-

摘要

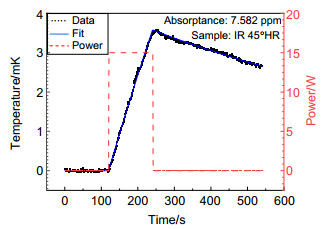

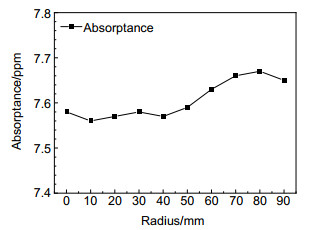

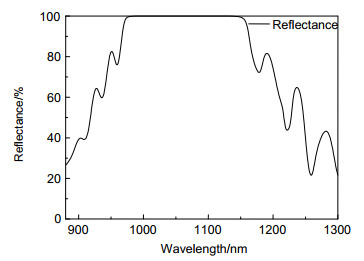

光学薄膜在制备和使用过程中会因缺陷和污染等产生吸收中心,当薄膜受激光辐照后,吸收中心吸收光能会产生热信号,根据热信号可以测量光学薄膜的光学吸收损耗。本文提出基于红外热像仪测量薄膜光学吸收损耗的方法,在测试中加入参考样品可以减少环境温度变化和热像仪噪声对于温度测试结果的影响,对测量过程温度场取一定面积进行平均减少了激光指向波动和光斑分布不理想导致的有限元仿真计算误差。使用本方法测试了小尺寸45°的高反膜吸收损耗,测试得到吸收损耗为7.60 ppm,且测试了同批次大尺寸光学薄膜样品吸收损耗的空间分布情况。使用本方法测量的光学薄膜吸收率和激光量热测试结果一致,不需要长时间的恒温和严格环境温度控制,且测试样品尺寸不受限制。

Abstract

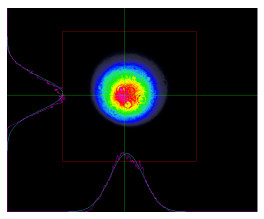

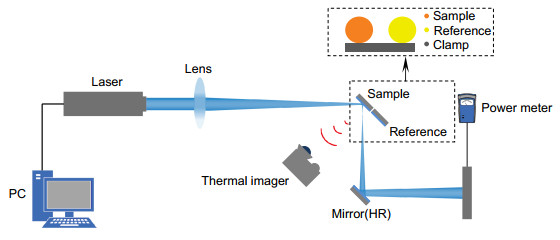

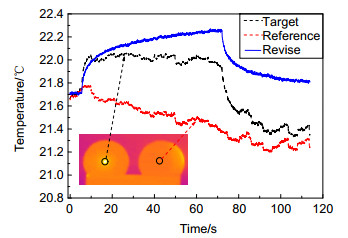

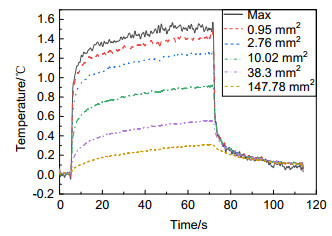

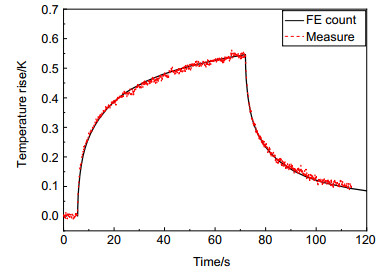

During the preparation and use of the optical thin film, the absorption center will be generated due to defects and pollution. When the optical thin film is irradiated by a laser, the absorption center absorbs light energy and generates thermal signals, according to which the optical absorption loss of an optical film can be measured. The method proposed in this paper for measuring the optical absorption loss of a thin film based on a thermal imager. The addition of a reference sample in the test can reduce the impact of the changes of environmental temperature and the thermal imager noise on the temperature test results. Taking a certain area of the temperature field recorded by the thermal imager during the entire laser irradiation process can reduce the errors of the finite element simulation calculation caused by the laser pointing fluctuations and the unsatisfactory spot distribution. Using this method, the absorption loss of a small-size 45° high-reflection film was tested to be 7.60 ppm, and the spatial distribution of the absorption loss of the same batch of large-size optical film samples were tested. The absorption of the optical film measured by this method is consistent with the result of the laser calorimetry test. This method does not require long-term constant temperature and strict environmental temperature control, and the tested sample size is not limited.

-

Key words:

- optical thin film /

- absorption loss /

- infrared thermography /

- finite element /

- absorption measurement

-

Overview

Overview: During the preparation and use of the optical thin film, the absorption center will be generated due to defects and pollution. When illuminating optical film by laser light, the absorption center will absorb light energy and effectively generate the thermal signals. There are many methods for measuring the optical absorption loss of optical films, such as the laser calorimeter method, photothermal deflection method, surface thermal lens method, and so on. These methods have some problems, such as long measurement time, the influence of scattering on optical absorption, and the high requirement of spatial light position detector. The accuracy of the infrared thermal imager has been able to measure relatively small temperature changes in recent years, which provides the possibility for the measurement of the optical thin film absorption based on the infrared thermal imager. Infrared thermal imaging has unique advantages in measuring the absorption loss of optical films due to their simple measurement of the optical path, rapid measurement, and non-contact accurate temperature measurement.

The method proposed in this paper is based on thermal imager to measure the optical absorption loss of thin films. The method proposed in this paper for measuring the optical absorption loss of a thin film based on a thermal imager is simpler than the existing method, and it can measure the absorption of thin films of optical elements in the laser. The addition of a reference sample in the test can reduce the impact of the changes of environmental temperature and the thermal imager noise on the temperature test results. Taking a certain area of the temperature field recorded by the thermal imager during the entire laser irradiation process can reduce the errors of the finite element simulation calculation caused by laser pointing fluctuations and the unsatisfactory spot distribution. The temperature change curve of the film during laser irradiation is obtained by a thermal imager, and the accurate absorption value of the film sample can be calculated through finite element simulation.

In this paper, a thermal imager was used to test the absorption loss of a small 45° high-reflection film. The absorption loss was 7.6 ppm, and the spatial distributions of the absorption loss of the same batch of large-size optical film samples were tested, the optical absorption was consistent. The absorption of the optical film measured by this method is consistent with the result of the laser calorimetry test. This method does not require long-term constant temperature and strict environmental temperature control, and the tested sample size is not limited.

-

-

表 1 熔融石英材料热物理参数

Table 1. Thermophysical parameters of fused silica

Material Thermal conductivity/(W·m-1·K-1) Density/(kg·m-3) Heat capacity/(J·kg-1·K-1) Fused silica 1.4 2200 746 表 2 不同面积区域平均温度计算吸收值

Table 2. The absorption values of average temperature in different areas were calculated

Area/(mm2) Max 0.95 2.76 10.02 38.30 149.79 Absorptivity/ppm 7.45 7.45 7.45 7.48 7.60 7.80 -

参考文献

[1] 孔明东, 李斌成, 郭春, 等. SiO2光学薄膜的吸收边特性[J]. 光电工程, 2019, 46(4): 180220. doi: 10.12086/oee.2019.180220

Kong M D, Li B C, Guo C, et al. Characterictics of absorption edge of SiO2 films[J]. Opto-Electron Eng, 2019, 46(4): 180220. doi: 10.12086/oee.2019.180220

[2] Willamowski U, Ristau D, Welsch E. Measuring the absolute absorptance of optical laser components[J]. Appl Opt, 1998, 37(36): 8362-8370. doi: 10.1364/AO.37.008362

[3] Kuo P K, Munidasa M. Single-beam interferometry of a thermal bump[J]. Appl Opt, 1990, 29(36): 5326-5331. doi: 10.1364/AO.29.005326

[4] Saito H, Irikura M, Haraguchi M, et al. New type of photothermal spectroscopic technique[J]. Appl Opt, 1992, 31(12): 2047-2054. doi: 10.1364/AO.31.002047

[5] 姜玉刚, 刘华松, 陈丹, 等. 基于离子束溅射Ta2O5薄膜的紫外吸收膜技术[J]. 光学精密工程, 2019, 27(3): 527-532. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201903004.htm

Jiang Y G, Liu H S, Chen D, et al. Ultraviolet absorption film technology based on ion beam sputtering Ta2O5 thin films[J]. Opt Prec Eng, 2019, 27(3): 527-532. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201903004.htm

[6] Commandré M, Roche P. Characterization of optical coatings by photothermal deflection[J]. Appl Opt, 1996, 35(25): 5021-5034. doi: 10.1364/AO.35.005021

[7] Wu Z L, Reichling M, Hu X Q, et al. Absorption and thermal conductivity of oxide thin films measured by photothermal displacement and reflectance methods[J]. Appl Opt, 1993, 32(28): 5660-5665. doi: 10.1364/AO.32.005660

[8] 王艳茹, 李斌成, 刘明强. 表面热透镜技术测量光学薄膜样品表面热变形[J]. 强激光与粒子束, 2010, 22(8): 1805-1809. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201008026.htm

Wang Y R, Li B C, Liu M Q. Measurement of thermal deformation using surface thermal lens technique[J]. High Power Laser Part Beams, 2010, 22(8): 1805-1809. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201008026.htm

[9] Mcdonald F A, Wetsel Jr G C. Generalized theory of the photoacoustic effect[J]. J Appl Phys, 1978, 49(4): 2313-2322. doi: 10.1063/1.325116

[10] ISO. Optics and photonics-Lasers and laser-related equipment-Test method for absorptance of optical laser components: ISO 11551: 2019[S]. Geneva, Switzerland: ISO, 2019.

[11] 杨立, 杨桢. 红外热成像测温原理与技术[M]. 北京: 科学出版社, 2012.

Yang L, Yang Z. Principle and Technology of Infrared Thermal Imaging Temperature Measurement[M]. Beijing: Science Press, 2012.

[12] FLIR Systems Inc. User Manual FLIR T10xx Series[M]. State of Oregon, America, 2018.

[13] 李云红, 孙晓刚, 原桂彬. 红外热像仪精确测温技术[J]. 光学精密工程, 2007, 15(9): 1336-1341. doi: 10.3321/j.issn:1004-924x.2007.09.005

Li Y H, Sun X G, Yuan G B. Accurate measuring temperature with infrared thermal imager[J]. Opt Prec Eng, 2007, 15(9): 1336-1341. doi: 10.3321/j.issn:1004-924x.2007.09.005

[14] Wood W L, Lewis R W. A comparison of time marching schemes for the transient heat conduction equation[J]. Int J Numer Methods Eng, 1975, 9(3): 679-689. doi: 10.1002/nme.1620090314

[15] 陈敏孙, 江厚满, 刘泽金. 激光辐照下复合材料树脂基热分解3维温度场模型[J]. 强激光与粒子束, 2011, 23(3): 642-646. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201103020.htm

Chen M S, Jiang H M, Liu Z J. Three-dimensional temperature field model of thermally decomposing resin composite irradiated by laser[J]. High Power Laser Part Beams, 2011, 23(3): 642-646. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201103020.htm

[16] 代福, 熊胜明, 张云洞. 激光辐照下光学薄膜元件温升的有限元分析[J]. 红外与激光工程, 2008, 37(4): 714-718. doi: 10.3969/j.issn.1007-2276.2008.04.036

Dai F, Xiong S M, Zhang Y D. Finite element analysis of temperature rise of optical thin film element under laser irradiation[J]. Infrared Laser Eng, 2008, 37(4): 714-718. doi: 10.3969/j.issn.1007-2276.2008.04.036

[17] 王艳茹, 李斌成, 刘明强. 激光照射有限尺寸高反射光学元件的温度场[J]. 强激光与粒子束, 2010, 22(2): 335-340. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201002028.htm

Wang Y R, Li B C, Liu M Q. Laser-induced temperature distributions in finite radial-size optical mirror[J]. High Power Laser Part Beams, 2010, 22(2): 335-340. https://www.cnki.com.cn/Article/CJFDTOTAL-QJGY201002028.htm

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: