Study on multi-layered CFRP patch bonding joint based on laser 3D engraving technology

-

摘要:

在航空飞行器的碳纤维复合材料(CFRP)结构件损伤修复时,挖补胶接技术是获得高性能的CFRP层合板接头的理想工艺。本文提出一种CFRP层合板的多梯层挖补胶接接头设计策略,设计了挖补胶接接头阴阳膜构建和分层切片激光三维雕刻扫描工艺代码生成算法,探索了CFRP梯层界面的激光烧蚀成型工艺规律和粘结性能改善机理,验证了胶接接头拉伸强度和冲击韧性的有效提升,接头失效方式符合所设计的粘接剂失效,提供了一种高自动化、柔性化的航空、航天、交通等领域CFRP构件的高性能挖补胶接接头设计和制备方法。

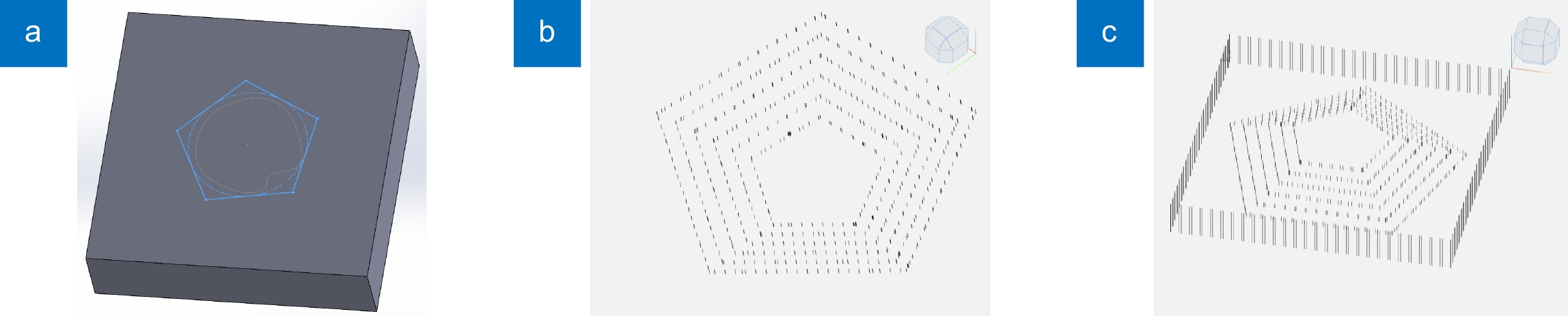

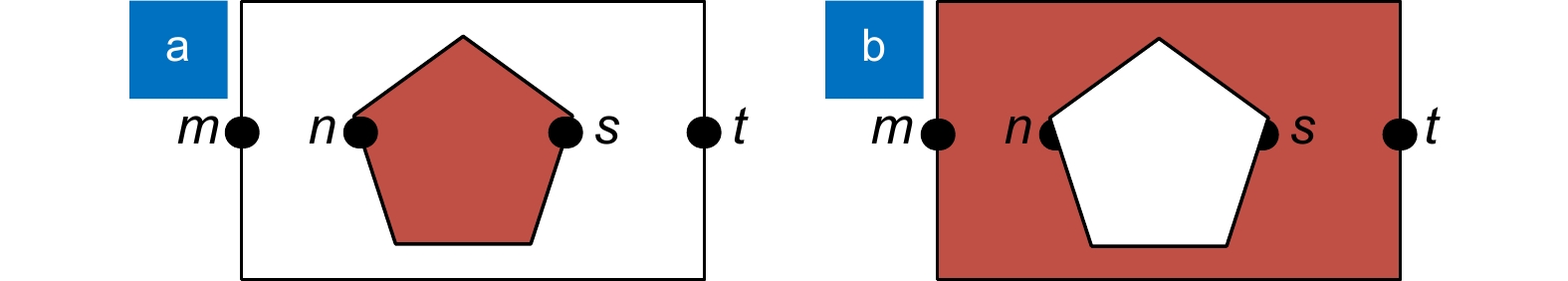

Abstract:To repair structural damage of carbon fiber reinforced polymers (CFRP) for aircrafts, the patch bonding technology is an ideal process to obtain a high-performance CFRP laminate joint. This study proposed a multi-ladder patch bonding adhesive joint design for CFRP laminates. The Yin and Yang film of patch bonding joint was designed and constructed. The code generation algorithms for the layered slice laser 3D engraving and scanning process were explored. The laser ablation processes of CFRP ladder layer interface and the bonding mechanism were investigated, which verified that the tensile strength and impact toughness of the adhesive joint were effectively improved. The failure mode of the joint is consistent with the designed adhesive failure. This study provides a design and fabrication technology to realize high-performance patch bonding joints for CFRP components, which can be applied in aviation, aerospace, and transportation etc.

-

Key words:

- patch bonding /

- the mold of yin and yang /

- laser ablation /

- slicing /

- tensile strength

-

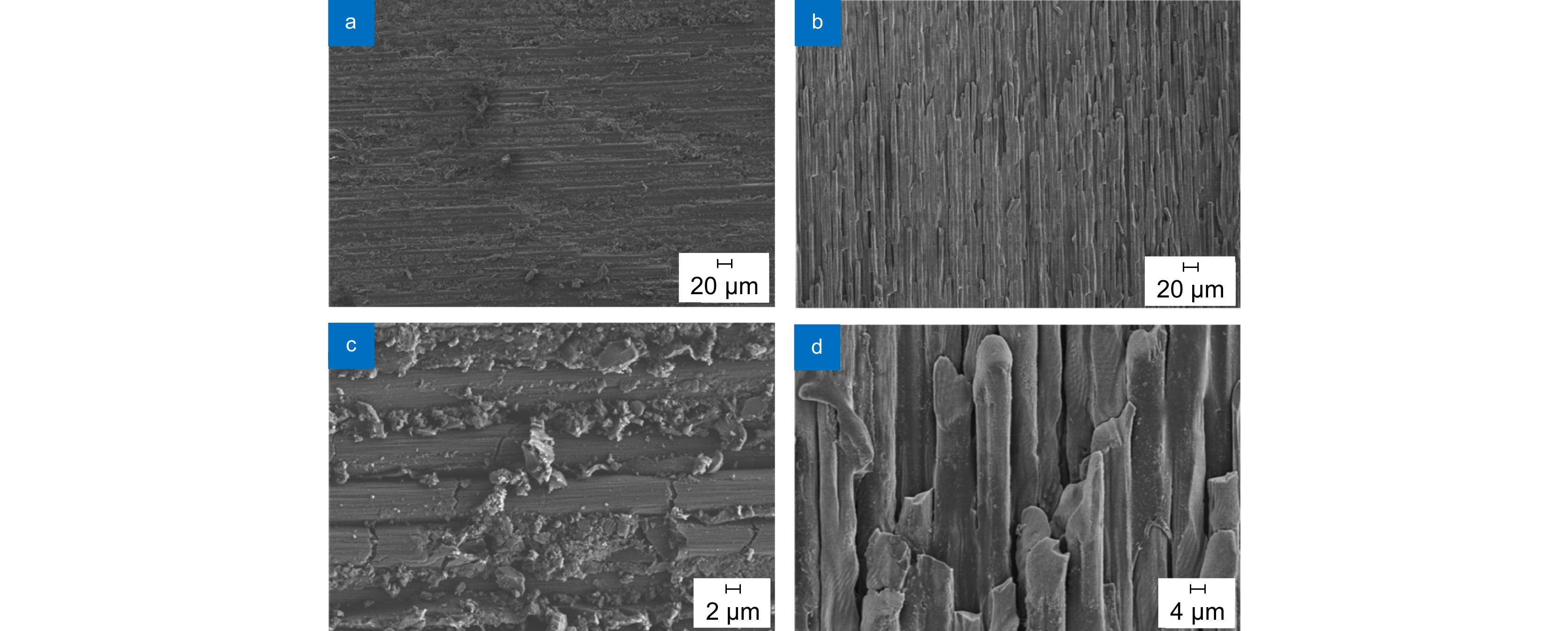

Overview: Carbon fiber reinforced polymers (CFRP) are widely used in high-end manufacturing fields such as aircraft skin, high-speed rail body and hull due to their high specific modulus and strength, low thermal expansion coefficient and fatigue resistance. CFRP laminates are made of unidirectional carbon fiber or braided fabric and resin matrix by lamination and hot pressing. The mechanical properties of CFRP laminates have typical anisotropic characteristics. This also places new demands on the maintenance of CFRP parts. The traditional fastener (bolt or rivet) connection repairing has the defect of hole edge layer fracture caused by hole making and mechanical compression force, which greatly affects the failure bearing capacity of the joint. To carry out damage repair of CFRP parts by patch bonding, high structural strength and good aerodynamic profile can be achieved, which is an ideal process to obtain high-performance repairing joints. Previous investigations on surface treatment have established that laser ablation, as an advanced processing method to remove the contamination impurities and change the structure and chemical properties of the surface, is regarded as the best choice for pretreatment of bonding interface. Nevertheless, how to obtain a high-performance patch bonding joint easily and quickly still faces challenges.

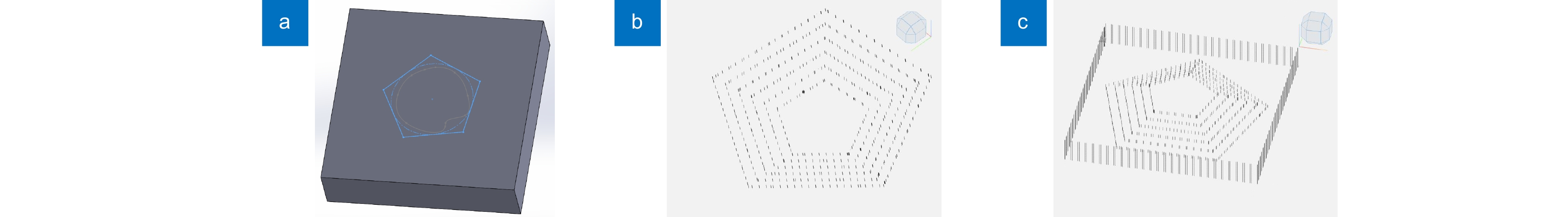

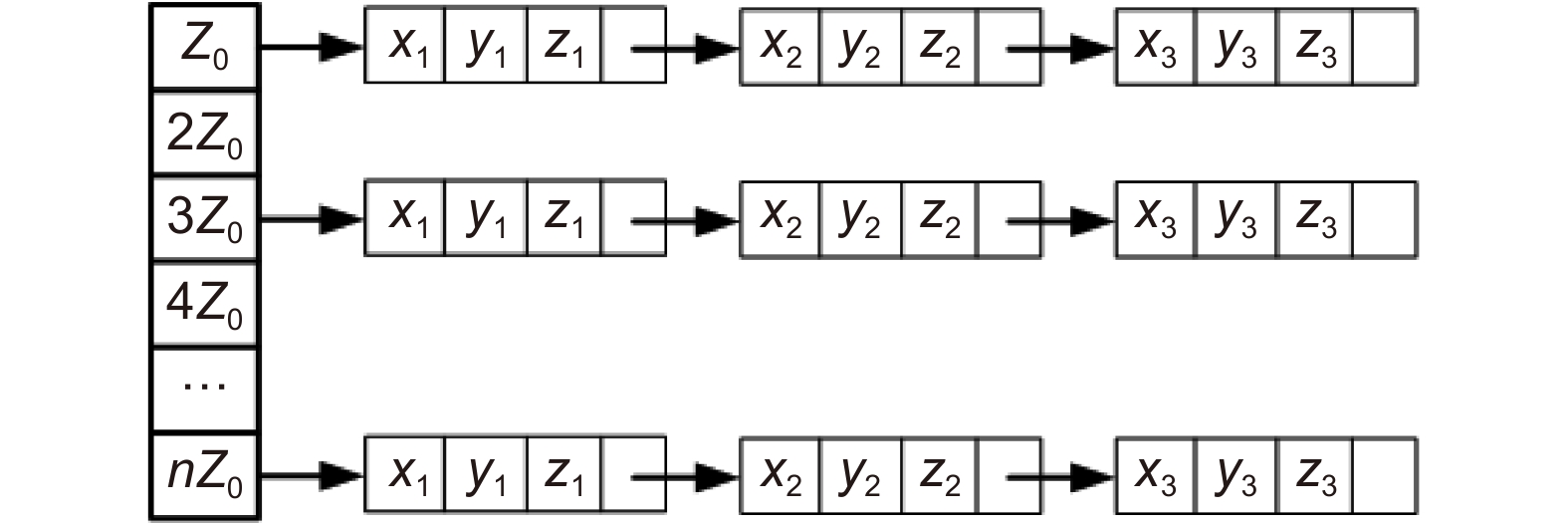

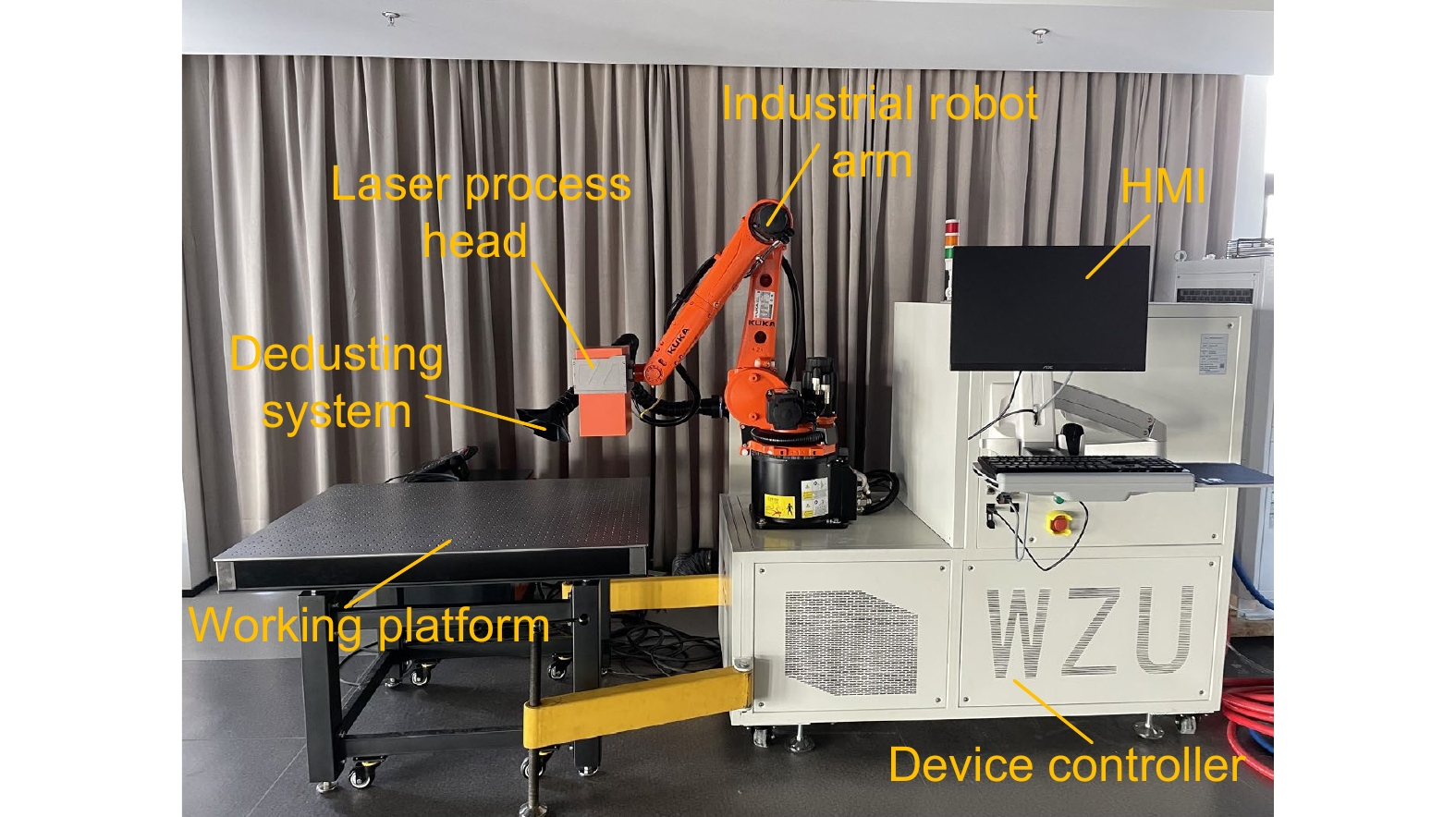

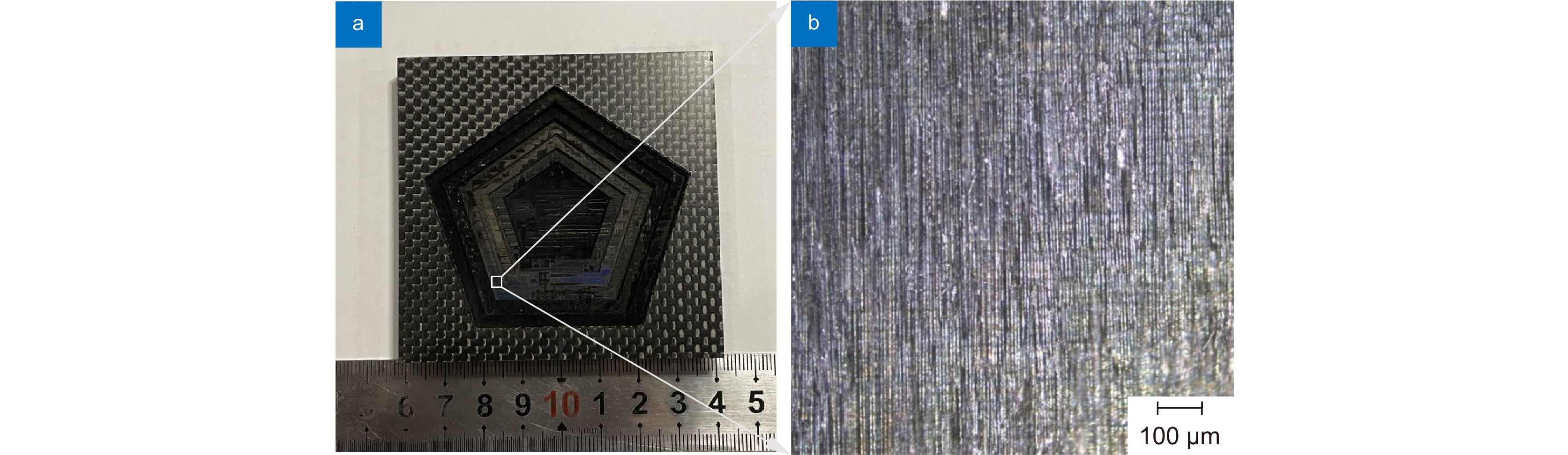

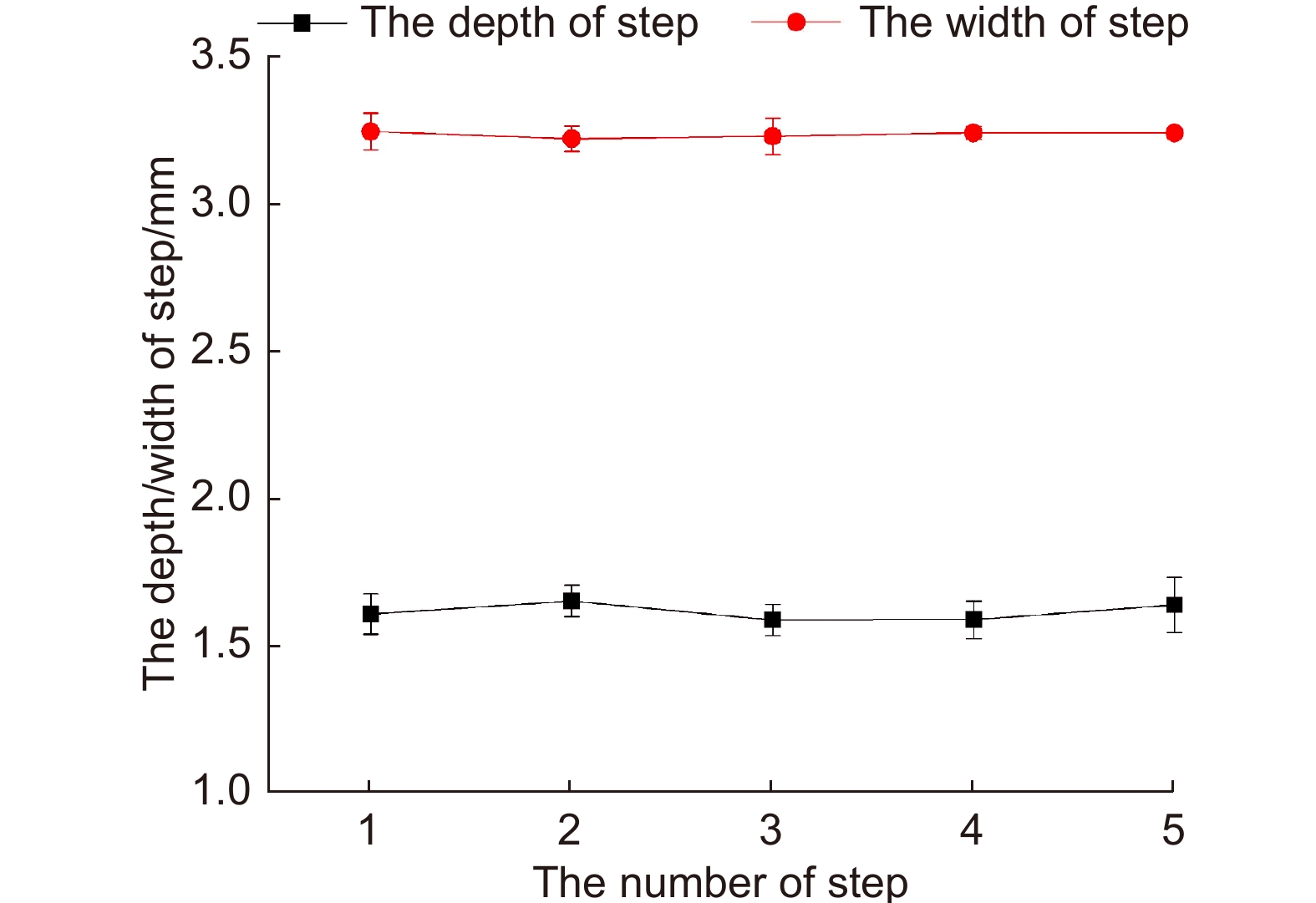

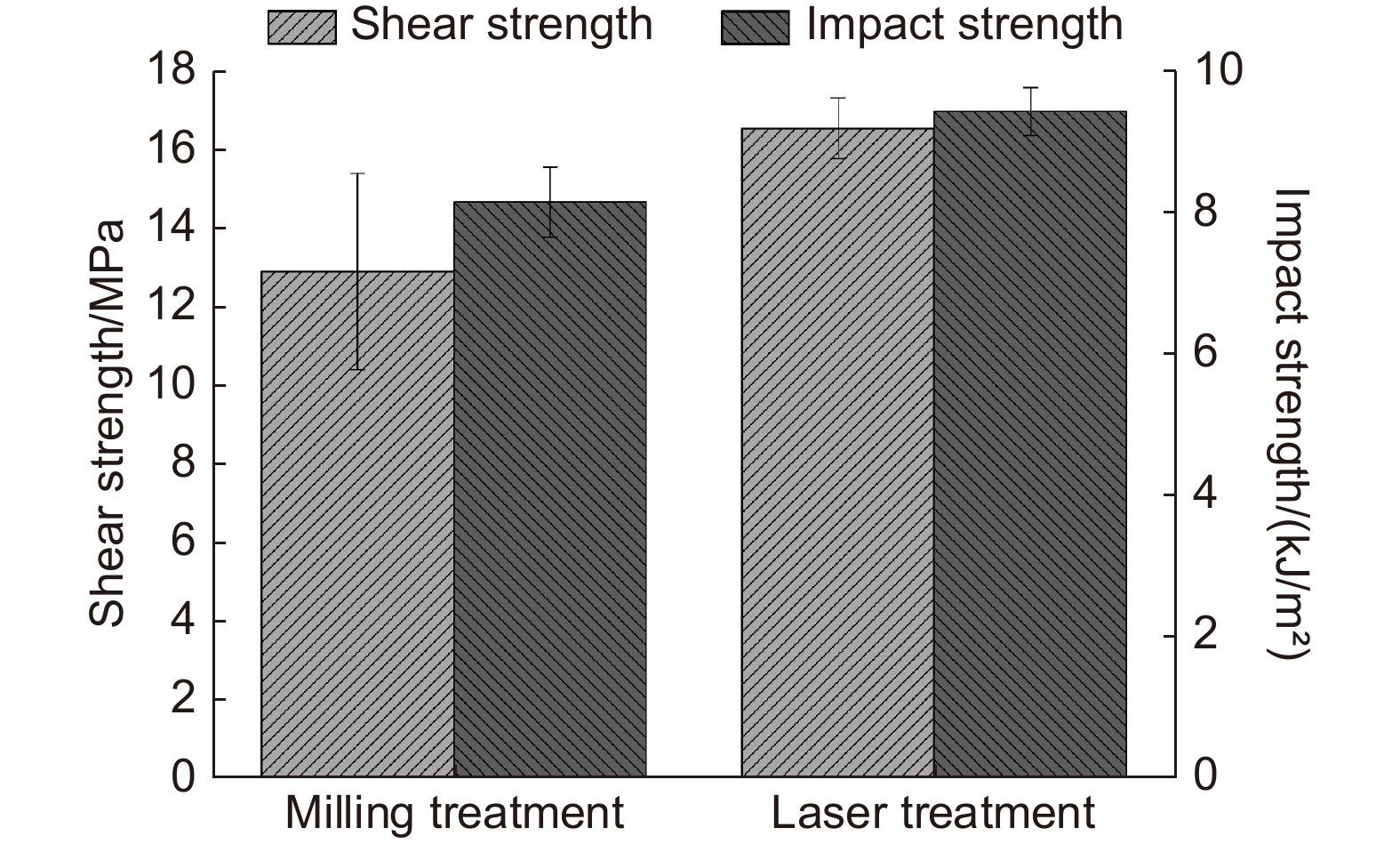

In this paper, a "6+2" axis general-purpose robot laser processing system is built for process validation and the design strategy for multi-ladder patch bonding joints of CFRP laminates is proposed. The construction algorithm of yin and yang molds of patch bonding joints based on automatic slicing of surface profile and the partition splicing laser galvanometer scanning process algorithm are designed. Multi-ladder bonding interface of CFRP parts by laser ablation and the bonding mechanism are investigated by experiments and performance tests. The results of these investigations indicate that surface quality of CFRP parts with laser treatment is good, and the induced surface microstructure greatly increases the roughness and surface area. Furthermore, the carbon fibers in the matrix material have less damage, and the bonding strength is improved. The tensile shear strength and impact toughness of the bonding joints are improved to 16.5 Mpa and 9.4 kJ/m2, which are increased by 28% and 15%, respectively, and the failure mode of the joints is cohesive failure. This study provides a design and fabrication technology to realize high-performance patch bonding joints for CFRP components, which can be applied in aviation, aerospace, and transportation etc.ss.

-

-

表 1 自定义的通用化激光加工代码及其解释

Table 1. Customized laser processing code and its description

字符 功能解释 LDS 激光器开关指令:后接数字00或01 LDS 01:激光器状态为开;LDS 00:激光器状态为关 LDPR 激光器功率指令:后接0~100% LDPR 80:激光器当前功率为80% LDPW 激光器脉冲宽度 LDPW 20:激光器脉冲宽度为20 μs LDF 激光器重复频率 LDF 200:激光器重复频率为200 kHz LDOD 激光器开光延时 LDOD 35:激光器开光延时为35 ms LDFD 激光器关闭延时 LDFD 30:激光器关闭延时为30 ms G0 控制振镜扫描指令:后接数字0或1

G00 X10.00Y15.00 F1000 振镜从当前点跳转到点(10,15),跳转速度为1000 mm/s

G01 X10.00Y15.00 F1000 振镜从当前点标刻到点(10,15),标刻速度为1000 mm/sALIGN 驱动机器人手臂执行激光加工头与待维修部位区域对齐 FOCUS 驱动机器人手臂执行激光加工头与待维修部位区域对焦 -

[1] Soutis C. Fibre reinforced composites in aircraft construction[J]. Progr Aerosp Sci, 2005, 41(2): 143−151. doi: 10.1016/j.paerosci.2005.02.004

[2] Malkapuram R, Kumar V, Negi Y S. Recent development in natural fiber reinforced polypropylene composites[J]. J Reinf Plast Compos, 2009, 28(10): 1169−1189. doi: 10.1177/0731684407087759

[3] Xu L Y, Lu J R, Li K M, et al. Experimental study of CFRP laser surface modification and bonding characteristics of CFRP/Al6061 heterogeneous joints[J]. Compos Struct, 2022, 283: 115030. doi: 10.1016/j.compstruct.2021.115030

[4] 蔡菊生. 先进复合材料在航空航天领域的应用[J]. 合成材料老化与应用, 2018, 47(6): 94−97.

Cai J S. Application of advanced composite materials in aerospace[J]. Synth Mater Ag Appl, 2018, 47(6): 94−97.

[5] 包建文, 蒋诗才, 张代军. 航空碳纤维树脂基复合材料的发展现状和趋势[J]. 科技导报, 2018, 36(19): 52−63.

Bao J W, Jiang S C, Zhang D J. Current status and trends of aeronautical resin matrix composites reinforced by carbon fiber[J]. Sci Technol Rev, 2018, 36(19): 52−63.

[6] Katnam K B, Da Silva L F M, Young T M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities[J]. Progr Aerosp Sci, 2013, 61: 26−42. doi: 10.1016/j.paerosci.2013.03.003

[7] Baker A, Wang J. Proposed through-life management approaches for adhesively bonded repair of primary structures[J]. Int J Adhes Adhes, 2018, 87: 151−163. doi: 10.1016/j.ijadhadh.2018.10.001

[8] 徐绯, 刘斌, 李文英, 等. 复合材料修理技术研究进展[J]. 玻璃钢/复合材料, 2014, 8: 105−112. doi: 10.3969/j.issn.1003-0999.2014.08.021

Xu F, Liu B, Li W Y, et al. Research progress of composite repair technique[J]. Fiber Reinf Plast Compos, 2014, 8: 105−112. doi: 10.3969/j.issn.1003-0999.2014.08.021

[9] 陈绍杰. 复合材料结构修理指南[M]. 北京: 航空工业出版社, 2001: 39–44.

[10] Harder S, Schmutzler H, Hergoss P, et al. Effect of infrared laser surface treatment on the morphology and adhesive properties of scarfed CFRP surfaces[J]. Compos A Appl Sci Manuf, 2019, 121: 299−307. doi: 10.1016/j.compositesa.2019.02.025

[11] Zhao Y Z, Su Y L, Hou X Y, et al. Directional sliding of water: biomimetic snake scale surfaces[J]. Opto-Electron Adv, 2021, 4(4): 210008. doi: 10.29026/oea.2021.210008

[12] Papanikolaou A, Tserevelakis G J, Melessanaki K, et al. Development of a hybrid photoacoustic and optical monitoring system for the study of laser ablation processes upon the removal of encrustation from stonework[J]. Opto-Electron Adv, 2020, 3(2): 190037. doi: 10.29026/oea.2020.190037

[13] Fischer F, Kreling S, Jäschke P, et al. Laser surface pre-treatment of CFRP for adhesive bonding in consideration of the absorption behavior[J]. J Adhes, 2012, 88(4-6): 350−363. doi: 10.1080/00218464.2012.660042

[14] 杨文锋, 李俊磊, 曹宇, 等. 激光处理对民机复合材料胶接维修母体表面自由能的影响研究[J]. 硅酸盐通报, 2015, 34(S1): 298−302.

Yang W F, Li J L, Cao Y, et al. Effect of laser processing treatment on bonding repair parent surface free energy of civil aircraft composites[J]. Bull Chin Ceram Soc, 2015, 34(S1): 298−302.

[15] 占小红, 范喜祥, 高川云, 等. 脉冲激光清洗碳纤维增强树脂基复合材料表面研究[J]. 航空制造技术, 2017(20): 38−42. doi: 10.16080/j.issn1671-833x.2017.20.038

Zhan X H, Fan X X, Gao C Y, et al. Study on the surface of carbon fiber reinforced epoxy resin composites for pulse laser cleaning technology[J]. Aeronaut Manuf Technol, 2017(20): 38−42. doi: 10.16080/j.issn1671-833x.2017.20.038

[16] Oliveira V, Sharma S P, De Moura M F S F, et al. Surface treatment of CFRP composites using femtosecond laser radiation[J]. Opt Lasers Eng, 2017, 94: 37−43. doi: 10.1016/j.optlaseng.2017.02.011

[17] 熊文骏. 向形心收缩的变距偏置填充算法[D]. 武汉: 华中科技大学, 2007: 19–34.

Xiong W J. The Distance changing filing algorithm based on center retracting[D]. Wuhan: Huazhong University of Science & Technology, 2007: 19–34.

[18] 曹宇, 魏鑫磊, 李春林, 等. 基于曲面工件外形的表面阵列微结构激光刻蚀制备方法: 104741794B[P]. 2016-05-25.

[19] Nattapat M, Marimuthu S, Kamara A M, et al. Laser surface modification of carbon fiber reinforced composites[J]. Mater Manuf Processes, 2015, 30(12): 1450−1456. doi: 10.1080/10426914.2015.1019097

[20] Herzog D, Jaeschke P, Meier O, et al. Investigations on the thermal effect caused by laser cutting with respect to static strength of CFRP[J]. Int J Mach Tools Manuf, 2008, 48(12-13): 1464−1473. doi: 10.1016/j.ijmachtools.2008.04.007

[21] Encinas N, Oakley B R, Belcher M A, et al. Surface modification of aircraft used composites for adhesive bonding[J]. Int J Adhes Adhes, 2014, 50: 157−163. doi: 10.1016/j.ijadhadh.2014.01.004

[22] Zaldivar R J, Kim H I, Steckel G L, et al. The effect of abrasion surface treatment on the bonding behavior of various carbon fiber-reinforced composites[J]. J Adhes Sci Technol, 2012, 26(10-11): 1573−1590. doi: 10.1163/156856111X618425

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: