-

摘要

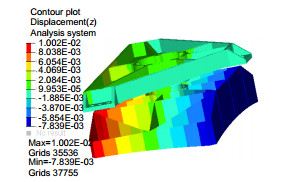

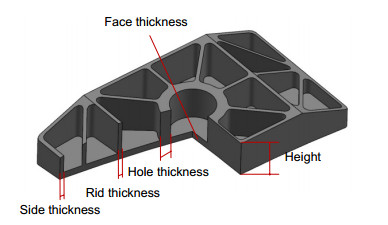

为解决空间反射镜镜体质量和面形精度在轻量化设计过程中会引起相互冲突的问题,针对某型离轴三反光学系统的长条形主反射镜进行了结构优化设计研究,提出了一种基于SiC材料的中心支撑的轻量化结构,同时引入了多目标集成优化方法,以镜体质量(Mass)和面形(RMS)同时作为优化目标,得到一个反射镜最佳结构模型,其质量为2.32 kg,轻量化率达到了73.8%;然后,对反射镜支撑结构进行了结构设计和说明,并对该组件进行了仿真分析,在X、Y、Z三轴方向1 g重力工况下的RMS值分别达到2.5 nm、2.2 nm、7.3 nm,4 ℃均匀温升载荷工况下的RMS值为3.2 nm,远小于设计要求的RMS≤λ/50(λ=632.8 nm),满足设计要求。

Abstract

In order to solve the problem that the mass and the surface figure accuracy of the space reflective mirror are often contradictory in the lightweight design process, a structural optimization design of a lightweight rectangular reflective mirror of an off-axis three-reflection optical system is performed. In this study, a lightweight structure based on the center support of SiC materials is proposed. At the same time, a multi-objective optimization method is introduced. With the RMS value and Mass as the optimization targets at the same time, a mirror optimal structure model is obtained with a mass of 2.32 kg. Compared with the solid mirror, the lightweight ratio is 73.8%. Then the mirror subassembly is designed and the integrated performance of it is simulated. It shows that the RMS value of the mirror reaches respectively 2.5 nm, 2.2 nm and 7.3 nm when gravity load is applied in the directions of X, Y and Z axes. Furthermore, the RMS value is 3.2 nm when the mirror subassembly is under the load condition of uniform temperature rise of 4 ℃, which is far less than the requirement of RMS≤λ/50(λ=632.8 nm). Therefore the data meets the design requirements.

-

Overview

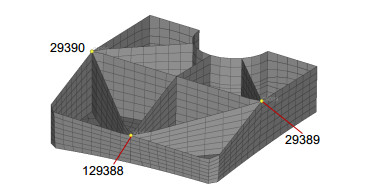

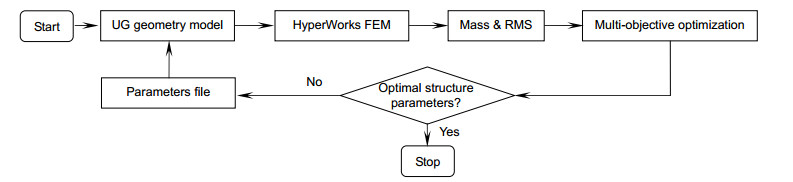

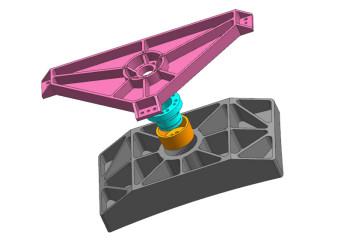

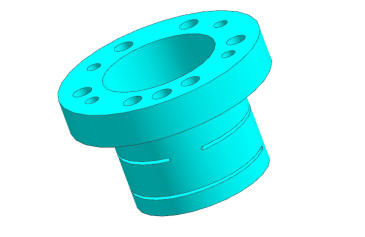

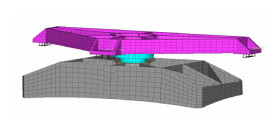

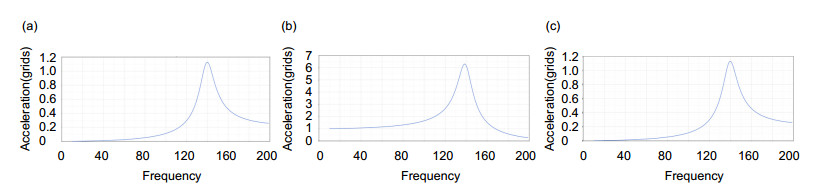

Overview: The research area of this paper is the field of off-axis three-reflective space optical remote sensor. As a core element of the system, the rectangular reflective mirror has been the focus. Increasing the degree of lightweight will also bring new problems, which cause a certain degree of structural strength reduction. Obviously, RMS(root mean square) will get worse. The purpose of this paper is to propose a feasible solution to this conflict of performance. First of all, select SiC as the mirror body material. Secondly, a flexible structure is based on the center support, which facilitates lightweight and reduces the overall design difficulty. Next, use the classical theoretical formula to create the initial structure of the mirror. The most important step is to introduce a multi-objective optimization method. The structural parameters of the lens body are used as design variables, and then the surface RMS values under X and Y gravity conditions are used as constraints. It is the mass of the mirror and the RMS values under the most sensitive Z-direction gravity conditions that are commonly set as the optimization goal. Furthermore, using GRSM(global response surface method) algorithm for optimization iterations. A mirror optimal structure model is obtained with a mass of 2.32 kg. Compared with the solid mirror, the lightweight ratio is 73.8%. Besides, the mirror subassembly is designed. It includes a cone sleeve, a flexible component, and a backplane. The main considerations of the assembly are the stiffness of the materials and the thermal compatibility between each other. The specific explanation is as follows. Thermal expansion coefficient of the cone sleeve and the mirror need to be the same, and these are connected by glue. The flexible component adopts a flexible hinge structure so as to improve RMS of the mirror due to thermal stress. The backplane connects the mirror assembly to one space remote sensor. Therefore, the rigidity of the backplane must be qualified. Finally, the integrated performance of the assembly is simulated. It shows that the RMS value of the mirror reaches respectively 2.5 nm, 2.2 nm and 7.3 nm when gravity load is applied in the directions of X, Y and Z axes. Furthermore, the RMS value is 3.2 nm when the mirror subassembly is under the load condition of uniform temperature rise of 4 ℃, which is far less than the requirement of RMS≤λ/50(λ=632.8 nm). As a result, the data meets the design requirements. To sum up, the method provides reference experience for structural optimization design of the same type of lightweight rectangular reflective mirror.

-

-

表 1 常用反射镜材料的性能

Table 1. Performance of rational materials for mirror

材料 密度ρ/(g/cm3) 弹性模量E /(GPa) 比刚度E/ρ /(GN·(m/g)) 线胀系数α /(10-6/K) 导热系数λ /(W/(m·K)) 比热容c/(J/(kg·K)) 热稳定性λ/α 综合品质(λ/α)·(E/ρ) FS 2.19 72.00 32.88 0.50 1.40 750.00 2.80 92.05 Zerodur 2.53 91.00 35.97 0.05 1.64 821.00 32.80 1179.76 Al 2.70 68.00 25.19 22.50 167.00 896.00 7.42 186.93 Be 1.85 287.00 155.14 11.40 216.00 1925.00 18.95 2962.53 Si 2.33 131.00 56.22 2.60 137.00 710.00 52.69 2962.53 SiC 3.20 400.00 125.00 2.40 155.00 650.00 64.58 8072.92 表 2 设计变量和优化结果

Table 2. Design variables and optimization results

Name Height Face thickness Hole thickness Side thickness θ(Chamfer) Rib thickness Mass RMS_X RMS_Y RMS_Z Ranges [30, 60] [5, 30] [5, 20] [1.5, 10] [0, 60] [1.5, 10] (0, 5] [0, 12] [0, 12] [0, 12] Value 42 mm 8 mm 9.4 mm 4 mm 23° 4 mm 2.32 kg 3.0 nm 1.8 nm 4.5 nm 表 3 空间主要应用的结构材料列表

Table 3. Main structural materials in space

材料 密度ρ/(g/cm3) 弹性模量E/(GPa) 比刚度E/ρ/(GN·(m/g)) 线胀系数α/(10-6/K) 导热系数λ/(W/(m·K)) 比热容c/(J/(kg·K)) 热稳定性λ/α 综合品质(λ/α)·(E/ρ) TC4 4.40 114.00 25.91 9.10 7.40 611.00 0.81 21.07 Invar 8.90 141.00 15.84 0.65 13.70 460.00 21.08 333.92 高体份SiC/Al 3.00 180.00 60.00 8.00 225.00 7115.00 28.13 1687.50 -

参考文献

[1] 张科科, 阮宁娟, 傅丹鹰.国外空间用三反离轴相机发展分析与思考[J].航天返回与遥感, 2008, 29(3): 63-70. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=htfhyyg200803012

Zhang K K, Ruan N J, Fu D Y. Analysis and consideration of development of overseas space off-axis TMA system camera[J]. Spacecraft Recovery & Remote Sensing, 2008, 29(3): 63-70. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=htfhyyg200803012

[2] 张亮, 安源, 金光.大视场、长焦距离轴三反射镜光学系统的设计[J].红外与激光工程, 2007, 36(2): 278-280. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc200702034

Zhang L, An Y, Jin G. Optical design of the uncoaxial three-mirror system with wide field of view and long focal length[J]. Infrared and Laser Engineering, 2007, 36(2): 278-280. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc200702034

[3] 朱俊青, 沙巍, 陈长征, 等.空间长条形反射镜背部三支撑点的设置[J].光学 精密工程, 2015, 23(9): 2562-2569. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201509018

Zhu J Q, Sha W, Chen C Z, et al. Position layout of rear three point mounting for space rectangular mirror[J]. Optics and Precision Engineering, 2015, 23(9): 2562-2569. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201509018

[4] 辛宏伟, 关英俊, 李景林, 等.大孔径长条反射镜支撑结构的设计[J].光学 精密工程, 2011, 19(7): 1560-1568. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201107018

Xin H W, Guan Y J, Li J L, et al. Design of support for large aperture rectangular mirror[J]. Optics and Precision Engineering, 2011, 19(7): 1560-1568. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxjmgc201107018

[5] Park K S, Lee J H, Youn S K. Lightweight mirror design method using topology optimization[J]. Optical Engineering, 2005, 44(5): 053002. doi: 10.1117/1.1901685

[6] 辛宏伟.小型轻质长条反射镜挠性支撑方案研究[J].光机电信息, 2010, 27(7): 51-55. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gjdxx201007009

Xin H W. Design and analysis on the flexible structure of the optical reflector[J]. OME Information, 2010, 27(7): 51-55. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gjdxx201007009

[7] 包奇红, 沙巍, 陈长征, 等.中心支撑长条形反射镜轻型优化设计[J].红外与激光工程, 2017, 46(7): 157-163. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc201707024

Bao Q H, Sha W, Chen C Z, et al. Lightweight and optimization design of rectangular reflective mirror supported in centre[J]. Infrared and Laser Engineering, 2017, 46(7): 157-163. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc201707024

[8] 汪奎, 辛宏伟, 徐宏, 等.空间相机快速反射镜的结构轻量化设计[J].红外与激光工程, 2019, 48(4): 0418001. http://www.cqvip.com/QK/91846A/201904/72878974504849574852485054.html

Wang K, Xin H W, Xu H, et al. Lightweight design of fast steering mirror for space cameras[J]. Infrared and Laser Engineering, 2019, 48(4): 0418001. http://www.cqvip.com/QK/91846A/201904/72878974504849574852485054.html

[9] 张学军, 李志来, 张忠玉.基于SiC材料的空间相机非球面反射镜结构设计[J].红外与激光工程, 2007, 36(5): 577-582. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc200705001

Zhang X J, Li Z L, Zhang Z Y. Space telecope aspherical mirror structure design based on SiC material[J]. Infrared and Laser Engineering, 2007, 36(5): 577-582. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hwyjggc200705001

[10] Friedman E. Photonics Rules of Thumb[M]. New York: McGraw Hill, 2003.

[11] 王克军, 董吉洪.空间遥感器Ф2m量级大口径SiC反射镜镜坯结构设计[J].红外与激光工程, 2017, 46(7): 0718005.

Wang K J, Dong J H. Structural design of Ф2m-level large-diameter SiC reflector used in space remote sensor[J]. Infrared and Laser Engineering, 2017, 46(7): 0718005.

[12] Parks R E, Wortley R W, Cannon J E. Engineering with lightweight mirrors[J]. Proceedings of SPIE, 1990, 1236: 735-743. doi: 10.1117/12.19243

[13] Anderson D, Parks R E, Hansen Q M, et al. Gravity deflections of lightweighted mirrors[J]. Proceedings of SPIE, 1982, 0332: 424-435. doi: 10.1117/12.933550

[14] Vukobratovich D, Iraninejad B, Richard R M, et al. Optimum Shapes for Lightweighted Mirrors[J]. Proceedings of SPIE, 1982, 0332: 419-423. doi: 10.1117/12.933549

[15] 王晓宇, 周平伟.长条形空间反射镜镜体及其支撑结构设计[J].长春理工大学学报(自然科学版), 2017, 40(2): 6-9, 13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ccgxjmjxxyxb201702002

Wang X Y, Zhou P W. Design of rectangular space mirror and its support structure[J]. Journal of Changchun University of Science and Technology (Natural Science Edition), 2017, 40(2): 6-9, 13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ccgxjmjxxyxb201702002

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: