Scale bar: 10 μm[79]

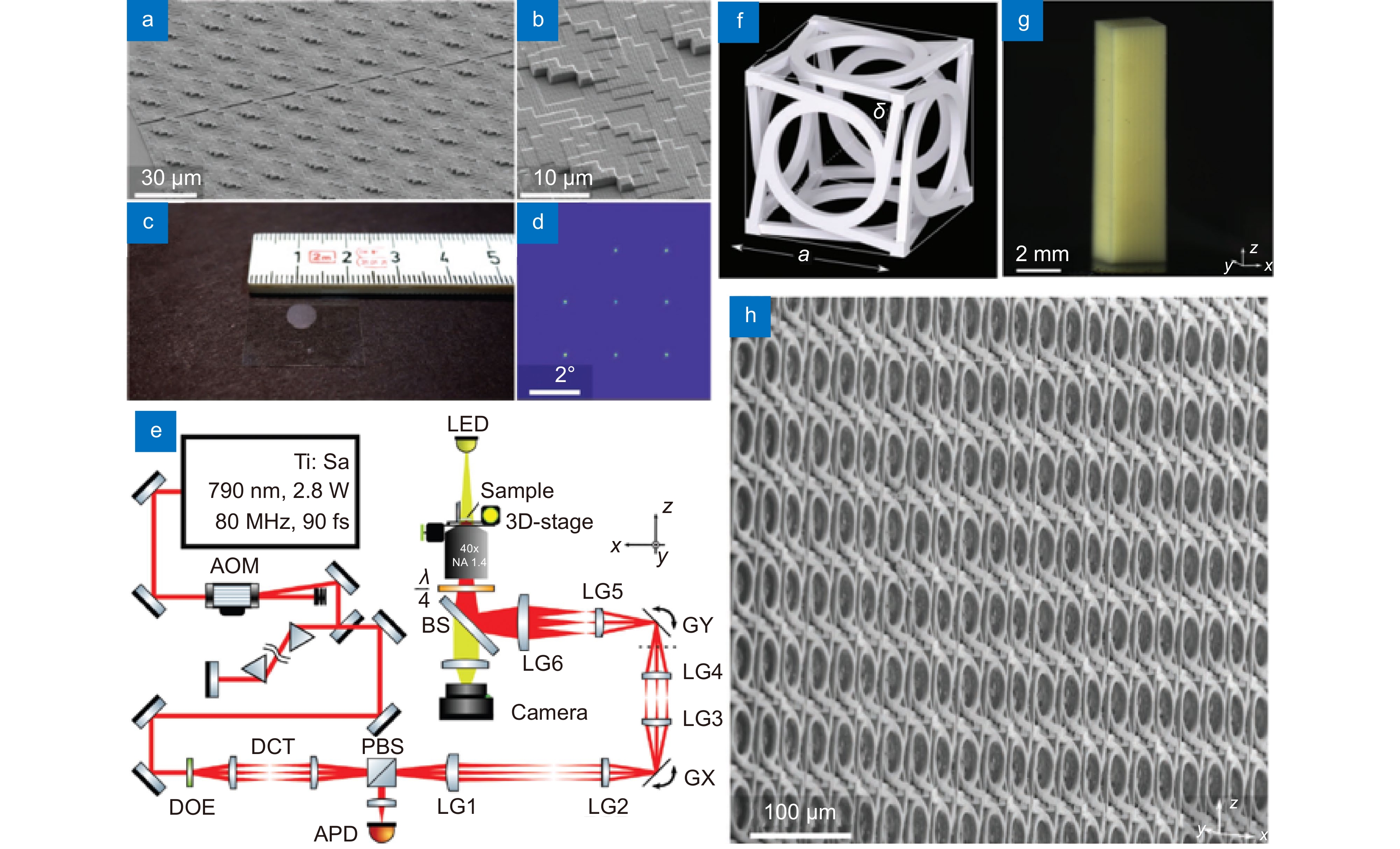

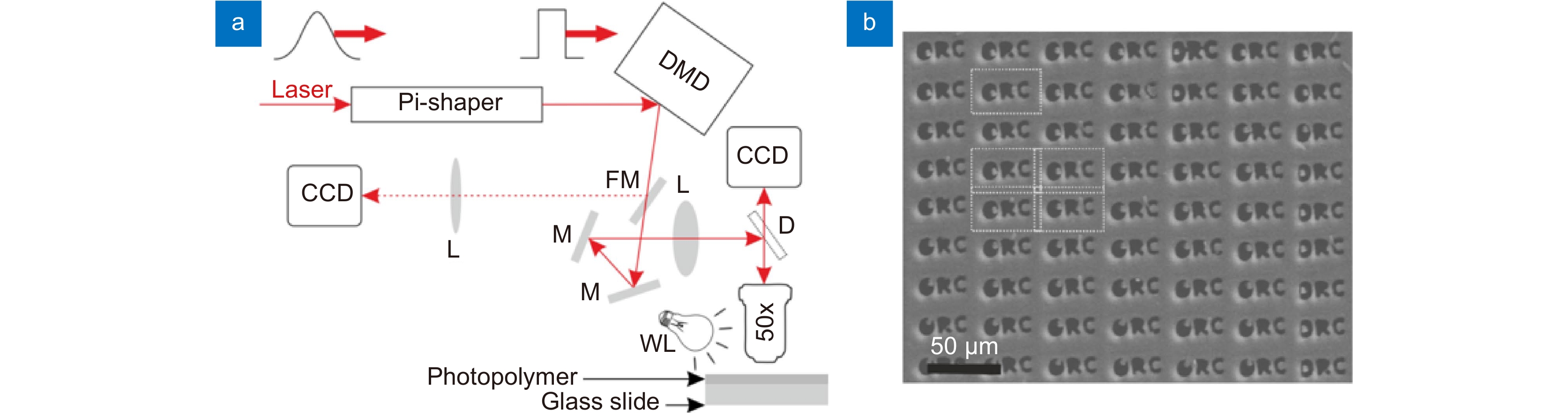

图 17 (a) 基于飞秒时空同步聚焦特性的DMD数字掩模投影面曝光方案;(b) 一美分硬币上2.2 mm×2.2 mm×0.25 mm立方体结构,刻写耗时8 min 20 s;(c) 二维刻写层堆叠而成的三维微柱结构;(d) 单层螺旋结构,耗时几毫秒;(e) 三维悬伸结构[30]

Figure 17. (a) Schematic diagram of DMD-based projection system using the spatial and temporal focusing of femtosecond laser; (b) 2.2 mm×2.2 mm×0.25 mm cube supported on a U.S. penny fabricated in 8 min 20 s; (c) Fabricated 3D micropillar stacked with2D layers; (d) Spiral structures through once projection within several millisecond; (e) Overhanging 3D structures[30]

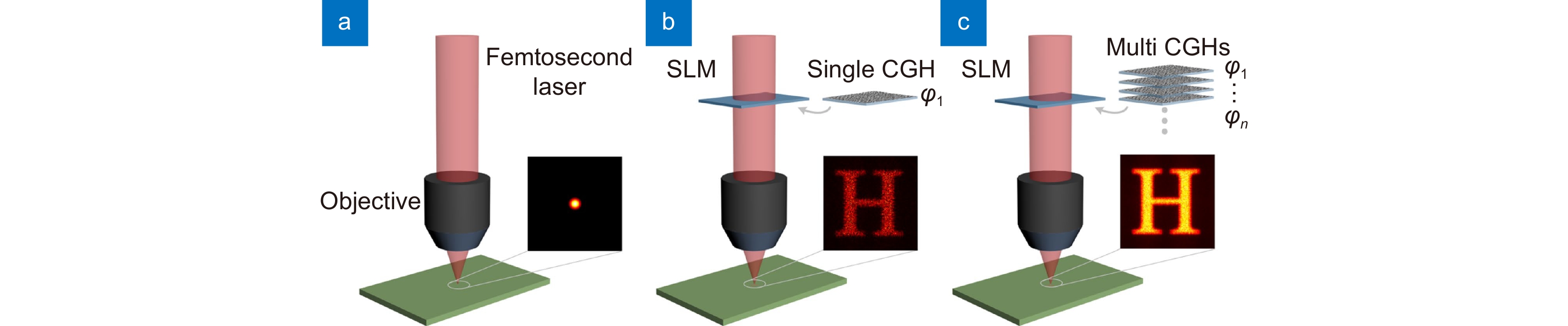

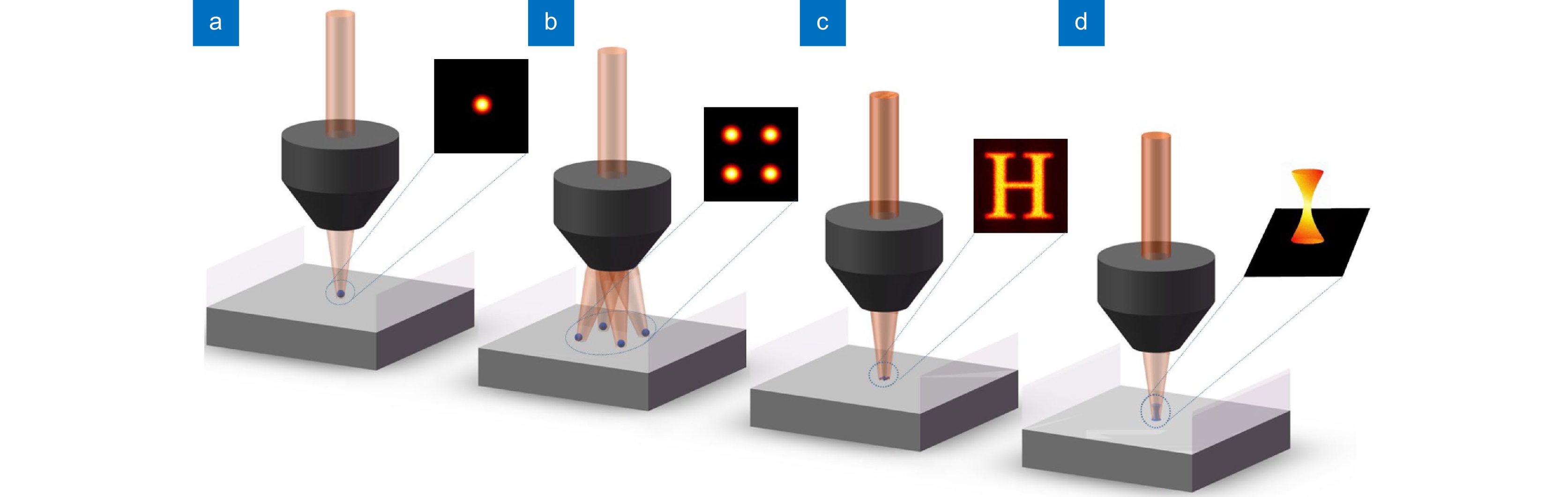

图 18 (a)飞秒激光直写原理图,光强在焦平面上呈圆形分布;(b) 单曝光全息飞秒激光打印。离焦面处的光强分布是由计算全息设计的“H”图案结构。然而,这种方法信噪比低,导致微/纳米结构制造的表面质量低;(c) 多次曝光全息飞秒激光打印,在离焦面处的光强分布是由多个不同相位全息图所组成的“H”图案结构。由于对策略的改进,强度分布具有更高的信噪比,从而实现高质量的微/纳米结构[81-82]

Figure 18. (a) Schematic diagram of femtosecond laser direct writing. The optical intensity distribution at the focal plane is a round point; (b) Schematic diagram of single-exposure holographic femtosecond laser direct patterning. The optical intensity distribution at the defocused plane is a complex pattern ‘H’ designed by computer generated hologram (CGH). However, the distribution shows low signal-to-noise and leads to low surface quality in fabricating micro/nanostructures; (c) Multiexposure holographic femtosecond laser direct patterning. The optical intensity distribution at the defocused plane is a complex pattern ‘H’ designed by multi-CGH with different phases. Due to the improved strategy, the distribution shows high signal-to-noise and thus high quality micro/nanostructures will be realized[81-82]

-

[1] Fang L M, Qiao Z, Zhang J, et al. Study on micromachining of femtosecond laser biomedical polymer materials[J]. Key Eng Mater, 2020, 852: 109−118. doi: 10.4028/www.scientific.net/KEM.852.109

[2] Huang R T, Knox W H. Quantitative photochemical scaling model for femtosecond laser micromachining of ophthalmic hydrogel polymers: effect of repetition rate and laser power in the four photon absorption limit[J]. Opt Mater Express, 2019, 9(3): 1049−1061. doi: 10.1364/OME.9.001049

[3] Balbus G H, Echlin M P, Grigorian C M, et al. Femtosecond laser rejuvenation of nanocrystalline metals[J]. Acta Mater, 2018, 156: 183−195. doi: 10.1016/j.actamat.2018.06.027

[4] Kudryashov S I, Levchenko A O, Danilov P A, et al. Direct femtosecond-laser writing of optical-range nanoscale metagratings/metacouplers on diamond surfaces[J]. Appl Phys Lett, 2019, 115(7): 073102. doi: 10.1063/1.5114630

[5] Li W J, Zheng J Q, Zhang Y P, et al. Temperature and depth evaluation of the in vitro effects of femtosecond laser on oral soft tissue, with or without air-cooling[J]. Lasers Med Sci, 2019, 34(4): 649−658. doi: 10.1007/s10103-018-2634-2

[6] Wang L, Chen Q D, Cao X W, et al. Plasmonic nano-printing: large-area nanoscale energy deposition for efficient surface texturing[J]. Light Sci Appl, 2017, 6(12): e17112. doi: 10.1038/lsa.2017.112

[7] Sugioka K, Cheng Y. Femtosecond laser three-dimensional micro-and nanofabrication[J]. J Appl Phys, 2014, 1(4): 041303. doi: 10.1063/1.4904320

[8] Baldacchini T. Three-Dimensional Microfabrication Using Two-Photon Polymerization[M]. 2nd ed. Norwich: William Andrew, 2020.

[9] Ahmmed K M T, Grambow C, Kietzig A M. Fabrication of micro/nano structures on metals by femtosecond laser micromachining[J]. Micromachines, 2014, 5(4): 1219−1253. doi: 10.3390/mi5041219

[10] Maruo S, Nakamura O, Kawata K. Three-dimensional microfabrication with two-photon-absorbed photopolymerization[J]. Opt Lett, 1997, 22(2): 132−134. doi: 10.1364/ol.22.000132

[11] Blaicher M, Billah M R, Kemal J, et al. Hybrid multi-chip assembly of optical communication engines by in situ 3D nano-lithography[J]. Light Sci Appl, 2020, 9(1): 71. doi: 10.1038/s41377-020-0272-5

[12] Rhee H W, Shim J, Kim J Y, et al. Direct optical wire bonding through open-to-air polymerization for silicon photonic chips[J]. Opt Lett, 2022, 47(3): 714−717. doi: 10.1364/OL.445526

[13] Khorasaninejad M, Chen W T, Devlin R C, et al. Metalenses at visible wavelengths: diffraction-limited focusing and subwavelength resolution imaging[J]. Science, 2016, 352(6290): 1190−1194. doi: 10.1126/science.aaf6644

[14] Agrawal L, Saidani M, Guillaud L, et al. Development of 3D culture scaffolds for directional neuronal growth using 2-photon lithography[J]. Mater Sci Eng C, 2021, 131: 112502. doi: 10.1016/j.msec.2021.112502

[15] Jayne R K, Karakan M Ç, Zhang K H, et al. Direct laser writing for cardiac tissue engineering: a microfluidic heart on a chip with integrated transducers[J]. Lab Chip, 2021, 21(9): 1724−1737. doi: 10.1039/D0LC01078B

[16] Sanli U T, Messer T, Weigand M, et al. High-resolution kinoform X-ray optics printed via 405 nm 3D laser lithography[J]. Adv Mater Technol, 2022,doi: 10.1002/admt.202101695.

[17] Fischer J, von Freymann G, Wegener M. The materials challenge in diffraction-unlimited direct-laser-writing optical lithography[J]. Adv Mater, 2010, 22(32): 3578−3582. doi: 10.1002/adma.201000892

[18] Fischer J, Wegener M. Three-dimensional direct laser writing inspired by stimulated-emission-depletion microscopy [Invited][J]. Opt Mater Express, 2011, 1(4): 614−624. doi: 10.1364/OME.1.000614

[19] Müller P, Müller R, Hammer L, et al. STED-inspired laser lithography based on photoswitchable spirothiopyran moieties[J]. Chem Mater, 2019, 31(6): 1966−1972. doi: 10.1021/acs.chemmater.8b04696

[20] Sankaranarayanan J, Muthukrishnan S, Gudmundsdottir A D. Photoremovable protecting groups based on photoenolization[J]. Adv Phys Org Chem, 2009, 43: 39−77. doi: 10.1016/S0065-3160(08)00002-6

[21] Cao C, Liu J T, Xia X M, et al. Click chemistry assisted organic-inorganic hybrid photoresist for ultra-fast two-photon lithography[J]. Addit Manuf, 2022, 51: 102658. doi: 10.1016/j.addma.2022.102658

[22] 曹春, 邱毅伟, 刘建亭, 等. 聚乙烯吡咯烷酮杂化双色光敏激光直写光刻胶研究[J]. 高分子学报, 2022, 53(6): 608−616. doi: 10.11777/j.issn1000-3304.2021.21323

Cao C, Qiu Y W, Liu J T, et al. Polyvinylpyrrolidone hybrid photoresist for two-color sensitive direct laser writing[J]. Acta Polym Sin, 2022, 53(6): 608−616. doi: 10.11777/j.issn1000-3304.2021.21323

[23] Mueller P, Zieger M M, Richter B, et al. Molecular switch for sub-diffraction laser lithography by photoenol intermediate-state Cis-trans isomerization[J]. ACS Nano, 2017, 11(6): 6396−6403. doi: 10.1021/acsnano.7b02820

[24] Netto-Ferreira J C, Scaiano J C. A laser flash photolysis study of the mechanism of the photocyclization of ɑ-chloro-o-methylacetophenones[J]. J Am Chem Soc, 1991, 113(15): 5800−5803. doi: 10.1021/ja00015a038

[25] Gruendling T, Oehlenschlaeger K K, Frick E, et al. Rapid UV light-triggered macromolecular click conjugations via the use of o-quinodimethanes[J]. Macromol Rapid Commun, 2011, 32(11): 807−812. doi: 10.1002/marc.201100159

[26] Kathan M, Hecht S. Photoswitchable molecules as key ingredients to drive systems away from the global thermodynamic minimum[J]. Chem Soc Rev, 2017, 46(18): 5536−5550. doi: 10.1039/C7CS00112F

[27] Bertrand O, Gohy J F. Photo-responsive polymers: synthesis and applications[J]. Polym Chem, 2017, 8(1): 52−73. doi: 10.1039/C6PY01082B

[28] Ding C L, Zhu D Z, Wei Z, et al. A compact and high-precision method for active beam stabilization system[J]. Opt Commun, 2021, 500: 127328. doi: 10.1016/j.optcom.2021.127328

[29] Hell S W, Wichmann J. Breaking the diffraction resolution limit by stimulated emission: stimulated-emission-depletion fluorescence microscopy[J]. Opt Lett, 1994, 19(11): 780−782. doi: 10.1364/OL.19.000780

[30] Saha S K, Wang D E, Nguyen V H, et al. Scalable submicrometer additive manufacturing[J]. Science, 2019, 366(6461): 105−109. doi: 10.1126/science.aax8760

[31] Pawlicki M, Collins H A, Denning R G, et al. Two-photon absorption and the design of two-photon dyes[J]. Angew Chem Int Ed, 2009, 48(18): 3244−3266. doi: 10.1002/anie.200805257

[32] Gu J, Yulan W, Chen W Q, et al. Carbazole-based 1D and 2D hemicyanines: synthesis, two-photon absorption properties and application for two-photon photopolymerization 3D lithography[J]. New J Chem, 2007, 31(1): 63−68. doi: 10.1039/B609309D

[33] Xing J F, Chen W Q, Gu J, et al. Design of high efficiency for two-photon polymerization initiator: combination of radical stabilization and large two-photon cross-section achieved by N-benzyl 3, 6-bis (phenylethynyl) carbazole derivatives[J]. J Mater Chem, 2007, 17(14): 1433−1438. doi: 10.1039/b616792f

[34] Cao X B, Jin F, Li Y F, et al. Triphenylamine-modified quinoxaline derivatives as two-photon photoinitiators[J]. New J Chem, 2009, 33(7): 1578−1582. doi: 10.1039/b900464e

[35] Holzer B, Lunzer M, Rosspeintner A, et al. Towards efficient initiators for two-photon induced polymerization: fine tuning of the donor/acceptor properties[J]. Mol Syst Des Eng, 2019, 4(2): 437−448. doi: 10.1039/c8me00101d

[36] Chi T, Somers P, Wilcox D A, et al. Tailored thioxanthone-based photoinitiators for two-photon-controllable polymerization and nanolithographic printing[J]. J Polym Sci Part B Polym Phys, 2019, 57(21): 1462−1475. doi: 10.1002/polb.24891

[37] Hu P, Qiu W W, Naumov S, et al. Conjugated bifunctional carbazole-based oxime esters: efficient and versatile photoinitiators for 3D printing under one-and two-photon excitation[J]. Chem Photo Chem, 2020, 4(3): 224−232. doi: 10.1002/cptc.201900246

[38] Li Z Q, Pucher N, Cicha K, et al. A straightforward synthesis and structure-activity relationship of highly efficient initiators for two-photon polymerization[J]. Macromolecules, 2013, 46(2): 352−361. doi: 10.1021/ma301770a

[39] He M F, Zhang Z M, Cao C, et al. 3D sub-diffraction printing by multicolor photoinhibition lithography: from optics to chemistry[J]. Laser Photonics Rev, 2022, 16(2): 2100229. doi: 10.1002/LPOR.202100229

[40] Chen S, Zheng M L, Dong X Z, et al. Nondegenerate two-photon absorption in a zinc blende-type ZnS single crystal using the femtosecond pump-probe technique[J]. J Opt Soc Am B, 2013, 30(12): 3117−3122. doi: 10.1364/JOSAB.30.003117

[41] Chen S, Zheng Y C, Zheng M L, et al. Nondegenerate two-photon absorption properties of a newly synthesized carbazole derivative[J]. J Mater Chem C, 2017, 5(2): 470−475. doi: 10.1039/C6TC04676B

[42] Yoo H W, Ito S, Schitter G. High speed laser scanning microscopy by iterative learning control of a galvanometer scanner[J]. Control Eng Pract, 2016, 50: 12−21. doi: 10.1016/j.conengprac.2016.02.007

[43] 唐建波. 基于光束扫描的共焦显微三维测量技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2011.

Tang J B. Three dimensional confocal imaging based on beam scanning technology[D]. Harbin: Harbin Institute of Technology, 2011.

[44] De Loor R. Polygon scanner system for ultra short pulsed laser micro-machining applications[J]. Phys Procedia, 2013, 41: 544−551. doi: 10.1016/j.phpro.2013.03.114

[45] Schille J, Schneider L, Streek A, et al. High-throughput machining using a high-average power ultrashort pulse laser and high-speed polygon scanner[J]. Opt Eng, 2016, 55(9): 096109. doi: 10.1117/1.OE.55.9.096109

[46] Iyer V, Hoogland T M, Saggau P. Fast functional imaging of single neurons using random-access multiphoton (RAMP) microscopy[J]. J Neurophysiol, 2006, 95(1): 535−545. doi: 10.1152/jn.00865.2005

[47] Grewe B F, Langer D, Kasper H, et al. High-speed in vivo calcium imaging reveals neuronal network activity with near-millisecond precision[J]. Nat Methods, 2010, 7(5): 399−405. doi: 10.1038/nmeth.1453

[48] Lechleiter J D, Lin D T, Sieneart I. Multi-photon laser scanning microscopy using an acoustic optical deflector[J]. Biophys J, 2002, 83(4): 2292−2299. doi: 10.1016/S0006-3495(02)73989-1

[49] Roorda R D, Hohl T M, Toledo-Crow R, et al. Video-rate nonlinear microscopy of neuronal membrane dynamics with genetically encoded probes[J]. J Neurophysiol, 2004, 92(1): 609−621. doi: 10.1152/jn.00087.2004

[50] Iyer V, Losavio B E, Saggau P. Compensation of spatial and temporal dispersion for acousto-optic multiphoton laser-scanning microscopy[J]. J Biomed Opt, 2003, 8(3): 460−471. doi: 10.1117/1.1580827

[51] Salomé R, Kremer Y, Dieudonné S, et al. Ultrafast random-access scanning in two-photon microscopy using acousto-optic deflectors[J]. J Neurosci Methods, 2006, 154(1–2): 161−174. doi: 10.1016/j.jneumeth.2005.12.010

[52] Kirkpatrick S M, Baur J W, Clark C M, et al. Holographic recording using two-photon-induced photopolymerization[J]. Appl Phys A, 1999, 69(4): 461−464. doi: 10.1007/s003390051033

[53] Matsuo S, Kondo T, Juodkazis S, et al. Fabrication of three-dimensional photonic crystals by femtosecond laser interference[J]. Proc SPIE, 2002, 4655: 327−334. doi: 10.1117/12.463891

[54] Kondo T, Matsuo S, Juodkazis S, et al. Multiphoton fabrication of periodic structures by multibeam interference of femtosecond pulses[J]. Appl Phys Lett, 2003, 82(17): 2758−2760. doi: 10.1063/1.1569987

[55] Kondo T, Juodkazis S, Mizeikis V, et al. Fabrication of three-dimensional periodic microstructures in photoresist SU-8 by phase-controlled holographic lithography[J]. New J Phys, 2006, 8(10): 250. doi: 10.1088/1367-2630/8/10/250

[56] Stankevičius E, Malinauskas M, Gedvilas M, et al. Fabrication of periodic micro-structures by multi-photon polymerization using the femtosecond laser and four-beam interference[J]. Mater Sci, 2011, 17(3): 244−248. doi: 10.5755/j01.ms.17.3.587

[57] Girsault A, Meller A. Sub-second, super-resolved imaging of biological systems using parallel EO-STED[J]. Opt Lett, 2020, 45(10): 2712−2715. doi: 10.1364/OL.392822

[58] Bergermann F, Alber L, Sahl S J, et al. 2000-fold parallelized dual-color STED fluorescence nanoscopy[J]. Opt Express, 2015, 23(1): 211−223. doi: 10.1364/OE.23.000211

[59] Yang B, Fang C Y, Chang H C, et al. Polarization effects in lattice-STED microscopy[J]. Faraday Discuss, 2015, 184: 37−49. doi: 10.1039/c5fd00092k

[60] Li D, Shao L, Chen B C, et al. Extended-resolution structured illumination imaging of endocytic and cytoskeletal dynamics[J]. Science, 2015, 349(6251): 527. doi: 10.1126/science.aab3500

[61] Förster R, Lu-Walther H W, Jost A, et al. Simple structured illumination microscope setup with high acquisition speed by using a spatial light modulator[J]. Opt Express, 2014, 22(17): 20663−20677. doi: 10.1364/OE.22.020663

[62] Chmyrov A, Keller J, Grotjohann T, et al. Nanoscopy with more than 100, 000 'doughnuts'[J]. Nat Methods, 2013, 10(8): 737−740. doi: 10.1038/nmeth.2556

[63] Tang M, Chen Z C, Huang Z Q, et al. Maskless multiple-beam laser lithography for large-area nanostructure/microstructure fabrication[J]. Appl Opt, 2011, 50(35): 6536−6542. doi: 10.1364/AO.50.006536

[64] Matsuo S, Juodkazis S, Misawa H. Femtosecond laser microfabrication of periodic structures using a microlens array[J]. Appl Phys A, 2005, 80(4): 683−685. doi: 10.1007/s00339-004-3108-x

[65] Kato J I, Takeyasu N, Adachi Y, et al. Multiple-spot parallel processing for laser micronanofabrication[J]. Appl Phys Lett, 2005, 86(4): 044102. doi: 10.1063/1.1855404

[66] Formanek F, Takeyasu N, Tanaka T, et al. Three-dimensional fabrication of metallic nanostructures over large areas by two-photon polymerization[J]. Opt Express, 2006, 14(2): 800−809. doi: 10.1364/OPEX.14.000800

[67] Račiukaitis G, Stankevičius E, Gečys P, et al. Laser processing by using diffractive optical laser beam shaping technique[J]. JLMN-J Laser Micro/Nanoeng, 2011, 6(1): 37−43. doi: 10.2961/jlmn.2011.01.0009

[68] Hilton P A, Lloyd D, Tyrer J R. Use of a diffractive optic for high power laser cutting[J]. J Laser Appl, 2016, 28(1): 012014. doi: 10.2351/1.4938279

[69] Kuchmizhak A A, Porfirev A P, Syubaev S A, et al. Multi-beam pulsed-laser patterning of plasmonic films using broadband diffractive optical elements[J]. Opt Lett, 2017, 42(14): 2838−2841. doi: 10.1364/OL.42.002838

[70] Kwon H H, Yang S H, Cho Y J, et al. Comparison of a 1064-nm neodymium‐doped yttrium aluminum garnet picosecond laser using a diffractive optical element vs. a nonablative 1550-nm erbium-glass laser for the treatment of facial acne scarring in Asian patients: a 17-week prospective, randomized, split-face, controlled trial[J]. J Eur Acad Dermatol Venereol, 2020, 34(12): 2907−2913. doi: 10.1111/jdv.16643

[71] Vandenhouten R, Hermerschmidt A, Fiebelkorn R. Design and quality metrics of point patterns for coded structured light illumination with diffractive optical elements in optical 3D sensors[J]. Proc SPIE, 2017, 10335: 1033518. doi: 10.1117/12.2270248

[72] Dong X Z, Zhao Z S, Duan X M. Micronanofabrication of assembled three-dimensional microstructures by designable multiple beams multiphoton processing[J]. Appl Phys Lett, 2007, 91(12): 124103. doi: 10.1063/1.2789661

[73] Hahn V, Kiefer P, Frenzel T, et al. Rapid assembly of small materials building blocks (voxels) into large functional 3D metamaterials[J]. Adv Funct Mater, 2020, 30(26): 1907795. doi: 10.1002/adfm.201907795

[74] Gittard S D, Nguyen A, Obata K, et al. Fabrication of microscale medical devices by two-photon polymerization with multiple foci via a spatial light modulator[J]. Biomed Opt Express, 2011, 2(11): 3167−3178. doi: 10.1364/BOE.2.003167

[75] Yang L, El-Tamer A, Hinze U, et al. Parallel direct laser writing of micro-optical and photonic structures using spatial light modulator[J]. Opt Lasers Eng, 2015, 70: 26−32. doi: 10.1016/j.optlaseng.2015.02.006

[76] Li X P, Cao Y Y, Tian N, et al. Multifocal optical nanoscopy for big data recording at 30 TB capacity and gigabits/second data rate[J]. Optica, 2015, 2(6): 567−570. doi: 10.1364/OPTICA.2.000567

[77] Xu B, Du W Q, Li J W, et al. High efficiency integration of three-dimensional functional microdevices inside a microfluidic chip by using femtosecond laser multifoci parallel microfabrication[J]. Sci Rep, 2016, 6(1): 19989. doi: 10.1038/srep19989

[78] Hu Y L, Feng W F, Xue C, et al. Self-assembled micropillars fabricated by holographic femtosecond multi-foci beams for in situ trapping of microparticles[J]. Opt Lett, 2020, 45(17): 4698−4701. doi: 10.1364/OL.398682

[79] Geng Q, Wang D E, Chen P F, et al. Ultrafast multi-focus 3-D nano-fabrication based on two-photon polymerization[J]. Nat Commun, 2019, 10(1): 2179. doi: 10.1038/s41467-019-10249-2

[80] Mills B, Grant-Jacob J A, Feinaeugle M, et al. Single-pulse multiphoton polymerization of complex structures using a digital multimirror device[J]. Opt Express, 2013, 21(12): 14853−14858. doi: 10.1364/OE.21.014853

[81] Aagedal H, Schmid M, Beth T, et al. Theory of speckles in diffractive optics and its application to beam shaping[J]. J Mod Opt, 1996, 43(7): 1409−1421. doi: 10.1080/09500349608232814

[82] Zhang C C, Hu Y L, Li J W, et al. An improved multi-exposure approach for high quality holographic femtosecond laser patterning[J]. Appl Phys Lett, 2014, 105(22): 221104. doi: 10.1063/1.4902925

[83] Aharoni T, Shoham S. Phase-controlled, speckle-free holographic projection with applications in precision optogenetics[J]. Neurophotonics, 2018, 5(2): 025004. doi: 10.1117/1.NPh.5.2.025004

[84] Wang Z P, Li X W, Jiang L, et al. High-quality micropattern printing by interlacing-pattern holographic femtosecond pulses[J]. Nanophotonics, 2020, 9(9): 2895−2904. doi: 10.1515/nanoph-2020-0138

[85] Nomura T, Okamura M, Nitanai E, et al. Image quality improvement of digital holography by superposition of reconstructed images obtained by multiple wavelengths[J]. Appl Opt, 2008, 47(19): D38−D43. doi: 10.1364/AO.47.000D38

[86] Fan H, Cao X W, Wang L, et al. Control of diameter and numerical aperture of microlens by a single ultra-short laser pulse[J]. Opt Lett, 2019, 44(21): 5149−5152. doi: 10.1364/OL.44.005149

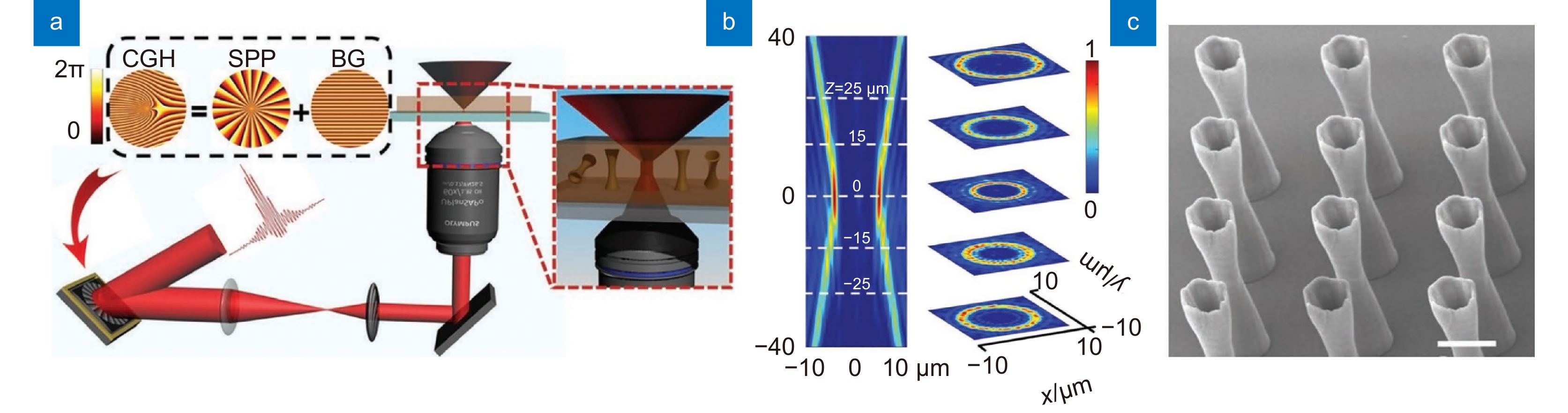

[87] Yang L, Hu Z J, Xin C, et al. One-step synthesis of three-dimensional microtubes with single exposure of structured femtosecond optical vortices[J]. Proc SPIE, 2018, 10522: 105221H. doi: 10.1117/12.2289043

[88] Xin C, Yang L, Li J W, et al. Conical hollow microhelices with superior swimming capabilities for targeted cargo delivery[J]. Adv Mater, 2019, 31(25): 1808226. doi: 10.1002/adma.201808226

[89] Yang L, Chen X X, Wang L, et al. Targeted single‐cell therapeutics with magnetic tubular micromotor by one‐step exposure of structured femtosecond optical vortices[J]. Adv Funct Mater, 2019, 29(45): 1905745. doi: 10.1002/adfm.201905745

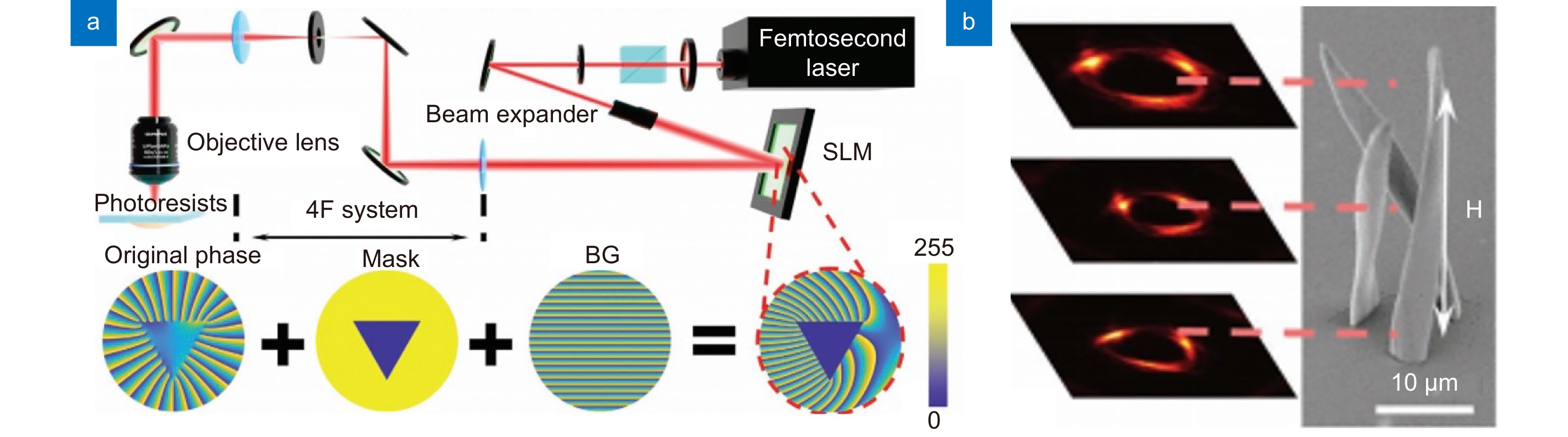

[90] Pan D, Liu S L, Li J W, et al. Rapid fabrication of 3D chiral microstructures by single exposure of interfered femtosecond vortex beams and capillary-force-assisted self-assembly[J]. Adv Funct Mater, 2022, 32(4): 2106917. doi: 10.1002/adfm.202106917

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: