Research on laser composite decontamination technology of radioactive contaminated metal parts in nuclear power plant

-

摘要

探究放射性污染金属部件的清洁解控或重新利用新技术,可用于减少核电站废金属产生量。本研究针对锈蚀的4140钢,提出激光复合去污技术,并与单一的干冰去污和激光去污进行对比试验。通过对基体试样的微观形貌、成分分布、金相组织、三维形貌进行测试,分析其表面粗糙度、显微硬度的变化趋势,以确定激光复合去污效果,最后在核电站中实现工程验证。测试和验证结果表明,激光复合去污技术可将4140钢表面的锈蚀层完全去除,获得最佳的去污效果,且不影响基体材料的成分、组织及力学性能。沾污电机叶轮去污后表面沾污水平均<0.4 Bq/cm2,表面接触剂量率均<40 nSv/h,达到核电站固体废物清洁解控标准。因此,激光复合去污技术可为核电站放射性污染金属部件的去污提供新方法,实现废物最小化。

Abstract

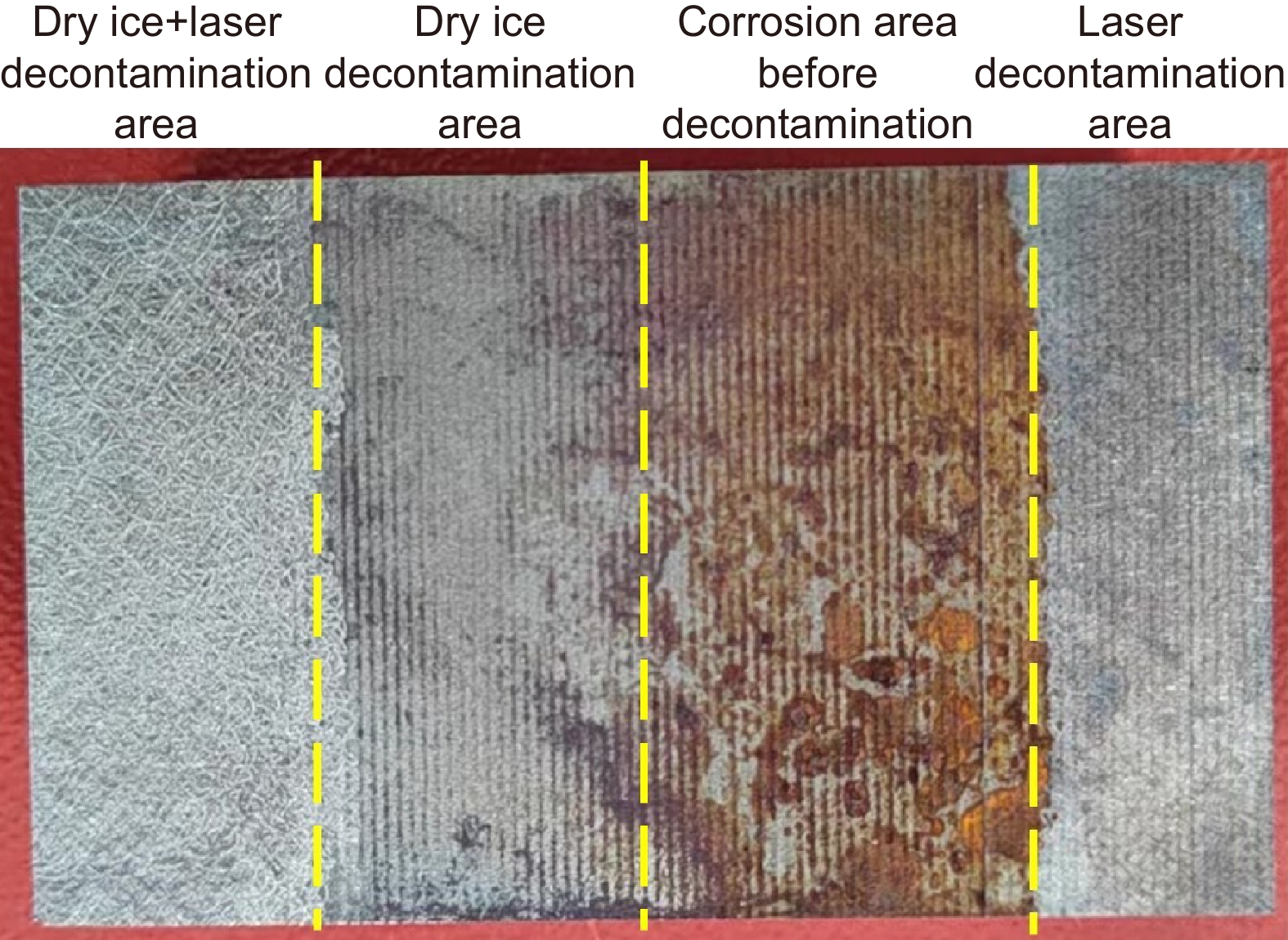

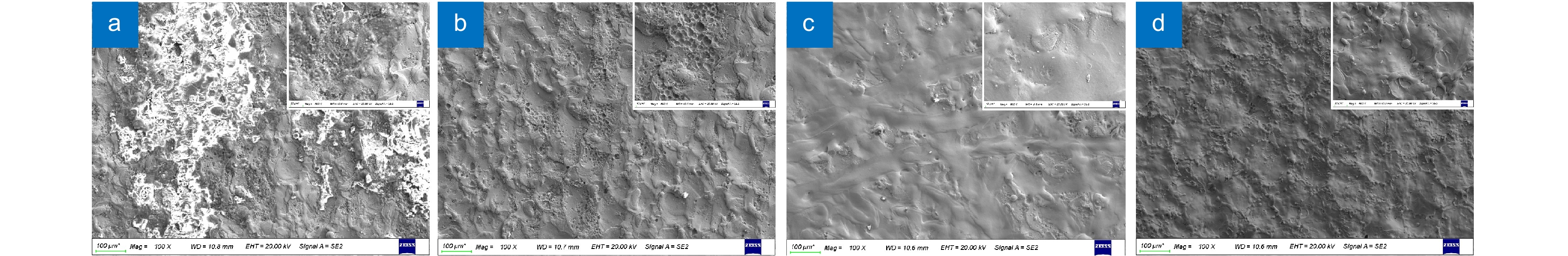

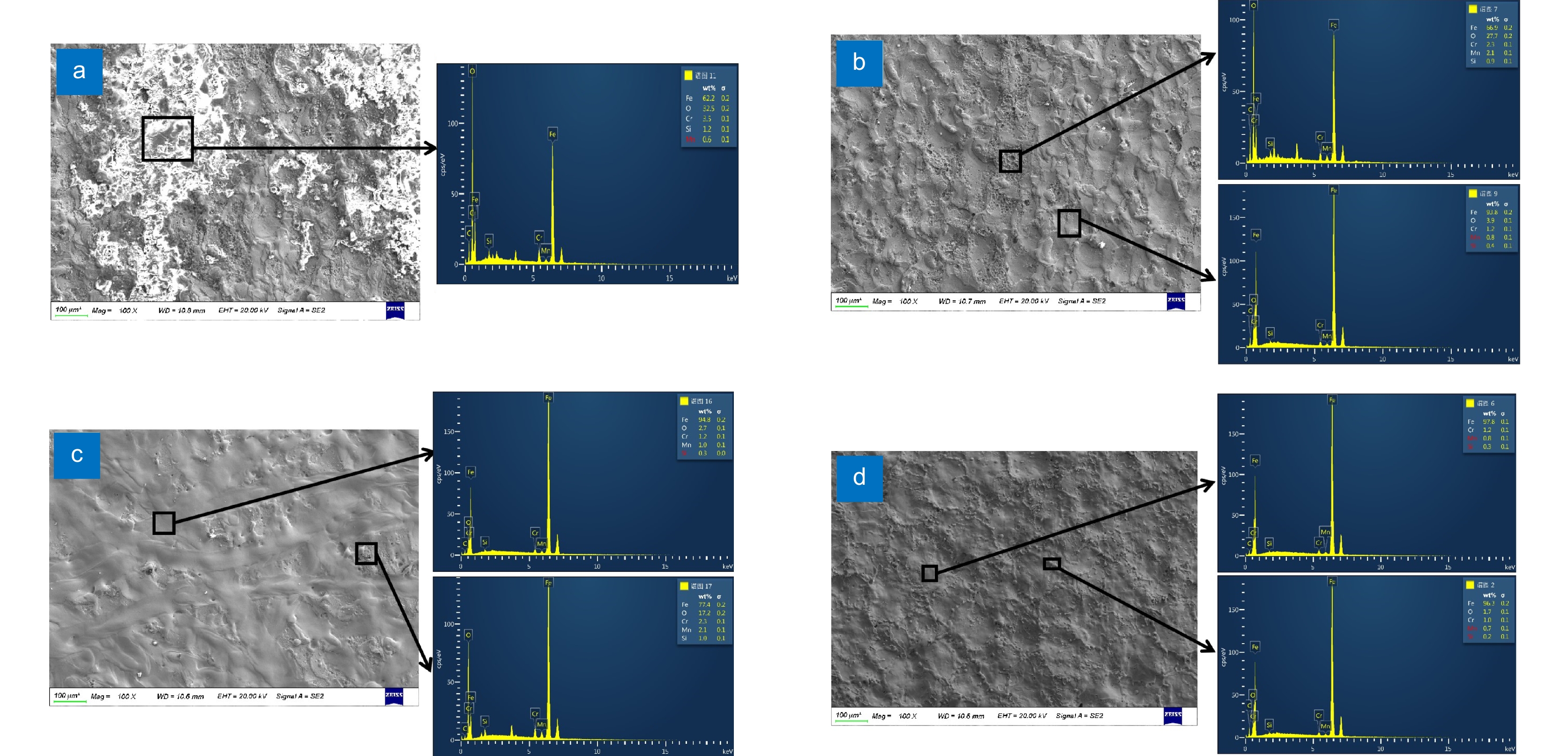

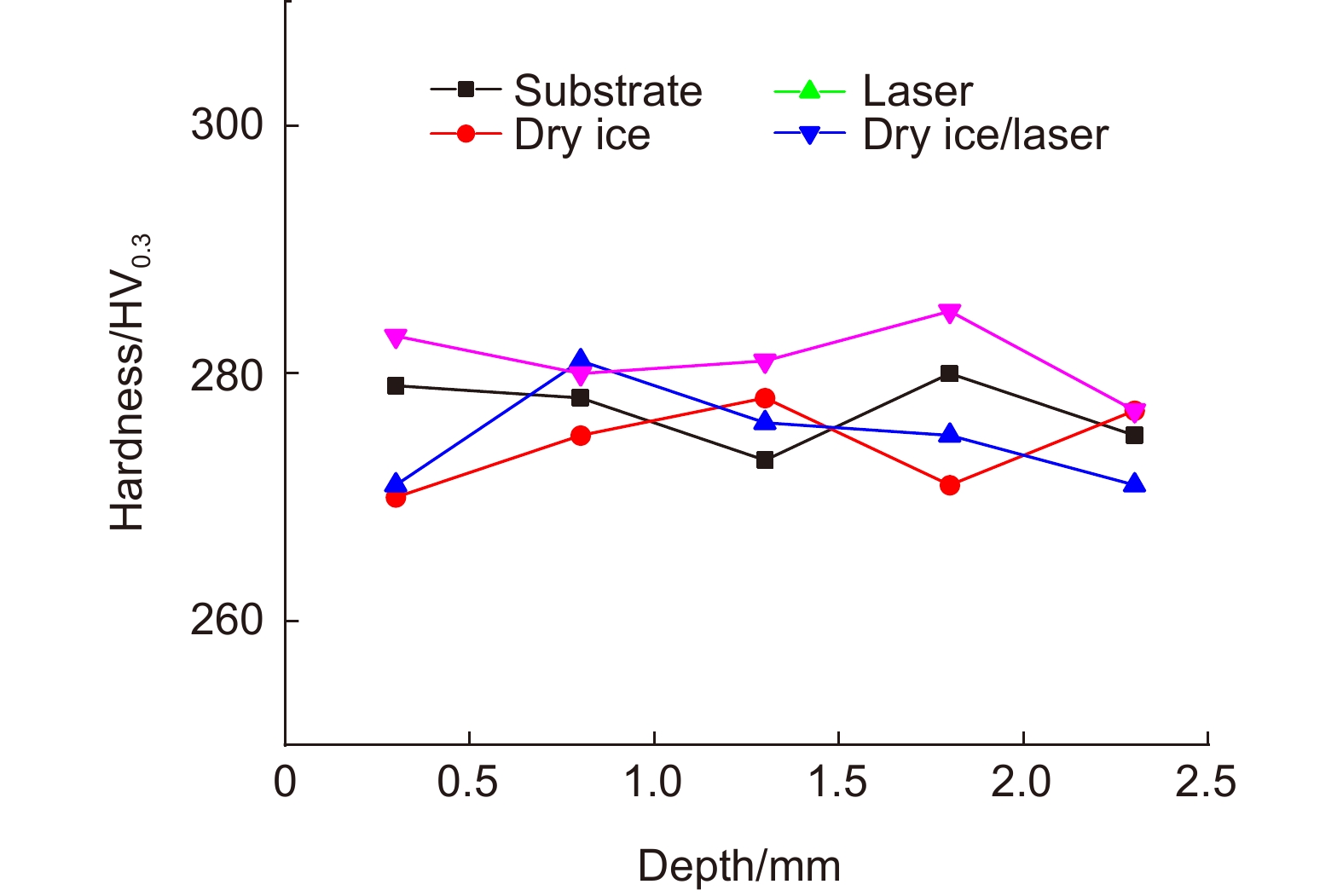

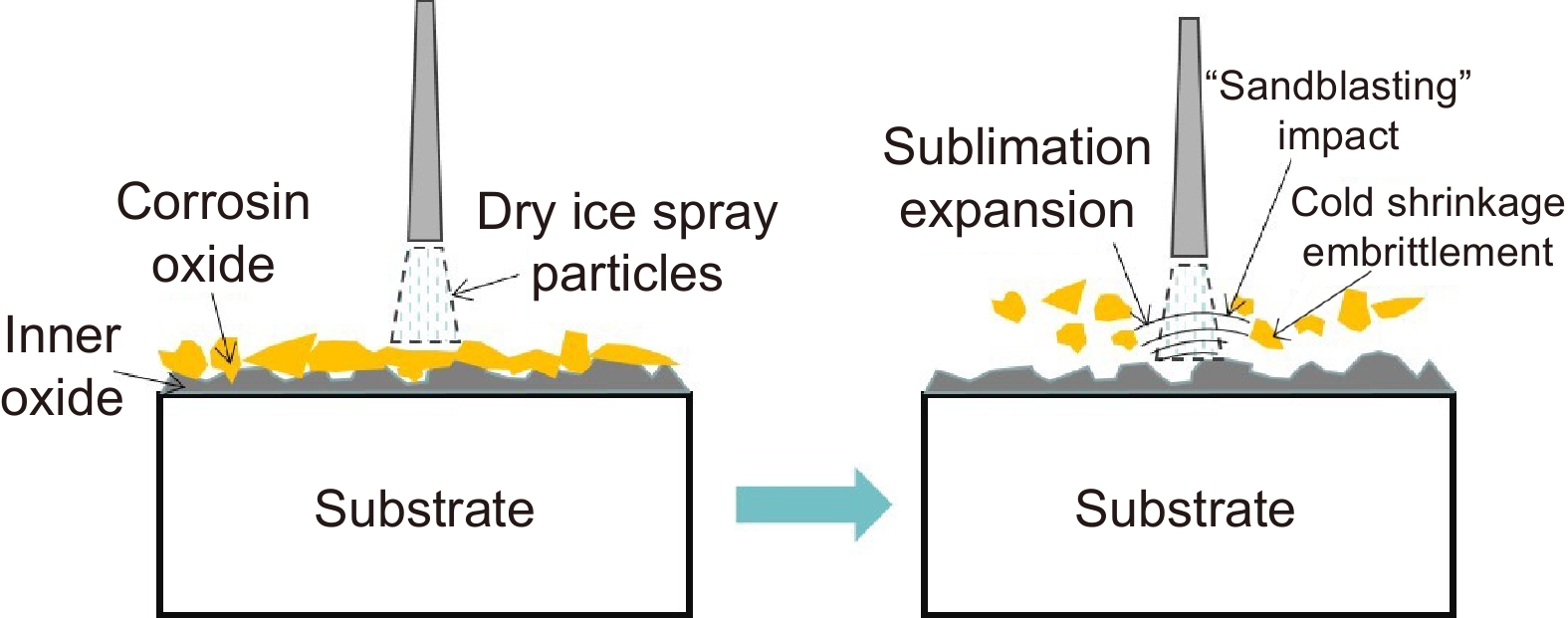

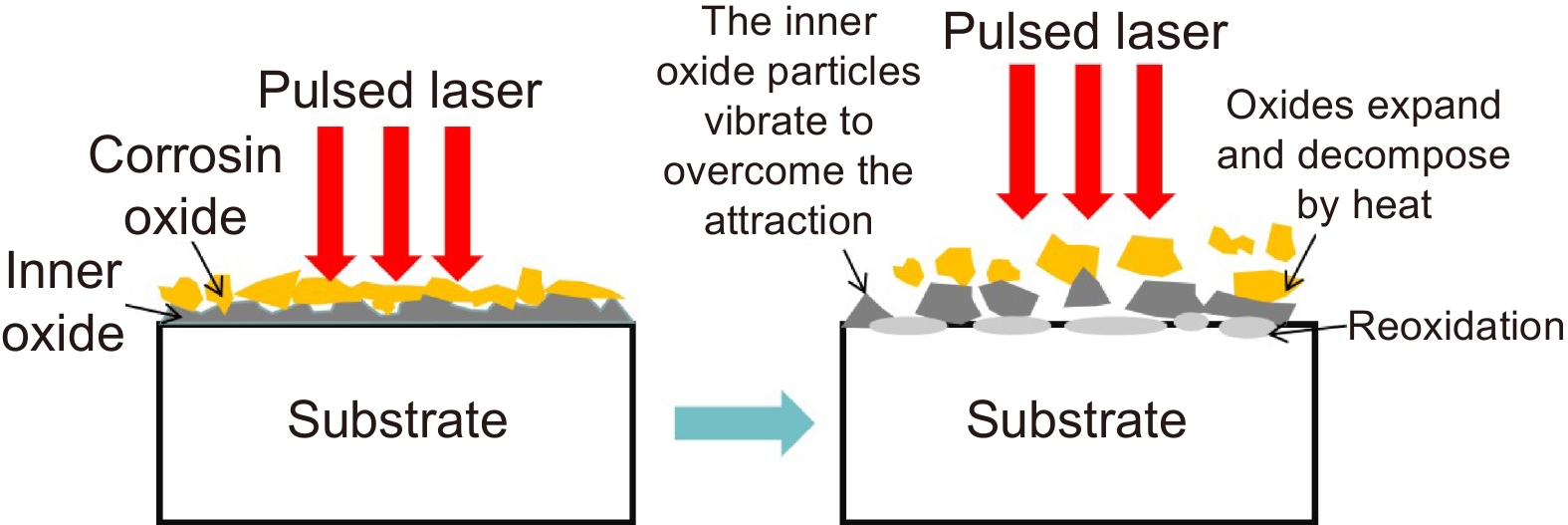

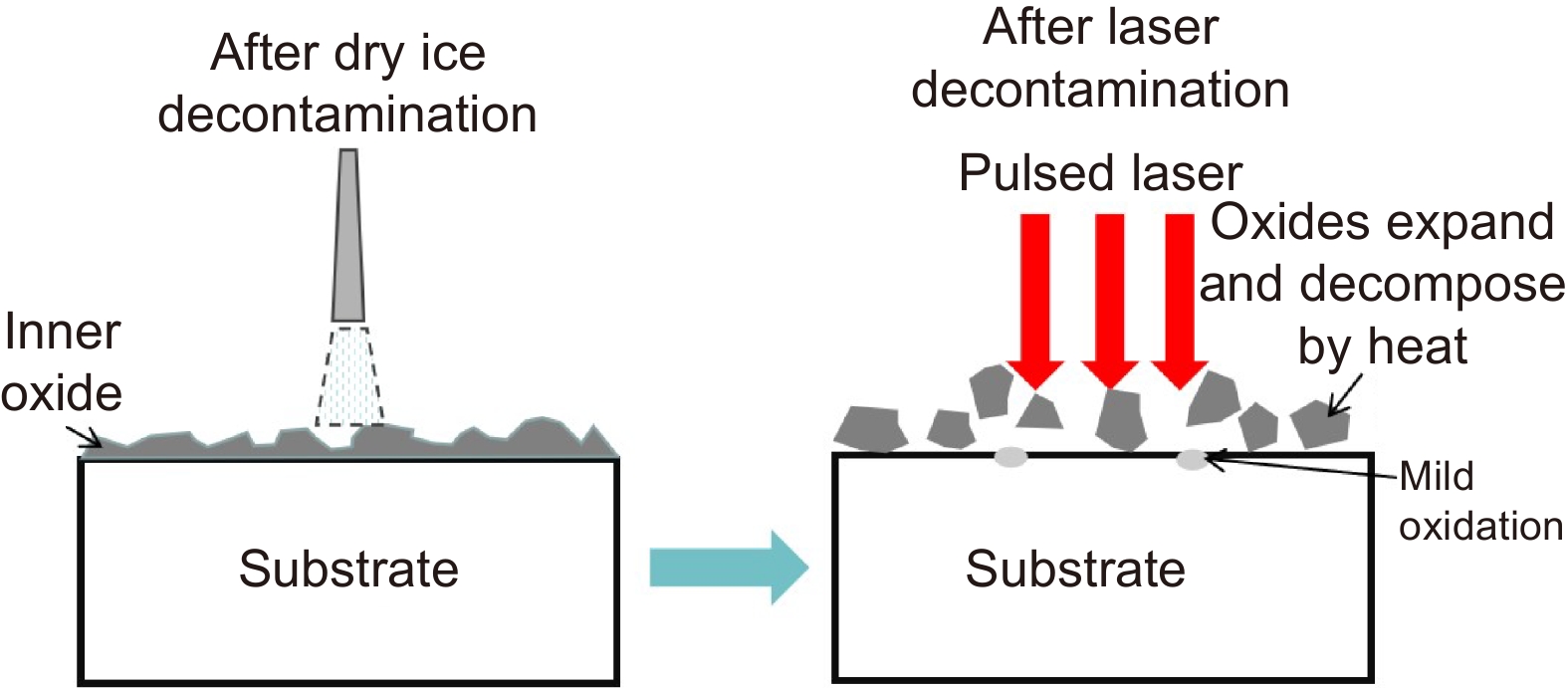

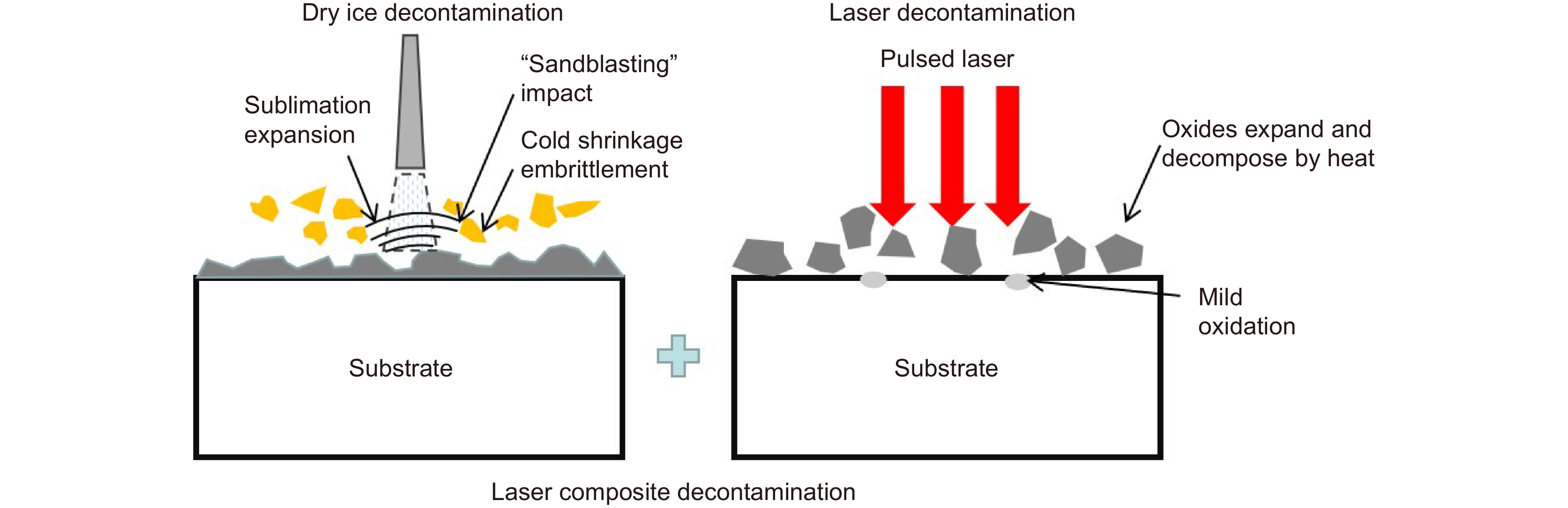

In order to reduce the amount of waste metal produced by nuclear power plants, a new technology for clean control or reuse of radioactively contaminated metal components is been studied. In this study, laser composite decontamination technology was proposed for corroded 4140 steel, and compared with dry ice decontamination and laser decontamination alone. By testing the microstructure, composition distribution, metallographic structure, and three-dimensional morphology of the matrix sample, the variation trend of surface roughness and microhardness was analyzed to determine the composite decontamination effect. Finally, the engineering verification was realized in the nuclear power plant. The test and verification results show that the laser composite decontamination technology can completely remove the rust layer on the surface of 4140 steel and obtain the best decontamination effect. Furthermore, it does not affect the composition, microstructure, and mechanical properties of the matrix material. The average amount of sewage on the surface of the contaminated motor impeller after decontamination is less than 0.4 Bq/cm2, and the surface contact dose rate is less than 40 nSv/h, which meets the clearance level of solid waste in nuclear power plants. Thus, laser composite decontamination technology can provide a new method for decontamination of radioactively contaminated metal components in nuclear power plants and minimize waste.

-

Key words:

- laser composite decontamination /

- surface morphology /

- roughness /

- damage /

- clean decontrol

-

Overview

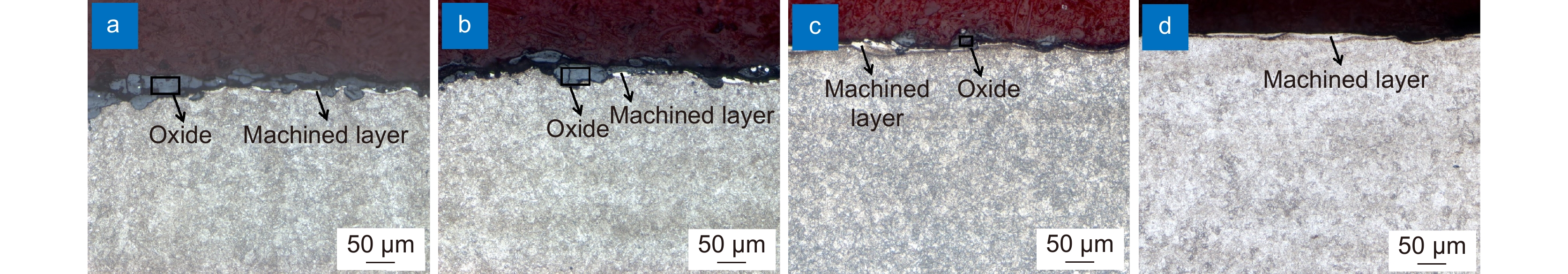

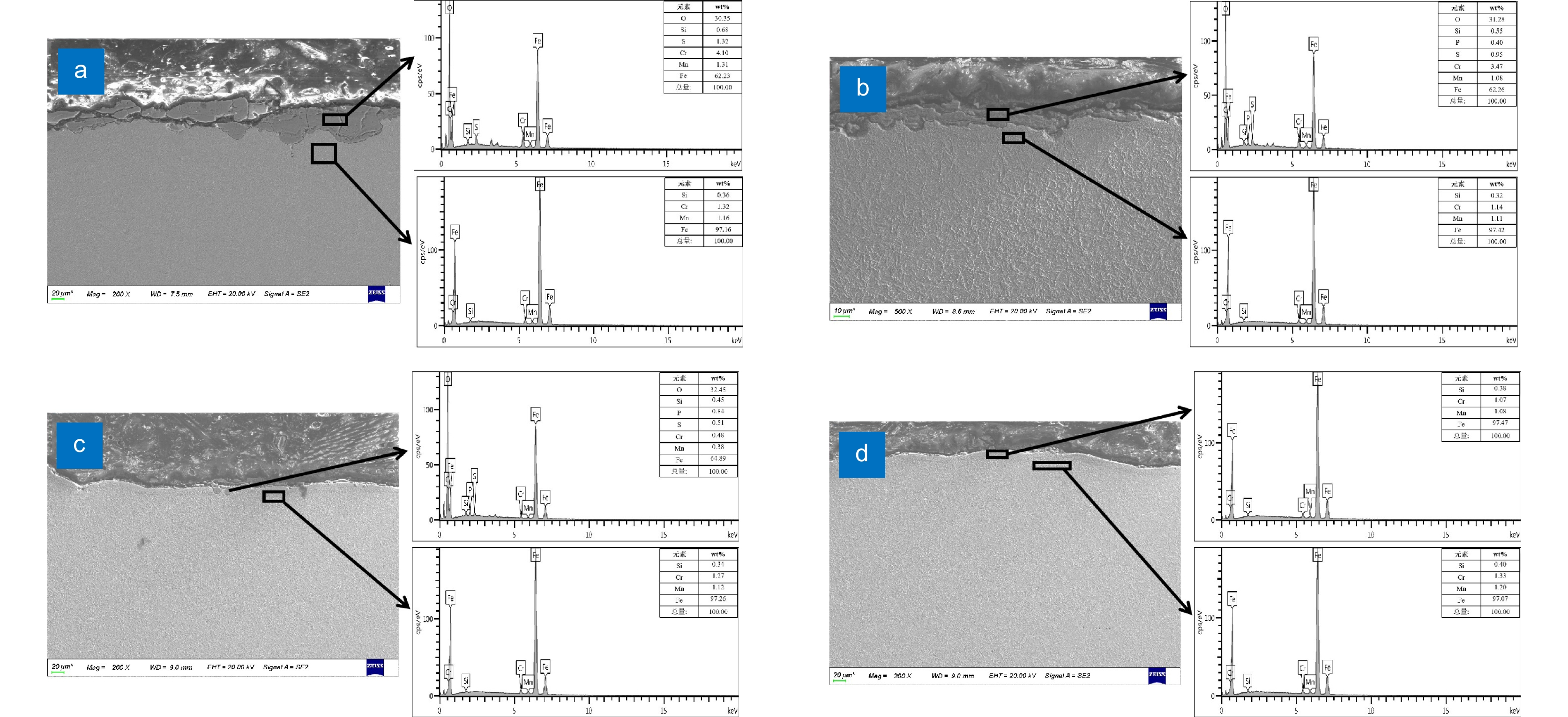

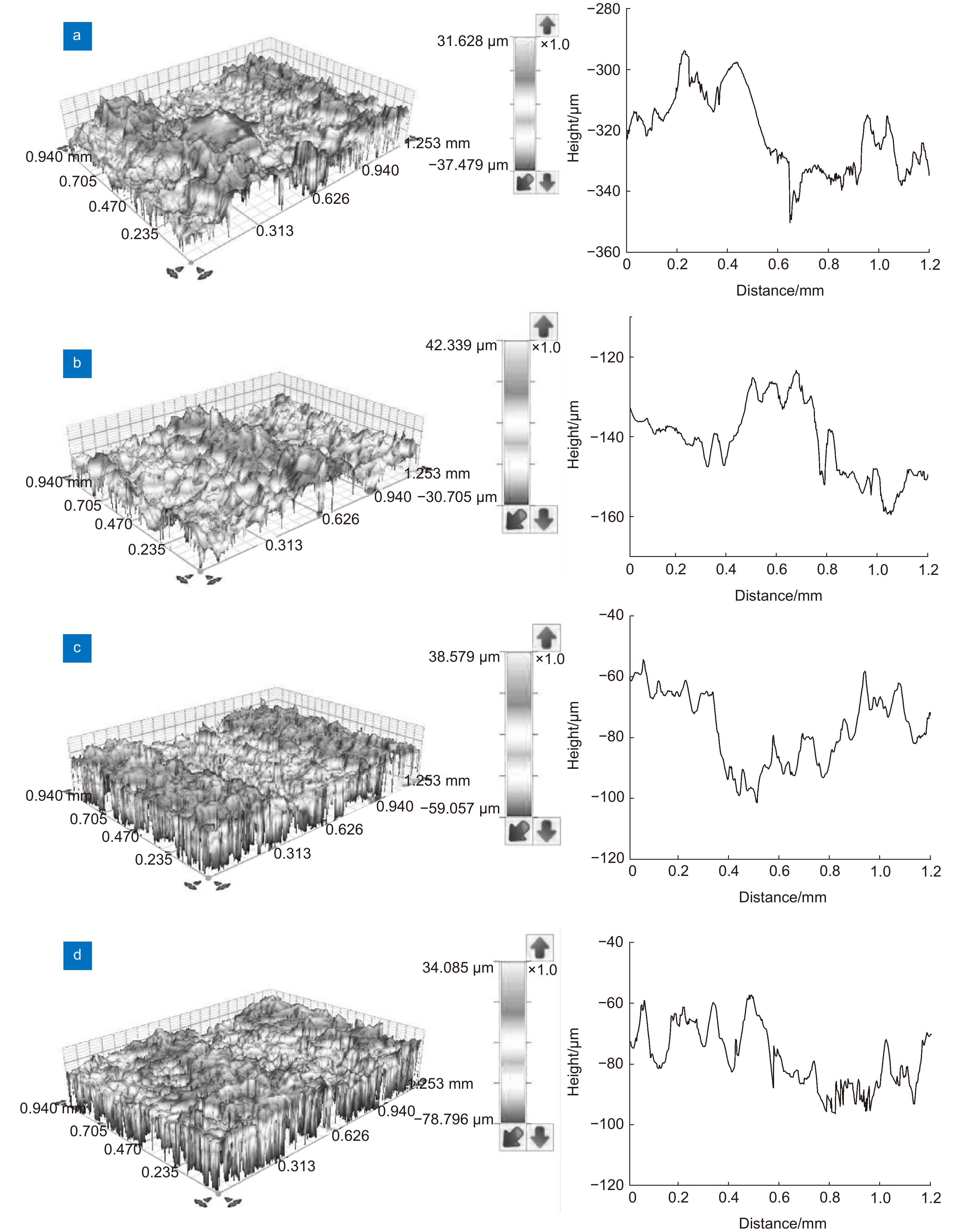

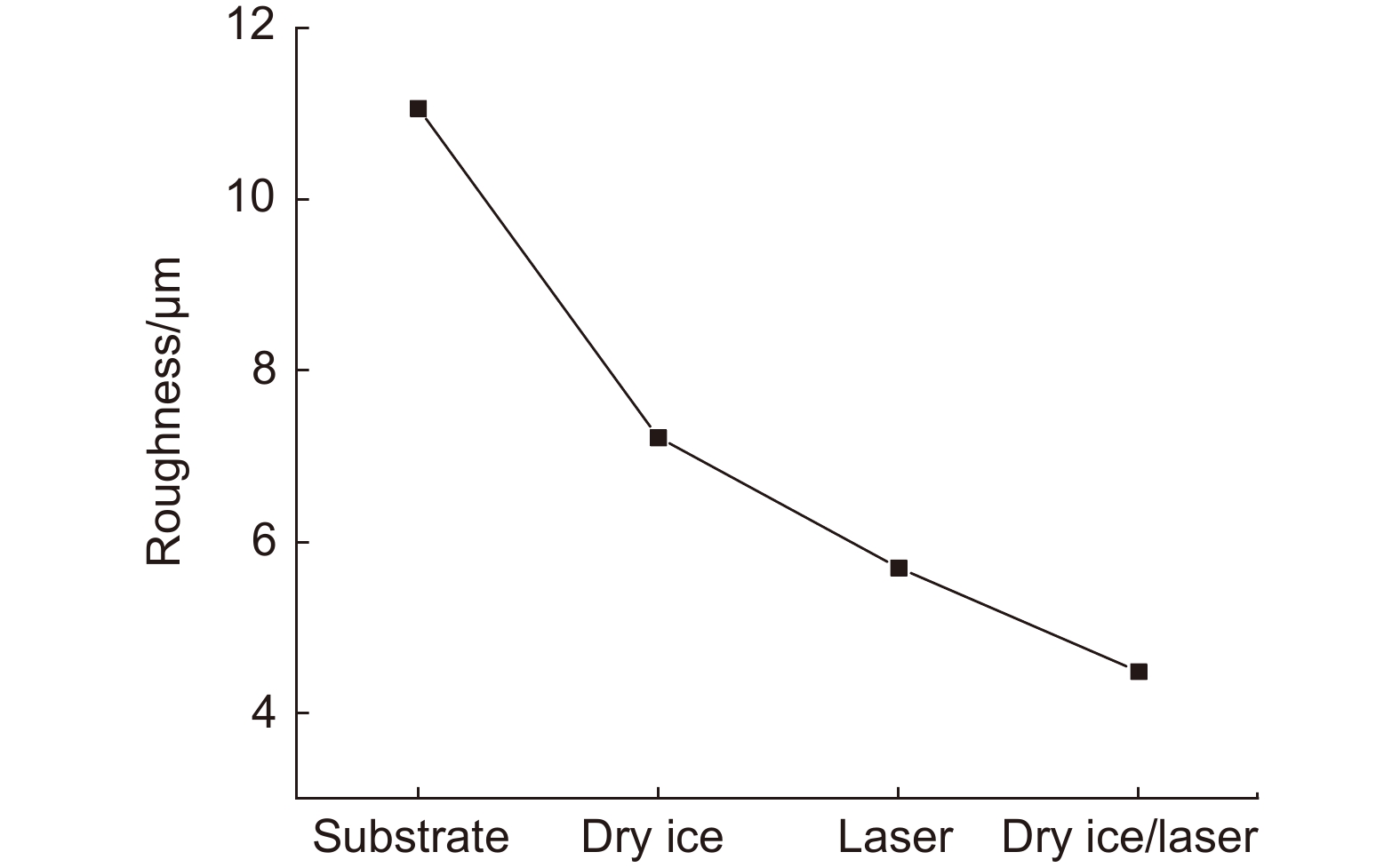

Overview: In order to reduce the pressure on nuclear power plants to store and dispose of radioactive solid waste, waste minimization has become the mainstream development concept. As a new decontamination technology in the field of nuclear energy, laser decontamination and dry ice decontamination solve the problems that some traditional decontamination methods are difficult to deal with. However, based on the diversity of radioactive solid waste types and pollutants in nuclear power plants, a single decontamination scheme is difficult to meet the demand. In this work, laser composite decontamination was carried out on the surface of corroded 4140 steel, and the decontamination effect of a single laser and dry ice was compared to explore its decontamination mechanism. By testing the microstructure, composition distribution, metallographic structure, and three-dimensional morphology of the matrix sample, the variation trend of surface roughness and microhardness was analyzed to determine the composite decontamination effect. Finally, the engineering verification was realized in the nuclear power plant. The main results show that: 1) Laser composite decontamination can completely remove the rust layer and oxide on the surface of 4140 steel and expose the metal surface of the matrix. Only a few point objects exist. The oxygen content is reduced from 32.5 wt% of the matrix to 1.7 wt%, and the decontamination effect is better than that of single dry ice decontamination and laser decontamination technology; 2) After laser composite decontamination, the surface roughness of the corroded substrate reached 4.49 μm, which was 59.4% lower than that of the substrate ( 11.06 μm ). The metallographic structure of the matrix cross-section did not change, and it was still tempered sorbite. The composition distribution and hardness value of the cross-section are similar to the standard value of the matrix before decontamination. It shows that the laser composite decontamination has no damaging effect on the substrate; 3) The laser composite decontamination technology parameters determined by the test were used to decontaminate the contaminated motor impeller of the nuclear power plant. After decontamination, the average contaminated sewage of each part of the motor impeller was less than 0.4 Bq/cm2, and the surface contact dose rate was less than 40 nSv/h, which reached the solid waste cleaning and control standard of the nuclear power plant. Laser composite decontamination technology can become a new technology to minimize waste in nuclear power plants and will be widely used in the future.

-

-

表 1 干冰清洗机参数

Table 1. Parameters of the dry ice decontamination equipment

参数 数值 干冰流量/(kg/h) 0~50 气体压力/(105 Pa) 2~10 干冰料斗容量/kg 25 干冰尺寸/mm Φ3×3-6,圆柱形 表 2 激光去污设备参数

Table 2. Parameters of the laser decontamination equipment

参数 数值 激光器类型 脉冲 输出中心波长/nm 1064 单脉冲能量/mJ 1.8 脉冲宽度/ns 10~500 功率调节范围/W 0~200 重复频率/kHz 1~4000 表 3 去污前后污染水平及表面剂量率测量结果

Table 3. Measurement results of pollution level and surface dose rate before and after decontamination

电机叶轮 去污前 干冰去污后 激光去污后 去污因子 去污效率 沾污水平

/(Bq/cm2)表面剂量率

/(nSv/h)沾污水平

/(Bq/cm2)表面剂量率

/(nSv/h)沾污水平

(/Bq/cm2)表面剂量率

(nSv/h)根部 6.30 4790 0.92 1510 0.32 29.9 19.7 94.9% 叶片 5.78 3760 0.8 1270 0.20 10.0 28.9 96.5% 轴心 5.13 3420 0.83 1390 0.26 31.7 19.7 94.9% -

参考文献

[1] 陈诚. 后处理放射性固体废物管理及处置有关问题研究[J]. 中国核电, 2020, 13(1): 104−108. doi: 10.12058/zghd.youxian.119

Chen C. Study on the management and disposal of the solid reprocessing radioactive waste[J]. China Nucl Power, 2020, 13(1): 104−108. doi: 10.12058/zghd.youxian.119

[2] 张蔚华, 张一民, 郭海峰, 等. 运行核电厂放射性固体废物管理实践与探讨[J]. 核安全, 2022, 21(1): 19−25. doi: 10.16432/j.cnki.1672-5360.2022.01.003

Zhang W H, Zhang Y M, Guo H F, et al. Practice and discussion on management of radioactive solid waste in nuclear power plant[J]. Nucl Saf, 2022, 21(1): 19−25. doi: 10.16432/j.cnki.1672-5360.2022.01.003

[3] 张根, 熊骁, 任丽丽, 等. 核电厂放射性废物管理策略研究[J]. 核安全, 2022, 21(1): 104−111. doi: 10.16432/j.cnki.1672-5360.2022.01.008

Zhang G, Xiong X, Ren L L, et al. Reflections and suggestions on radioactive waste management in nuclear power plants[J]. Nucl Saf, 2022, 21(1): 104−111. doi: 10.16432/j.cnki.1672-5360.2022.01.008

[4] 皮煜鑫. 放射性固体废物焚烧设备及工艺管路腐蚀与防护[J]. 中国核电, 2016, 9(3): 279−285.

Pi Y X. Corrosion and protection of the equipment and piping of the incineration for radioactive solid wastes[J]. China Nucl Power, 2016, 9(3): 279−285.

[5] 蒋磊, 王昭, 罗劲松. 某核电厂放射性固体废物处理最小化实践[J]. 辐射防护通讯, 2020, 40(2): 35−39. doi: 10.3969/j.issn.1004-6356.2020.02.008

Jiang L, Wang Z, Luo J S. Practice of radioactive solid waste minimization in a nuclear power plant[J]. Radiat Prot Bull, 2020, 40(2): 35−39. doi: 10.3969/j.issn.1004-6356.2020.02.008

[6] 姚志猛, 朱剑锐, 冯金才, 等. 阳江核电厂放射性固体废物最小化实践和探索[J]. 辐射防护, 2021, 41(2): 151−156.

Yao Z M, Zhu J R, Feng J C, et al. Practice and exploration of radioactive solid waste minimization in Yangjiang Nuclear Power Plant[J]. Radiat Prot, 2021, 41(2): 151−156.

[7] Gonçalves M F S, Petraconi Filho G, Couto A A, et al. Evaluation of thermal plasma process for treatment disposal of solid radioactive waste[J]. J Environ Manage, 2022, 311: 114895. doi: 10.1016/j.jenvman.2022.114895

[8] 魏鑫, 徐乐昌, 仇月双, 等. 化学与超声协同去除铀放射性污染研究[J]. 原子能科学技术, 2023, 57(S): 18−25. doi: 10.7538/yzk.2023.youxian.0088

Wei X, Xu L C, Qiu Y S, et al. Study on chemical and ultrasound Co-removal of uranium radioactive contamination[J]. At Energy Sci Technol, 2023, 57(S): 18−25. doi: 10.7538/yzk.2023.youxian.0088

[9] 廖能斌, 毛莉, 李斌. 核电厂放射性化学去污废液预处理新技术[J]. 中国资源综合利用, 2019, 37(6): 134−136. doi: 10.3969/j.issn.1008-9500.2019.06.043

Liao N B, Mao L, Li B. New technology for pretreatment of radioactive chemical decontamination waste liquid in nuclear power plants[J]. China Resour Compr Util, 2019, 37(6): 134−136. doi: 10.3969/j.issn.1008-9500.2019.06.043

[10] 李玉鑫, 贾建召. 核电站放射性污染液压扭力扳手的去污实践[J]. 辐射防护, 2020, 40(3): 223−230.

Li Y X, Jia J Z. Decontamination practice of radioactive contaminated hydraulic torsion wrenches in NPP[J]. Radiat Prot, 2020, 40(3): 223−230.

[11] 王焕志, 张凯, 魏世超, 等. 废弃放射性油气管道清洗技术的研究[J]. 石油和化工设备, 2021, 24(10): 20−23,19. doi: 10.3969/j.issn.1674-8980.2021.10.004

Wang H Z, Zhang K, Wei S C, et al. Research on cleaning technology of radioactive waste in oil and gas drilling[J]. Petro Chem Equip, 2021, 24(10): 20−23,19. doi: 10.3969/j.issn.1674-8980.2021.10.004

[12] 赵菀, 曹俊杰, 王帅, 等. 放射性表面污染金属废物激光去污工艺研究[J]. 核动力工程, 2021, 42(5): 250−255. doi: 10.13832/j.jnpe.2021.05.0250

Zhao W, Cao J J, Wang S, et al. Study on laser decontamination technology for metal scraps with radioactively contaminated surfaces[J]. Nucl Power Eng, 2021, 42(5): 250−255. doi: 10.13832/j.jnpe.2021.05.0250

[13] 陈国星, 陆海峰, 赵滢, 等. 激光功率对不锈钢表面清洗效果影响的研究[J]. 光电工程, 2017, 44(12): 1217−1224. doi: 10.3969/j.issn.1003-501X.2017.12.010

Chen G X, Lu H F, Zhao Y, et al. Effect of power on laser cleaning result of stainless steel surface[J]. Opto-Electron Eng, 2017, 44(12): 1217−1224. doi: 10.3969/j.issn.1003-501X.2017.12.010

[14] Li X G, Huang T T, Chong A W, et al. Laser cleaning of steel structure surface for paint removal and repaint adhesion[J]. Opto-Electron Eng, 2017, 44(3): 340−344. doi: 10.3969/j.issn.1003-501X.2017.03.009

[15] 段成红, 陈晓奎, 罗翔鹏. 激光清洗在石化领域的应用前景浅析[J]. 光电工程, 2020, 47(11): 200030. doi: 10.12086/oee.2020.200030

Duan C H, Chen X K, Luo X P. Application prospect of laser cleaning in petrochemical field[J]. Opto-Electron Eng, 2020, 47(11): 200030. doi: 10.12086/oee.2020.200030

[16] Papanikolaou A, Tserevelakis G J, Melessanaki K, et al. Development of a hybrid photoacoustic and optical monitoring system for the study of laser ablation processes upon the removal of encrustation from stonework[J]. Opto-Electron Adv, 2020, 3(2): 190037. doi: 10.29026/oea.2020.190037

[17] 任茂鑫, 关珮雯, 徐鹏, 等. MOPA脉冲光纤激光清洗电力绝缘子的工艺探索[J]. 激光技术, 2022, 46(5): 648−652. doi: 10.7510/jgjs.issn.1001-3806.2022.05.011

Ren M X, Guan P W, Xu P, et al. Research on cleaning technology of electrical insulators by MOPA pulsed fiber laser[J]. Laser Technol, 2022, 46(5): 648−652. doi: 10.7510/jgjs.issn.1001-3806.2022.05.011

[18] 王见强. 核设施(取样柜)表面污染干冰去污技术研究[D]. 衡阳: 南华大学, 2020. https://doi.org/10.27234/d.cnki.gnhuu.2020.000996.

Wang J Q. Study on decontamination technology of contaminatedusing dry ice on the surface of nuclearfacilities (sampling cabinets)[D]. Hengyang: University of South China, 2020. https://doi.org/10.27234/d.cnki.gnhuu.2020.000996.

[19] 李烨, 谭昭怡, 张东, 等. 干冰喷射去除表面放射性污染技术研究[J]. 辐射防护, 2018, 38(2): 142−147.

Li Y, Tan Z Y, Zhang D, et al. Experimental study on decontamination of surface radioactivity by dry-ice blasting[J]. Radiat Prot, 2018, 38(2): 142−147.

[20] 何云飞, 王晨, 丁诗炳. 干冰清洁技术在航电产品中的应用[J]. 航空电子技术, 2023, 54(4): 62−67. doi: 10.12175/j.issn.1006-141X.2023.04.09

He Y F, Wang C, Ding S B. Application of dry ice blasting technology in avionics products[J]. Avion Technol, 2023, 54(4): 62−67. doi: 10.12175/j.issn.1006-141X.2023.04.09

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: