-

摘要

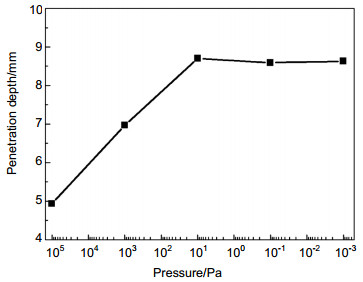

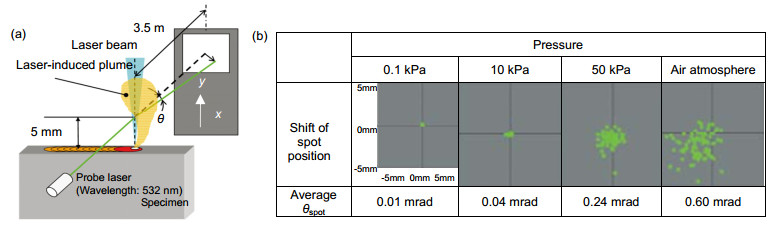

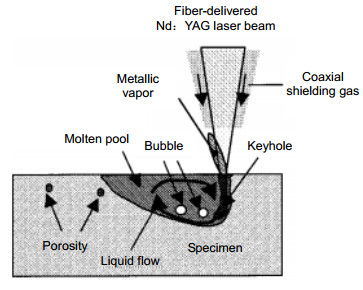

真空环境下激光焊接熔深得到显著提高,焊缝成形及气孔等缺陷得到极大改善,可以获得常规激光焊接方法难以获得的显著效果。近些年,有关真空激光焊接过程机理,低真空甚至局部负压环境激光焊接装置的研究日益完善,真空激光焊接技术在船舶、核电及压力容器等领域大厚板焊接中展现出良好的应用前景。本文首要概述环境压力变化对激光焊缝熔深,焊缝表面成形及气孔等缺陷的影响规律,从焊接过程等离子体羽辉及匙孔、熔池的动态行为特性方面总结国内外学者有关真空激光焊接机理的研究成果,并介绍了真空焊接技术在工业领域的应用情况,最后对目前已报道的研究中存在的问题进行分析并对真空焊接技术的发展前景进行展望。

Abstract

Compared with conventional laser welding, the welding quality was improved significantly while the laser welding was conducted under vacuum. The penetration depth of the weld seam increased sharply. The welding formation was improved and the porosity defects were suppressed effectively. In recent years, numerous researches on the mechanism of welding process, low vacuum and local subatmospheric pressure laser welding equipments have been undertaken. The laser welding under vacuum exhibits the wonderful application prospects to weld the thick plates in the shipbuilding, nuclear instrument and pressure vessel industries. The influences of ambient pressure on the laser welding penetration depth, surface formation and porosity defect were summarized. The domestic and overseas research findings on mechanism of laser welding under vacuum were elaborated from the aspects of plasma plume, keyhole and molten pool behaviors. In addition, the applications of laser welding under vacuum in the industry were introduced. Finally, the problems of reported researches were analyzed and the prospects of the technology were discussed.

-

Key words:

- vacuum /

- laser welding /

- plasma plume /

- keyhole and molten pool behaviors

-

Overview

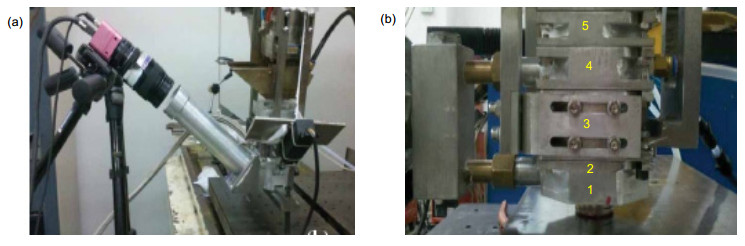

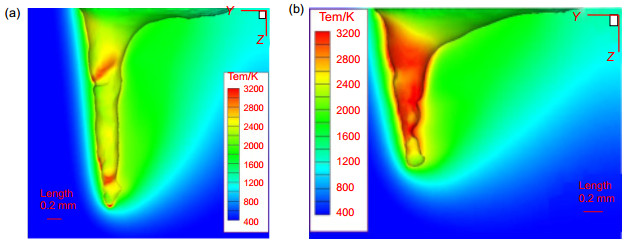

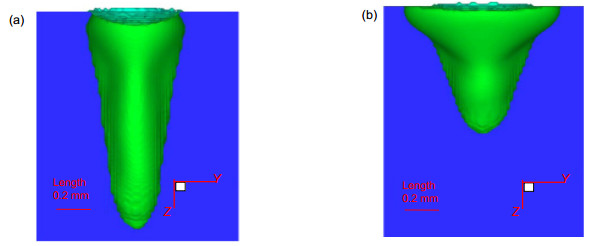

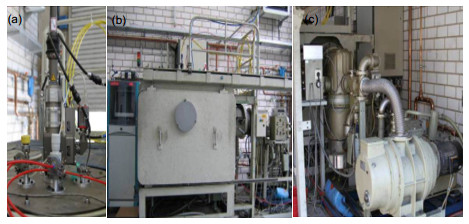

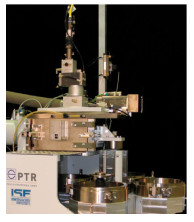

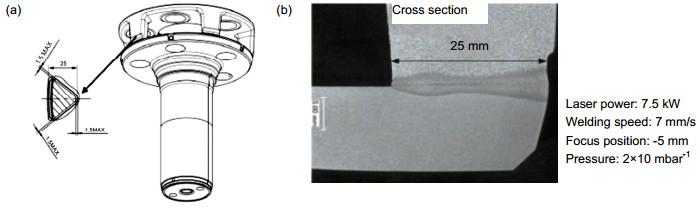

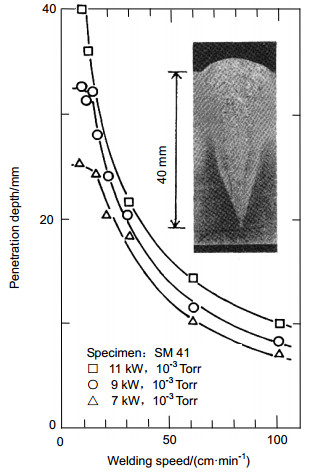

Compared to electron beam welding, the penetration depth of high power laser welding is smaller due to theattenuation effect of the plasma plume on laser power deposition. To date, numerous researches on the suppression oflaser plasma plume had been undertaken, such as pulse laser welding, weaving laser welding, change the shielding gascompositions, and apply the side-assistant gas and electromagnetic fields. However, the increase of the penetration depthand the improvement of the weld quality were inconspicuous. Compared with conventional laser welding, the weldingformation and quality was improved significantly while the laser welding was conducted under vacuum. In this work,the influences of ambient pressure on the laser welding penetration depth, surface formation and porosity defect weresummarized. The domestic and overseas research findings on mechanism of laser welding under vacuum were elaborated from the aspects of plasma plume, keyhole and molten pool behaviors. In addition, the applications of laser welding under vacuum in the industry were introduced. Finally, the problems of reported researches were analyzed and theprospects of the technology were discussed. The previous researches on the laser welding under vacuum indicated thatthe penetration depth of the weld seams increased sharply, the welding formation was improved and the porosity defectswere suppressed effectively. Critical vacuum degree enough for improving the weld penetration depth and quality wasdetected for aluminum alloy, titanium alloy, nickel-base alloy and steel. The laser welding characteristics under vacuumwas related to the plasma plume, keyhole and molten pool flow behaviors. The planet wheel carrier in the power stationhad been welded successfully by applying this technology. The laser welding under vacuum exhibits the wonderful application prospects to weld the thick plates in the shipbuilding, nuclear instrument and pressure vessel industries. In thefuture works, the authors suggest that the laser power deposition mechanism should be investigated systematically byconsidering the physical properties of the materials and the collision characteristics of the ions in the plasma plume. Besides, the heat and mass transfer characteristics, solidification behavior of the molten pool should be studied. In order toexpand the application fields of laser welding under vacuum, the low vacuum and local subatmospheric pressure laserwelding equipments should be developed towards higher adaptability and integration. Local subatmospheric pressurelaser welding equipments with the excellent pressure maintaining property should be developed. Moreover, the feasibility of laser welding with filler and laser hybrid welding under vacuum is of vital interest for the development this technology.

-

-

-

参考文献

[1] Ishide T, Shono S, Ohmae T, et al. Fundamental study of laser plasma reduction method in high power CO2 laser welding[C]//Proceedings of the International Conference on Laser Materials Processing-Science and Application, Osaka, Japan, 1987: 187-191.

[2] Arata Y, Abe N, Oda T. Fundamental phenomena in high power CO2 laser welding[J]. Transactions of JWRI, 1985, 14(1): 5-11. https://core.ac.uk/display/38189589

[3] Beck M, Berger P, Hugel H. The effect of plasma formation on beam focusing in deep penetration welding with CO2 Lasers[J]. Journal of Physics D: Applied Physics, 1995, 28(12): 2430-2442. doi: 10.1088/0022-3727/28/12/007

[4] Wang C M, Meng X X, Huang W, et al. Role of side assisting gas on plasma and energy transmission during CO2 laser welding[J]. Journal of Materials Processing Technology, 2011, 211(4): 668-674. doi: 10.1016/j.jmatprotec.2010.12.001

[5] Tse H C, Man H C, Yue T M. Effect of magnetic field on plasma control during CO2 laser welding[J]. Optics & Laser Technology, 1999, 31(5): 363-368. http://cn.bing.com/academic/profile?id=71e9cd76a7f7c24a27762e04bf8b381e&encoded=0&v=paper_preview&mkt=zh-cn

[6] Peng Yun, Chen Wuzhu, Wang Cheng, et al. Controlling the plasma of deep penetration laser welding to increase power efficiency[J]. Journal of Physics D: Applied Physics, 2001, 34(21): 3145-3149. doi: 10.1088/0022-3727/34/21/307

[7] Arata Y, Abe N, Oda T. Fundamental phenomena in high power CO2 laser (Report II): vacuum laser welding[J]. Transactions of JWRI, 1985, 14(2): 217-222. https://www.researchgate.net/publication/279582069_FUNDAMENTAL_PHENOMENA_IN_HIGH_POWER_CO2_LASER_REPORT_II_-_VACUUM_LASER_WELDING

[8] Katayama S, Kobayashi Y, Mizutani M, et al. Effect of vacuum on penetration and defects in laser welding[J]. Journal of Laser Applications, 2001, 13(5): 187-192. doi: 10.2351/1.1404413

[9] Katayama S, Abe Y, Mizutani M, et al. Deep penetration welding with high-power laser under vacuum[J]. Transactions of JWRI, 2011, 40(1): 15-19. http://www.jwri.osaka-u.ac.jp/publication/trans-jwri/pdf/401-03.pdf

[10] Katayama S, Youhei A, Mizutani M, et al. Development of deep penetration welding technology with high brightness laser under vacuum[J]. Physics Prodedia, 2011, 12: 75-80. doi: 10.1016/j.phpro.2011.03.010

[11] Börner C, Dilger K, Rominger V, et al. Influence of ambient pressure on spattering and weld seam quality in laser beam welding with the solid-state laser[C]//Proceedings of the 30th International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 2011: 621-629.

[12] Cai C, Peng G C, Li L Q, et al. comparative Study on Laser Welding Characteristics of Aluminium Alloy under Atmospheric and Subatmospheric Pressures[J]. Science and Technology of Welding and Joining, 2014, 19(7): 547-553. doi: 10.1179/1362171814Y.0000000223

[13] 彭根琛. 铝与镍合金的真空环境激光焊接特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2015: 28-44.

Peng Genchen. Laser welding characteristics of aluminum and nickel-base alloys under vacuum environment[D]. Harbin: Harbin Institute of Technology, 2015: 28-44.

[14] 罗燕. 负压激光焊接过程蒸气羽烟及熔池行为研究[D]. 上海: 上海交通大学, 2015: 32-33.

Luo Yan. Research on plasma plume and molten pool behavior in fiber laser welding under subatmospheric pressure[D]. Shanghai: Shanghai Jiao Tong University, 2015: 32-33.

[15] Chen Qintao, Tang Xinhua, Lu Fenggui, et al. Study on the effect of laser-induced plasma plume on penetration in fiber laser welding under subatmospheric pressure[J]. The International Journal of Advanced Manufacturing Technology, 2015, 78(1-4): 331-339. doi: 10.1007/s00170-014-6634-5

[16] Luo Yan, Tang Xinhua, Lu Fenggui, et al. Experimental study on deep penetrated laser welding under local subatmospheric pressure[J].The International Journal of Advanced Manufacturing Technology, 2014, 73(5-8): 699-706. doi: 10.1007/s00170-014-5870-z

[17] 罗燕, 唐新华, 芦凤桂, 等.局部负压激光焊缝成形特点及其影响因素[J].中国激光, 2014, 41(6): 0603008. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz201406018&dbname=CJFD&dbcode=CJFQ

Luo Yan, Tang Xinhua, Lu Fenggui, et al. Effects of welding parameters on bead formation of laser welding under subatmospheric pressures[J]. Chinese Journal of Lasers, 2014, 41(6): 0603008. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jjzz201406018&dbname=CJFD&dbcode=CJFQ

[18] Yang S, Wang J, Carlson B E, et al. Vacuum-assisted laser welding of zinc-coated steels in a gap-free lap joint configuration[J]. Welding Journal, 2013, 92(7): 197-s-204-s. https://www.researchgate.net/publication/271763988_Vacuum-Assisted_Laser_Welding_of_Zinc-Coated_Steels_in_a_Gap-Free_Lap_Joint_Configuration

[19] 包海涛, 刘金合, 刘锟, 等.真空激光焊接工艺参数对AZ31镁合金熔深的影响及缺陷分析[J].应用激光, 2008, 28(5): 366-370. http://www.cnki.com.cn/Article/CJFDTOTAL-YYJG200805005.htm

Bao Haitao, Liu Jinhe, Liu Kun, et al. Effect of vacuum laser welding parameter on AZ31 magnesium alloy penetration and flaw analysing[J]. Applied Laser, 2008, 28(5): 366-370. http://www.cnki.com.cn/Article/CJFDTOTAL-YYJG200805005.htm

[20] 包海涛, 刘金合, 刘锟, 等.低功率YAG激光真空焊接工艺[J].航空制造技术, 2008(23): 92-95. doi: 10.3969/j.issn.1671-833X.2008.23.018

Bao Haitao, Liu Jinhe, Liu Kun, et al. Low-power YAG laser welding process under vacuum condition[J]. Aeronautical Manufacturing Technology, 2008(23): 92-95. doi: 10.3969/j.issn.1671-833X.2008.23.018

[21] Youhei A, Yousuke K, Hiroshi N, et al. Effect of reduced pressure atmosphere on weld geometry in partial penetration laser welding of stainless steel and aluminium alloy with high power and high brightness laser[J]. Science and Technology of Welding and Joining, 2014, 19(4): 324-332. doi: 10.1179/1362171813Y.0000000182

[22] Verwaerde A, Fabbro R, Deshors G. Experimental study of continuous CO2 laser welding at subatmospheric pressures[J]. Journal of Applied Physics, 1995, 78(5): 2981-2984. doi: 10.1063/1.360046

[23] 姜梦. 真空环境下激光焊接等离子体特性研究[D]. 哈尔滨: 哈尔工业大学, 2015: 37-48.

Jiang Meng. Study on the characteristics of plasma in laser welding under vacuum conditions[D]. Harbin: Harbin Institute of Technology, 2015: 37-48.

[24] 姜梦, 陶汪, 陈彦宾, 等.真空激光焊接焊缝成形及等离子体特征[J].中国激光, 2016, 43(4): 0403010. http://www.opticsjournal.net/Abstract.htm?id=OJ160329000031gMjPlS

Jiang Meng, Tao Wang, Chen Yanbin, et al. Characteristics of bead formation and plasma plume in fiber laser welding under vacuum[J]. Chinese Journal of Lasers, 2016, 43(4): 0403010. http://www.opticsjournal.net/Abstract.htm?id=OJ160329000031gMjPlS

[25] Luo Yan, Tang Xinhua, Lu Fenggui, et al. Spatial distribution characteristics of plasma plume on attenuation of laser radiation under subatmospheric pressure[J]. Applied Optics, 2015, 54(5): 1090-1096. doi: 10.1364/AO.54.001090

[26] Pang Shengyong, Hirano K, Fabbro R, et al. Explanation of penetration depth variation during laser welding under variable ambient pressure[J]. Journal of Laser Applications, 2015, 27(2): 022007. doi: 10.2351/1.4913455

[27] Pang Shengyong, Chen Xin, Zhou Jianxin, et al. 3D transient multiphase model for keyhole, vapor plume, and weld pool dynamics in laser welding including the ambient pressure effect[J]. Optics and Lasers in Engineering, 2015, 74: 47-58. doi: 10.1016/j.optlaseng.2015.05.003

[28] Fabbro R, Hirano K, Pang Shengyong. Analysis of the physical processes occurring during deep penetration laser welding under reduced pressure[J]. Journal of Laser Applications, 2016, 28(2): 022427. doi: 10.2351/1.4944002

[29] Börner C, Krüssel T, Dilger K. Process characteristics of laser beam welding at reduced ambient pressure[C]//Proceeding of the SPIE Volume 8603, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications Ⅱ, San Francisco, CA, US, 2013: 86030M.

[30] Reisgen U, Olschok S, Jakobs S, et al. Welding with the laser beam in vacuum[J]. Laser Technik Journal, 2015, 12(2): 42-46. doi: 10.1002/latj.201500014

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: