-

摘要

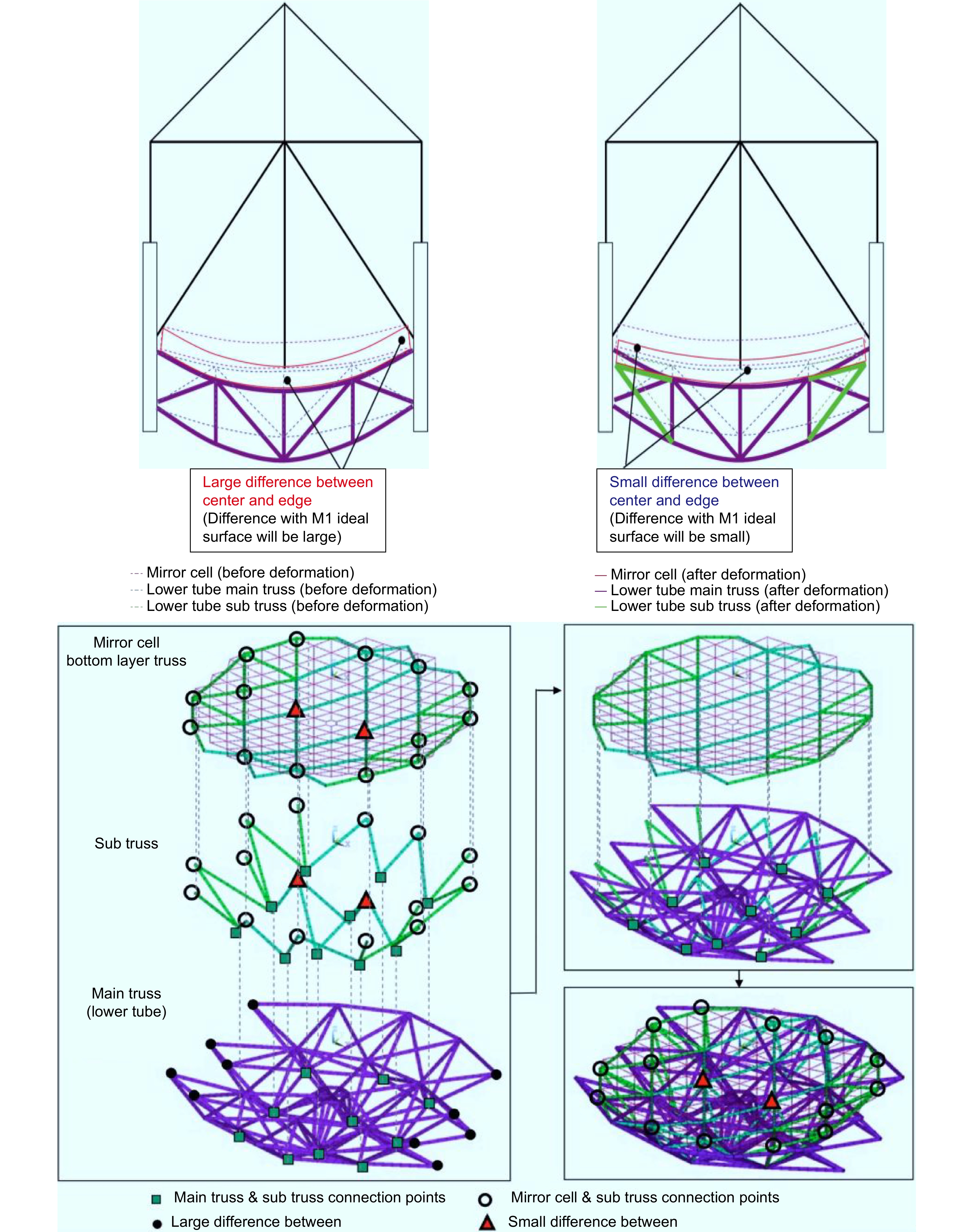

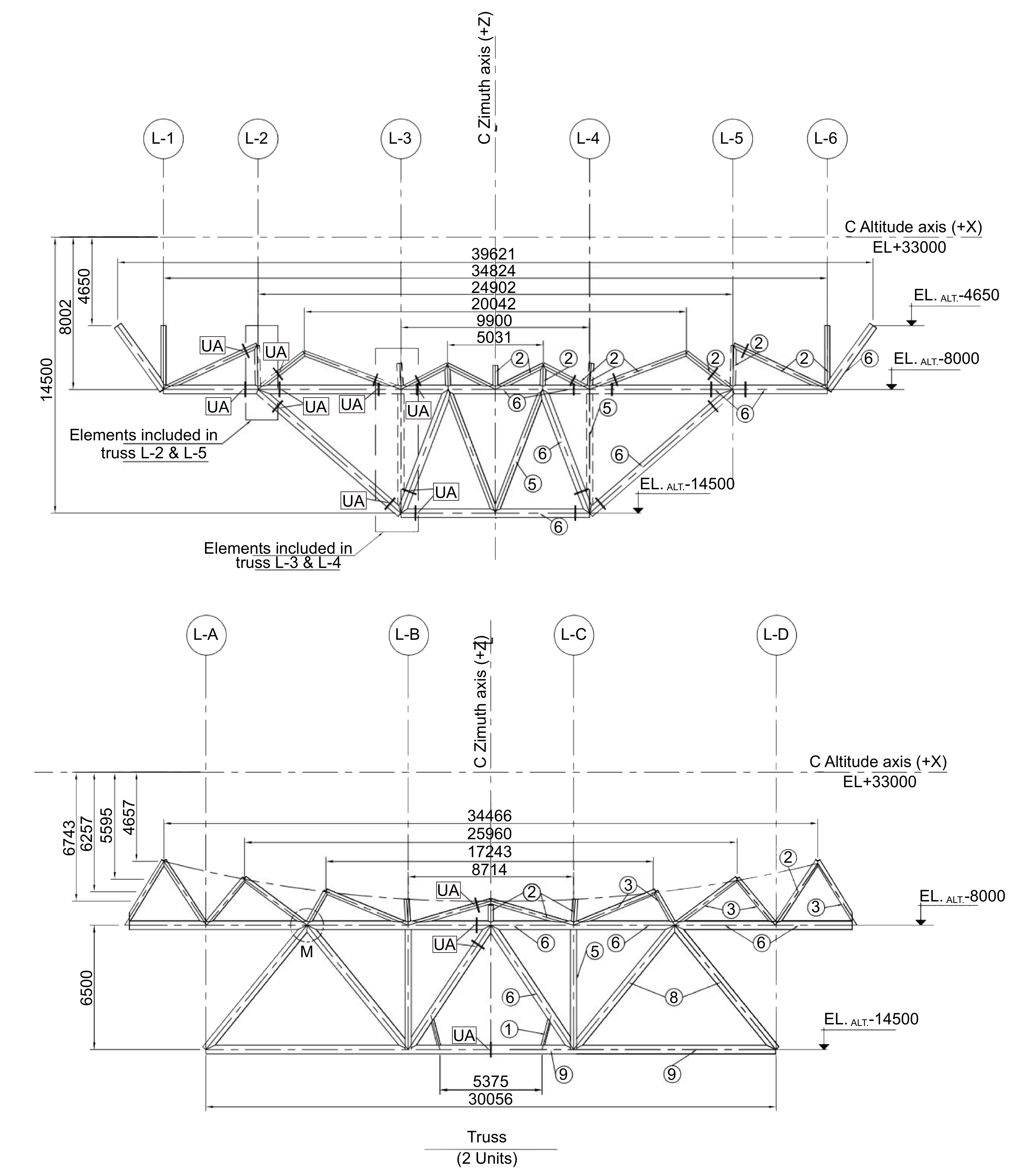

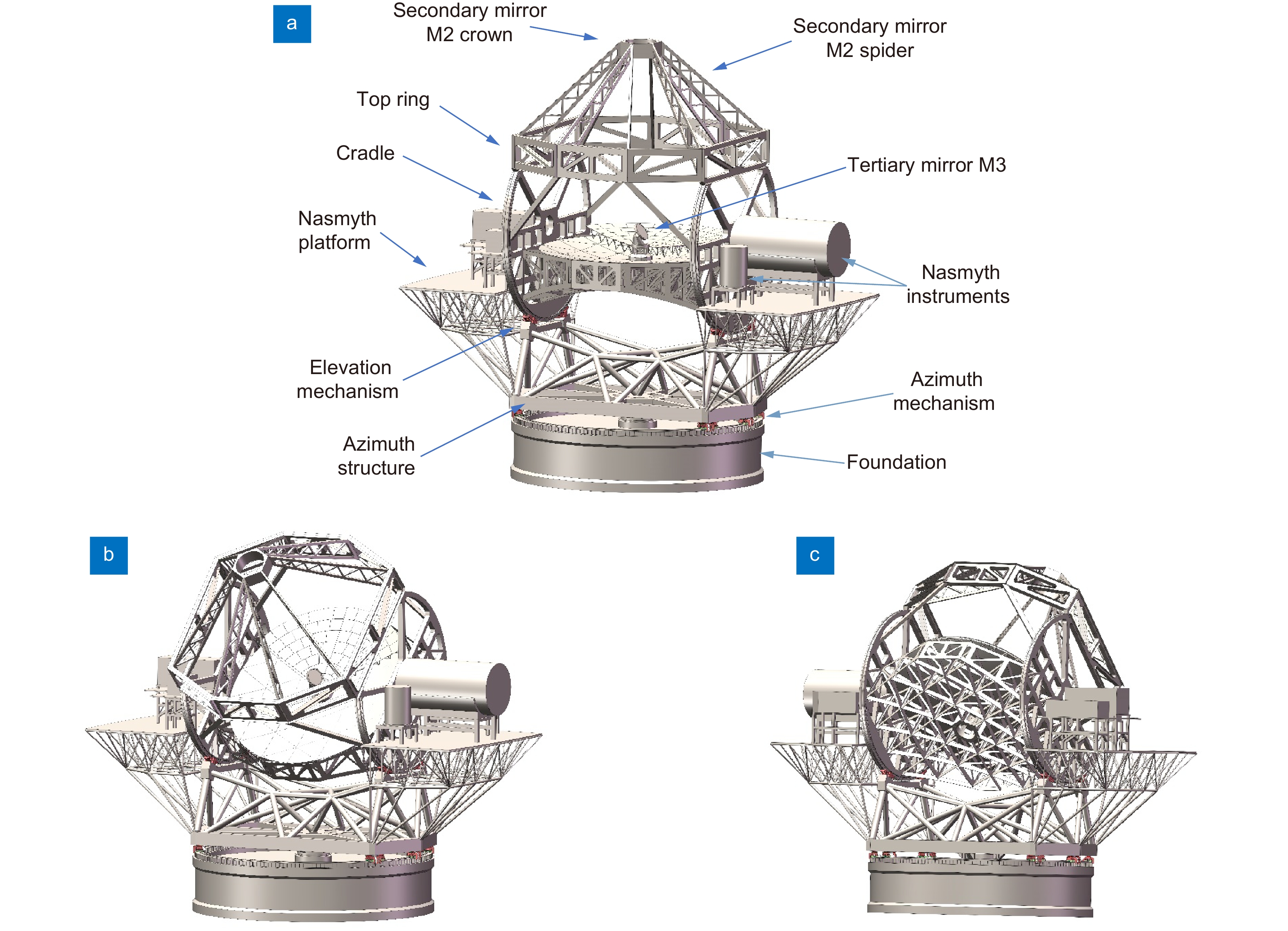

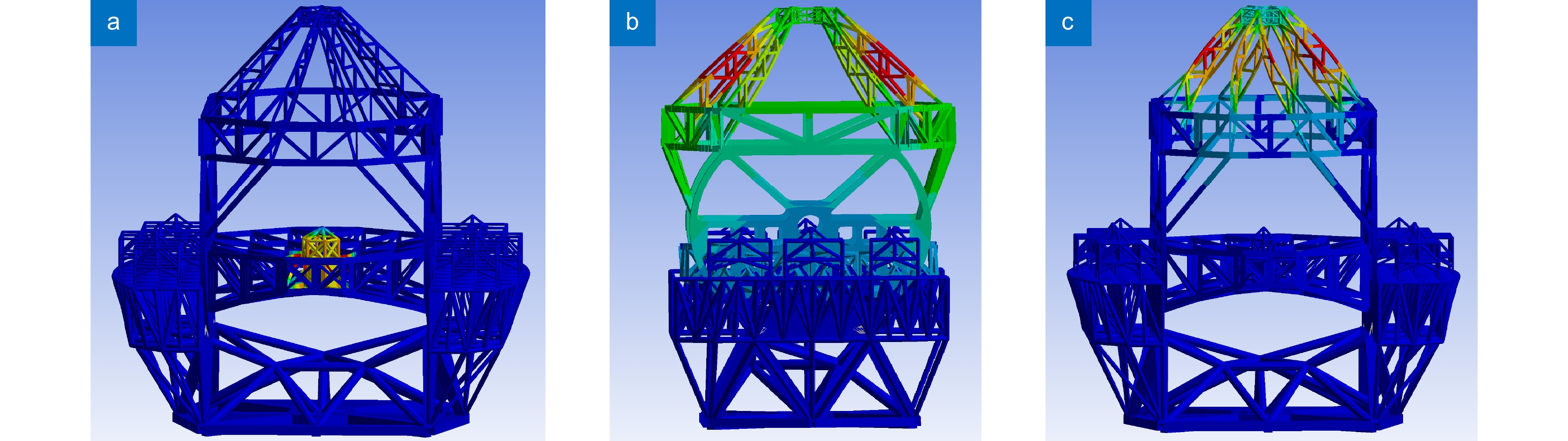

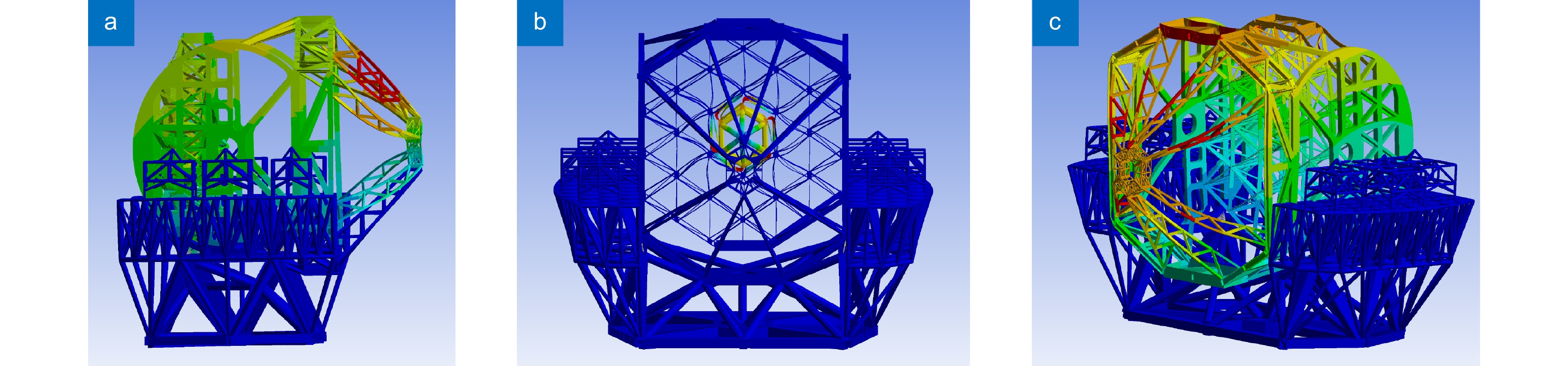

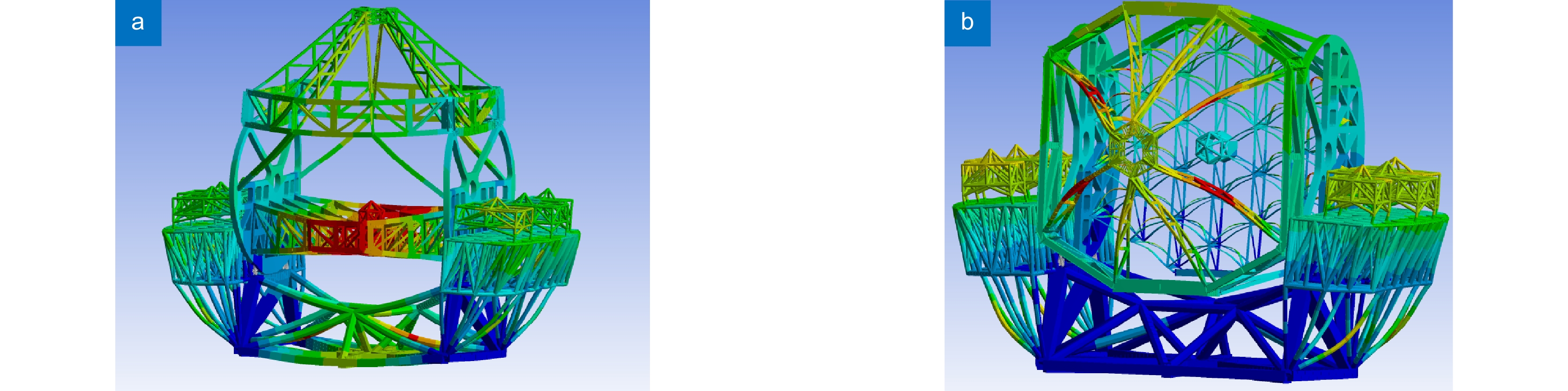

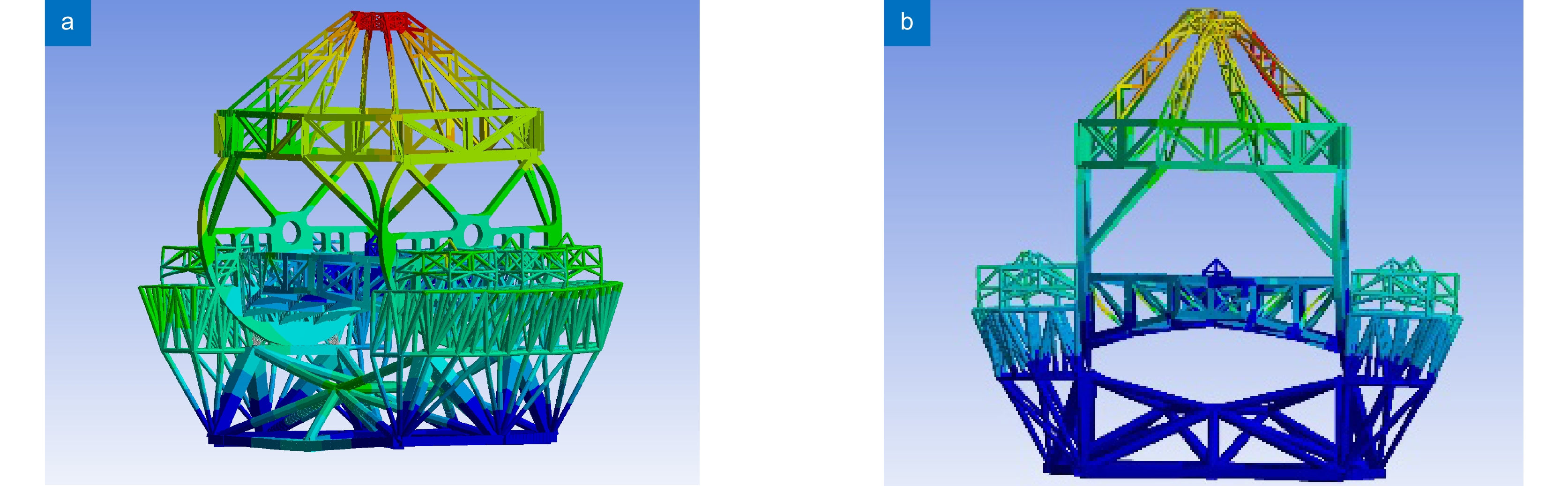

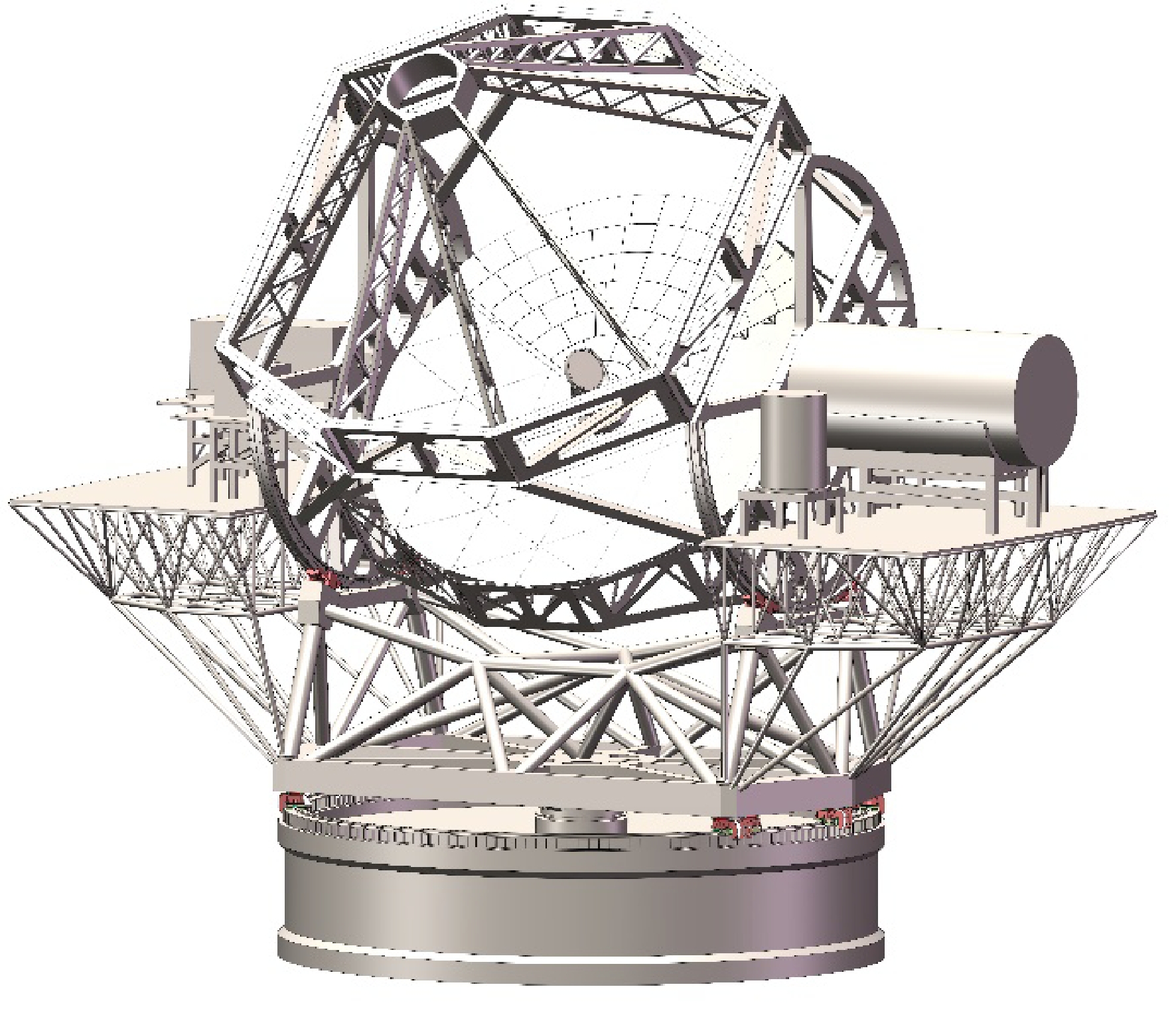

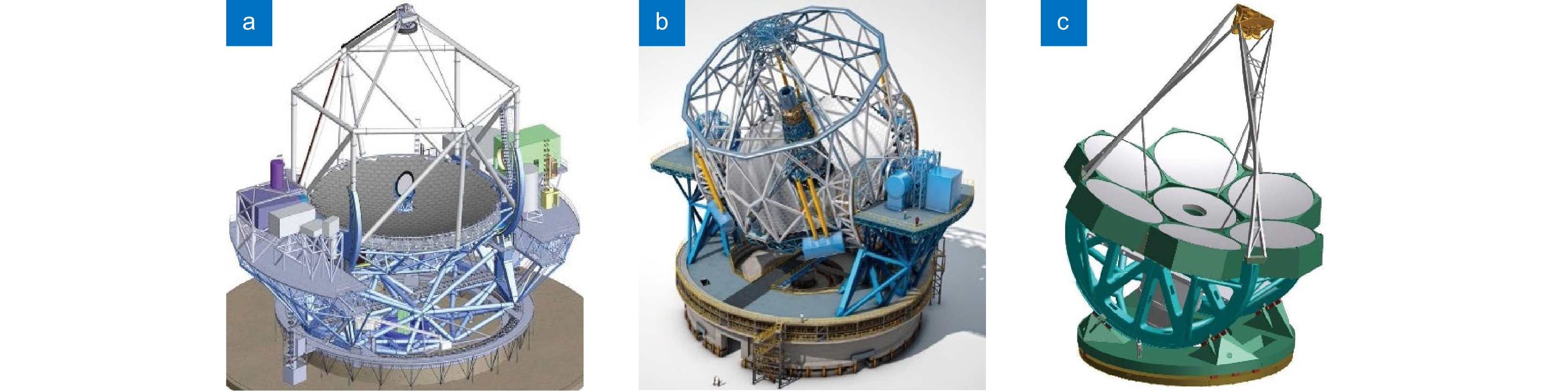

随着天文科学日新月异的发展和对性能越来越高的天文望远镜的迫切需求,目前,国际上正在积极建设口径20 m~40 m量级的极大口径光学红外望远镜。这些望远镜为了实现更大口径,也面临着巨大的技术挑战。其中,为使望远镜达到光学设计要求,需要创新解决方案来满足足够的负荷分担要求。本文简单介绍了国际上极大望远镜主桁架结构及关键结构件的多种设计方法,分析了各种方案的优缺点,提出了一种新的轻量化钣金焊接结构的30 m中国未来巨型望远镜方案,并在此基础上进行了大量的有限元建模、优化和仿真分析。分析结果显示,望远镜指向天顶时,第一阶模态频率为2.3 Hz,结构最大变形为3.8 mm;而望远镜指向水平方向时,第一阶模态频率减小为2.1 Hz,结构最大变形为2.9 mm,满足了望远镜的相关技术要求,为我国未来巨型望远镜的研制提供了技术参考。

Abstract

In recent years, with the fast development of astronomical science and higher requirements for astronomical telescope's performance, the ground-based extremely large astronomical optical telescopes with aperture 20 m~40 m in diameter are being actively studied and constructed internationally. With the increase of the telescope aperture, these telescopes should face even greater challenges. In order to make them meet their optical design requirements, new solutions are needed to provide adequate load sharing. In this paper, several design methods of the main structures and key components of the extremely large telescopes are summarized, the advantages and disadvantages of various schemes are analyzed, a lightweight sheet metal welding structure for the 30 m Chinese Future Giant Telescope (CFGT) is put forward, and the finite element model design and analysis are carried out. The results show that when the telescope points to the zenith, the first modal frequency is 2.3 Hz and the maximum deformation of the structure is 3.8 mm. While the telescope points in the horizontal direction, the first modal frequency is reduced to 2.1 Hz and the maximum deformation of the structure is 2.9 mm, which meets the technical requirements of CFGT. The design provides a technical reference for the development of extremely large telescopes in China in the future.

-

Overview

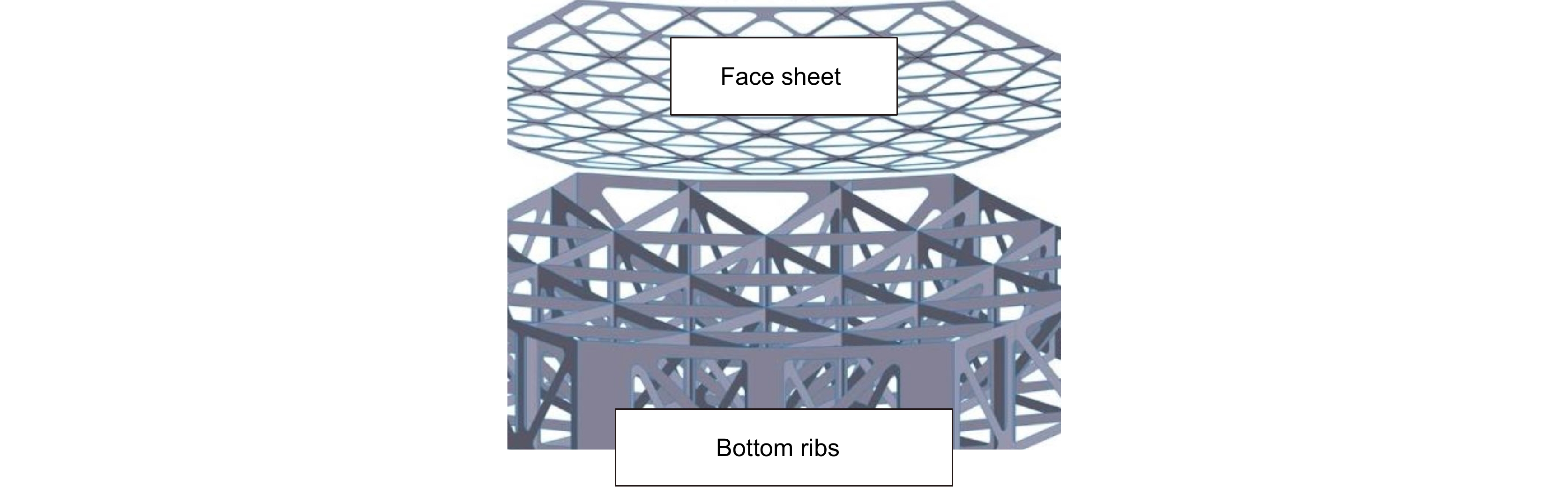

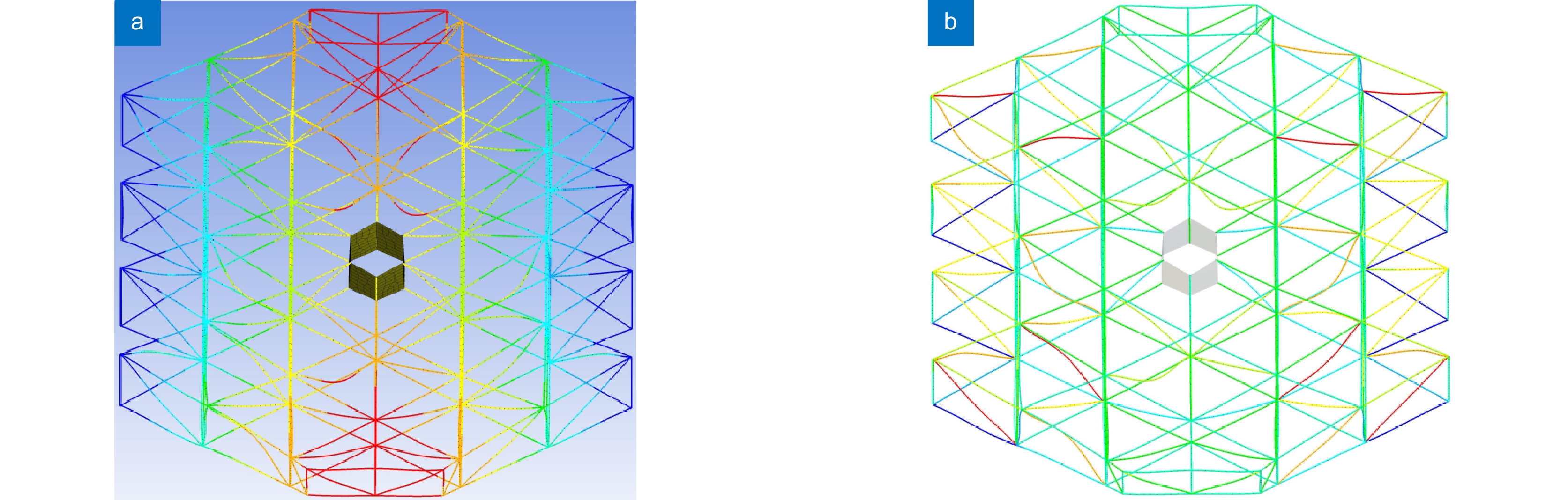

Overview: In order to achieve the desired performance a compact and lightweight isogrid fully integrated into the Altitude Structure is proposed. This structure is adapted to the mirror interfaces of the 30 m Chinese Future Giant Telescope. The aim of the M1 Support Structure is to provide stiff support for the Primary Mirror and, at the same time, contribute to the stiffness of the Altitude Structure, using a lightweight solution so that the unbalance of the altitude structure does not increase in an important way. Besides, the M1 Cell needs to offer an adequate interface to the different mirrors and thus avoid the generation of important local displacements at their support due to the weight of that mirrors. Furthermore, the M1 Cell must allow easy access for maintenance. The isogrid consists of a series of top and bottom plates welded to each other using a series of ribs extending in different directions and using a triangular pattern, resulting in a structure behaving like a lightweight isotropic material. The isogrid will have a constant thickness of 3200 mm to be accessed and will follow the same curved surface as the mirrors. Apart from being a lightweight solution, the fabrication and assembly of such an isogrid are simpler than those of a conventional space frame, which is the traditional solution for M1 Support Structures. Besides, the isogrid allows more open room below the mirrors, so that access from below to the mirrors for maintenance can be achieved easily and even carts up to 1 m height would be able to drive below the mirrors, which is difficult to achieve in the case of a space frame. This can be achieved using a continuous floor on the bottom plate. In order to avoid the fact that the ribs are an obstacle to the continuous floor, we propose using a modular and puzzle-like grating made of galvanized steel that can be mounted easily and the top surface is at the same height as the ribs. A grating based on 40 mm × 4 mm steel members with a spacing of 50 mm ×50 mm is proposed to fulfil the requirements. The different elements of the grating will be planar elements. Due to the low curvature of the surface containing the mirrors, it is expected that carts will be able to travel through it.

-

-

表 1 有限元模型中使用的弹簧刚度

Table 1. Spring stiffnesses used in finite element model

弹簧类型 弹簧方向 刚度/(N/m) 静压油垫 方位轴轴向 2.65×1010 方位径向 1.67×109 高度径向 1.25×1010 高度轴向 1.55×109 直线驱动 方位切向 1.75×108 高度切向 1.49×108 表 2 CFGT望远镜指向天顶时的模态值

Table 2. Eigenfrequencies for the CFGT telescope pointing at zenith

模态 频率/Hz 状态 1 2.3 M1桁架中心扭转 2 2.4 M2 spider 弯曲 3 2.5 M2 spider 扭转 表 4 CFGT望远镜与其它极大望远镜主模态频率对比

Table 4. Comparison about dominant modal eigenfrequencies for the extremely large telescopes

描述 GMT TMT E-ELT 本设计 主模态频率范围/Hz 3~12 2~5 1.56~6.0 2~5 表 3 CFGT望远镜指向水平时的模态值

Table 3. Eigenfrequencies for the CFGT telescope pointing at horizon

模态 频率/Hz 状态 1 2.1 M2 spider 弯曲 2 2.2 M1桁架中心扭转 3 2.4 M2 spider 扭转 -

参考文献

[1] Usuda T, Ezaki Y, Kawaguchi N, et al. Preliminary design study of the TMT telescope structure system: overview[J]. Proc SPIE, 2014, 9145: 91452F.

[2] Ezaki Y, Kato A, Hattori T, et al. Overview of key technologies for TMT telescope structure[J]. Proc SPIE, 2016, 9906: 99060Y. doi: 10.1117/12.2233847

[3] Kamikawa K, Nagai A, Ashida T, et al. High precision machining in TMT (Thirty Meter Telescope) structure manufacturing[J]. Proc SPIE, 2020, 11445: 114451R.

[4] The E-ELT Project Office. The E-ELT Construction Proposal[M]. Garching: European Southern Observatory, 2011.

[5] Chiozzi G, Kiekebusch M, Kornweibel N, et al. The ELT control system[J]. Proc SPIE, 2018, 10707: 107070U.

[6] Argomedo J, Andolfato L, Diaz Cano C, et al. ESO ELT M1 local control system software design and development status (Conference Presentation)[J]. Proc SPIE, 2018, 10707: 107070V.

[7] Nijenhuis J, Heijmans J, den Breeje R, et al. Designing the primary mirror support for the E-ELT[J]. Proc SPIE, 2016, 9906: 990616. doi: 10.1117/12.2232525

[8] Tamai R, Koehler B, Cirasuolo M, et al. The ESO's ELT construction progress[J]. Proc SPIE, 2020, 11445: 114451E.

[9] Fanson J, McCarthy P J, Bernstein R, et al. Overview and status of the Giant Magellan Telescope project[J]. Proc SPIE, 2018, 10700: 1070012.

[10] Angeli G Z, Bernstein R, Walls B, et al. Systems engineering for the Giant Magellan Telescope[J]. Proc SPIE, 2018, 10705: 107050I.

[11] Martin H M, Allen R, Gasho V, et al. Manufacture of primary mirror segments for the Giant Magellan Telescope[J]. Proc SPIE, 2018, 10706: 107060V.

[12] Fischer B M, Ranka T, Aguayo F, et al. The purpose, plan, and progress of the Giant Magellan Telescope primary mirror off-axis segment test cell[J]. Proc SPIE, 2020, 11445: 114451H.

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: