Laser-induced periodic surface structure for microscale anti-counterfeiting structural colors

-

摘要:

激光诱导表面周期结构由于其周期相关的光栅衍射特性在明场下显示出鲜艳的结构色,备受研究人员的广泛关注,而微纳结构在显微镜暗场显示的颜色通常容易被忽略。本文报道通过飞秒激光对氧化铟锡薄膜加工形成双周期光栅结构,利用其在明场和暗场的观察下具有不同的颜色特性实现图像加密应用。通过控制飞秒激光的偏振、脉冲能量和扫描速度在氧化铟锡薄膜上形成与偏振和波长相关的亚波长周期光栅,通过控制激光加工线条行间距形成大周期光栅。本文研究了激光加工能量和加工线条之间的间距对其形成双周期结构在明场和暗场显色的影响,利用不同加工参数结构在明场和暗场下显示不同的颜色实现图像加密。激光直写加工可以快速制备大面积区域,有望在商品防伪、图案装饰、超表面设计等方面发挥潜在的应用价值。

-

关键词:

- 结构色 /

- 激光诱导表面周期结构 /

- 信息防伪 /

- 激光加工

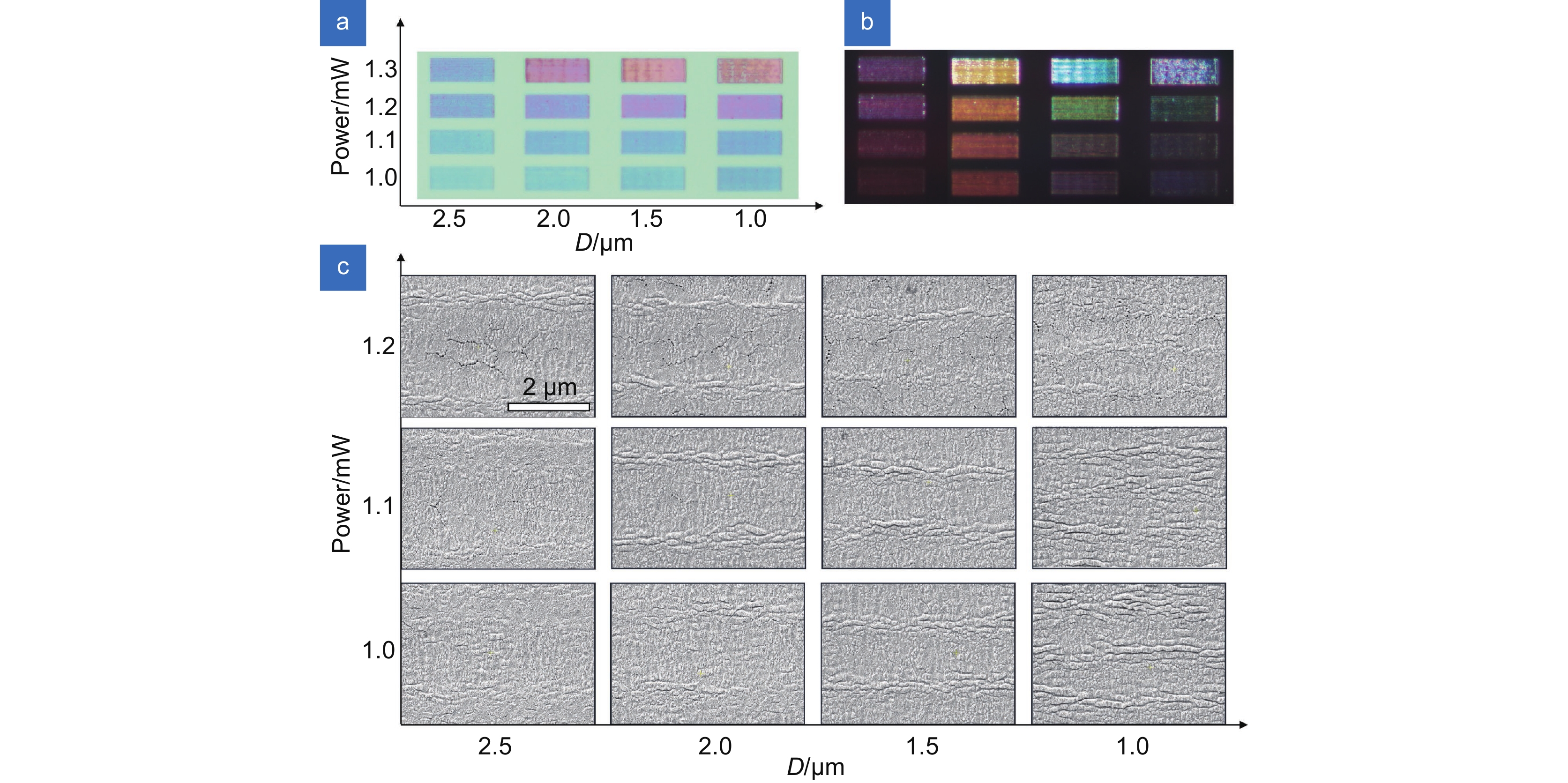

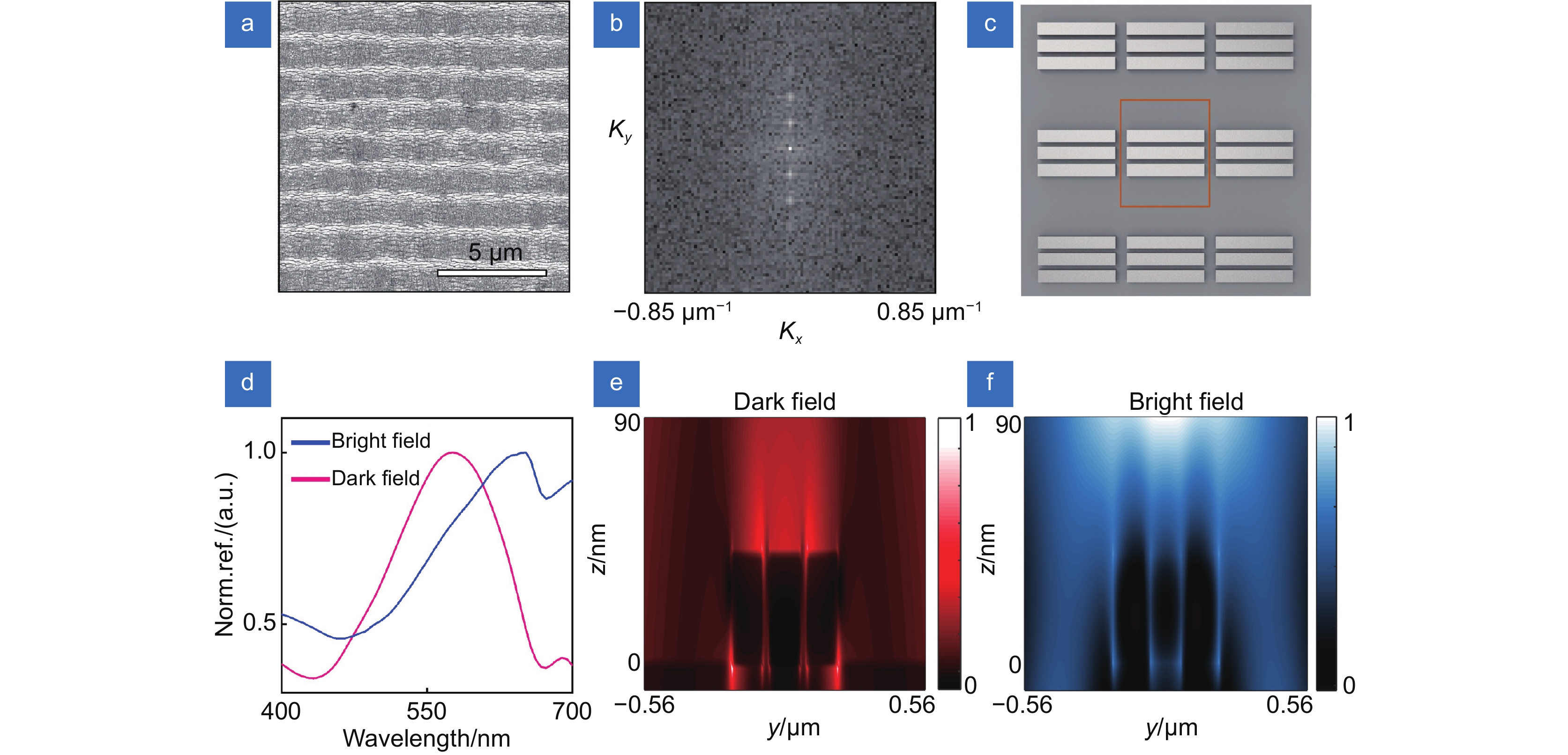

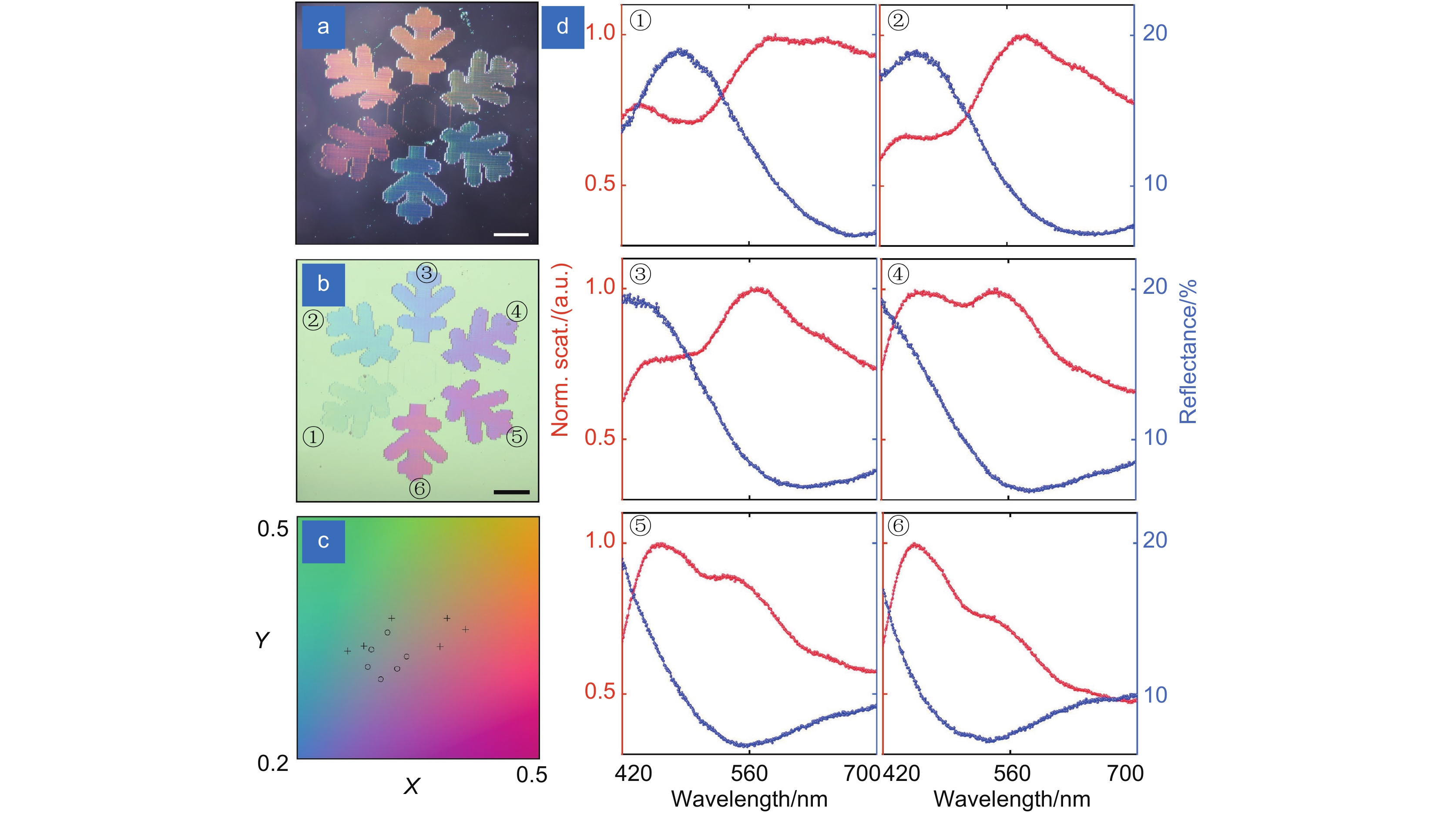

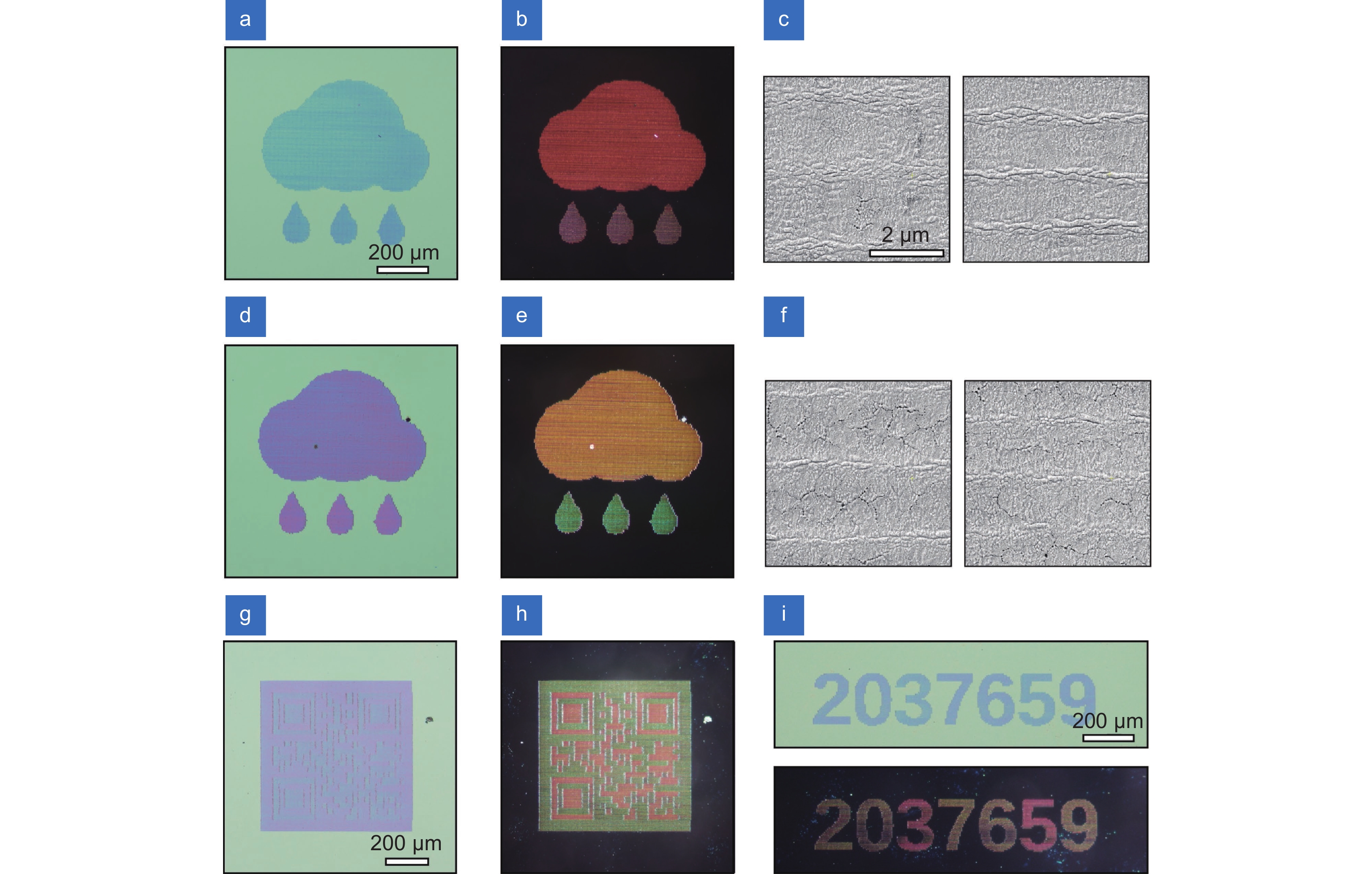

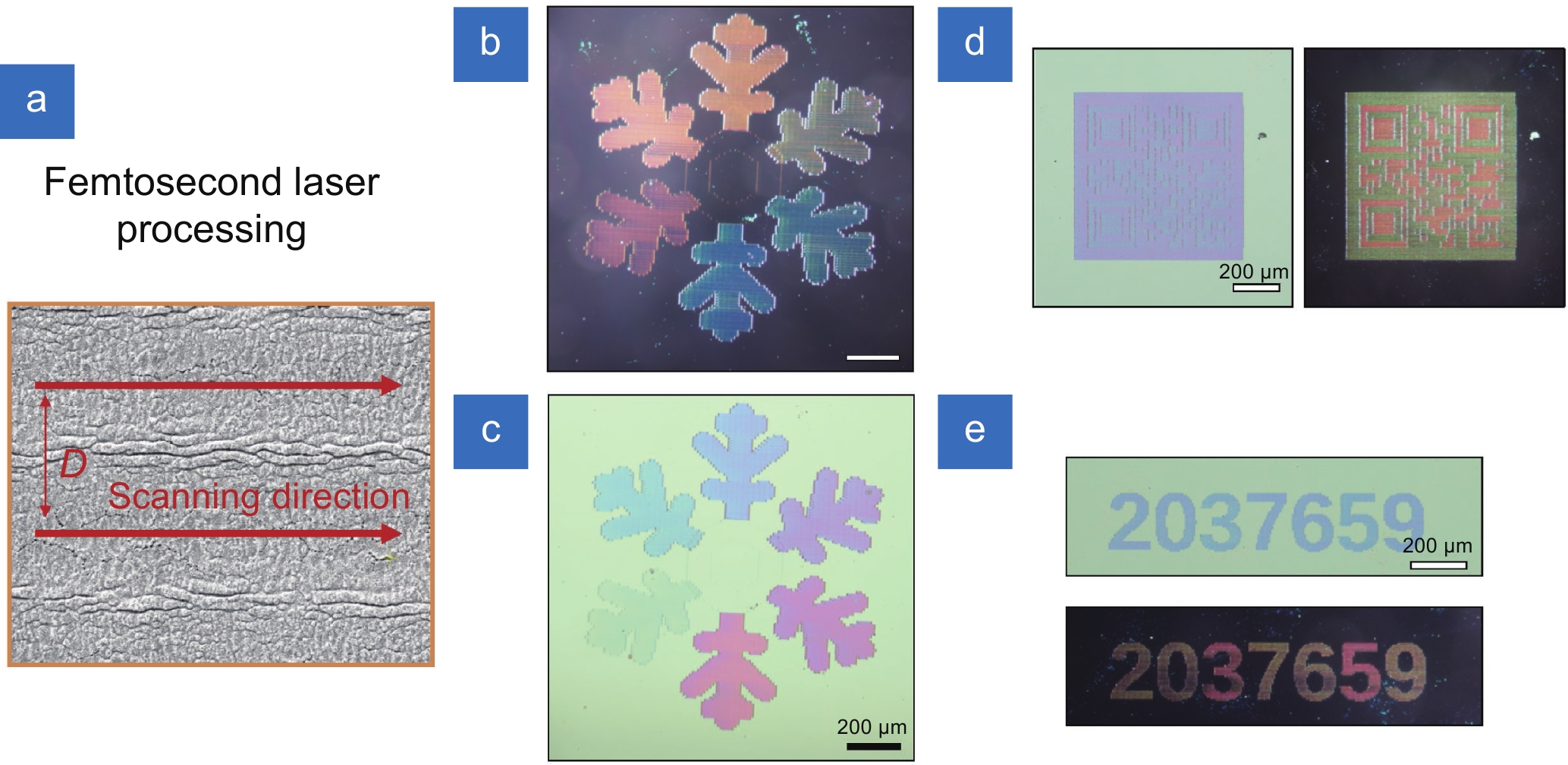

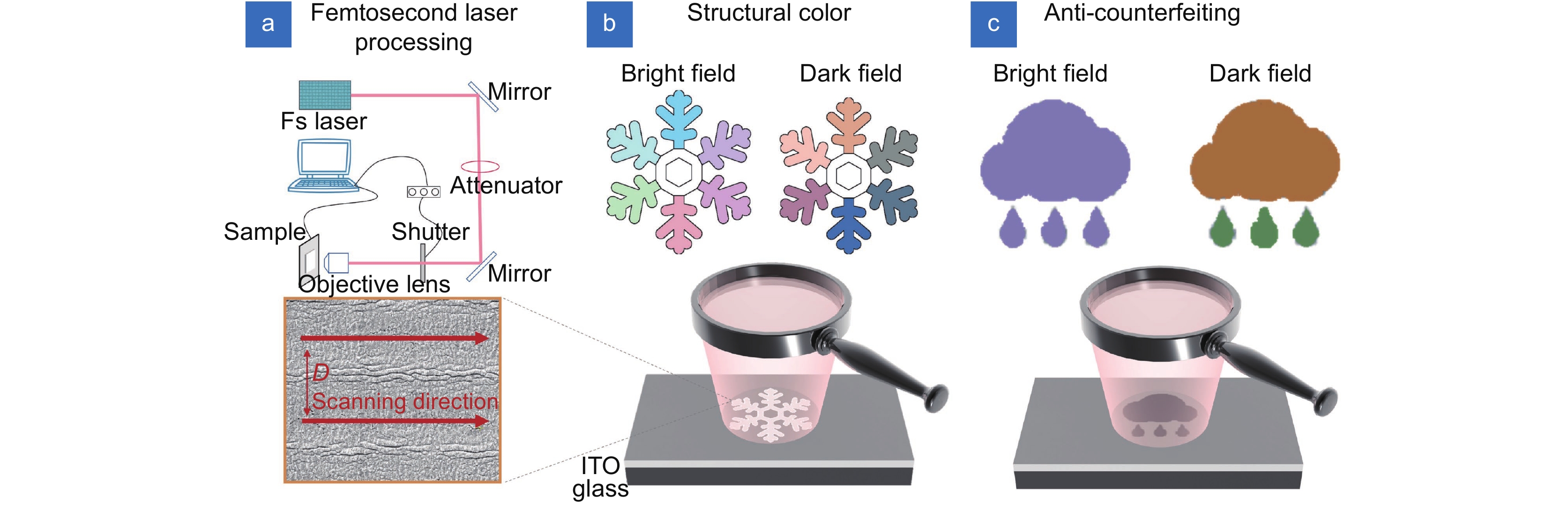

Abstract:The vivid color appearance of laser-induced periodic surface structures (LIPSS) has received intense research interests. The vibrant structural color associated with the periodicity of LIPSS is normally concerned under bright -field illumination, while the colors of structures under dark-field illumination are commonly overlooked. In this paper, we report an image encryption method based on laser-induced dual-period grating structures in indium tin oxide thin films, exhibiting different colors under bright-field and dark-field illumination. Following the standard laser recipe by judiciously controlling the polarization, pulse energy and scanning speed, subwavelength period LIPSS can be fabricated. By controlling the space between the fabricated lines, another grating with a larger periodicity can be formed. Consequently, the dual-period grating structure displays different colors under bright-field and dark-field illumination depending on the laser recipe with different pulse energies and line spaces. Leveraging this effect, information can be encoded in the color image, which displays the same color appearance under bright -field illumination while revealing different colors under dark-field illumination has been demonstrated. Combing the flexibility and scalability of laser fabrication, we envisage the potential applications in anti-counterfeiting, pattern decoration, metasurface, etc.

-

Overview: The vivid color appearance of laser-induced periodic surface structures (LIPSS) has received intense research interests. The vibrant structural color associated with the periodicity of LIPSS is normally concerned under bright-field illumination, while the colors of the structures under dark-field illumination are commonly overlooked. In this paper, we report an image encryption method based on laser-induced dual-period grating structures in indium tin oxide (thickness 180 nm) thin films, exhibiting different colors under bright-field and dark-field illumination. Following the standard laser recipe by judiciously controlling the polarization, pulse energy and scanning speed, subwavelength period LIPSS can be fabricated. By controlling the space between the fabricated lines, another grating with a larger periodicity can be formed. Leveraging this effect, we studied the effect of laser processing energy and the distance (D) between fabricated lines on the color appearance of the structures under bright-field and dark-field illumination. The experimental results indicate that the structures formed by different laser processing energies have rich colors under the bright-field and dark-field when the scanning speed is 0.5 mm/s and the distance D between scanning lines is 1.5 μm. When the laser energy and laser scanning speed are constant, using different distances D between laser fabricated lines can make the structures display the same color under bright-field illumination while different colors under dark-field illumination. This feature can be used for image hiding such as the QR code. The colors displayed under bright-field illumination is the same, and the QR code cannot be recognized. In contrast, the QR code shows distinct colors under dark-field illumination. Furthermore, it is possible to introduce disturbance information under bright-field illumination image to realize data encryption. Only concealed information can be clearly distinguished under dark-field illumination. Combing the flexibility and scalability of laser fabrication, we envisage the potential applications in anti-counterfeiting, pattern decoration, metasurface, etc.

-

-

-

[1] 欧阳旭, 徐毅, 冼铭聪, 等. 基于无序金纳米棒编码的多维光信息存储[J]. 光电工程, 2019, 46(3): 180584. doi: 10.12086/oee.2019.180584

Ouyang X, Xu Y, Xian M C, et al. Encoding disorder gold nanorods for multi-dimensional optical data storage[J]. Opto-Electron Eng, 2019, 46(3): 180584. doi: 10.12086/oee.2019.180584

[2] Ouyang X, Xu Y, Feng Z W, et al. Polychromatic and polarized multilevel optical data storage[J]. Nanoscale, 2019, 11(5): 2447−2452. doi: 10.1039/C8NR09192G

[3] Ouyang X, Xu Y, Xian M C, et al. Synthetic helical dichroism for six-dimensional optical orbital angular momentum multiplexing[J]. Nat Photonics, 2021, 15(12): 901−907. doi: 10.1038/s41566-021-00880-1

[4] 黎显继, 白忠臣, 彭嫚, 等. 激光诱导光栅表面等离子体增强CdSe量子点荧光[J]. 光电工程, 2019, 46(5): 180464. doi: 10.12086/oee.2019.180464

Li X J, Bai Z C, Peng M, et al. Surface plasma enhanced fluorescence of CdSe quantum dots induced by laser on a grating surface[J]. Opto-Electron Eng, 2019, 46(5): 180464. doi: 10.12086/oee.2019.180464

[5] 杨焕, 曹宇, 李峰平, 等. 激光制备超疏水表面研究进展[J]. 光电工程, 2017, 44(12): 1160−1168. doi: 10.3969/j.issn.1003-501X.2017.12.003

Yang H, Cao Y, Li F P, et al. Research progress in superhydrophobic surfaces fabricated by laser[J]. Opto-Electron Eng, 2017, 44(12): 1160−1168. doi: 10.3969/j.issn.1003-501X.2017.12.003

[6] Van Driel H M, Sipe J E, Young J F. Laser-induced periodic surface structure on solids: a universal phenomenon[J]. Phys Rev Lett, 1982, 49(26): 1955−1958. doi: 10.1103/PhysRevLett.49.1955

[7] Bonse J, Gräf S. Maxwell meets Marangoni—a review of theories on laser-induced periodic surface structures[J]. Laser Photonics Rev, 2020, 14(10): 2000215. doi: 10.1002/lpor.202000215

[8] Bonse J, Höhm S, Kirner S V, et al. Laser-induced periodic surface structures—A scientific evergreen[J]. IEEE J Sel Top Quantum Electron, 2017, 23(3): 9000615. doi: 10.1109/JSTQE.2016.2614183

[9] Birnbaum M. Semiconductor surface damage produced by ruby lasers[J]. J Appl Phys, 1965, 36(11): 3688−3689. doi: 10.1063/1.1703071

[10] Vorobyev A Y, Makin V S, Guo C L. Periodic ordering of random surface nanostructures induced by femtosecond laser pulses on metals[J]. J Appl Phys, 2007, 101(3): 034903. doi: 10.1063/1.2432288

[11] Tsukamoto M, Asuka K, Nakano K, et al. Periodic microstructures produced by femtosecond laser irradiation on titanium plate[J]. Vacuum, 2006, 80(11‒12): 1346−1350. doi: 10.1016/j.vacuum.2006.01.016

[12] Ashkenasi D, Rosenfeld A, Varel H, et al. Laser processing of sapphire with picosecond and sub-picosecond pulses[J]. Appl Surf Sci, 1997, 120(1‒2): 65−80. doi: 10.1016/S0169-4332(97)00218-3

[13] Rohloff M, Das S K, Höhm S, et al. Formation of laser-induced periodic surface structures on fused silica upon multiple cross-polarized double-femtosecond-laser-pulse irradiation sequences[J]. J Appl Phys, 2011, 110(1): 014910. doi: 10.1063/1.3605513

[14] Bonse J, Kirner S V, Griepentrog M, et al. Femtosecond laser texturing of surfaces for tribological applications[J]. Materials, 2018, 11(5): 801. doi: 10.3390/ma11050801

[15] Nivas J J J, He S T, Rubano A, et al. Direct femtosecond laser surface structuring with optical vortex beams generated by a q-plate[J]. Sci Rep, 2015, 5: 17929. doi: 10.1038/srep17929

[16] Liang F, Vallée R, Chin S L. Pulse fluence dependent nanograting inscription on the surface of fused silica[J]. Appl Phys Lett, 2012, 100(25): 251105. doi: 10.1063/1.4729620

[17] Forster M, Kautek W, Faure N, et al. Periodic nanoscale structures on polyimide surfaces generated by temporally tailored femtosecond laser pulses[J]. Phys Chem Chem Phys, 2011, 13(9): 4155−4158. doi: 10.1039/c0cp01798a

[18] Lin Z Y, Hong M H. Femtosecond laser precision engineering: from micron, submicron, to nanoscale[J]. Ultraf Sci, 2021, 2021: 9783514. doi: 10.34133/2021/9783514

[19] Reif J, Varlamova O, Uhlig S, et al. On the physics of self-organized nanostructure formation upon femtosecond laser ablation[J]. Appl Phys A, 2014, 117(1): 179−184. doi: 10.1007/s00339-014-8339-x

[20] Garrelie F, Colombier J P, Pigeon F, et al. Evidence of surface Plasmon resonance in ultrafast laser-induced ripples[J]. Opt Express, 2011, 19(10): 9035−9043. doi: 10.1364/OE.19.009035

[21] Le Harzic R, Dörr D, Sauer D, et al. Generation of high spatial frequency ripples on silicon under ultrashort laser pulses irradiation[J]. Appl Phys Lett, 2011, 98(21): 211905. doi: 10.1063/1.3593493

[22] Dong Y Y, Molian P. Coulomb explosion-induced formation of highly oriented nanoparticles on thin films of 3C–SiC by the femtosecond pulsed laser[J]. Appl Phys Lett, 2004, 84(1): 10−12. doi: 10.1063/1.1637948

[23] Bhardwaj V R, Simova E, Rajeev P P, et al. Optically produced arrays of planar nanostructures inside fused silica[J]. Phys Rev Lett, 2006, 96(5): 057404. doi: 10.1103/PhysRevLett.96.057404

[24] Zhao Y Z, Su Y L, Hou X Y, et al. Directional sliding of water: biomimetic snake scale surfaces[J]. Opto-Electron Adv, 2021, 4(4): 210008. doi: 10.29026/oea.2021.210008

[25] Dusser B, Sagan Z, Soder H, et al. Controlled nanostructrures formation by ultra fast laser pulses for color marking[J]. Opt Express, 2010, 18(3): 2913−2924. doi: 10.1364/OE.18.002913

[26] 李昊, 胡德骄, 秦飞, 等. 原子层厚度超表面光场调控原理及应用[J]. 中国光学, 2021, 14(4): 851−866. doi: 10.37188/CO.2021-0069

Li H, Hu D J, Qin F, et al. Principle and application of metasurface optical field modulation of atomic layer thickness[J]. Chin Opt, 2021, 14(4): 851−866. doi: 10.37188/CO.2021-0069

[27] Lu Y D, Hu D J, Zhang M S, et al. Laser printing based on curvature-driven shape transition of aluminum nanodiscs[J]. Chin Opt Lett, 2021, 19(5): 053602. doi: 10.3788/COL202119.053602

[28] Li G Q, Li J W, Hu Y L, et al. Femtosecond laser color marking stainless steel surface with different wavelengths[J]. Appl Phys A, 2015, 118(4): 1189−1196. doi: 10.1007/s00339-014-8868-3

[29] Hu D J, Lu Y D, Cao Y Y, et al. Laser-splashed three-dimensional plasmonic nanovolcanoes for steganography in angular anisotropy[J]. ACS Nano, 2018, 12(9): 9233−9239. doi: 10.1021/acsnano.8b03964

[30] Wang W, Rosenmann D, Czaplewski D A, et al. Realizing structural color generation with aluminum plasmonic V-groove metasurfaces[J]. Opt Express, 2017, 25(17): 20454−20465. doi: 10.1364/OE.25.020454

[31] Zeng B B, Gao Y K, Bartoli F J. Ultrathin nanostructured metals for highly transmissive plasmonic subtractive color filters[J]. Sci Rep, 2013, 3: 2840. doi: 10.1038/srep02840

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: