-

摘要:

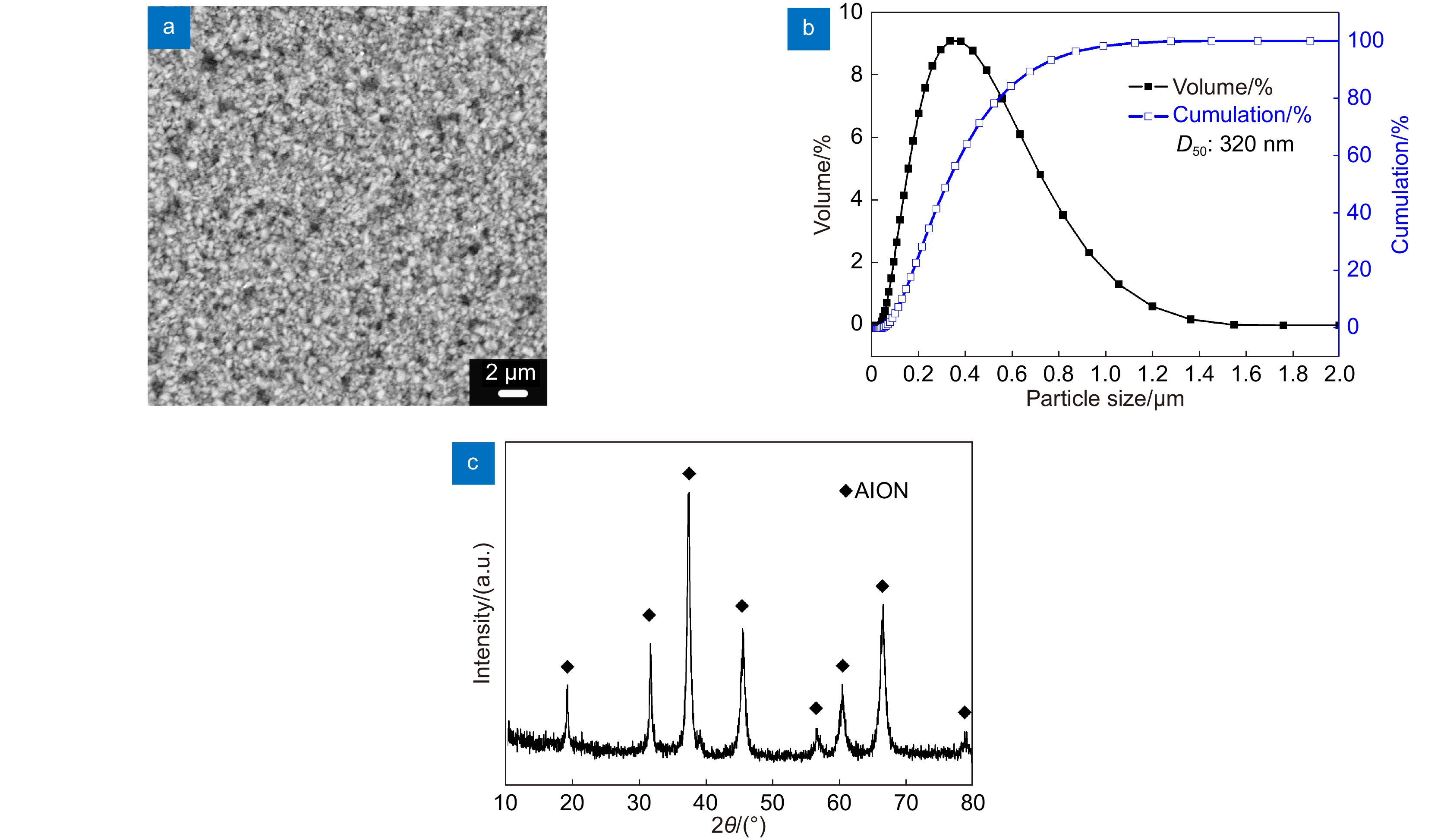

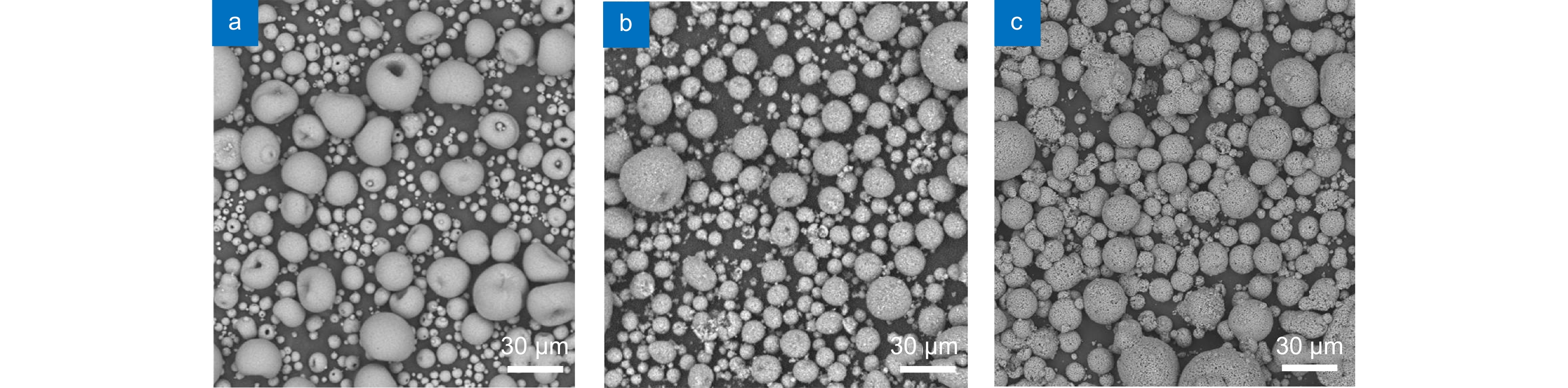

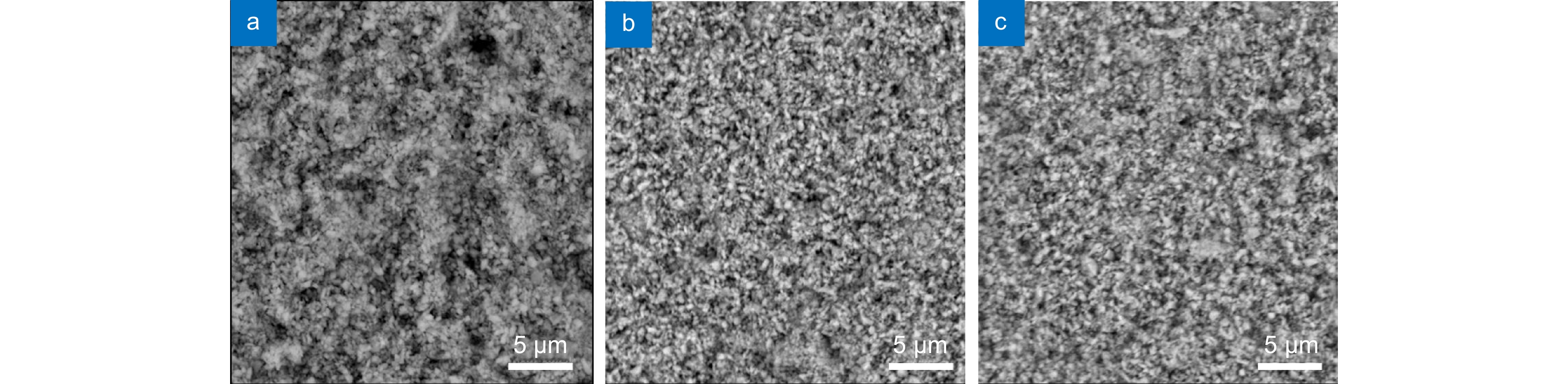

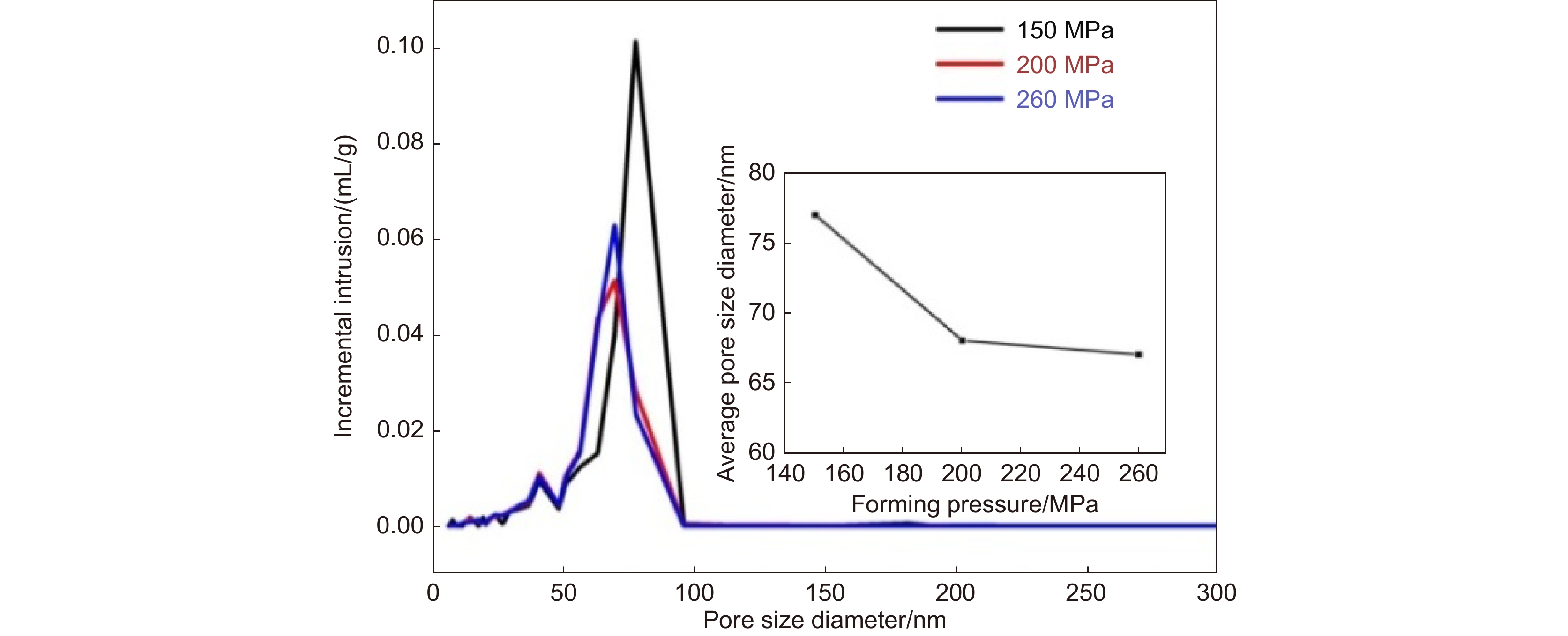

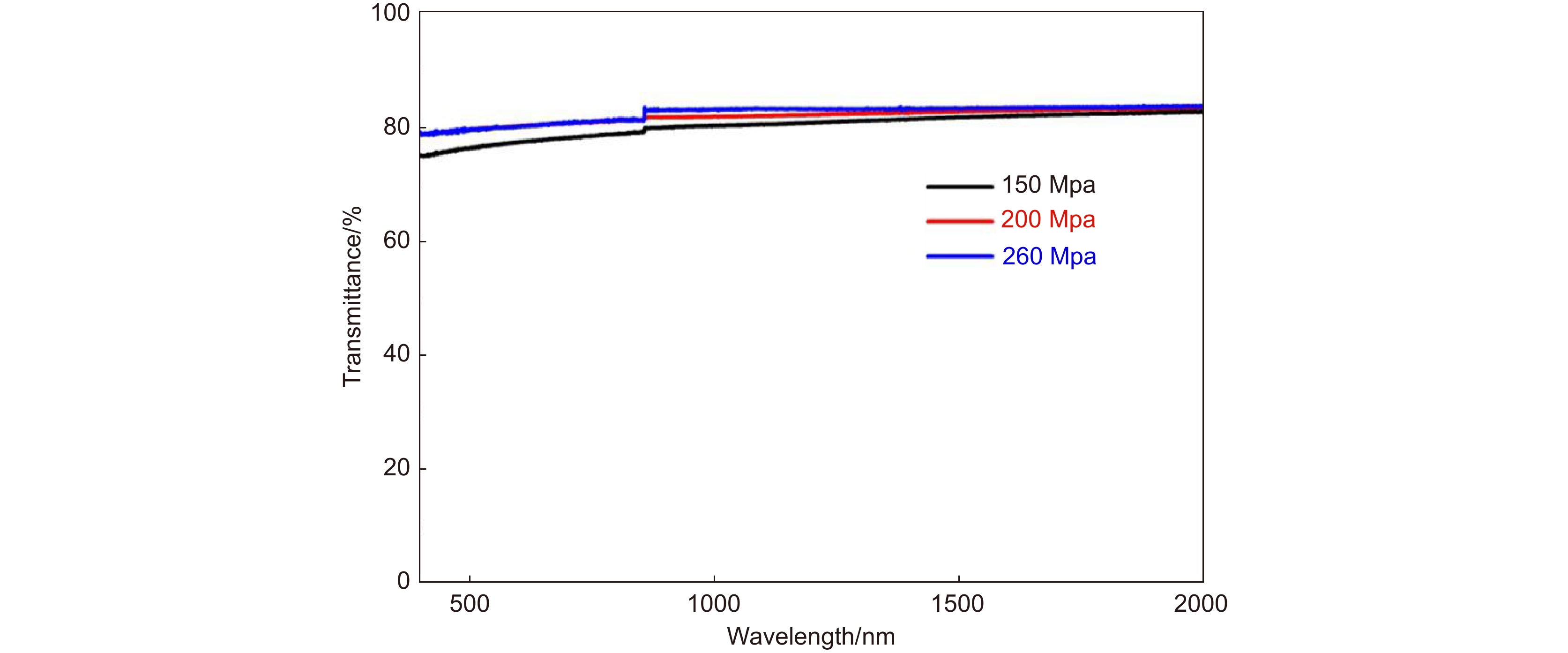

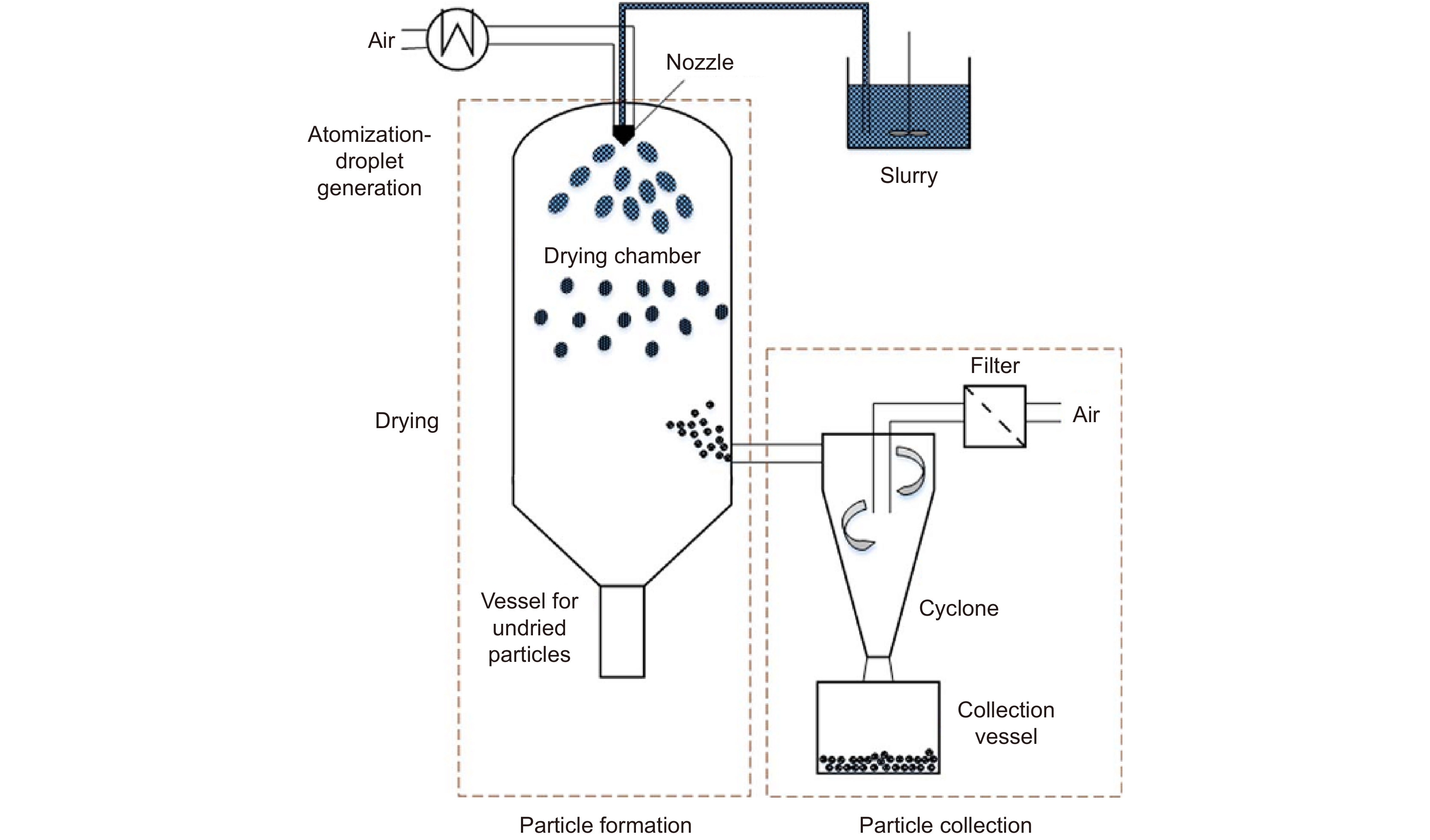

氮氧化铝(AlON)透明陶瓷具有优异的光学、热学和机械性能,可广泛应用于光电窗口、整流罩、透明装甲等领域。成型高致密度、结构均匀的素坯是制备氮氧化铝透明陶瓷的关键技术环节。但是纳米粉体比表面积大,易产生非均匀团聚,导致成型坯体致密度差。为了提高素坯密度和均匀性,本文首先通过优化喷雾造粒工艺实现纳米粉体微球化,获得直径大于10 μm、具有良好流动性的致密球形颗粒。然后分析成型压力对素坯的密度、微观结构、平均孔径及陶瓷性能的影响,得到相对密度58.8%的素坯,烧结陶瓷片在200 nm处直线透过率达到83%(厚度2 mm)。最后采用冷等静压成型/常压烧结技术制备出Φ170 mm平板和Φ110 mm球罩样件。

Abstract:AlON transparent ceramic is a new structure-function integration optical material with excellent optical, thermal, and mechanical properties, which can be widely used in missile domes, and transparent armors and other fields. The preparation of green body with high density and homogeneous microstructure is the key technical procedure for fabricating AlON transparent ceramic. However, nanopowders possess high specific surface area and are easy to form non-uniform agglomeration, resulting in poor density of formed green body. In order to improve density and homogeneity of green body, micro-spheroidization of nanopowders and dense spherical particles with a diameter greater than 10 μm and good fluidity were obtained by optimizing the spray granulation process. The effect of cold isostatic pressing pressure on density, microstructure, average pore diameter of green bodies, and optical transmittance of sintered ceramics were intensively investigated. Green bodies with relative density of 58.8% were obtained. The in-line transmittance of sintered ceramics reached 83% at 2000 nm (thickness 2 mm). AlON transparent ceramics with diameter of Φ170 mm plate and Φ110 mm dome were obtained by cold isostatic pressing and pressureless sintering.

-

Overview: Aluminum Oxynitride (AlON) transparent ceramic has high transparency from the ultraviolet to mid-infrared range, excellent mechanical properties, high temperature resistance and excellent chemical stability. It’s a new structure-function integration optical material and an ideal material for photoelectric windows, missile domes, and transparent armors. The fabrication of AlON transparent ceramic mainly includes synthesis of the AlON nanopowders, forming nanopowders to green body, sintering of the green body into a dense transparent ceramic, grinding and polishing. The preparation of green body with high density and homogeneous microstructure is the key technical procedure for fabricating AlON transparent ceramic. Generally, cold isostatic pressing is used for fabricating AlON green body. However, AlON nanopowders possess high specific surface area and are easy to form non-uniform agglomeration. If the nanopowders are directly formed by cold isostatic pressing, the density of the green body will be poor, and finally resulting in poor performance of the sintered AlON ceramic. In order to solve the problem of non-uniform agglomeration of AlON nanopowders, the AlON powders can be granulation processed into uniform, dense, good fluidity spherical particles, and then dense green body can be obtained by cold isostatic pressing. Spray granulation is an effective method to realize nanopowders micro-spheroidization, but, there is no report on dealing with spray granulation of AlON nanopowders. In this paper, we aimed to improve density and homogeneity of AlON green body by spray granulation combined with cold isostatic pressing, and fabricate AlON ceramics with larger size and more complex structure. First, single phase AlON powders were prepared by solid-state reaction method and ball-milled into nanopowders with an average particle diameter of 320 nm, and narrow size distribution. Second, We optimized the spray granulation process. The effect of solid content of AlON slurries on properties of spray granulated particles were investigated. When the solid content of AlON slurry was 50 wt%, dense spherical particles with a diameter greater than 10 μm and good fluidity were obtained. Third, The effect of cold isostatic pressing pressure on density, microstructure, average pore diameter of green bodies and optical transmittance of sintered ceramics were intensively investigated. The results showed that when cold isostatic pressing pressure was increased to 200 MPa, the density of AlON green body reached to 2.17 g/cm3, the relative density increased to 58.8%, and the green body had small pore and uniform microstructure. The in-line transmittance of AlON ceramic fabricated by cold isostatic pressing and pressureless sintering reached 83% at 2000 nm for the thickness of 2 mm. Last, we have demonstrated our work on fabricating AlON transparent ceramics with a diameter of Φ170 mm plate and Φ110 mm dome. Those spray granulation, cold isostatic pressing and pressureless sintering techniques can be used to fabricate high quality, large size AlON transparent ceramics in the future.

-

-

表 1 不同成型压力坯体密度

Table 1. Green body density of different forming pressures

序号 成型压力/MPa AlON素坯密度/(g/cm3) 1 150 1.98±0.03 2 200 2.17±0.02 3 260 2.18±0.02 表 2 不同成型压力陶瓷密度

Table 2. AlON transparent ceramic density of different forming pressures

序号 成型压力/MPa AlON透明陶瓷密度/(g/cm3) 1 150 3.667±0.006 2 200 3.676±0.004 3 260 3.675±0.005 -

[1] Corbin N D. Aluminum oxynitride spinel: a review[J]. J Eur Ceram Soc, 1989, 5(3): 143−154. doi: 10.1016/0955-2219(89)90030-7

[2] Hartnett T M, Bernstein S D, Maguire E A, et al. Optical properties of ALON (aluminum oxynitride)[J]. Infrared Phys Technol, 1998, 39(4): 203−211.

[3] Klement R, Rolc S, Mikulikova R, et al. Transparent armour materials[J]. J Eur Ceram Soc, 2008, 28(5): 1091−1095. doi: 10.1016/j.jeurceramsoc.2007.09.036

[4] McCauley J W, Patel P, Chen M W, et al. AlON: a brief history of its emergence and evolution[J]. J Eur Ceram Soc, 2009, 29(2): 223−236. doi: 10.1016/j.jeurceramsoc.2008.03.046

[5] 陈凤. AlON透明陶瓷的研究进展[J]. 湖北理工学院学报, 2019, 35(3): 58−62,70. doi: 10.3969/j.issn.2095-4565.2019.03.013

Chen F. Progress and prospect of AlON transparent ceramics[J]. J Hubei Polytech Univ, 2019, 35(3): 58−62,70. doi: 10.3969/j.issn.2095-4565.2019.03.013

[6] 雷景轩, 施鹰, 石坚波. 碳热还原氮化法合成AlON粉体的表征及透明陶瓷的制备[J]. 硅酸盐通报, 2018, 37(5): 1520−1524.

Lei J X, Shi Y, Shi J B. Characterization of the AlON powders fabricated by carbothermal reduction and nitridation method and preparation of the transparent ceramic[J]. Bull Chin Ceram Soc, 2018, 37(5): 1520−1524.

[7] 许建鑫, 单英春, 王光, 等. 形核密度对AlON粉体合成及其透明陶瓷制备的影响[J]. 无机材料学报, 2018, 33(4): 373−379. doi: 10.15541/jim20170206

Xu J X, Shan Y C, Wang G, et al. Nucleation density on the synthesis of AlON powder and preparation of transparent ceramics[J]. J lnorg Mater, 2018, 33(4): 373−379. doi: 10.15541/jim20170206

[8] 刘学建, 袁贤阳, 张芳, 等. 碳热还原氮化工艺制备AlON透明陶瓷[J]. 无机材料学报, 2010, 25(7): 678−682. doi: 10.3724/SP.J.1077.2010.00678

Liu X J, Yuan X Y, Zhang F, et al. Fabrication of aluminum oxynitride transparent ceramics by carbothermal reduction nitridation processing[J]. J Inorg Mater, 2010, 25(7): 678−682. doi: 10.3724/SP.J.1077.2010.00678

[9] 田庭燕, 杜洪兵, 姜华伟, 等. AlON透明陶瓷的制备与性能[J]. 硅酸盐学报, 2010, 38(8): 1455−1458.

Tian T Y, Du H B, Jiang H W, et al. Preparation and properties of AlON transparent ceramics[J]. J Chin Ceram Soc, 2010, 38(8): 1455−1458.

[10] 齐建起, 周纪承, 庞微, 等. 固相反应法制备ALON陶瓷粉体的研究[J]. 稀有金属材料与工程, 2007, 36(S1): 88−91.

Qi J Q, Zhou J C, Pang W, et al. Study on the preparation of ALON powder by solid state reaction method[J]. Rare Met Mater Eng, 2007, 36(S1): 88−91.

[11] 魏巍, 傅正义, 王皓, 等. 放电等离子烧结氮氧化铝透明陶瓷的研究[J]. 武汉理工大学学报, 2009, 31(15): 13−14,44. doi: 10.3963/j.issn.1671-4431.2009.15.004

Wei W, Fu Z Y, Wang H, et al. Research on AlON transparent ceramics by SPS[J]. J Wuhan Univ Technol, 2009, 31(15): 13−14,44. doi: 10.3963/j.issn.1671-4431.2009.15.004

[12] Goldman L M, Balasubramanian S, Smith M, et al. Conformal ALON® windows[J]. Proc SPIE, 2015, 9453: 945306. doi: 10.1117/12.2177236

[13] Goldman L M, Kashalikar U, Ramisetty M, et al. Scale up of large ALON® and spinel windows[J]. Proc SPIE, 2017, 10179: 101790J. doi: 10.1117/12.2269467

[14] Goldman L M, Smith M, Ramisetty M, et al. Scale up of large ALON windows[J]. Proc SPIE, 2019, 10985: 109850F.

[15] Li J M, Zhang B H, Tian R, et al. Hot isostatic pressing of transparent AlON ceramics assisted by dissolution of gas inclusions[J]. J Eur Ceram Soc, 2021, 41(7): 4327−4336. doi: 10.1016/j.jeurceramsoc.2021.02.035

[16] Feng Z, Qi J Q, Guo X F, et al. A new and highly active sintering additive: SiO2 for highly-transparent AlON ceramic[J]. J Alloys Compd, 2019, 787: 254−259. doi: 10.1016/j.jallcom.2019.02.106

[17] 施剑林. 固相烧结−Ⅰ气孔显微结构模型及其热力学稳定性, 致密化方程[J]. 硅酸盐学报, 1997, 25(5): 499−513. doi: 10.3321/j.issn:0454-5648.1997.05.001

Shi J L. Solid state sintering I —— pore microstructural model and thermodynamic stability, densification equations[J]. J Chin Ceram Soc, 1997, 25(5): 499−513. doi: 10.3321/j.issn:0454-5648.1997.05.001

[18] Stunda-Zujeva A, Irbe Z, Berzina-Cimdina L. Controlling the morphology of ceramic and composite powders obtained via spray drying – A review[J]. Ceram Int, 2017, 43(15): 11543−11551. doi: 10.1016/j.ceramint.2017.05.023

[19] Zhang L, Yang H, Qiao X B, et al. Systematic optimization of spray drying for YAG transparent ceramics[J]. J Eur Ceram Soc, 2015, 35(8): 2391−2401. doi: 10.1016/j.jeurceramsoc.2015.02.004

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: