Design of flexure support of space compact reflector subassembly and dynamic analysis

-

摘要:

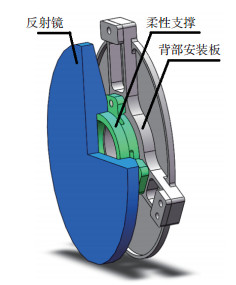

针对某星载激光通信中光电跟瞄系统的反射镜组件进行研究,对比了三种柔性支撑方案,结合空间载荷实际应用情景综合评估结构的刚度优势和面形精度。分析结果表明,颈口侧壁开槽的柔性支撑方案在重力和温度变化影响下的面形精度(RMS)可达2.05 nm和8.88 nm,基频模态为926.1 Hz,在保证面形精度的柔性要求与高刚度抵御振动损坏的平衡中,这种柔性设计方案最为合理。进一步完成了柔性支撑结构的参数优化设计并进行了动力学分析,频率响应下应力最大值为96 MPa,小于材料的抗拉强度极限;随机振动分析结果表明,反射镜加速度响应均方根为11.14 g RMS,并满足3σ准则。文章最后通过0.2 g正弦扫频试验,验证了有限元模态分析相对误差为2.4%。实验结果表明,分析结果基本准确可靠,柔性环节设计可靠,满足使用要求。

Abstract:

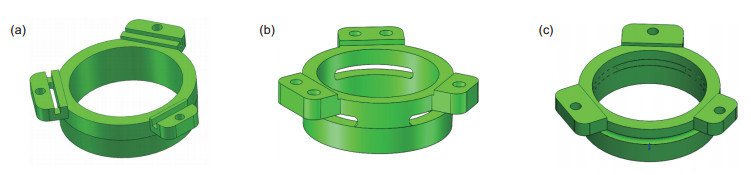

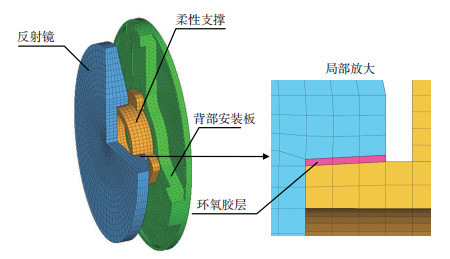

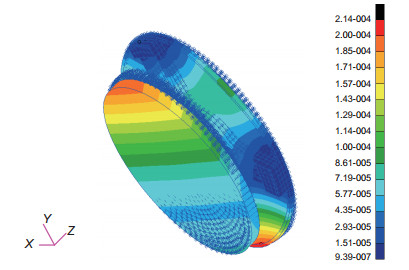

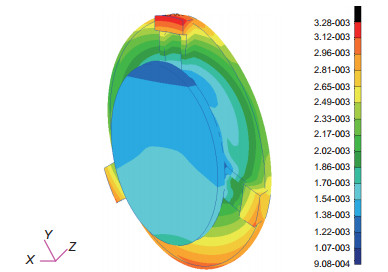

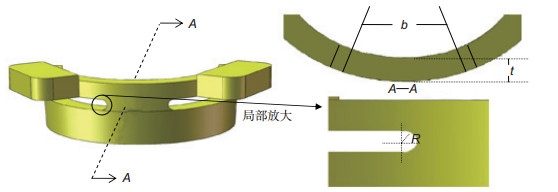

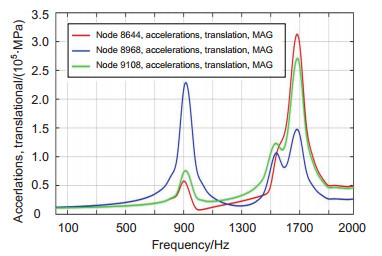

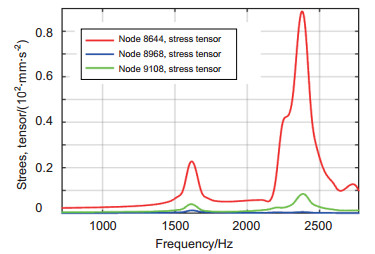

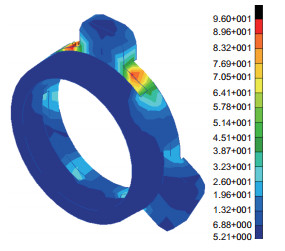

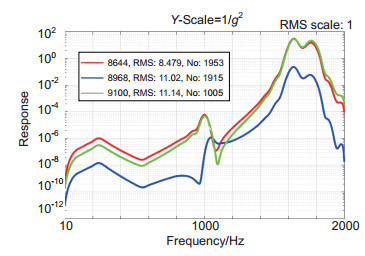

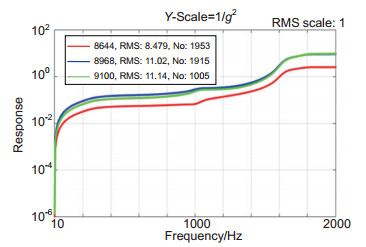

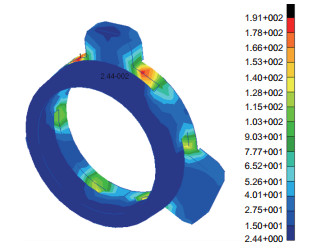

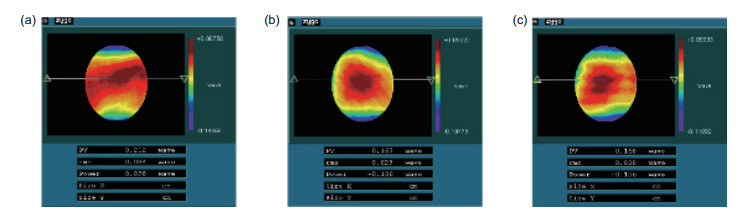

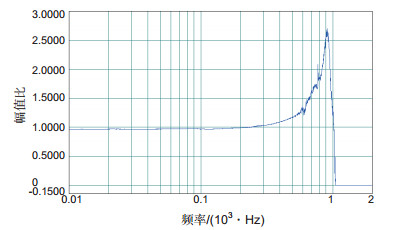

Abstract:The mirror assembly of an electro-optical tracking and pointing system for a space borne laser communication system is studied, three flexible supports are contrasted, according to practical applications of space load, the structural stiffness advantage and surface figure of the three flexible support scheme have been evaluated. The analysis results show that the surface figure RMS of neck side grooving flexible support scheme resisting microgravity and thermal environment change can reach 2.05 nm and 8.88 nm, the fundamental frequency mode is 926.1 Hz, in the balance between the surface figure RMS and the higher stiffness resisting hevibration damage, the flexible design is most reasonable. On this basis, the parameterized design of the flexible support structure of the reflector is completed and dynamic analysis have been done. The maximum stress of the frequency response is 96 Mpa, which is less than the material's tensile strength limit. The results of random vibration analysis show that root mean square of acceleration response is 11.14 g RMS, meeting 3σ law. Finally, a 0.2 g sine sweeptest proves that the relative error of the modal analysis is 2%, the experimental result show that the analysis results are basically accurate and reliable, that is, flexible support design is reliable to meet the requirements of use.

-

Overview: The reflector assembly of a telescopic week scan electro-optical tracking and pointing system for a space borne laser communication system is studied. There are many reflection links in the electro-optical tracking and pointing system, so the requirements for the surface figure and dynamic stiffness of the reflector assembly under the operating conditions are high. The surface figure of neck side grooving flexible support, neck side ring grooving flexible support and underside grooving flexible support with the same grooving width resisting microgravity and thermal environment change are contrasted, and the modes of the three flexible support structures are also analyzed, According to practical applications of space load, the structural stiffness advantage and surface figure of the three flexible support scheme have been evaluated. The analysis results show that the surface figure RMS of neck side grooving flexible support scheme resisting microgravity and thermal environment change can reach 2.05 nm and 8.88 nm, the fundamental frequency mode is 926.1 Hz and there is no dense frequency phenomenon in all modes. In the balance between the surface figure RMS and the higher stiffness resisting he vibration damage, the flexible design is most reasonable. On this basis, the parameterized design of the flexible support structure of the reflector is completed. To further verification of the dynamic stiffness of neck side grooving flexible support structure in space vibration environment, frequency response analysis and random vibration analysis of neck side grooving flexible support are have been done. The frequency response analysis results show that the magnification of the acceleration response is 2.86 times, the maximum stress is 96 MPa under the resonance which is less than the tensile strength limit of the material, the safety factor is 5.35; The frequency response analysis results show that the root mean square of the acceleration response of the reflector assembly is 11.14 g RMS, and the RMS of acceleration response is less than 3 times the input satisfying the 3σ criterion. The mean stress response of the flexible support under random vibration is 191 MPa which is also less than the tensile strength limit of the material, and the safety factor is 2.83. Finally the reliability of the stiffness of the flexible support structure is verified by a 0.2 g sinusoidal sweep test. The experimental results show that the primary natural frequency of the reflector components is 904.3 Hz, and the relative error with the modal analysis results is 2.4%, that is, the analysis results are basically accurate and reliable. So the flexible support design of reflector assembly is reliable to meet the requirements of the use.

-

-

表 1 材料属性表

Table 1. Material parameters of reflector subassembly

弹性模量/GPa 密度/(g·cm-3) 柏松比 线膨胀系数/(10-6·℃-1) 微晶玻璃 90.6 2.52 0.24 0.1 铟钢 141 8.05 0.36 0.038 钛合金 114 4.43 0.31 8.9 环氧胶 0.696 1.22 0.45 236 表 2 反射镜面形误差分析结果

Table 2. Analysis results of surface shape error of reflector subassembly

支撑方案 重力释放下的面形误差/nm ΔT=5℃温度变化下的面形误差/nm PV RMS PV RMS 底面直线开槽 11.4 2.29 63.12 14.06 颈口侧壁开槽 9.21 2.05 39.14 8.88 颈口环形深切槽 7.66 1.68 43.02 12.88 表 3 反射镜组件模态分析结果

Table 3. Results of MODAL analysis of reflector subassembly

模态频率 底面直线开槽 颈口侧壁开槽 颈口环形深切槽 一阶频率/Hz 1097.4 926.1 793.4 二阶频率/Hz 1653.5 1521.4 1493.8 三阶频率/Hz 1882.6 1702.9 1676.8 表 4 正弦振动试验条件

Table 4. Sine vibration test condition

条件参数 数值 频率范围/Hz 10~2000 振级/g 1 扫描速率oct/min 4 加载方向 Z向 表 5 随机振动加速度功率谱密度

Table 5. Power spectrum density (PSD) of the acceleration under random vibration

频率范围/Hz 鉴定级 总均方根加速度 加载方向 10~150 +3 dB/oct 3.89 g RMS X、Y和Z向 150~600 0.016 g2/Hz 600~2000 -6 dB/oct -

[1] 李行, 徐振邦, 李静秋.空间反射镜新型柔性支撑结构设计[J].电子测量技术, 2014, 37(8): 1-6. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=dzcl201408001&dbname=CJFD&dbcode=CJFQ

Li X, Xu Z B, Li J Q. Design of new flexure hinge support of space reflector subassembly[J]. Electronic Measurement Technology, 2014, 37(8): 1-6. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=dzcl201408001&dbname=CJFD&dbcode=CJFQ

[2] Schaffer C B, Jamison A O, Mazur E. Morphology of femtosecond laser-induced structural changes in bulk transparent materials[J]. Applied Physics Letters, 2004, 84(9): 1441-1443. doi: 10.1063/1.1650876

[3] Liu M, Zhang X M, Fatikow S. Design and analysis of a multi-notched flexure hinge for compliant mechanisms[J]. Precision Engineering, 2017, 48: 292-304. doi: 10.1016/j.precisioneng.2016.12.012

[4] Du Z J, Yang M, Dong W, et al. Static deformation modeling and analysis of flexure hinges made of a shape memory alloy[J]. Smart Materials and Structures, 2016, 25(11) : 158-163. http://dx.doi.org/10.1088/0964-1726/25/11/115029

[5] Paros J M, Weisbor L. How to design flexure hinges[J]. Machine Design, 1965, 37(27): 151-157. http://ci.nii.ac.jp/naid/10020009602

[6] Smith S T, Badami V G, Dale J S, et al. Elliptical flexure hinges[J]. Review of Scientific Instruments, 1997, 68(3): 1474-1483. doi: 10.1063/1.1147635

[7] 陈贵敏, 刘小院, 贾建援.椭圆柔性铰链的柔度计算[J].机械工程学报, 2006, 42(S1): 111-115. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxxb2006s1024&dbname=CJFD&dbcode=CJFQ

Chen G M, Liu X Y, Jia J Y. Compliance calculation of elliptical flexure hinge[J]. Chinese Journal of Mechanical Engineering, 2006, 42(S1): 111-115. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxxb2006s1024&dbname=CJFD&dbcode=CJFQ

[8] 左行勇, 刘晓明.三种形状柔性铰链转动刚度的计算与分析[J].仪器仪表学报, 2006, 27(12): 1725-1728. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yqxb200612037&dbname=CJFD&dbcode=CJFQ

Zuo X Y, Liu X M. Calculation and analysis of rotational stiffness for three types of flexure hinges[J]. Chinese Journal of Scientific Instrument, 2006, 27(12): 1725-1728. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yqxb200612037&dbname=CJFD&dbcode=CJFQ

[9] 李宗轩, 陈雪, 张雷, 等.大口径空间反射镜Cartwheel型柔性支撑设计[J].光学学报, 2014, 34(6): 210-218. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxxb201406034&dbname=CJFD&dbcode=CJFQ

Li Z X, Chen X, Zhang L, et al. Design of cartwheel flexural support for a large aperture space mirror[J]. Acta Optica Sinica, 2014, 34(6): 210-218. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxxb201406034&dbname=CJFD&dbcode=CJFQ

[10] 李晓峰, 汪波, 胡渝.在轨运行热环境下的天线镜面热变形对空地激光通信链路的影响[J].宇航学报, 2005, 26(5): 581-585. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yhxb200505010&dbname=CJFD&dbcode=CJFQ

Li X F, Wang B, Hu Y. Influence of mirror thermal distortion in thermosphere to space-to-ground laser communication links[J]. Journal of Astronautics, 2005, 26(5): 581-585. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yhxb200505010&dbname=CJFD&dbcode=CJFQ

[11] 孙宝玉.基于CAE的光学反射镜柔性结构设计与分析[J].光电工程, 2009, 36(1): 103-106. http://www.oee.ac.cn/CN/abstract/abstract602.shtml

Sun B Y. Design and analysis on the flexible structure of the optical reflector based on the computer aided engineering[J]. Opto-Electronic Engineering, 2009, 36(1): 103-106. http://www.oee.ac.cn/CN/abstract/abstract602.shtml

[12] 张银刚, 寇生, 余建军, 等.星敏感器主反射镜组件的设计与分析[J].航空精密制造技术, 2010, 46(5): 14-16. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hjzj201005004&dbname=CJFD&dbcode=CJFQ

Zhang Y G, Kou S, Yu J J, et al. Design and analysis of the primary mirror subassembly in a star sensor[J]. Aviation Precision Manufacturing Technology, 2010, 46(5): 14-16. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hjzj201005004&dbname=CJFD&dbcode=CJFQ

[13] 张新建, 余建军, 郭旭红, 等.轻型空间CCD相机镜筒的动力学分析[J].机械设计与制造工程, 2008, 37(5): 27-30, 34. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxzz200805008&dbname=CJFD&dbcode=CJFQ

Zhang X J, Yu J J, Guo X H, et al. Dynamic analysis of CCD drawtube of the lightweight space camera[J]. Machine Design and Manufacturing Engineering, 2008, 37(5): 27-30, 34. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jxzz200805008&dbname=CJFD&dbcode=CJFQ

[14] 李浩, 余建军, 郭旭红, 等.航空光谱相机反射镜部件的有限元分析[J].光学技术, 2013, 39(3): 263-266. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxjs201303013&dbname=CJFD&dbcode=CJFQ

Li H, Yu J J, Guo X H, et al. Finite-element analysis of the reflect component of an aerial spectral camera[J]. Optical Technique, 2013, 39(3): 263-266. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxjs201303013&dbname=CJFD&dbcode=CJFQ

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: