-

摘要:

激光除锈技术是一种新型、绿色环保的除锈方法。对一些在极易生锈的工作环境中的低碳钢构件,采用激光除锈技术代替传统除锈方法,有广阔的发展前景。激光除锈技术主要利用辐射在锈蚀表面的激光能量高、脉冲短的特点,使锈蚀温度很快达到熔点以上。但在除锈的同时,会有部分激光透过锈蚀层直接与金属基底作用,以及辐射在锈蚀表面的激光也会通过热传导将部分能量传递到金属基底表面。本文采用实验分析手段,对金属基底表面的微观组织、力学性能、硬度等进行对比研究。结果表明,所采用的激光除锈工艺在获得良好的除锈效果情况下,对金属基底没有造成损伤,对金属基底表面性能没有产生显著影响.

Abstract:

Abstract:Laser derusting technology is a new and green rust removing method. For some low carbon steel in an environment prone to rust, traditional rust removing method can be replaced by laser derusting technology, which has broad prospects. The corrosion surface of the laser radiation has the characteristics of high laser energy and short pulse, so that the corrosion temperature quickly reaches above the melting point. But at the same time of laser rust removal, there will be some laser directly through the rust layer, and the laser radiation on the corrosion surface will also transfer part of the energy to the metal substrate surface through heat conduction. By means of experimental analysis on the surface of the metal base, microstructure, mechanical properties and hardness were studied and compared. The results show that the laser derusting process has a good rust removal effect, laser derusting technology does not damage to the metal substrates and the properties of the surface has not been affected.

-

Key words:

- laser cleaning /

- rust removal mechanism /

- low carbon steel /

- surface properties

-

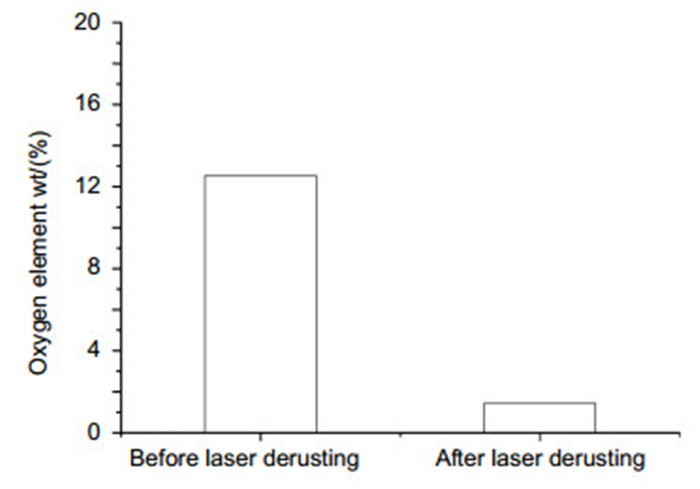

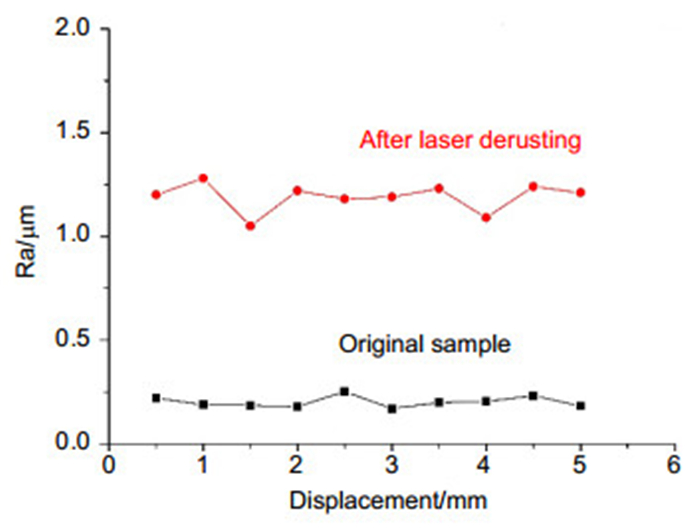

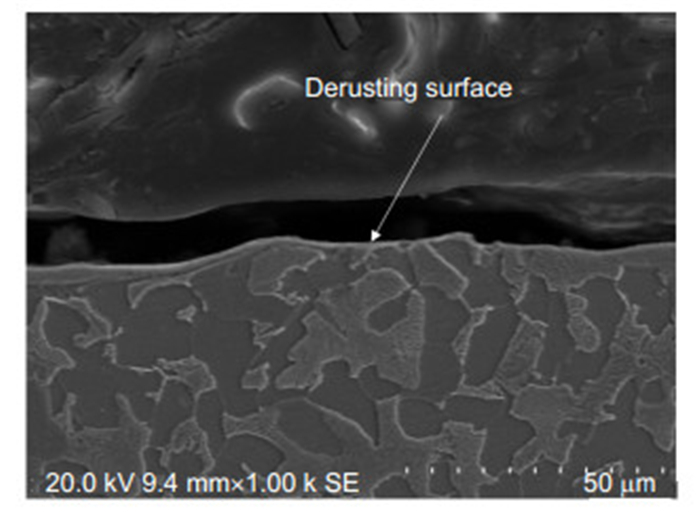

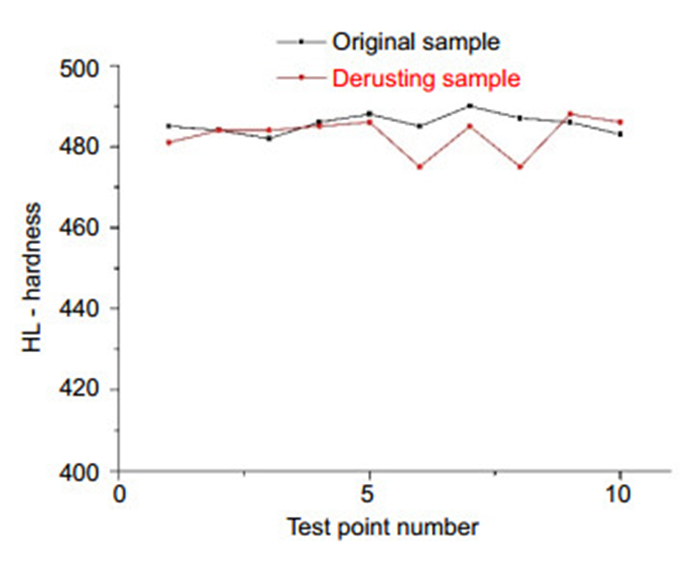

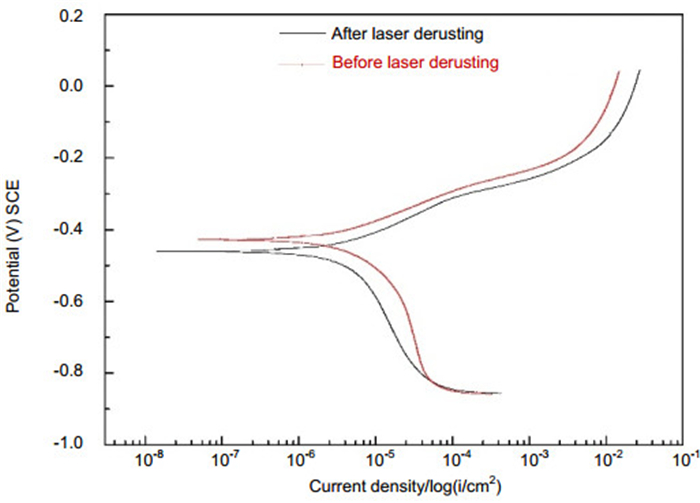

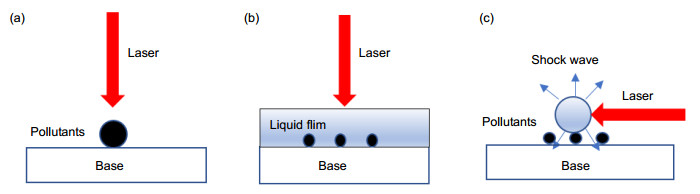

Laser cleaning technology is very useful and promising in mechanical industry, micro-electronic industry, artwork restoration and other special areas, which has attracted great attention among researchers. Many experimental and theoretical studies on laser cleaning have been carried out in the past years. Low steel has wide application. But for some low steels in an environment prone to rust, traditional rust removing methods can be replaced by laser derusting technology, which has a broad prospect. The corrosion surface of the laser radiation has the characteristics of high laser energy and short pulse, so that the corrosion temperature quickly reaches above the melting point. So laser derusting is mainly through the ablation mechanism to achieve cleaning effect. The corrosion of low carbon steel is mainly composed of the mixture of Fe oxide and its hydrate, and the surface oxygen content can be used to effectively characterize the effect of rust removal. The laser spot area is much smaller than the cleaning corrosion area and the laser pulse has short pulse width, so that the range of laser heat conduction is very small in the plane direction. It can be considered that the plane direction has uniform heat, so the Fourier heat conduction model is used to characterize the corrosion of surface heat conduction. In fact, when a laser beam irradiates the rust layer surface, it can not only remove the rust layer but also influence the performance of the cleaned surface. At the same time of laser rust removal, there will be some laser directly through the rust layer, and the laser radiation on the corrosion surface will also transfer part of the energy to the metal substrate surface through heat conduction. By means of experimental analysis on the surface of the metal base, microstructure, mechanical properties and hardness were studied and compared that indicate laser derusting technology does not damage to the metal substrates and the properties of the surface has not been affected. Laser derusting has little effect on metal, so the mechanical properties of metal substrate are characterized by using technology instrumented indentation technique. The technique needs to measure the load and displacement data during the whole indentation process and plot the load-displacement curve (P-h curve). And then, mechanical properties, such as elastic modulus, yield strength, ultimate tensile strength, strain hardening exponent and extension ratio, can be calculated from the P-h curve with the specific algorithm.

-

-

表 1 原始试样力学性能表征结果.

Table 1. Characterization of mechanical properties of original specimens.

Detection point number Yield strength/MPa Tensile strength/MPa n Elongation/(%) 1 214 473 0.24 33.5 2 198 455 0.26 28.6 3 205 482 0.23 32.5 4 264 450 0.18 24.8 5 275 458 0.17 20.3 Average value 231 463 0.22 27.9 表 2 除锈试样的力学性能表征结果.

Table 2. Characterization of mechanical properties of derusting specimens.

Detection point number Yield strength/MPa Tensile strength/MPa n Elongation/(%) 1 231 486 0.22 30.5 2 240 496 0.25 28.6 3 225 472 0.18 25.2 4 262 452 0.19 20.5 5 211 440 0.26 21.2 Average value 233 469 0.22 21.1 -

[1] 解宇飞, 刘洪伟, 胡永祥.船舶板材激光除锈工艺参数确定方法研究[J].中国激光, 2016, 43(4): 0403008. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz201604016&dbname=CJFD&dbcode=CJFQ

Xie Yufei, Liu Hongwei, Hu Yongxiang. Determining process parameters for laser derusting of ship steel plates[J]. Chinese Journal of Lasers, 2016, 43(4): 0403008. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz201604016&dbname=CJFD&dbcode=CJFQ

[2] Tam A C, Park H K, Grigoropoulos C P. Laser cleaning of surface contaminants[J]. Applied Surface Science, 1998, 127–129: 721–725. doi: 10.1016/S0169-4332(97)00788-5

[3] Koh Y S, Powell J, Kaplan A, et al. Laser cleaning of corroded steel surfaces: a comparison with mechanical cleaning meth-ods[M]//Nimmrichter J, Kautek W, Schreiner M. Lasers in the Conservation of Artworks. Berlin Heidelberg: Springer, 2007: 13–20.

[4] Lu Y F, Song W D, Hong M H, et al. Mechanism of and method to avoid discoloration of stainless steel surfaces in laser cleaning[J]. Applied Physics A, 1997, 64(6): 573–578. doi: 10.1007/s003390050518

[5] Li Xiaoguang, Huang Tingting, Chong Angwei, et al. Laser cleaning of steel structure surface for paint removal and repaint adhesion[J]. Opto-Electronic Engineering, 2017, 44(3): 340–344. http://cn.bing.com/academic/profile?id=9208ef6c5cb06805ea3558d746549686&encoded=0&v=paper_preview&mkt=zh-cn

[6] Chen G X, Kwee T J, Tan K P, et al. Laser cleaning of steel for paint removal[J]. Applied Physics A, 2010, 101(2): 249–253. doi: 10.1007/s00339-010-5811-0

[7] Pini R, Siano S, Salimbeni R, et al. Tests of laser cleaning on archeological metal artefacts[J]. Journal of Cultural Heritage, 2000, 1(S1): S129–S137. https://www.sciencedirect.com/science/article/pii/S1296207400001394

[8] 凌晨, 季凌飞, 吴燕, 等.金属正畸托槽皮秒激光清洗实验及其机理研究[J].中国激光, 2014, 41(4): 0403005. http://www.opticsjournal.net/abstract.htm?id=OJ140325000056C9FbIe

Ling Chen, Ji Lingfei, Wu Yan, et al. Research and mechanism study on refurbishing stainless bracket using picosecond laser based on laser cleaning technology[J]. Chinese Journal of Lasers, 2014, 41(4): 0403005. http://www.opticsjournal.net/abstract.htm?id=OJ140325000056C9FbIe

[9] Cherenda N N, Smilgin A A, Uglov V V, et al. Cleaning of steel surface from scale by compression plasma flows[J]. Surface and Coatings Technology, 2014, 255: 79–83. doi: 10.1016/j.surfcoat.2014.01.002

[10] 崔航, 陈怀宁, 陈静, 等.球形压痕法评价材料屈服强度和应变硬化指数的有限元分析[J].金属学报, 2009, 45(2): 189–194. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_jsxb200902011

Cui Hang, Chen Huaining, Chen Jing, et al. Fea of evaluating material yield strength and strain hardening exponent using a spherical indentation[J]. Acta Metallurgica Sinica, 2009, 45(2): 189–194. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_jsxb200902011

[11] Wang Zemin, Zeng Xiaoyan, Huang Weiling. Parameters and surface performance of laser removal of rust layer on A3 steel[J]. Surface and Coatings Technology, 2003, 166(1): 10–16. doi: 10.1016/S0257-8972(02)00736-3

[12] Koh Y, Sárady I. Cleaning of corroded iron artefacts using pulsed TEA CO2-and Nd: YAG-lasers[J]. Journal of Cultural Heritage, 2003, 4(S1): 129–133. https://www.sciencedirect.com/science/article/pii/S1296207402011408

[13] 崔晓鸣, 刘登瀛, 淮秀兰.高能脉冲激光作用下材料表面温度场[J].北京科技大学学报, 2000, 22(5): 470–474. http://doi.wanfangdata.com.cn/10.3321/j.issn:1001-053X.2000.05.020

Cui Xiaoming, Liu Dengying, Huai Xiulan. Temperature fields on materials surface under high-energy pulse laser irradia-tion[J]. Journal of University of Science and Technology Beijing, 2000, 22(5): 470–474. http://doi.wanfangdata.com.cn/10.3321/j.issn:1001-053X.2000.05.020

[14] 杨波, 顾济华, 桂如胜.脉冲激光加热材料的温度场解析[J].苏州大学学报(自然科学版), 2008, 24(4): 41–44. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=suzhoudxxb-zr200804010

Yang Bo, Gu Jihua, Gui Rusheng. Study on model about the material heated by pulse laser[J]. Journal of Suzhou University (Natural Science), 2008, 24(4): 41–44. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=suzhoudxxb-zr200804010

[15] 邱兆飚, 朱海红.脉冲激光除锈工艺研究[J].应用激光, 2013, 33(4): 416–420. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yyjg201304013&dbname=CJFD&dbcode=CJFQ

Qiu Zhaobiao, Zhu Haihong. Process parameter study on the removing rust using pulsed laser[J]. Applied Laser, 2013, 33(4): 416–420. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=yyjg201304013&dbname=CJFD&dbcode=CJFQ

[16] 田彬, 邹万芳, 刘淑静, 等.激光干式除锈[J].清洗世界, 2006, 22(8): 33–38. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hxqx200608009

Tian Bin, Zou Wanfang, Liu Shujing, et al. Introduction of rust removed by dry laser cleaning[J]. Cleaning World, 2006, 22(8): 33–38. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hxqx200608009

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: