Preparation and environmental simulation tests of large-size silicon carbide brazed reflection mirrors

-

摘要

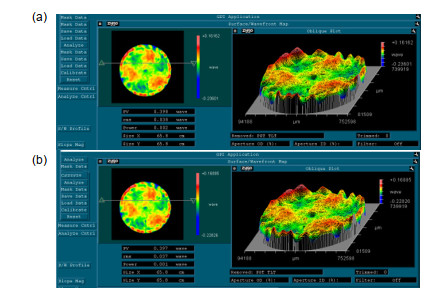

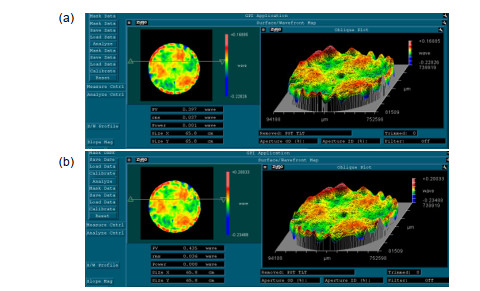

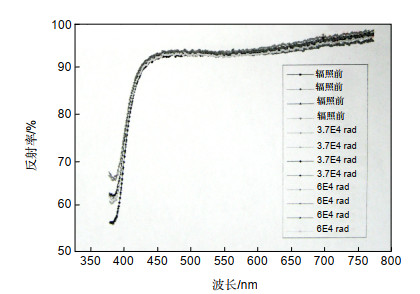

随着空间技术的快速发展,对大尺寸空间反射镜部件的需求愈发强烈。本文从材料和制备技术角度分析了大尺寸碳化硅反射镜的发展趋势,并以Φ1.0 m口径常压烧结碳化硅拼接式技术验证镜研制过程为例,对拼接式反射镜的分块镜设计制备、连接、光学加工等过程进行了探讨。此外,结合实际的工程化应用需求,对1.0 m口径碳化硅拼接式技术验证镜进行了包括热真空、振动和抗辐照等在内的环境模拟试验。试验结果表明:通过合理的制备技术,Φ1.0 m口径的碳化硅拼接式技术验证镜光学加工后面形RMS达到了0.038λ (λ=632.8 nm),经历热真空和振动的环境模拟考核后,其面形RMS分别为0.037λ和0.036λ;此外,拼接式反射镜经过60Co γ射线辐照测试后,反射率指标基本保持不变,显示了良好的工程应用前景。

Abstract

With the space technologies progress rapidly, demand of large-size mirrors is intensively growing. In this paper, the developing trend of large-size space mirrors was discussed from the angles of material and fabrication technology. Taking 1.0 m aperture technical validation brazed mirror as an example, the design and fabrication of segments, joining and optic machining were analyzed. In addition, the 1.0 m aperture technical validation brazed mirror was performed environmental tests including thermal-vacuum test, vibration test and anti-radiation test in order to evaluate its engineering applicability. The experimental results show that the surface figure of the 1.0 m aperture technical validation brazed mirror changed from 0.038λ (λ=632.8 nm) to 0.037λ and 0.036λ after thermo-vacuum test and vibration test. Additionally, reflectivity of the brazed mirror basically kept stable after 60Co γ-ray radiation test, indicating a brilliant application prospect.

-

Overview

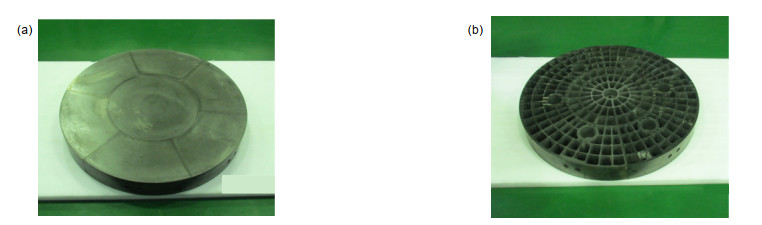

Overview: In recent years, deep space exploration space telescope and high resolution remote sensing systems are experiencing rapid development. As key part of space optic system, large-size reflecting mirrors is intensively needed. With the progress of large-size space mirrors, material and fabrication technology are facing more serious challenges. As candidate optic materials to fabricate large-size mirrors, it should have higher specific stiffness (E/ρ), better thermal properties (λ/α), high lightweight and excellent isotropy. Among all the optic materials, such as Zeroduo glass ceramics, ULE glass, beryllium and silicon carbide, silicon carbide is especially suitable for the preparation of large-size space mirrors with its excellent properties, which has been chosen in some space programs by several countries. So, from the angle of material, silicon carbide is becoming the main-stream optic material to fabricate large-size space mirrors. However, restrained by preparation progress and equipment size, it is difficult to fabricate large-size monolithic space mirrors. So, brazing segments to assemble is a good technical path to solve the difficulty, which has realized engineering application in Herschel space telescope. Shanghai Institute of Ceramics have been involving the study of Sintered silicon carbide material space mirrors and joining technology of silicon carbide for a long time, and in this paper taking a 1.0 m aperture silicon carbide brazed technical validation mirror as example, the fabrication progress of brazed mirror was analyzed. Meanwhile, in order to evaluate engineering applicability of the brazed mirror, several environmental simulation tests, including thermal-vacuum test, vibration test and anti-radiation teste were performed. The 1.0 m aperture brazed mirror was designed as the structure of 6 fan-shape segments and 1 circular segment, which can be used for the off-axis optical system. Using the proper brazing material and optimized joining structure, the 1.0 m aperture brazed mirror was successfully fabricated. Then, the 1.0 m aperture brazed mirror was carried out optical machining, and the surface figure RMS was 0.038λ (λ=632.8 nm), indicating stiffness of the brazed mirror is satisfied with requirements of optic machining. The 1.0 m aperture brazed mirror was first performed thermal-vacuum test with the condition of 10-3 Pa vacuum and 15~25 centigrade Celsius temperature cycle, and the surface figure was 0.037λ after the thermal-vacuum test. Then, the 1.0 m aperture brazed mirror was performed vibration test, and surface figure was 0.036λ after the vibration test. Finally, the brazed mirror of 100 mm aperture was carried out anti-radiation test in order to evaluate the effect of high energy rays on the reflectivity of the brazed mirror, and the experiment showed that the reflectivity of the brazed mirror after coating kept basically constant after 60Co γ ray radiation. The environmental simulation tests indicated that the brazed mirrors have better engineering applicability.

-

-

表 1 大尺寸空间反射镜材料性能

Table 1. Properties of material to fabricate large-size space mirrors

材料性能 Zerodur ULE Be SSiC*@siccas RB-SiC[10] Cf/SiC[11] 密度ρ/(g/cm3) 2.52 2.2 1.84 3.11 3.03 2.65 弹性模量E/GPa 92.9 67 303 404 360 249 比刚度E/ρ 36.9 30.5 164.7 129.9 118.8 94 热导率λ/(W/m·K) 1.64 1.3 216 172 130 120 热膨胀系数α/(10-6/K) 0.05 0.03 11.5 2.34 2.5 2.1 热学稳定性λ/α 32.8 43.3 18.8 73.5 52 57.1 泊松比 0.24 0.17 0.12 0.17 0.18 各相异性 < 5% < 5% *中国科学院上海硅酸盐研究所研制的常压烧结碳化硅 表 2 1.0 m口径碳化硅拼接技术验证镜的热真空试验条件

Table 2. Testing condition of thermal-vacuum experiment for 1.0 m aperture brazed mirror

真空度/Pa 温度范围/(℃) 升温速率/(℃/min) 保温时间/h 循环次数 设定值 10-3 15~25 2 3 5 表 3 Φ100 mm碳化硅拼接镜的抗辐照空试验条件

Table 3. Testing condition of anti-radiation experiment for Φ100 mm brazed mirror

样品尺寸 样品测试前反射率 辐照源 辐照剂量 辐照时间 环境温度 Φ100 mm R > 98%(0.38 μm~0.76 μm) 60Co γ射线 37 krad和60 krad (Si) 6天 (20±3)℃ -

参考文献

[1] Pilbratt G L. Herschel space observatory mission overview[J]. Proceedings of SPIE, 2003, 4850: 586-597. doi: 10.1117/12.461767

[2] Deny P, Bougoin M. Silicon carbide components for optics: Present and near future capabilities[J]. Proceedings of SPIE, 2005, 5868: 58680G. http://www.researchgate.net/publication/253481251_Silicon_carbide_components_for_optics_present_and_near_future_capabilities

[3] Gardner J D. The James webb space telescope: extending the science[J]. Proceedings of SPIE, 2012, 8842: 884228. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.1177/019263655704122910

[4] Greenhouse M A. The JWST Science Instrument payload: mission context and status[J]. Proceedings of SPIE, 2016, 9143: 914307.

[5] Kaneda H, Naitoh M, Nakagawa T, et al. Manufacturing and optical testing of 800 mm lightweight all C/SiC optics[J]. Proceedings of SPIE, 2013, 8837: 88370I. http://www.researchgate.net/publication/260957529_Manufacturing_and_optical_testing_of_800_mm_lightweight_all_CSiC_optics

[6] Liu Y, Ma Z. Chen J, et al. Environmental simulation evaluation of SSiC brazed optical mirrors[J]. Proceedings of SPIE, 2014, 9280: 928009. doi: 10.1117/12.2068140

[7] Zhang B Z, Wang X, Wang X K, et al. Fabrication and testing of a 600mm diameter brazing SiC mirror[J]. Proceedings of SPIE, 2008, 7281: 72810O. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=CC029899339

[8] 齐亚范, 方敬忠, 杨力, 等.轻型反射镜研究与发展[J].光学技术, 1998(3): 49–52. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199800157576

Qi Y F, Fang J Z, Yang L, et al. Investigated and development of lightweight mirror[J]. Optical Technique, 1998(3): 49–52. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199800157576

[9] 陈欢欢. 4米碳化硅反射镜诞生记[J].发明与创新, 2018(9): 16–17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fmygx201809009

[10] Tsuno C, Irikado H, Ono K, et al. NTSIC (New technology SiC): the progress of recent two years[J]. Proceedings of SPIE, 2006, 10567: 1056716. http://www.researchgate.net/publication/321201281_NTSICNew_Technology_SiC_the_progress_of_recent_two_years

[11] Boy J, Krödelb M. CESIC light-weight SiC composite for optics and structure[J]. Proceedings of SPIE, 2005, 5868: 586807. doi: 10.1117/12.617208

[12] Zhang G, Zhao R C, Zhao W X, et al. Manufacture of Φ1.2m reaction bonded silicon carbide mirror blank CFID[J]. Proceedings of SPIE, 2010, 7654: 76541B. doi: 10.1117/12.866700

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: