-

摘要:

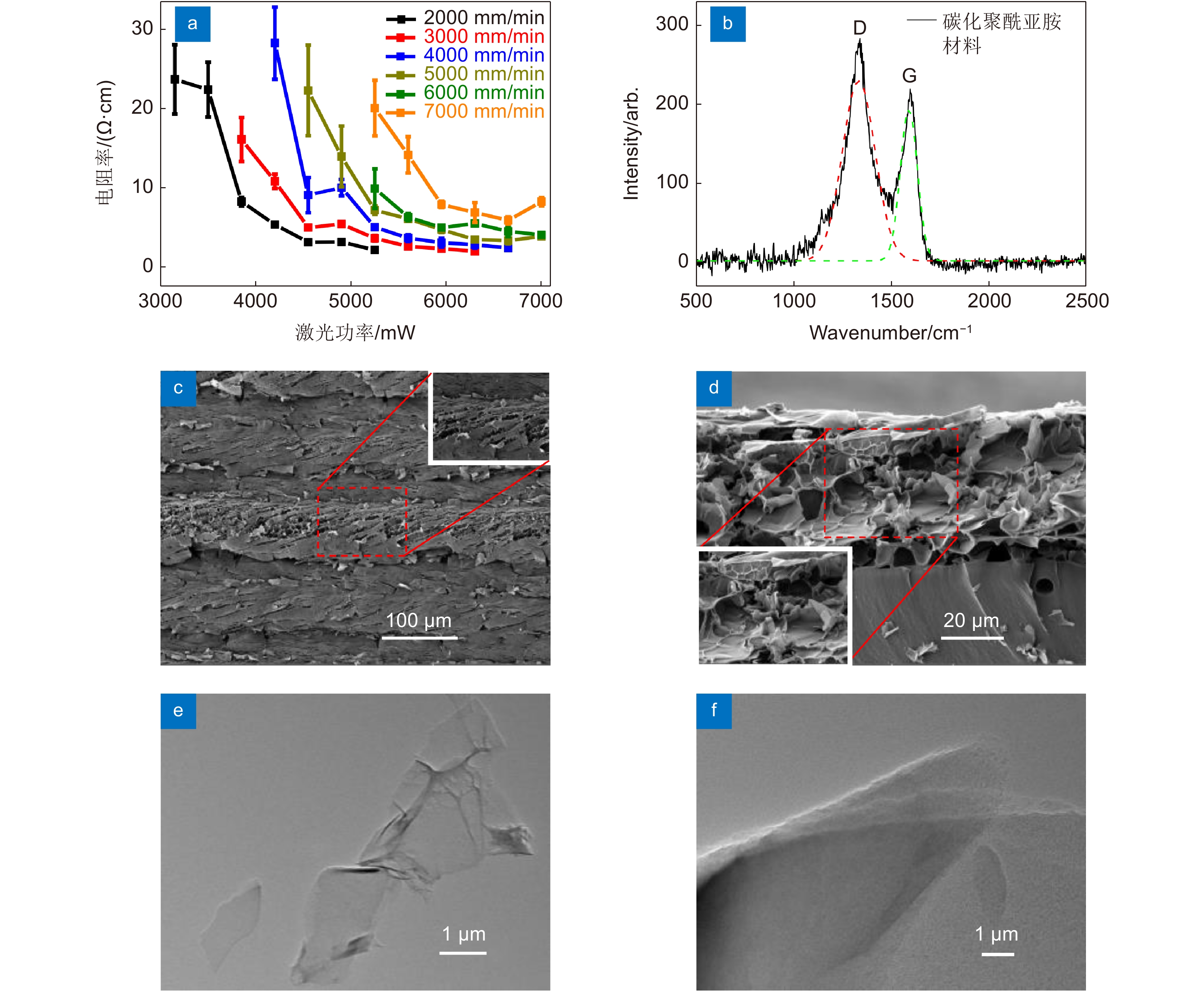

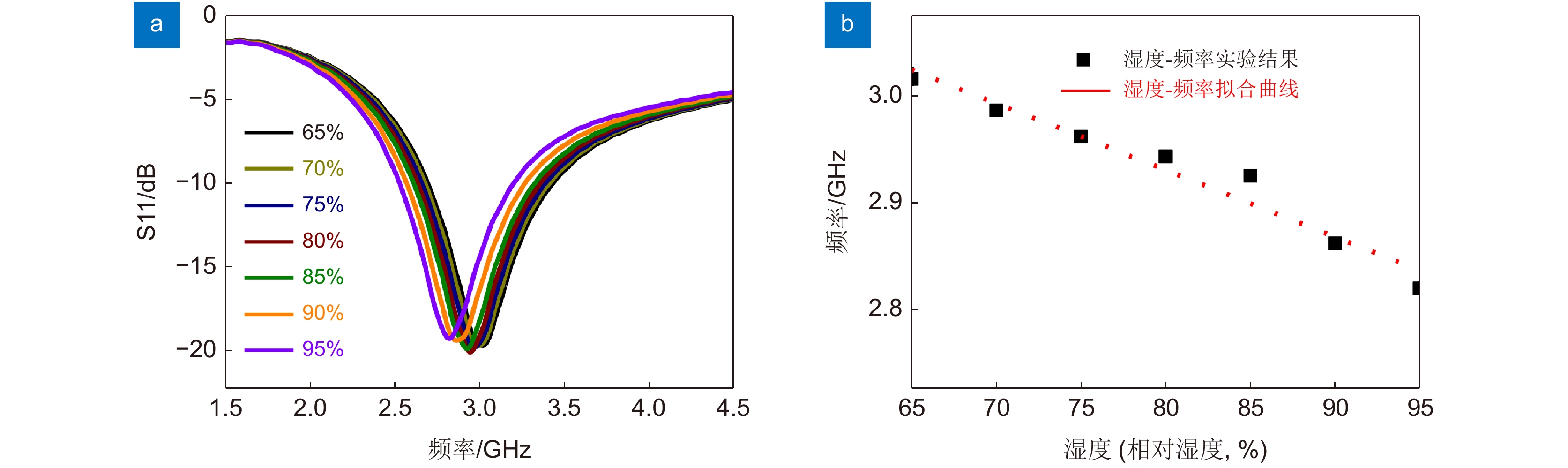

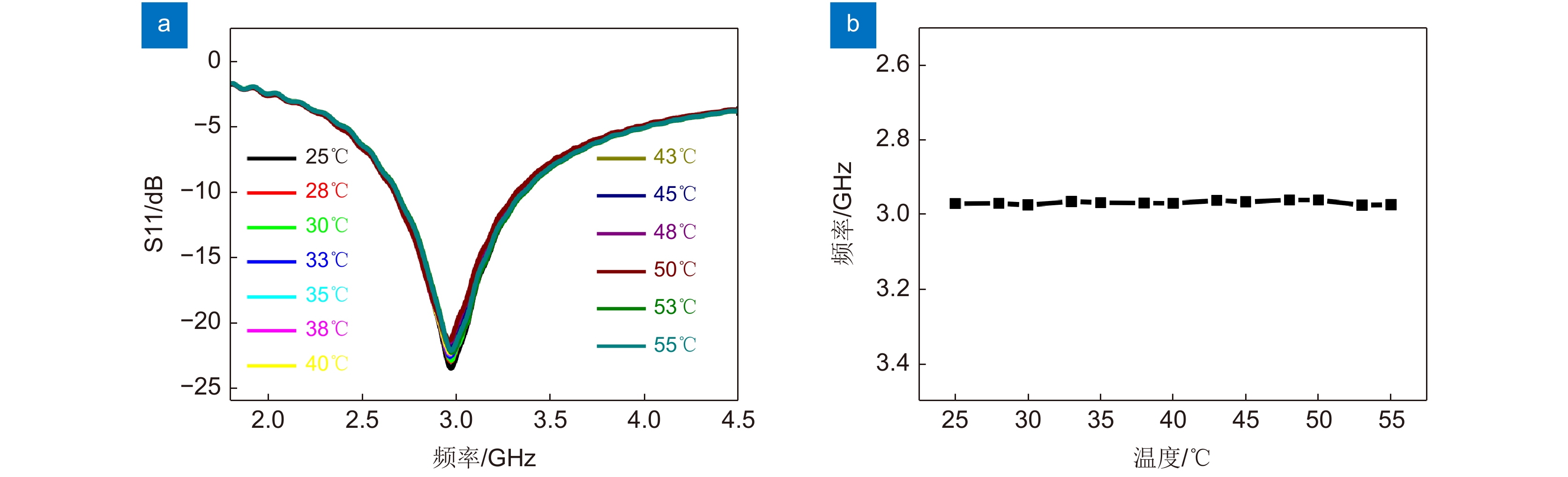

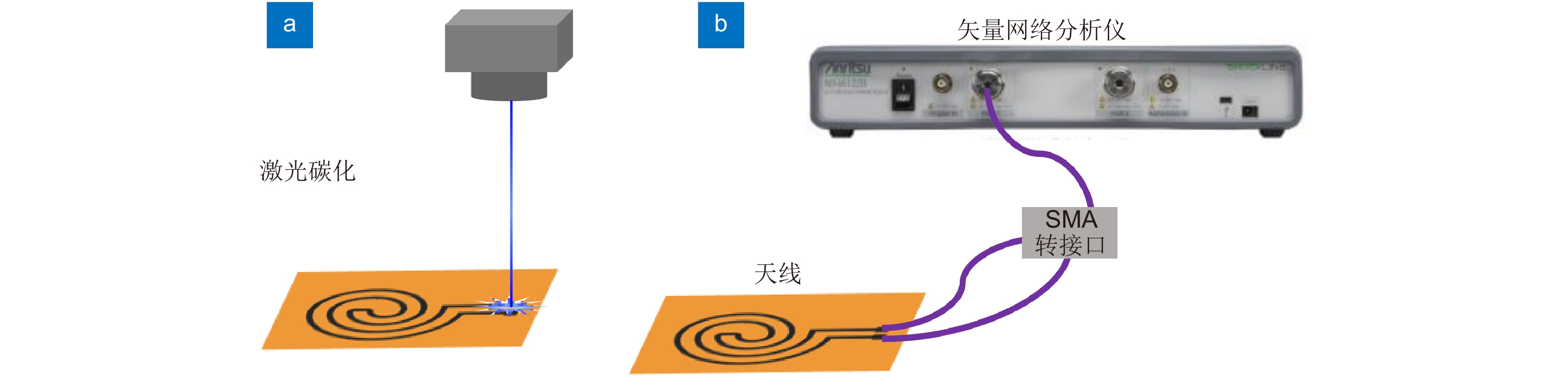

激光直写是一种高效、可规模化制备柔性电子器件的技术。本文采用激光直写技术在具有良好介电性能的聚酰亚胺薄膜上制备了一种可用于应变传感和湿度传感的柔性环形天线传感器。利用激光碳化聚酰亚胺获得的材料表面呈现多孔及堆叠片层碳结构,当施加于天线上的应变和环境湿度改变时,天线的谐振频率会发生规律变化,进而实现应变和湿度感知。制备的环形天线传感器的应变响应灵敏度为−8.943 kHz/με,湿度响应灵敏度为−6.45 MHz/RH%。采用激光直写技术制备的天线传感器可以广泛应用于结构健康监测等领域。

Abstract:Laser direct writing (LDW) is a highly efficient and scalable technology to fabricate flexible electronic devices. In this work, a type of flexible circle antenna sensor is developed by LDW on polyimide film with good dielectric property in response to strain and humidity. The carbonized polyimide has good conductivity and great adhesion to the substrate, which could be used as the active material for antenna. The carbonized polyimide presents porous stacked carbon structures and has the excellent electrical properties, which facilitate strain sensing and make the antenna have low loss, respectively. The resonance frequency of the LDW-generated antenna sensor changes with the variation of applied strain and environmental humidity. The sensitivities of LDW-generated antenna sensor response to applied strain and humidity are −8.943 kHz/με and −6.45 MHz/RH%, respectively. The flexible antenna sensor prepared by the LDW provides a new possibility for the application of structural health monitoring.

-

Key words:

- laser direct writing /

- antenna sensors /

- strain sensing /

- humidity sensing

-

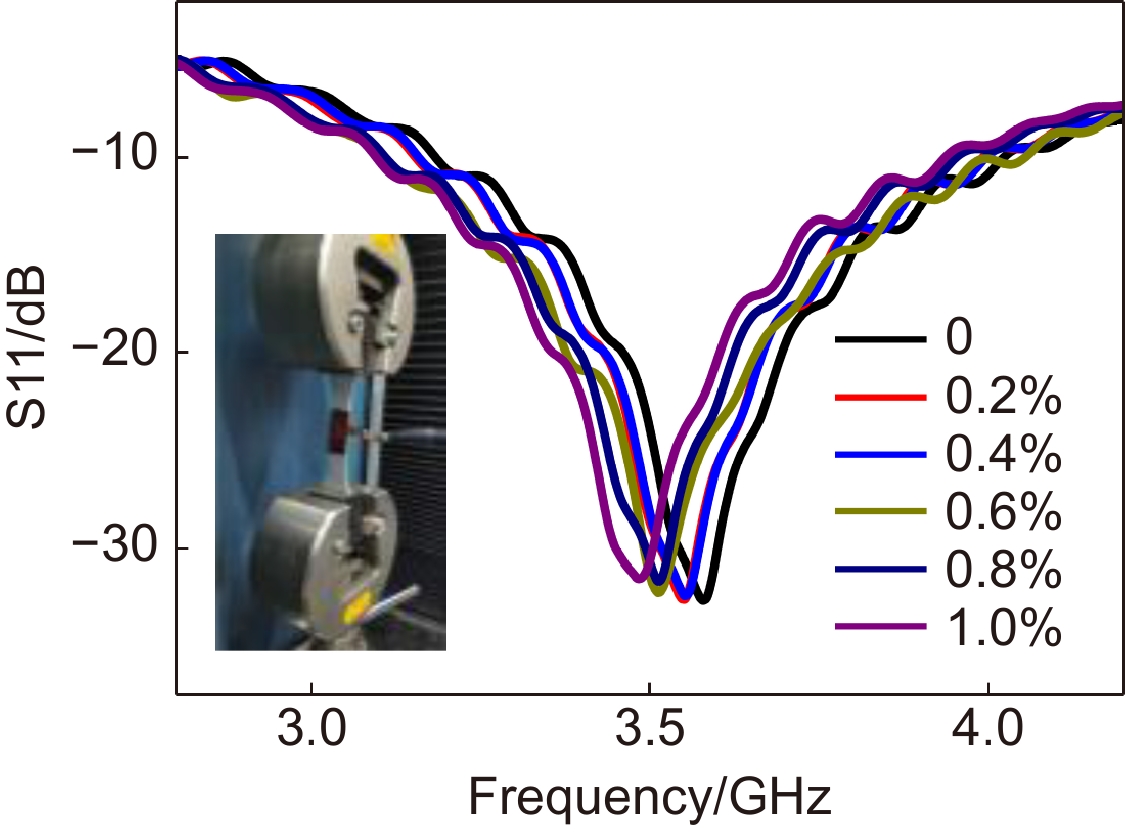

Overview: Laser direct writing (LDW) is a highly efficient and scalable method to prepare flexible electronic devices. The LDW can obtain the electronics devices by simple operation processes, which has been applied on energy storage devices, stress/strain sensors, gas sensors etc. During the LDW process, the laser works as a heat source to directly generate porous carbon on flexible substrates. In this study, LDW is developed to fabricate flexible antenna-based sensors on polyimide (PI) film. PI is a type of polymer with imide groups as its characteristic structure, which possesses excellent dielectric properties and is applied as the functional materials in many fields. The carbonized PI has good conductivity and great adhesion to the substrate, which could be used as the active material for antenna. Antenna is the component used to transmit and emit electromagnetic waves, and its performance is mainly determined by its structure and material. The variation of environmental conditions such as humidity and temperature as well as the applied strain will lead to the changes of the resonant frequency, reflection coefficient and other electromagnetic parameters of antenna. Currently, antenna-based sensors are typically fabricated by lithography or printing technology, which is either complicated or time-consuming. The resonance frequency of the LDW-generated antenna sensor changes upon the variation of applied strain and environmental humidity. The carbonized polyimide presents porous and stacked carbon structures. In addition, the electrical properties of carbonized PI are excellent with the resistivity of about 2.4 Ω•cm. The carbonized PI is a good candidate for antenna sensor because of the structures and the electrical properties, which facilitate strain sensing and make the antenna have low loss, respectively. The sensitivities of the devices in response to applied strain and humidity are −8.943 kHz/με and −6.45 MHz/RH%, respectively. In addition, the proposed antenna sensor can resist the temperature interference, and the performance of the antenna sensor hardly changes under different room temperatures from 25 ℃ to 55 ℃. Furthermore, in order to demonstrate the stability of the LDW-generated antenna sensor, we measured the performance of antenna sensor after 1 month and 4 months. The sensitivity and the resonance frequency of antenna sensor have almost no change. As for the repeatability of LDW-generated antenna, we repeated the fabrication processes under the same laser power and laser speed, the experiment results show that the antenna sensors have the excellent repeatability because the sensitivity and the resonance frequency of antenna sensors are almost identical. Overall, the flexible antenna sensor prepared by the LDW provides a new possibility for the application of structural health monitoring.

-

-

图 3 (a) 在不同应变下环形天线的性能曲线; (b) 应用于测量金属拉伸应变时天线传感器的性能曲线 ;(c) 天线传感器实验及模拟数据拟合曲线; (d) 环形天线的重复性及稳定性实验结果; (e) 同一样品不同时间的天线谐振频率及灵敏度;(f) 不同样品的天线谐振频率及灵敏度

Figure 3. (a) The curves of the refection coefficient (S11) for the circle antenna sensor at different applied strain; (b) The schematic diagram of antenna sensor for measuring the strain of metal sample and the curves of the refection coefficient (S11); (c) The fitting curves of circle antenna sensor by experiments and simulation; (d) The curves of the refection coefficient (S11) for the circle antenna sensor at different times and the curves of the refection coefficient (S11) for different circle antenna sensors; (e) The resonance frequencies and sensitivities of the antenna sensor at different times; (f) The resonance frequencies and sensitivities of different samples

-

[1] Lin J, Peng Z W, Liu Y Y, et al. Laser-induced porous graphene films from commercial polymers[J]. Nat Commun, 2014, 5: 5714. doi: 10.1038/ncomms6714

[2] Cai J G, Lv C, Watanabe A. Cost-effective fabrication of high-performance flexible all-solid-state carbon micro-supercapacitors by blue-violet laser direct writing and further surface treatment[J]. J Mater Chem A, 2016, 4(5): 1671−1679. doi: 10.1039/C5TA09450J

[3] In J B, Hsia B, Yoo J H, et al. Facile fabrication of flexible all solid-state micro-supercapacitor by direct laser writing of porous carbon in polyimide[J]. Carbon, 2015, 83: 144−151. doi: 10.1016/j.carbon.2014.11.017

[4] Li L, Zhang J, Peng Z, et al. High-Performance Pseudocapacitive microsupercapacitors from laser-Induced graphene[J]. Adv Mater, 2016, 28(5): 838−845. doi: 10.1002/adma.201503333

[5] Peng Z W, Lin J, Ye R Q, et al. Flexible and stackable laser-Induced graphene supercapacitors[J]. ACS Appl Mater Interfaces, 2015, 7(5): 3414−3419. doi: 10.1021/am509065d

[6] Gao Y, Li Q, Wu R Y, et al. Laser direct writing of ultrahigh sensitive SiC-based strain sensor arrays on elastomer toward electronic skins[J]. Adv Funct Mater, 2019, 29(2): 1806786. doi: 10.1002/adfm.201806786

[7] Luo S D, Hoang P T, Liu T. Direct laser writing for creating porous graphitic structures and their use for flexible and highly sensitive sensor and sensor arrays[J]. Carbon, 2016, 96: 522−531. doi: 10.1016/j.carbon.2015.09.076

[8] Rahimi R, Ochoa M, Yu W Y, et al. Highly stretchable and sensitive unidirectional strain sensor via laser carbonization[J]. ACS Appl Mater Interfaces, 2015, 7(8): 4463−4470. doi: 10.1021/am509087u

[9] Watanabe A, Cai J G. On demand process based on laser direct writing and the sensor application[J]. J Photopol Sci Technol, 2017, 30(3): 341−343. doi: 10.2494/photopolymer.30.341

[10] Cai Z X, Li X Y, Zeng X Y. Direct fabrication of SnO2-based thick film gas sensor using Micropen direct writing and laser microcladding[J]. Sens Actuators B Chem, 2009, 137(1): 340−344. doi: 10.1016/j.snb.2009.01.007

[11] Guan Y Z, Li C H, Cheng X Y, et al. Highly sensitive mixed-potential-type NO2 sensor with YSZ processed using femtosecond laser direct writing technology[J]. Sens Actuators B Chem, 2014, 198: 110−113. doi: 10.1016/j.snb.2014.02.098

[12] Wu D Z, Peng Q Q, Wu S, et al. A simple graphene NH3 gas sensor via laser direct writing[J]. Sensors, 2018, 18(12): 4405. doi: 10.3390/s18124405

[13] Faraj M G, Pakhuruddin M Z, Taboada P. Structural and optical properties of cadmium sulfide thin films on flexible polymer substrates by chemical spray pyrolysis technique[J]. J Mater Sci Mater Electron, 2017, 28(9): 6628−6634. doi: 10.1007/s10854-017-6353-4

[14] Tiwari A, Gupta M K, Pandey K N, et al. Encapsulation of air-filled poly(dimethylsiloxane) microballoons in polyimide as a polymeric lowεdielectric[J]. Polym Int, 2004, 53(11): 1744−1751. doi: 10.1002/pi.1567

[15] Vygodskii Y S, Sakharova A A, Matieva A M. Polymers based on fluoro (meth) acrylates and a fluorinated polymide[J]. Vysokomol Soedin Ser Ser B, 2000, 42(3): 538−541.

[16] Liaw D J, Wang K L, Huang Y C, et al. Advanced polyimide materials: Syntheses, physical properties and applications[J]. Prog Polym Sci, 2012, 37(7): 907−974.

[17] Smith G. New materials improve P. C. board windings design for planar transformers[J]. PCIM Power Electron Syst, 2001, 27(2): 54−56.

[18] Kim B S, Bae S H, Park Y H, et al. Polyimide/Carbon nanotubes composite films: A potential for FPCB[C]//International Conference on Nanoscience and Nanotechnology, 2006.

[19] Li J. The effect of surface modification with nitric acid on the mechanical and tribological properties of carbon fiber-reinforced thermoplastic polyimide composite[J]. Surf Interface Anal, 2009, 41(9): 759−763. doi: 10.1002/sia.3089

[20] Singh P, Pramanik D, Singh R V. Finite element analysis of Pilot’s helmet design using composite materials for military aircraft[J]. J Aerosp Technol Manage, 2016, 8(1): 33−39. doi: 10.5028/jatm.v8i1.559

[21] Xia X, Yin J H, Li G Y, et al. Study on the corona resistant property of polymide/TiO2@SiO2 films[C]//2013 8th International Forum on Strategic Technology (IFOST), 2013: 101–104.

[22] Manzari S, Musa T, Randazzo M, et al. A passive temperature radio-sensor for concrete maturation monitoring[C]//2014 IEEE RFID Technology and Applications Conference (RFID-TA), 2014: 121–126.

[23] Borgese M, Dicandia F A, Costa F, et al. An inkjet printed chipless RFID sensor for wireless humidity monitoring[J]. IEEE Sens J, 2017, 17(15): 4699−4707. doi: 10.1109/JSEN.2017.2712190

[24] Pursula P, Marttila I, Nummila K, et al. High frequency and ultrahigh frequency radio frequency identification passive sensor transponders for humidity and temperature measurement within building structures[J]. IEEE Trans Instrum Meas, 2013, 62(9): 2559−2566. doi: 10.1109/TIM.2013.2258763

[25] Potyrailo R A, Surman C. A passive radio-frequency identification (RFID) gas sensor with self-correction against fluctuations of ambient temperature[J]. Sens Actuators B Chem, 2013, 185: 587−593. doi: 10.1016/j.snb.2013.04.107

[26] Occhiuzzi C, Paggi C, Marrocco G. Passive RFID strain-sensor based on meander-line antennas[J]. IEEE Trans Antennas Propag, 2011, 59(12): 4836−4840. doi: 10.1109/TAP.2011.2165517

[27] Song L N, Myers A C, Adams J J, et al. Stretchable and reversibly deformable radio frequency antennas based on silver nanowires[J]. ACS Appl Mater Interfaces, 2014, 6(6): 4248−4253. doi: 10.1021/am405972e

[28] Tata U, Huang H, Carter R L, et al. Exploiting a patch antenna for strain measurements[J]. Meas Sci Technol, 2008, 20(1): 015201.

[29] Zhang Y F, Huo Z H, Wang X D, et al. High precision epidermal radio frequency antenna via nanofiber network for wireless stretchable multifunction electronics[J]. Nat Commun, 2020, 11(1): 5629. doi: 10.1038/s41467-020-19367-8

[30] Wang C, Wang C, Wan G C, et al. RFID antenna sensor for quantitatively monitoring surface crack growth[C]//2019 IEEE International Conference on Computational Electromagnetics (ICCEM), 2019: 1–3.

[31] Yi X H, Wu T, Wang Y, et al. Sensitivity modeling of an RFID-Based strain-sensing antenna with dielectric constant change[J]. IEEE Sens J, 2015, 15(11): 6147−6155. doi: 10.1109/JSEN.2015.2453947

[32] Amin E M, Bhuiyan S, Karmakar N, et al. A novel EM barcode for humidity sensing[C]//2013 IEEE International Conference on RFID (RFID), 2013: 82–87.

[33] Jun J, Oh J, Shin D H, et al. Wireless, Room temperature volatile organic compound sensor based on polypyrrole nanoparticle immobilized ultrahigh frequency radio frequency identification Tag[J]. ACS Appl Mater Interfaces, 2016, 8(48): 33139−33147. doi: 10.1021/acsami.6b08344

[34] Sadezky A, Muckenhuber H, Grothe H, et al. Raman microspectroscopy of soot and related carbonaceous materials: Spectral analysis and structural information[J]. Carbon, 2005, 43(8): 1731−1742. doi: 10.1016/j.carbon.2005.02.018

[35] Wang J, Hernandez Y, Lotya M, et al. Broadband nonlinear optical response of graphene dispersions[J]. Adv Mater, 2009, 21(23): 2430−2435. doi: 10.1002/adma.200803616

[36] Lee C, Wei X D, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science, 2008, 321(5887): 385−388. doi: 10.1126/science.1157996

[37] Chae H K, Siberio-Pérez D Y, Kim J, et al. A route to high surface area, porosity and inclusion of large molecules in crystals[J]. Nature, 2004, 427(6974): 523−527. doi: 10.1038/nature02311

[38] You R, Liu Y Q, Hao Y L, et al. Laser fabrication of graphene-based flexible electronics[J]. Adv Mater, 2020, 32(15): 1901981. doi: 10.1002/adma.201901981

[39] Schedin F, Geim A K, Morozov S V, et al. Detection of individual gas molecules adsorbed on graphene[J]. Nat Mater, 2007, 6(9): 652−655. doi: 10.1038/nmat1967

[40] Guo L, Jiang H B, Shao R Q, et al. Two-beam-laser interference mediated reduction, patterning and nanostructuring of graphene oxide for the production of a flexible humidity sensing device[J]. Carbon, 2012, 50(4): 1667−1673. doi: 10.1016/j.carbon.2011.12.011

[41] Muley S V, Ravindra N M. Thermoelectric properties of pristine and doped graphene nanosheets and graphene nanoribbons: Part I[J]. JOM, 2016, 68(6): 1653−1659. doi: 10.1007/s11837-016-1871-8

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: