-

摘要

消费电子市场正推动柔性电子器件向集成化、小型化及可穿戴的方向发展,同时也对柔性电子器件的制备提出了新的要求。光刻工艺加工精度高,但其成本昂贵、加工流程复杂且效率低。相比而言,飞秒激光加工兼有加工精度高和工艺流程简单的特点,已展现在制备柔性电子器件方面的独特优势和应用前景。为了更好地了解这一新兴领域的进展,本文概述了与柔性电子器件制备相关的五种飞秒激光加工工艺机理,包括激光液相纳米材料合成、激光纳米材料还原、激光诱导纳米连接、激光电极图案化及激光表面织构化,并介绍了制备的典型柔性电子器件性能,对存在的问题和未来发展趋势进行了分析和展望。

Abstract

Consumer electronical markets are now promoting a rapid advance in flexible electronics with high integration, miniaturization, and wearable properties, which in turn puts forward new requirements for the fabrication of flexible electronics. Photolithography techniques are advantageous for their high accuracy, but it is disadvantageous due to high cost, complexity, and low efficiency. In comparison, femtosecond (fs) laser micro-nano fabrication, as a high-efficiency and simple technique, has shown its capacity and potential for the fabrication of flexible electronics. This review summarizes five fs-laser based techniques for the fabrication of flexible electronics, including laser synthesis of nanomaterials in liquids, laser-induced nanomaterial chemical-reduction, laser-induced nano joining, laser electrode patterning, and laser surface texturing. The corresponding mechanisms are briefly introduced, followed by a demonstration of typical flexible electronics and their properties. Finally, the challenges in this field are analyzed, and our perspective is provided.

-

Key words:

- femtosecond laser /

- micro-nano fabrication /

- flexible electronics /

- nanojoining /

- nanomaterial synthesis

-

Overview

Overview: With the rapid development of information technology and the rise of consumer electronics, flexible electronic devices with high integration, miniaturization and lightweight have attracted wide research attentions. Such flexible electronic devices are typically composed of functional parts, conductive structures, and flexible substrates. The functional parts can respond to external stimuli and convert them into electrical signals. The conductive structures are used for electrical signal transmission and the flexible substrates are used to support functional and conductive structures. The preparation of flexible electronic devices requires nanomaterial synthesis, sintering, processing, and patterning, which is an intrinsically interdisciplinary subject that integrates material science, electronics science, and engineering science.

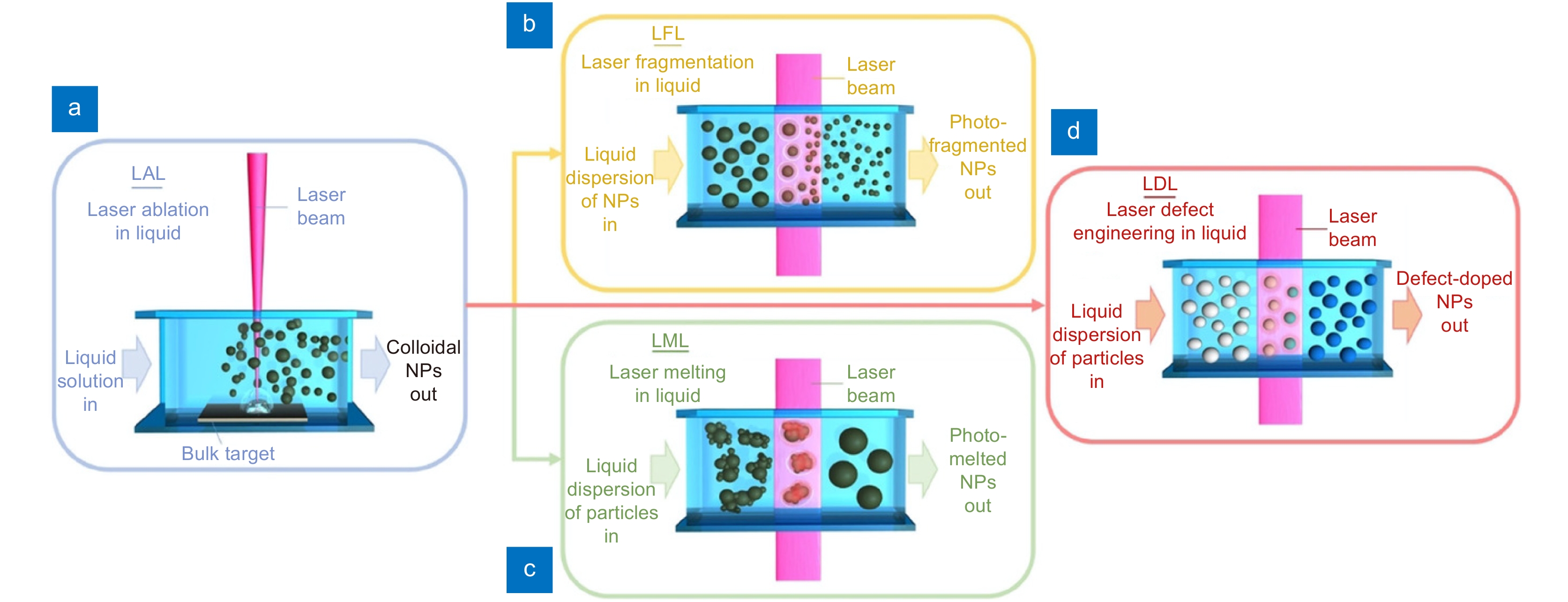

Laser processing, as a maskless process, is able to realize material synthesis and sintering, surface modification, texturing, patterning, and even develop entire flexible devices in one step. Femtosecond laser, benefiting from an ultrashort pulse width can not only achieve “cold” processing with low-damage high-resolution micro-nano structures, but also realize nanomaterial synthesis and nano-joining of multi-dimensional nanomaterials, showing great potentials for the fabrication of flexible electronics. In this paper, five femtosecond-laser based techniques for the fabrication of flexible electronics are reviewed, including laser synthesis of nanomaterials in liquids, laser-induced nanomaterial chemical-reduction, laser-induced nanojoining, laser electrode patterning, and laser surface texturing. The technique of laser synthesis of nanomaterials in liquids can be classified into laser ablation in liquids (LAL), laser fragmentation in liquids (LFL), laser melting in liquids (LML) and laser defect engineering in liquids (LDL). Specifically, LAL can be used to transform solid targets into functional nanomaterials whose physicochemical properties are manipulable via changing target compositions, liquid molecules, and processing parameters. LFL, LML and LDL are downstream techniques enabling to further tune the properties of LAL-synthesized nanomaterials. Laser synthesized nanomaterials show pure and active properties. They are good candidates to be the alternative of chemically synthesized nanomaterials for the fabrication of high-performance flexible electronic devices. Regarding laser-induced nanomaterial chemical-reduction, the mechanisms are mainly photochemical and photothermal reduction, allowing the transition of metal salts or graphene oxide/high polymer materials or their mixtures into metal, reduced graphene oxide/carbon, or metal/carbon composite electrodes. Femtosecond laser nano-joining, on the basis of laser-induced localized surface plasmonic effect can enhance the local temperature at the contact area between metallic nanoparticles, and facilitate the interconnection of nanoparticles for the fabrication of low-damage flexible conductive electrodes and nanowire sensors. Femtosecond laser ablation can also realize electrode patterning and surface texturing, which have been used for fabrication of flexible electronics including sensors, supercapacitors and triboelectric nanogenerators. In light of high flexibility and strong capacities of femtosecond laser ablation and processing, its extensive applications in flexible electronics can be envisaged to prosper in the near future. However, there are still some challenges ahead, so our perspectives are provided at the end of this review.

-

-

图 2 (a) 飞秒激光烧蚀合成氧化锌量子点制备光电探测器示意图; (b) 深紫外光下光电探测器的瞬时光电流产生; (c) 光电探测器的响应值随器件弯曲角度、次数变化关系,插图为光电探测器弯曲角度的照片[72]

Figure 2. (a) Schematic illustration of femtosecond laser ablation synthesis with ZnO QDs to fabricate photodetectors; (b) Transient photocurrent generation under deep-ultraviolet illumination for photodetector; (c) Responsivity measurement of photodetector as a function of the number of bending cycles. The inset photos show the photodetector bending degree[72]

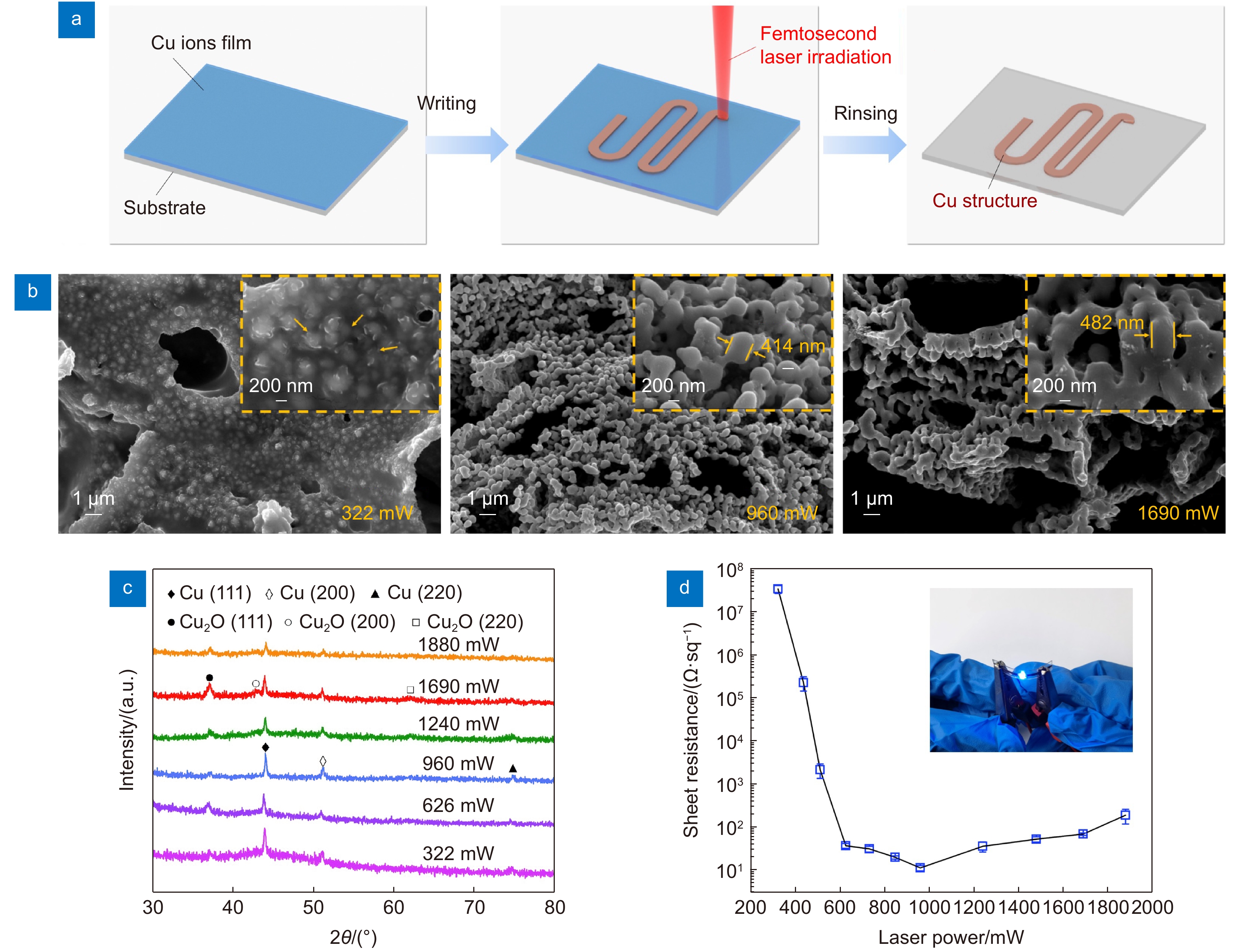

图 3 (a) 飞秒激光还原离子态铜盐前驱体制备铜微电极流程图;(b), (c) 不同激光功率下制备铜微电极的SEM图和XRD图;(d) 铜微电极方阻随激光功率变化曲线,插图:铜微电极所制备LED电路照片[39]

Figure 3. (a) Manufacturing process of femtosecond laser reduction based on Cu ionic precursor; (b), (c) SEM images and XRD pattern of Cu microelectrode prepared with different laser powers; (d) Copper microelectrode sheet resistance change curve with laser power, inset: photograph of the LED circuit prepared from Cu microelectrode[39]

图 4 (a) 飞秒激光制备还原氧化石墨烯/PDMS复合材料声学传感器制造工艺流程[85];(b) 水分子与GO纳米片之间相互作用示意图[86];(c) 模拟人类皮肤的非接触式湿度传感的电子皮肤原型演示[86]

Figure 4. (a) Manufacturing process of femtosecond laser writing rGO/PDMS composite acoustic sensor[85]; (b) Schematic illustration of the interaction between water molecules and GO nanosheets[86]; (c) Prototype demonstration of e-skin used for simulation of noncontact sensing properties of human skin[86]

图 5 (a) 利用空间形状的飞秒激光制备LIG/MnO2超级电容器的示意图; (b) 飞秒激光诱导形成LIG/MnO2复合材料机理图; (c) 不同形状超级电容器在不同电流密度下的面积比电容; (d) 叉指超级电容器在不同测试扫描速率下的面积比电容及体积比电容[87]

Figure 5. (a) Schematics of spatially shaped femtosecond laser strategy to fabricate the graphene/MnO2 micro-supercapacitors; (b) Schematic diagram of the formation of LIG/MnO2 composites induced by femtosecond laser; (c) The area-specific capacitance of different geometries under different current density; (d) The areal capacitance and volumetric capacitance of interdigital micro-supercapacitors under different scan rates[87]

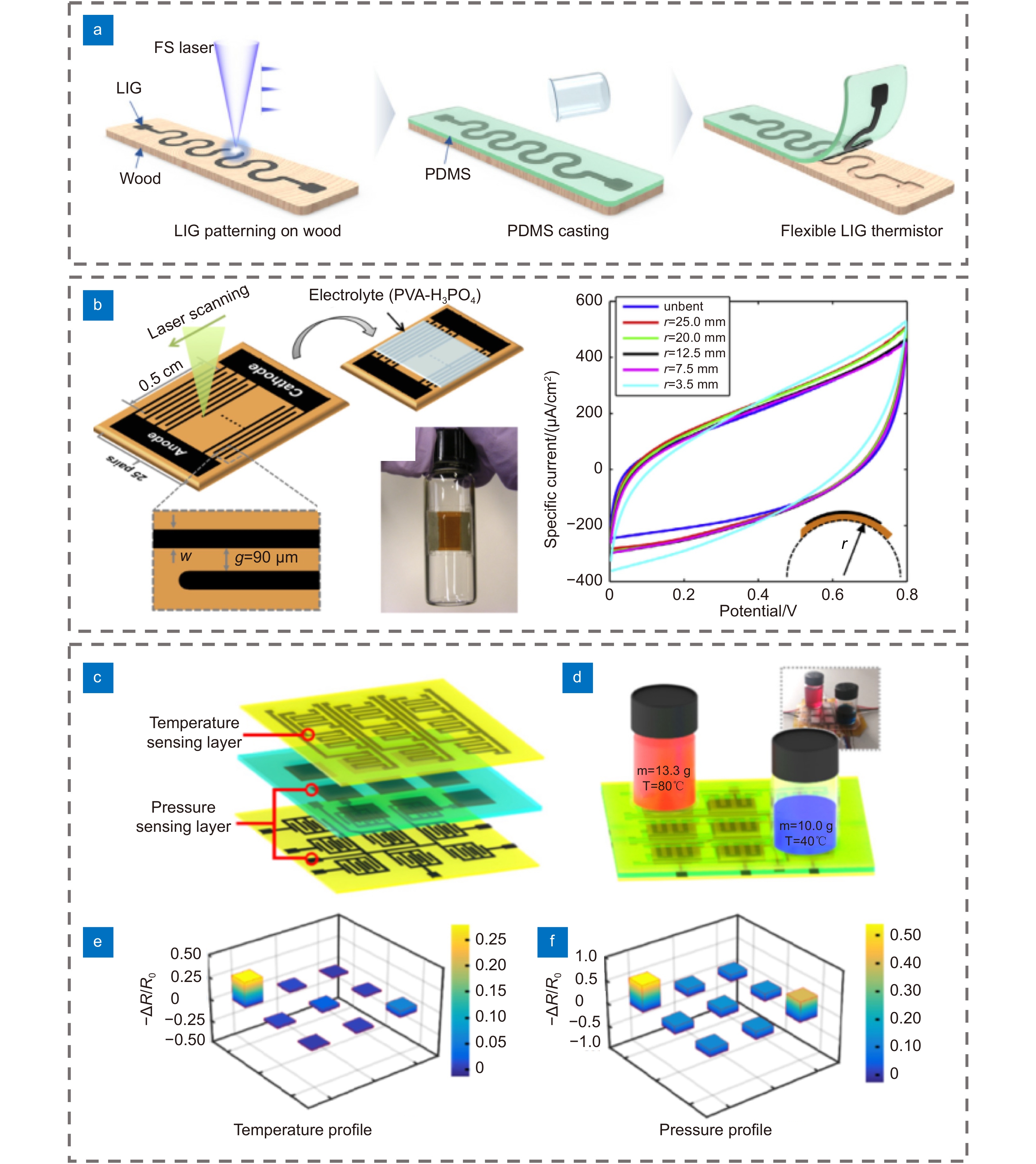

图 6 (a) 飞秒激光直写石墨烯柔性热敏电阻制备方法[89];(b) 飞秒激光碳化制备微型超级电容器流程图及照片,不同弯曲程度的微超级电容器的循环伏安(CV)曲线(扫描速度为1 V/s)[90];(c) 飞秒激光微加工法制备传感器阵列原理图[91];(d) 传感器阵列同时检测不同物体的温度及压力[91];(e) 受温度变化影响的温度传感器的电信号输出[91];(f) 受负载压力变化影响的压力传感器的电信号输出[91]

Figure 6. (a) Schematic diagram of femtosecond laser direct writing graphene flexible thermistor[89]; (b) Schematic diagram of fabrication of micro-supercapacitors by femtosecond laser carbonization and photographic image of micro-supercapacitor, cyclic voltammetry (CV) curves of micro-supercapacitors with different bending degrees ( the scanning speed is 1 V/s)[90]; (c) Schematic diagram of sensor array fabricated by femtosecond laser micromachining method[91]; (d) Sensor array simultaneously detects the temperature and pressure of different objects[91]; (e) Electrical signal output of the temperature sensor affected by temperature changes[91]; (f) Electrical signal output of the pressure sensor affected by load pressure changes[91]

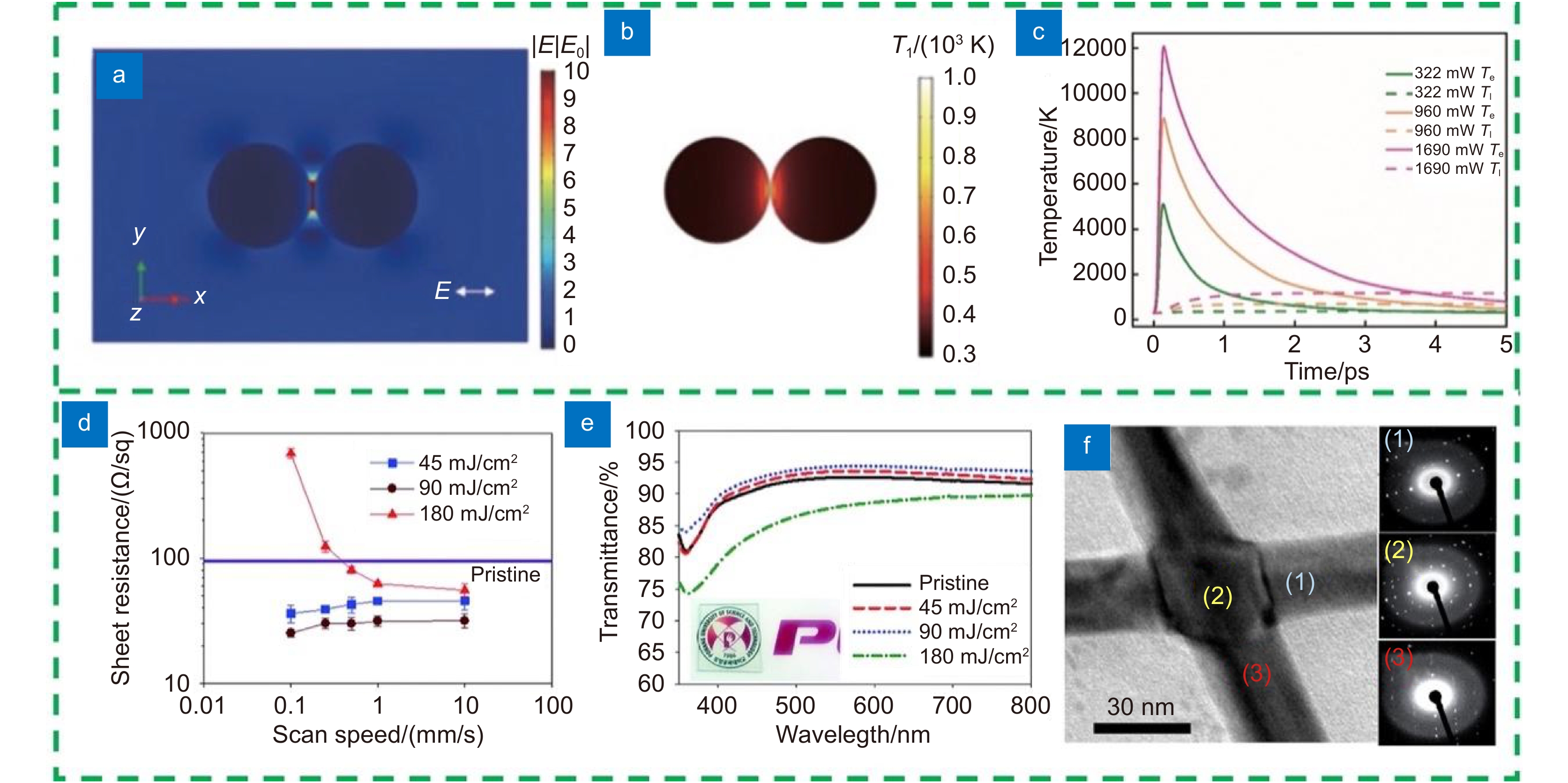

图 7 (a) 960 mW飞秒激光辐照下Cu纳米颗粒二聚体的相对电场增强(|E/E0|)分布[39]; (b) 960 mW飞秒激光辐照下 Cu纳米颗粒二聚体在5 ps后的温度场分布[39]; (c) 不同功率单脉冲激光下,前5 ps内Cu颗粒电子及晶格温度随时间变化关系[39]; (d), (e) 飞秒激光辐照前后Ag NWs薄膜的方阻变化及透射光谱变化[98]; (f) 飞秒激光辐照Ag NW连接接头及不同部位的SAED图案[98]

Figure 7. (a) Relative electric field enhancement |E/E0| distribution of the Cu nanoparticle dimer under 960 mW laser irradiation[39]; (b) Temperature field distribution of a Cu nanoparticle dimer under 960 mW single pulse laser irradiation after 5 ps[39]; (c) Relationship between electron and lattice temperature of Cu nanoparticles in the first 5 ps under different laser powers of single pulse laser irradiation[39]; (d), (e) Sheet resistances and transmittance spectra of Ag NWs films before and after femtosecond laser irradiation[98]; (f) SAED patterns of Ag NW joints and different parts irradiated by femtosecond laser[98]

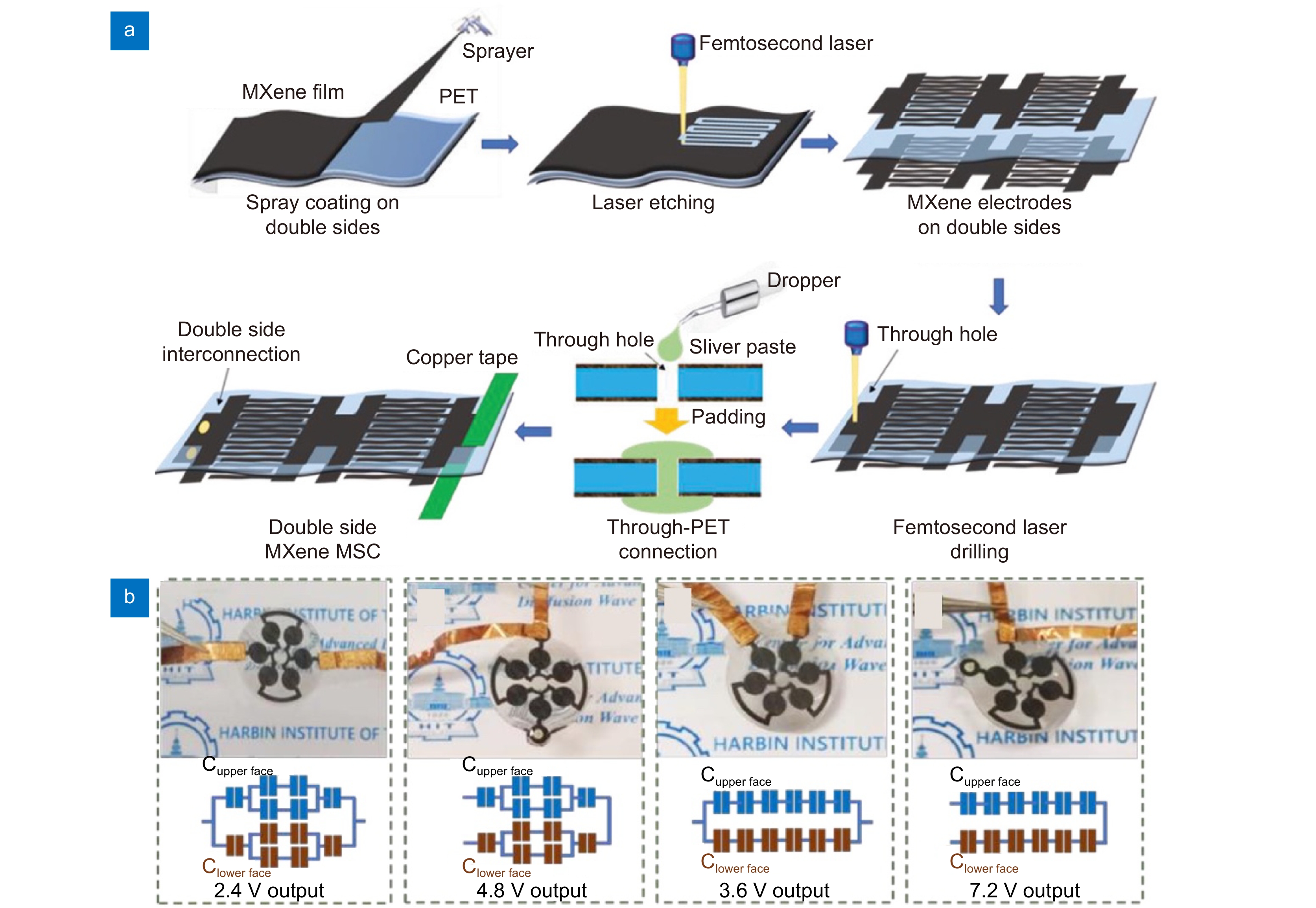

图 9 (a) 飞秒激光一步刻蚀制备双面微型超级电容器工艺流程图;(b) 12螺旋形单元间不同连接方式组成的“花瓣”图案超级电容器的照片[105]

Figure 9. (a) Schematic of fabrication of double sided micro-supercapacitors by one-step femtosecond laser etching; (b) Photographs of double-side micro-supercapacitors and different connections of twelve spiral units in ‘flower petal’ pattern[105]

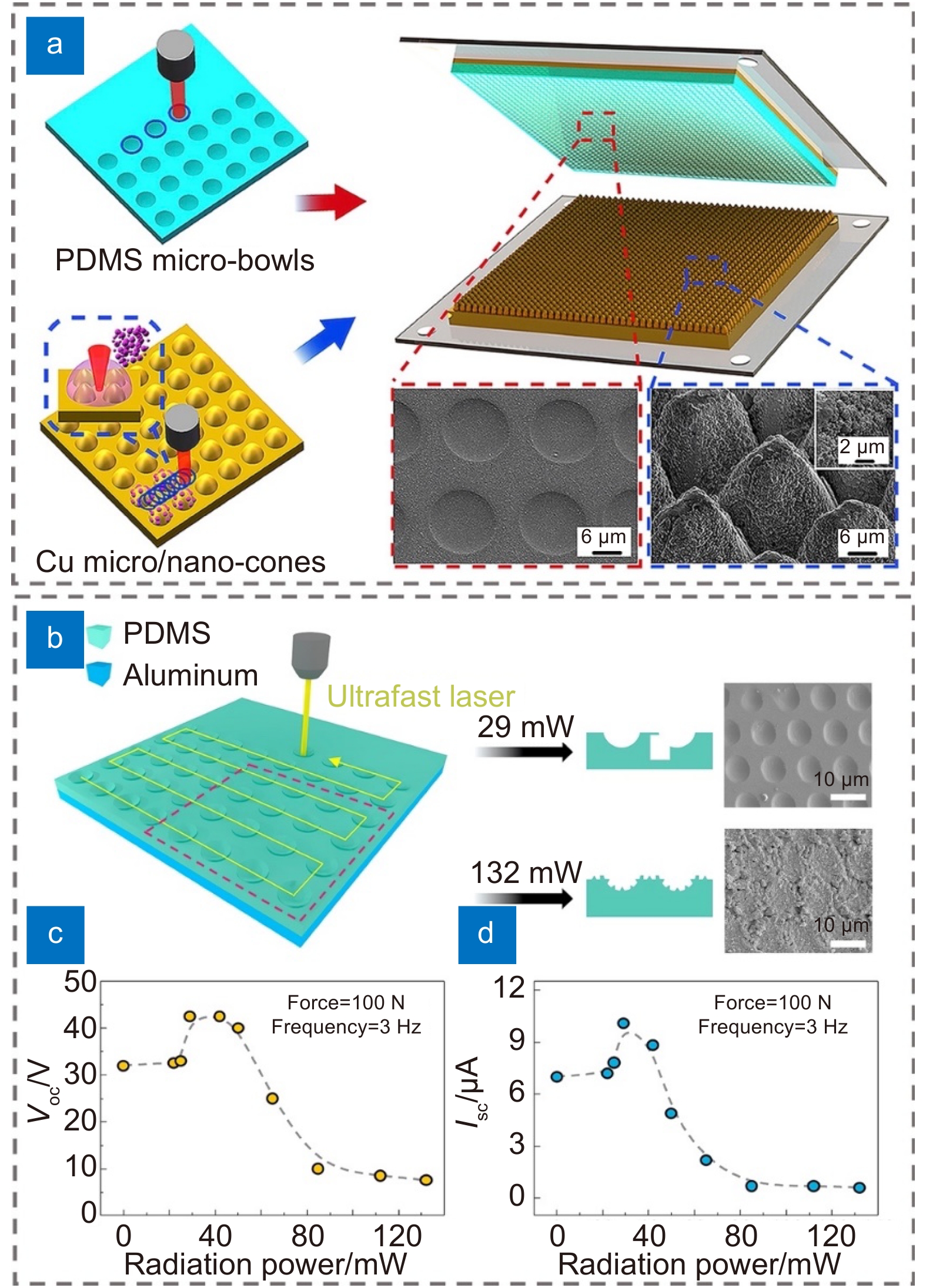

图 10 飞秒激光烧蚀的Cu微/纳锥结构及PDMS微碗状结构制备的TENG的制造工艺流程图[108];(b) 飞秒激光辐照制备PDMS摩擦层的示意图,29 mW和132 mW激光功率下制备的PDMS的SEM图像[27];0~132 mW激光功率范围下制备的TENGs的(c) 开路电压及(d) 短路电流[27]

Figure 10. Schematic of the fabrication process of TENG prepared by femtosecond laser ablation of Cu micro/nano-cones and PDMS micro-bowl[108]; (b) Schematic illustration of the fabrication of the PDMS by femtosecond laser irradiation and SEM images of the PDMS at laser power of 29 mW and 132 mW[27]; (c) open-circuit voltage (d) short-circuit current of the fabricated TENGs with laser power ranging from 0 to 132 mW[27]

-

参考文献

[1] Xu K C, Lu Y Y, Takei K. Multifunctional skin-inspired flexible sensor systems for wearable electronics[J]. Adv Mater Technol, 2019, 4(3): 1800628. doi: 10.1002/admt.201800628

[2] Wan Z F, Chen X, Gu M. Laser scribed graphene for supercapacitors[J]. Opto-Electron Adv, 2021, 4(7): 200079. doi: 10.29026/oea.2021.200079

[3] Park J, Hwang J C, Kim G G, et al. Flexible electronics based on one-dimensional and two-dimensional hybrid nanomaterials[J]. InfoMat, 2020, 2(1): 33−56. doi: 10.1002/inf2.12047

[4] Abid N, Khan A M, Shujait S, et al. Synthesis of nanomaterials using various top-down and bottom-up approaches, influencing factors, advantages, and disadvantages: a review[J]. Adv Colloid Interface Sci, 2022, 300: 102597. doi: 10.1016/j.cis.2021.102597

[5] Kim Y U, Kwon N Y, Park S H, et al. Patterned sandwich-type silver nanowire-based flexible electrode by photolithography[J]. ACS Appl Mater Interfaces, 2021, 13(51): 61463−61472. doi: 10.1021/acsami.1c19164

[6] Choi Y, Seong K D, Piao Y. Metal−organic decomposition ink for printed electronics[J]. Adv Mater Interfaces, 2019, 6(20): 1901002. doi: 10.1002/admi.201901002

[7] Ahn Y, Lee H, Lee D, et al. Highly conductive and flexible silver nanowire-based microelectrodes on biocompatible hydrogel[J]. ACS Appl Mater Interfaces, 2014, 6(21): 18401−18407. doi: 10.1021/am504462f

[8] Li L H, Gao M, Guo Y Z, et al. Transparent Ag@Au–graphene patterns with conductive stability via inkjet printing[J]. J Mater Chem C, 2017, 5(11): 2800−2806. doi: 10.1039/C6TC05227D

[9] Liao J N, Guo W, Peng P. Direct laser writing of copper-graphene composites for flexible electronics[J]. Opt Lasers Eng, 2021, 142: 106605. doi: 10.1016/j.optlaseng.2021.106605

[10] Zhou W P, Bai S, Ma Y, et al. Laser-direct writing of silver metal electrodes on transparent flexible substrates with high-bonding strength[J]. ACS Appl Mater Interfaces, 2016, 8(37): 24887−24892. doi: 10.1021/acsami.6b07696

[11] Wang C P, Chou C P, Wang P C, et al. Flexible graphene-based micro-capacitors using ultrafast laser ablation[J]. Microelectron Eng, 2019, 215: 111000. doi: 10.1016/j.mee.2019.111000

[12] Lin Z Y, Hong M H. Femtosecond laser precision engineering: from micron, submicron, to nanoscale[J]. Ultrafast Sci, 2021, 2021: 9783514.

[13] Shih C Y, Streubel R, Heberle J, et al. Two mechanisms of nanoparticle generation in picosecond laser ablation in liquids: The origin of the bimodal size distribution[J]. Nanoscale, 2018, 10(15): 6900−6910. doi: 10.1039/C7NR08614H

[14] Zhang D S, Wada H. Laser ablation in liquids for nanomaterial synthesis and applications[M]//Sugioka K. Handbook of Laser Micro- and Nano-Engineering. Cham: Springer, 2021: 1–35.

[15] Zhang D S, Zhang C, Liu J, et al. Carbon-encapsulated metal/metal carbide/metal oxide core-shell nanostructures generated by laser ablation of metals in organic solvents[J]. ACS Appl Nano Mater, 2019, 2(1): 28−39. doi: 10.1021/acsanm.8b01541

[16] Zhang Y Y, Jiao Y L, Li C Z, et al. Bioinspired micro/nanostructured surfaces prepared by femtosecond laser direct writing for multi-functional applications[J]. Int J Extrem Manuf, 2020, 2(3): 032002. doi: 10.1088/2631-7990/ab95f6

[17] Zhang D S, Ranjan B, Tanaka T, et al. Underwater persistent bubble-assisted femtosecond laser ablation for hierarchical micro/nanostructuring[J]. Int J Extrem Manuf, 2020, 2(1): 015001. doi: 10.1088/2631-7990/ab729f

[18] Zhang D S, Wu L C, Ueki M, et al. Femtosecond laser shockwave peening ablation in liquids for hierarchical micro/nanostructuring of brittle silicon and its biological application[J]. Int J Extrem Manuf, 2020, 2(4): 045001. doi: 10.1088/2631-7990/abb5f3

[19] Zhang D S, Ranjan B, Tanaka T, et al. Carbonized hybrid micro/nanostructured metasurfaces produced by femtosecond laser ablation in organic solvents for biomimetic antireflective surfaces[J]. ACS Appl Nano Mater, 2020, 3(2): 1855−1871. doi: 10.1021/acsanm.9b02520

[20] Amendola V, Amans D, Ishikawa Y, et al. Room-temperature laser synthesis in liquid of oxide, metal-oxide core-shells, and doped oxide nanoparticles[J]. Chem Eur J, 2020, 26(42): 9206−9242. doi: 10.1002/chem.202000686

[21] Arakane S, Mizoshiri M, Hata S. Direct patterning of Cu microstructures using femtosecond laser-induced CuO nanoparticle reduction[J]. Jpn Appl Phys, 2015, 54(6S1): 06FP07. doi: 10.7567/JJAP.54.06FP07

[22] Mizoshiri M, Yoshidomi K. Cu patterning using femtosecond laser reductive sintering of CuO nanoparticles under inert gas injection[J]. Materials, 2021, 14(12): 3285. doi: 10.3390/ma14123285

[23] Bharati M S S, Soma V R. Flexible SERS substrates for hazardous materials detection: recent advances[J]. Opto-Electron Adv, 2021, 4(11): 210048. doi: 10.29026/oea.2021.210048

[24] Noh J, Ha J, Kim D. Femtosecond and nanosecond laser sintering of silver nanoparticles on a flexible substrate[J]. Appl Surf Sci, 2020, 511: 145574. doi: 10.1016/j.apsusc.2020.145574

[25] Lamberti A, Perrucci F, Caprioli M, et al. New insights on laser-induced graphene electrodes for flexible supercapacitors: tunable morphology and physical properties[J]. Nanotechnology, 2017, 28(17): 174002. doi: 10.1088/1361-6528/aa6615

[26] Zhang D S, Liu R J, Li Z G. Irregular LIPSS produced on metals by single linearly polarized femtosecond laser[J]. Int J Extrem Manuf, 2022, 4(1): 015102. doi: 10.1088/2631-7990/ac376c

[27] Kim D, Tcho I W, Jin I K, et al. Direct-laser-patterned friction layer for the output enhancement of a triboelectric nanogenerator[J]. Nano Energy, 2017, 35: 379−386. doi: 10.1016/j.nanoen.2017.04.013

[28] Zhao L L, Liu Z, Chen D, et al. Laser synthesis and microfabrication of micro/nanostructured materials toward energy conversion and storage[J]. Nano-Micro Lett, 2021, 13(1): 49. doi: 10.1007/s40820-020-00577-0

[29] Bai S, Sugioka K. Recent advances in the fabrication of highly sensitive surface-enhanced raman scattering substrates: nanomolar to attomolar level sensing[J]. Light Adv Manuf, 2021, 2: 13.

[30] Zhang D S, Sugioka K. Hierarchical microstructures with high spatial frequency laser induced periodic surface structures possessing different orientations created by femtosecond laser ablation of silicon in liquids[J]. Opto-Electron Adv, 2019, 2(3): 190002.

[31] Zhou R, Lin S D, Ding Y, et al. Enhancement of laser ablation via interacting spatial double-pulse effect[J]. Opto-Electron Adv, 2018, 1(8): 180014.

[32] Zhang C Y, Zhou W, Geng D, et al. Laser direct writing and characterizations of flexible piezoresistive sensors with microstructures[J]. Opto-Electron Adv, 2021, 4(4): 200061.

[33] Xie X, Zhou C, Wei X, et al. Laser machining of transparent brittle materials: from machining strategies to applications[J]. Opto-Electron Adv, 2019, 2(1): 180017.

[34] Peng P, Li L H, He P, et al. One-step selective laser patterning of copper/graphene flexible electrodes[J]. Nanotechnology, 2019, 30(18): 185301. doi: 10.1088/1361-6528/aafe4c

[35] Park S, Lee H, Kim Y J, et al. Fully laser-patterned stretchable microsupercapacitors integrated with soft electronic circuit components[J]. NPG Asia Mater, 2018, 10(10): 959−969. doi: 10.1038/s41427-018-0080-z

[36] Zang X N, Shen C W, Chu Y, et al. Laser-induced molybdenum carbide-graphene composites for 3D foldable paper electronics[J]. Adv Mater, 2018, 30(26): 1800062. doi: 10.1002/adma.201800062

[37] Ba H, Sutter C, Papaefthimiou V, et al. Foldable flexible electronics based on few-layer graphene coated on paper composites[J]. Carbon, 2020, 167: 169−180. doi: 10.1016/j.carbon.2020.05.012

[38] Theodorakos I, Zacharatos F, Geremia R, et al. Selective laser sintering of Ag nanoparticles ink for applications in flexible electronics[J]. Appl Surf Sci, 2015, 336: 157−162. doi: 10.1016/j.apsusc.2014.10.120

[39] 廖嘉宁, 王欣达, 周兴汶, 等. 铜纳米颗粒的飞秒激光连接过程研究[J]. 中国激光, 2021, 48(8): 0802008. doi: 10.3788/CJL202148.0802008

Liao J N, Wang X D, Zhou X W, et al. Joining process of copper nanoparticles with femtosecond laser irradiation[J]. Chin J Lasers, 2021, 48(8): 0802008. doi: 10.3788/CJL202148.0802008

[40] An J N, Le T S D, Lim C H J, et al. Single-step selective laser writing of flexible photodetectors for wearable optoelectronics[J]. Adv Sc, 2018, 5(8): 1800496. doi: 10.1002/advs.201800496

[41] Sakka T, Saito K, Ogata Y H. Confinement effect of laser ablation plume in liquids probed by self-absorption of C2 Swan band emission[J]. J Appl Phys, 2005, 97(1): 014902. doi: 10.1063/1.1828214

[42] Zhang D S, Gökce B, Barcikowski S. Laser synthesis and processing of colloids: fundamentals and applications[J]. Chem Rev, 2017, 117(5): 3990−4103. doi: 10.1021/acs.chemrev.6b00468

[43] Zhang D S, Li Z G, Sugioka K. Laser ablation in liquids for nanomaterial synthesis: diversities of targets and liquids[J]. J Phys Photonics, 2021, 3(4): 042002. doi: 10.1088/2515-7647/ac0bfd

[44] Zhang D S, Liu J, Liang C H. Perspective on how laser-ablated particles grow in liquids[J]. Sci China Phys Mechan Astron, 2017, 60(7): 074201. doi: 10.1007/s11433-017-9035-8

[45] Li S H, Li Y, Liu K, et al. Laser fabricated carbon quantum dots in anti-solvent for highly efficient carbon-based perovskite solar cells[J]. J Colloid Interface Sci, 2021, 600: 691−700. doi: 10.1016/j.jcis.2021.05.034

[46] Shabalina A V, Svetlichnyi V A, Kulinich S A. Green laser ablation-based synthesis of functional nanomaterials for generation, storage, and detection of hydrogen[J]. Curr Opin Green Sustain Chem, 2022, 33: 100566. doi: 10.1016/j.cogsc.2021.100566

[47] Charipar K, Kim H, Piqué A, et al. ZnO nanoparticle/graphene hybrid photodetectors via laser fragmentation in liquid[J]. Nanomaterials, 2020, 10(9): 1648. doi: 10.3390/nano10091648

[48] Jian J, Xu Y X, Yang X K, et al. Embedding laser generated nanocrystals in BiVO4 photoanode for efficient photoelectrochemical water splitting[J]. Nat Commun, 2019, 10(1): 2609. doi: 10.1038/s41467-019-10543-z

[49] Nikolov A S, Stankova N E, Karashanova D B, et al. Synergistic effect in a two-phase laser procedure for production of silver nanoparticles colloids applicable in ophthalmology[J]. Opt Laser Technol, 2021, 138: 106850. doi: 10.1016/j.optlastec.2020.106850

[50] Suehara K, Takai R, Ishikawa Y, et al. Reduction mechanism of transition metal oxide particles in thermally induced nanobubbles during pulsed laser melting in ethanol[J]. Chemphyschem, 2021, 22(7): 675−683. doi: 10.1002/cphc.202001000

[51] Zhang D S, Liu J, Li P F, et al. Recent advances in surfactant-free, surface-charged, and defect-rich catalysts developed by laser ablation and processing in liquids[J]. ChemNanoMat, 2017, 3(8): 512−533. doi: 10.1002/cnma.201700079

[52] Menéndez-Manjón A, Wagener P, Barcikowski S. Transfer-matrix method for efficient ablation by pulsed laser ablation and nanoparticle generation in liquids[J]. J Phys Chem C, 2011, 115(12): 5108−5114. doi: 10.1021/jp109370q

[53] Zhang S D, Gökce B, Sommer S, et al. Debris-free rear-side picosecond laser ablation of thin germanium wafers in water with ethanol[J]. Appl Surf Sci, 2016, 367: 222−230. doi: 10.1016/j.apsusc.2016.01.071

[54] Tan D Z, Zhou S F, Qiu J R, et al. Preparation of functional nanomaterials with femtosecond laser ablation in solution[J]. J Photochem Photobiol C Photochem Rev, 2013, 17: 50−68. doi: 10.1016/j.jphotochemrev.2013.08.002

[55] Anisimov S I, Kapeliovich B L, Perel'man T L. Electron emission from metal surfaces exposed to ultra-short laser pulses[J]. Zh Eksp Teor Fiz, 1974, 66(776): 776−781.

[56] Xiao J, Liu P, Wang C X, et al. External field-assisted laser ablation in liquid: An efficient strategy for nanocrystal synthesis and nanostructure assembly[J]. Prog Mater Sc, 2017, 87: 140−220. doi: 10.1016/j.pmatsci.2017.02.004

[57] Qi L T, Nishii K, Yasui M, et al. Femtosecond laser ablation of sapphire on different crystallographic facet planes by single and multiple laser pulses irradiation[J]. Opt Lasers Eng, 2010, 48(10): 1000−1007. doi: 10.1016/j.optlaseng.2010.05.006

[58] Werner D, Hashimoto S. Improved working model for interpreting the excitation wavelength- and fluence-dependent response in pulsed laser-induced size reduction of aqueous gold nanoparticles[J]. J Phys Chem C, 2011, 115(12): 5063−5072. doi: 10.1021/jp109255g

[59] Lorazo P, Lewis L J, Meunier M. Short-pulse laser ablation of solids: from phase explosion to fragmentation[J]. Phys Rev Lett, 2003, 91(22): 225502. doi: 10.1103/PhysRevLett.91.225502

[60] Shih C Y, Wu C P, Shugaev M V, et al. Atomistic modeling of nanoparticle generation in short pulse laser ablation of thin metal films in water[J]. J Colloid Interface Sci, 2017, 489: 3−17. doi: 10.1016/j.jcis.2016.10.029

[61] Lasemi N, Rupprechter G, Liedl G, et al. Near-infrared femtosecond laser ablation of Au-coated Ni: effect of organic fluids and water on crater morphology, ablation efficiency and hydrodynamic properties of NiAu nanoparticles[J]. Materials, 2021, 14(19): 5544. doi: 10.3390/ma14195544

[62] von der Linde D, Schüler H. Breakdown threshold and plasma formation in femtosecond laser–solid interaction[J]. J Opt Soc Am B, 1996, 13(1): 216−222. doi: 10.1364/JOSAB.13.000216

[63] König J, Nolte S, Tünnermann A. Plasma evolution during metal ablation with ultrashort laser pulses[J]. Opt Express, 2005, 13(26): 10597−10607. doi: 10.1364/OPEX.13.010597

[64] Yan Z J, Chrisey D B. Pulsed laser ablation in liquid for micro-/nanostructure generation[J]. J Photochem Photobiol C Photochem Rev, 2012, 13(3): 204−223. doi: 10.1016/j.jphotochemrev.2012.04.004

[65] De Giacomo A, Dell'Aglio M, Santagata A, et al. Cavitation dynamics of laser ablation of bulk and wire-shaped metals in water during nanoparticles production[J]. Phys Chem Chem Phys, 2013, 15(9): 3083−3092. doi: 10.1039/C2CP42649H

[66] Zhang D S, Choi W, Jakobi J, et al. Spontaneous shape alteration and size separation of surfactant-free silver particles synthesized by laser ablation in acetone during long-period storage[J]. Nanomaterials, 2018, 8(7): 529. doi: 10.3390/nano8070529

[67] Tan D Z, Teng Y, Liu Y, et al. Preparation of zirconia nanoparticles by pulsed laser ablation in liquid[J]. Chem Lett, 2009, 38(11): 1102−1103. doi: 10.1246/cl.2009.1102

[68] Amans D, Diouf M, Lam J, et al. Origin of the nano-carbon allotropes in pulsed laser ablation in liquids synthesis[J]. J Colloid Interface Sci, 2017, 489: 114−125. doi: 10.1016/j.jcis.2016.08.017

[69] Dhanunjaya M, Byram C, Vendamani V S, et al. Hafnium oxide nanoparticles fabricated by femtosecond laser ablation in water[J]. Appl Phys A, 2019, 125(1): 74. doi: 10.1007/s00339-018-2366-y

[70] Camarda P, Vaccaro L, Sciortino A, et al. Synthesis of multi-color luminescent ZnO nanoparticles by ultra-short pulsed laser ablation[J]. Appl Surf Sci, 2020, 506: 144954. doi: 10.1016/j.apsusc.2019.144954

[71] Liu K W, Sakurai M, Aono M. ZnO-based ultraviolet photodetectors[J]. Sensors, 2010, 10(9): 8604−8634. doi: 10.3390/s100908604

[72] Mitra S, Aravindh A, Das G, et al. High-performance solar-blind flexible deep-UV photodetectors based on quantum dots synthesized by femtosecond-laser ablation[J]. Nano Energy, 2018, 48: 551−559. doi: 10.1016/j.nanoen.2018.03.077

[73] Huang Y J, Xie X Z, Li M N, et al. Copper circuits fabricated on flexible polymer substrates by a high repetition rate femtosecond laser-induced selective local reduction of copper oxide nanoparticles[J]. Opt Express, 2021, 29(3): 4453−4463. doi: 10.1364/OE.416772

[74] Lee H, Yang M Y. Effect of solvent and PVP on electrode conductivity in laser-induced reduction process[J]. Appl Phys A, 2015, 119(1): 317−323. doi: 10.1007/s00339-014-8970-6

[75] Mizoshiri M, Hata S. Direct writing of Cu-based micro-temperature sensors onto glass and Poly(dimethylsiloxane) substrates using femtosecond laser reductive patterning of CuO nanoparticles[J]. Res Rev J Mater Sci, 2016, 4(4): 47−54.

[76] Mizoshiri M, Ito Y, Arakane S, et al. Direct fabrication of Cu/Cu2O composite micro-temperature sensor using femtosecond laser reduction patterning[J]. Jpn Appl Phys, 2016, 55(6S1): 06GP05. doi: 10.7567/JJAP.55.06GP05

[77] 廖嘉宁, 王欣达, 周兴汶, 等. 飞秒激光直写铜微电极研究[J]. 中国激光, 2019, 46(10): 1002013. doi: 10.3788/CJL201946.1002013

Liao J N, Wang X D, Zhou X W, et al. Femtosecond laser direct writing of copper microelectrodes[J]. Chin J Lasers, 2019, 46(10): 1002013. doi: 10.3788/CJL201946.1002013

[78] Ferreira P H D, Vivas M G, De Boni L, et al. Femtosecond laser induced synthesis of Au nanoparticles mediated by chitosan[J]. Opt Express, 2012, 20(1): 518−523. doi: 10.1364/OE.20.000518

[79] Barton P, Mukherjee S, Prabha J, et al. Fabrication of silver nanostructures using femtosecond laser-induced photoreduction[J]. Nanotechnology, 2017, 28(50): 505302. doi: 10.1088/1361-6528/aa977b

[80] Ma Z C, Zhang Y L, Han B, et al. Femtosecond laser direct writing of plasmonic Ag/Pd Alloy nanostructures enables flexible integration of robust SERS substrates[J]. Adv Mater Technol, 2017, 2(6): 1600270. doi: 10.1002/admt.201600270

[81] Soni M, Kumar P, Pandey J, et al. Scalable and site specific functionalization of reduced graphene oxide for circuit elements and flexible electronics[J]. Carbon, 2018, 128: 172−178. doi: 10.1016/j.carbon.2017.11.087

[82] Guan H, Meng J W, Cheng Z Y, et al. Processing natural wood into a high-performance flexible pressure sensor[J]. ACS Appl Mater Interfaces, 2020, 12(41): 46357−46365. doi: 10.1021/acsami.0c12561

[83] Wan Z F, Streed E W, Lobino M, et al. Laser-reduced graphene: synthesis, properties, and applications[J]. Adv Mater Technol, 2018, 3(4): 1700315. doi: 10.1002/admt.201700315

[84] Low M J, Lee H, Lim C H J, et al. Laser-induced reduced-graphene-oxide micro-optics patterned by femtosecond laser direct writing[J]. Appl Surf Sci, 2020, 526: 146647. doi: 10.1016/j.apsusc.2020.146647

[85] Dinh Le T S, An J N, Huang Y, et al. Ultrasensitive anti-interference voice recognition by bio-inspired skin-attachable self-cleaning acoustic sensors[J]. ACS Nano, 2019, 13(11): 13293−13303. doi: 10.1021/acsnano.9b06354

[86] An J N, Le T S D, Huang Y, et al. All-graphene-based highly flexible noncontact electronic skin[J]. ACS Appl Mater Interfaces, 2017, 9(51): 44593−44601. doi: 10.1021/acsami.7b13701

[87] Yuan Y J, Jiang L, Li X, et al. Laser photonic-reduction stamping for graphene-based micro-supercapacitors ultrafast fabrication[J]. Nat Commun, 2020, 11(1): 6185. doi: 10.1038/s41467-020-19985-2

[88] Li R Z, Peng R, Kihm K D, et al. High-rate in-plane micro-supercapacitors scribed onto photo paper using in situ femtolaser-reduced graphene oxide/Au nanoparticle microelectrodes[J]. Energy Environ Sci, 2016, 9(4): 1458−1467. doi: 10.1039/C5EE03637B

[89] Kim Y J, Le T S D, Nam H K, et al. Wood-based flexible graphene thermistor with an ultra-high sensitivity enabled by ultraviolet femtosecond laser pulses[J]. CIRP Ann, 2021, 70(1): 443−446. doi: 10.1016/j.cirp.2021.04.031

[90] In J B, Hsia B, Yoo J H, et al. Facile fabrication of flexible all solid-state micro-supercapacitor by direct laser writing of porous carbon in polyimide[J]. Carbon, 2015, 83: 144−151. doi: 10.1016/j.carbon.2014.11.017

[91] Bai J R, Gao Y, Lu C, et al. Femtosecond laser micro-fabricated flexible sensor arrays for simultaneous mechanical and thermal stimuli detection[J]. Measurement, 2021, 169: 108348. doi: 10.1016/j.measurement.2020.108348

[92] Wang S T, Yu Y C, Li R Z, et al. High-performance stacked in-plane supercapacitors and supercapacitor array fabricated by femtosecond laser 3D direct writing on polyimide sheets[J]. Electrochim Acta, 2017, 241: 153−161. doi: 10.1016/j.electacta.2017.04.138

[93] Cheng C, Wang S T, Wu J, et al. Bisphenol a sensors on polyimide fabricated by laser direct writing for onsite river water monitoring at attomolar concentration[J]. ACS Appl Mater Interfaces, 2016, 8(28): 17784−17792. doi: 10.1021/acsami.6b03743

[94] Xiao M, Zheng S, Shen D Z, et al. Laser-induced joining of nanoscale materials: processing, properties, and applications[J]. Nano Today, 2020, 35: 100959. doi: 10.1016/j.nantod.2020.100959

[95] Deng Y B, Bai Y F, Yu Y C, et al. Laser nanojoining of copper nanowires[J]. J Laser Appl, 2019, 31(2): 022414. doi: 10.2351/1.5096137

[96] Han S, Hong S, Ham J, et al. Fast plasmonic laser nanowelding for a Cu-nanowire percolation network for flexible transparent conductors and stretchable electronics[J]. Adv Mater, 2014, 26(33): 5808−5814. doi: 10.1002/adma.201400474

[97] 林路禅, 邢松龄, 霍金鹏, 等. 超快激光纳米线连接技术研究进展[J]. 中国激光, 2021, 48(8): 0802001. doi: 10.3788/CJL202148.0802001

Lin L C, Xing S L, Huo J P, et al. Research progress of ultrafast laser-induced nanowires joining technology[J]. Chin J Lasers, 2021, 48(8): 0802001. doi: 10.3788/CJL202148.0802001

[98] Ha J, Lee B J, Hwang D J, et al. Femtosecond laser nanowelding of silver nanowires for transparent conductive electrodes[J]. RSC Adv, 2016, 6(89): 86232−86239. doi: 10.1039/C6RA19608J

[99] Yu Y C, Deng Y B, Al Hasan M A, et al. Femtosecond laser-induced non-thermal welding for a single Cu nanowire glucose sensor[J]. Nanoscale Adv, 2020, 2(3): 1195−1205. doi: 10.1039/C9NA00740G

[100] Acuautla M, Bernardini S, Bendahan M, et al. Ammonia sensing properties of ZnO nanoparticles on flexible substrate[J]. Int J Smart Sens Intell Syst, 2020, 7(5): 1−4.

[101] Schmiedt R E, Qian C, Behr C, et al. Flexible sensors on polymide fabricated by femtosecond laser for integration in fiber reinforced polymers[J]. Flex Print Electron, 2018, 3(2): 025003. doi: 10.1088/2058-8585/aabe45

[102] Das T, Sharma B K, Katiyar A K, et al. Graphene-based flexible and wearable electronics[J]. J Semicond, 2018, 39(1): 011007. doi: 10.1088/1674-4926/39/1/011007

[103] Kalita G, Qi L T, Namba Y, et al. Femtosecond laser induced micropatterning of graphene film[J]. Mater Lett, 2011, 65(11): 1569−1572. doi: 10.1016/j.matlet.2011.02.057

[104] Ye X H, Qi M, Yang Y F, et al. Pattern directive sensing selectivity of graphene for wearable multifunctional sensors via femtosecond laser fabrication[J]. Adv Mater Technol, 2020, 5(11): 2000446. doi: 10.1002/admt.202000446

[105] Li Q, Wang Q Z, Li L L, et al. Femtosecond laser‐etched mxene microsupercapacitors with double‐side configuration via arbitrary on‐ and through‐substrate connections[J]. Adv Energy Mater, 2020, 10(24): 2000470. doi: 10.1002/aenm.202000470

[106] Wang H, Cheng J, Wang Z Z, et al. Triboelectric nanogenerators for human-health care[J]. Sci Bull, 2021, 66(5): 490−511. doi: 10.1016/j.scib.2020.10.002

[107] 程广贵, 张伟, 方俊, 等. 基于织构表面的摩擦静电发电机制备及其输出性能研究[J]. 物理学报, 2016, 65(6): 060201. doi: 10.7498/aps.65.060201

Cheng G G, Zhang W, Fang J, et al. Fabrication of triboelectric nanogenerator with textured surface and its electric output performance[J]. Acta Phys Sin, 2016, 65(6): 060201. doi: 10.7498/aps.65.060201

[108] Huang J, Fu X P, Liu G X, et al. Micro/nano-structures-enhanced triboelectric nanogenerators by femtosecond laser direct writing[J]. Nano Energy, 2019, 62: 638−644. doi: 10.1016/j.nanoen.2019.05.081

[109] Xiao X Z, Lü C, Wang G, et al. Flexible triboelectric nanogenerator from micro-nano structured polydimethylsiloxane[J]. Chem Res Chin Univ, 2015, 31(3): 434−438. doi: 10.1007/s40242-015-4432-8

[110] Wang S, Xie G Z, Tai H L, et al. Ultrasensitive flexible self-powered ammonia sensor based on triboelectric nanogenerator at room temperature[J]. Nano Energy, 2018, 51: 231−240. doi: 10.1016/j.nanoen.2018.06.041

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: