-

摘要:

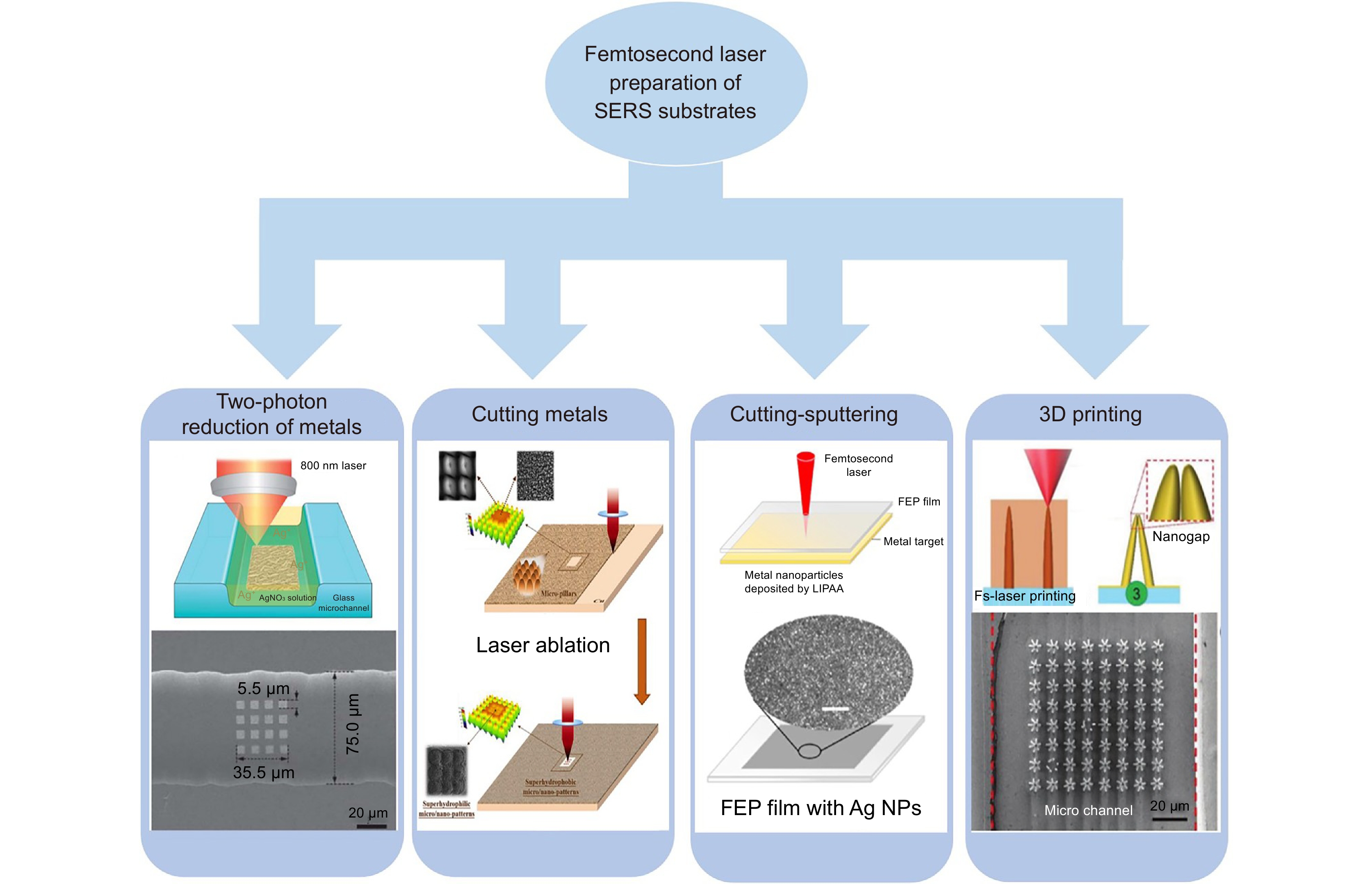

表面增强拉曼光谱(Surface-enhanced Raman spectroscopy,SERS)是一种高灵敏度、高分辨率的分子识别技术,在多个领域具有非常重要的应用价值。飞秒激光直写作为一种新兴的低成本、高分辨率、高灵活性的微纳加工方法,在制备SERS基底领域得到了广泛的应用。本文重点概述了四种飞秒激光直写制备SERS基底的加工方法,主要包括飞秒激光双光子还原、飞秒激光切割金属、飞秒激光切割-溅射、飞秒激光3D打印。文章简单介绍了各方法制备SERS基底的性能与应用场景,阐述了飞秒激光直写加工在制备SERS基底中的优势,旨在为今后相关研究提供参考。

Abstract:Surface-enhanced Raman spectroscopy (SERS) technique plays an important role in molecular recognition fields due to its highly sensitive and high-resolution. As an emerging low-cost, high machining accuracy, and high-flexibility processing method, femtosecond laser direct writing processing has been widely used in the field of preparing SERS substrates. This work introduces four methods of preparing SERS substrates by femtosecond laser direct writing, including femtosecond two-photon reduction, femtosecond laser cutting metal, femtosecond laser cutting-sputtering, and femtosecond laser 3D printing. The article introduces the performance and application scenarios of each method in preparing SERS substrates and illustrates the advantages of femtosecond laser direct writing processing in preparing SERS substrates, aiming to provide a reference for future related research.

-

Key words:

- SERS /

- femtosecond laser direct writing /

- micro/nano processing /

- SERS substrate

-

-

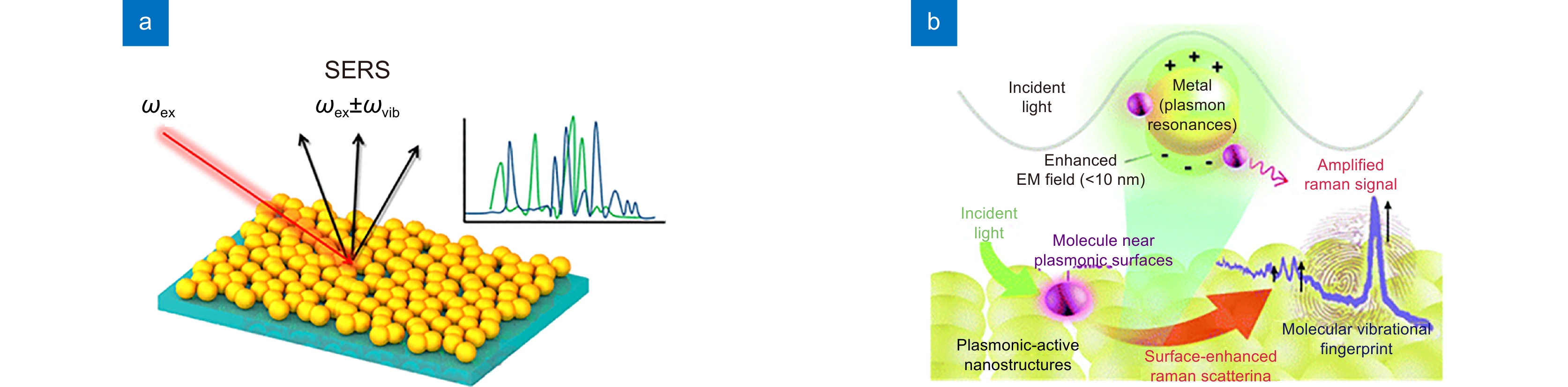

图 2 SERS原理。 (a) 波纹金属表面上分子的非弹性光散射[33]; (b) 贵金属表面发生等离子体共振现象[36]

Figure 2. SERS principle. (a) Inelastic light scattering of molecules on corrugated metal surfaces[33]; (b) localized surface plasmon resonances (LSPRs) on the surface of precious metals[36]. Figure reproduced with permission from: (a) ref. [33] © American Chemical Society; (b) ref. [36] © The Royal Society of Chemistry

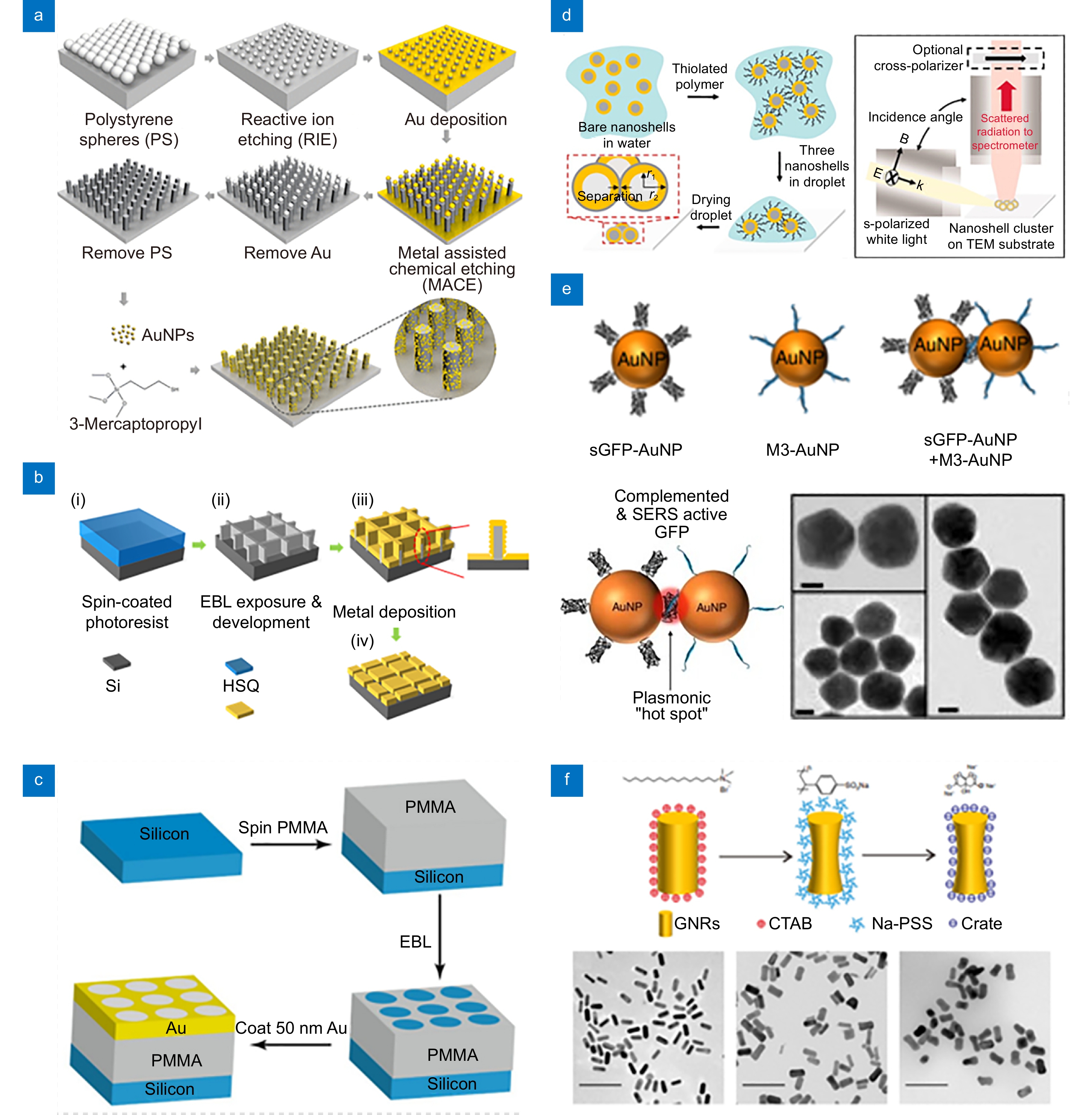

图 3 自上而下微加工和微粒自组装方法制备SERS微结构。 (a) RIE[45]; (b, c) EBL[46-47]; (d~f) 纳米颗粒自组装[48-50]. 比例尺:(e) 20 nm;(f) 200 nm

Figure 3. Preparation of SERS microstructures by top-down micromachining and particle self-assembly. (a) RIE[45]; (b, c) EBL[46-47]; (d-f) Nanoparticle self-assembly[48-50]; Scale bar: (e) 20 nm; (f) 200 nm. Figure reproduced with permission from: (a) ref. [45] © American Chemical Society; (b) ref. [46], (e) ref. [49] and (f) ref. [50] © under a Creative Commons Attribution-NonCommercial-No- Derivatives 4.0 International License; (c) ref. [47] © American Chemical Society; (d) ref. [48] © The American Association for the Advancement of Science

图 4 微柱自组装方法制备SERS微结构。 (a) 金纳米微柱自组装[55]; (b) 聚合物-银微柱自组装[56];(c) 聚合物-银微柱自组装[57]; (d) 银微柱自组装[58];(e)聚合物-金微柱自组装[59]

Figure 4. Preparation of SERS microstructure by microcolumn self-assembly methods. (a) Self-assembly of gold nanopillars[55]; (b) Self-assembly of polymer-silver micropillars[56]; (c) Self-assembly of polymer-silver micropillars[57]; (d) Self-assembly of silver micropillars[58]; (e) Self-assembly of polymer-gold micropillars[59]. Figure reproduced with permission from: (a) ref. [55] and (e) ref. [59] © American Chemical Society; (b) ref. [56], (c) ref. [57] and (d) ref. [58] © Wiley

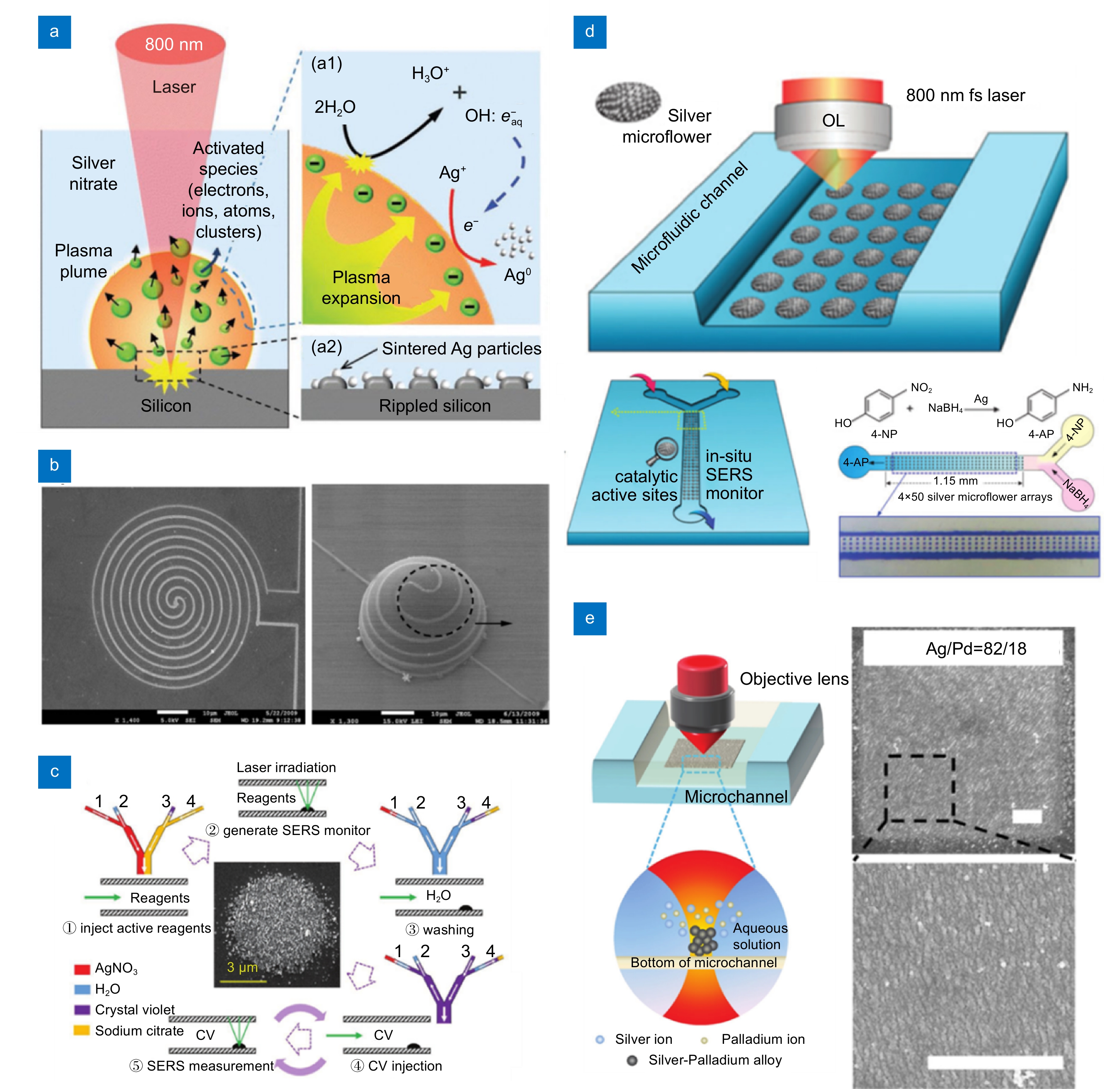

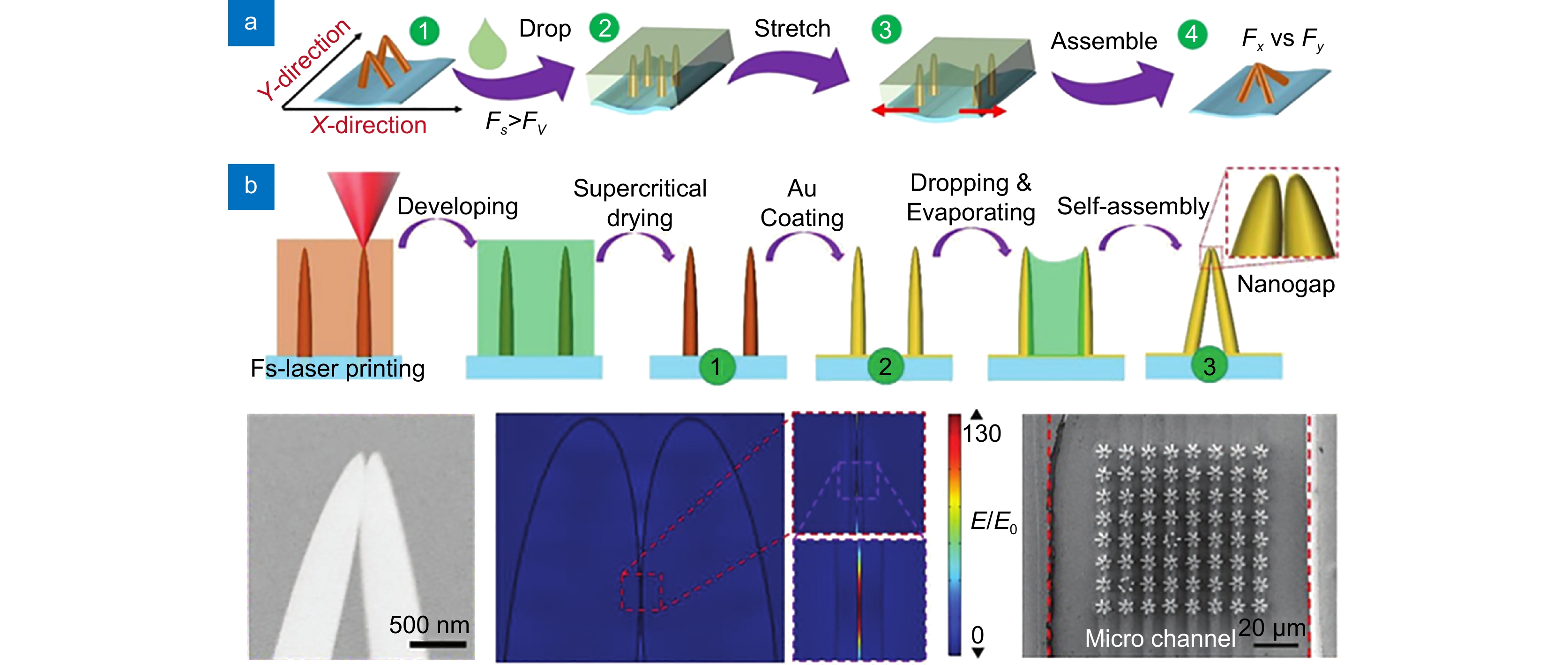

图 5 飞秒双光子金属还原制备SERS基底。(a) 双光子还原原理[70]; (b) 双光子还原银微线[71];(c~e) 微通道SERS基底[72-74]; 比例尺:(b) 10 µm; (e) 1 µm

Figure 5. Femtosecond two-photon reduction to prepare SERS substrates. (a) Two-photon reduction principle[70]; (b)Two-photon reduced silver microwire[71]; Scale bar: (b) 10 μm; (e) 1 μm. Figure reproduced with permission from: (a) ref. [70], (b) ref. [71], (c) ref. [74] and (e) ref. [71] © Wiley; (d) ref. [72] © The Royal Society of Chemistry

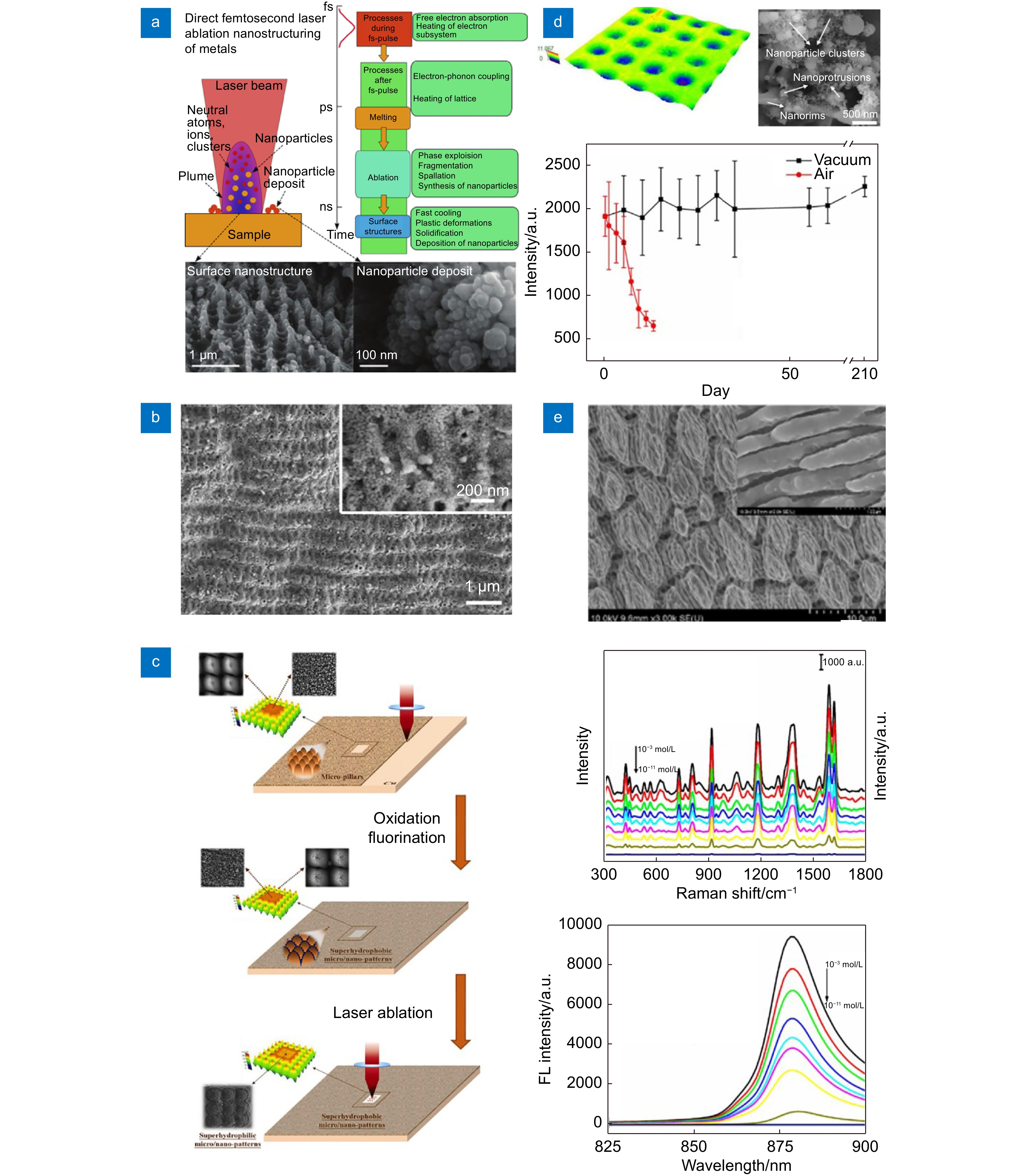

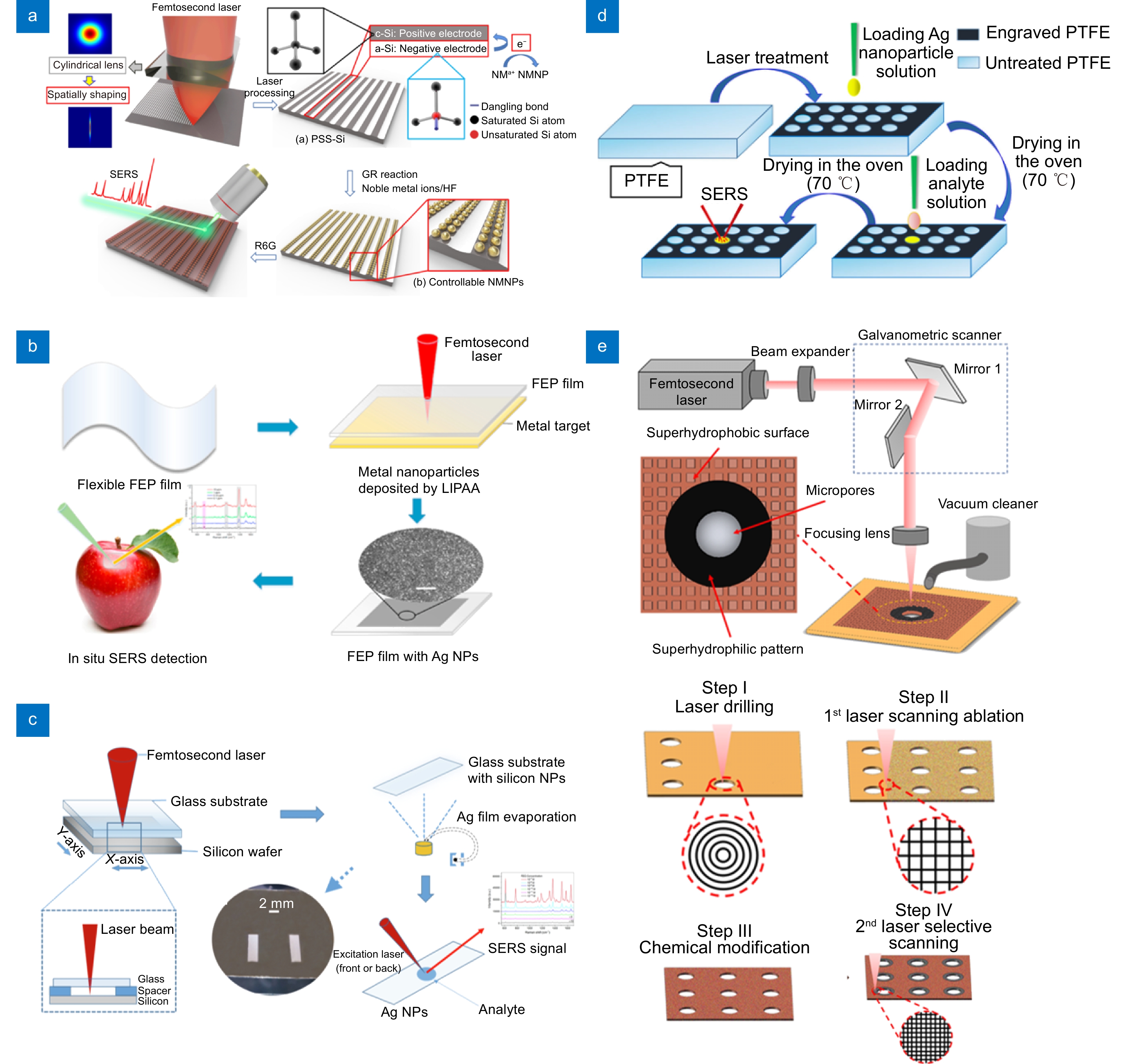

图 6 飞秒激光切割金属制备SERS基底。(a) 飞秒激光直接烧蚀金属表面形成纳米结构机理[80]; (b) Ag周期性表面[91]; (c) 铜表面直接制备超亲水-超疏水图案化基底结构[30];(d) S-Ag-Ar基底[92]; (e) 钛合金SERS基底[93]

Figure 6. Femtosecond laser cutting metal to prepare SERS substrate. (a) Femtosecond laser directly ablated metal surface forming nanostructure principle [80]; (b) Ag periodic surface[91]; (c) Superhydrophilic - superhydrophobic patterned substrate structures were prepared directly on copper surface [30]; (d) S-Ag-Ar substrate[92]; (e) Titanium alloy SERS substrate[93]. Figure reproduced with permission from: (a) ref. [80] © Elsevier; (b) ref. [91], (c) ref. [30] and (d) ref. [92] © Elsevier; (e) ref. [93] © under a Creative Commons Attribution-NonCommercial-No- Derivatives 4.0 International License

图 7 飞秒激光切割-溅射制备SERS基底。(a) 大面积SERS基底[105]; (b) 柔性透明SERS基底[31]; (c) 玻璃SERS基底[106]; (d) 疏水-超疏水SERS基底[107]; (e) 超疏水-亲水SERS基底[108]

Figure 7. Femtosecond laser cutting-sputtering to prepare a SERS substrate. (a) Large area SERS substrate[105]; (b) Flexible transparent SERS substrate[31]; (c) Glass SERS substrate[106]; (d) Hydrophobic-superhydrophobic SERS substrate[107]; (e) Superhydrophobic-hydrophilic SERS substrate[108] . Figure reproduced with permission from: (a) ref. [108], (b) ref. [31] and (c) ref. [106] © Elsevier; (d) ref. [107] © BioMed Central Ltd unless otherwise stated; (e) ref. [108] © American Chemical Society

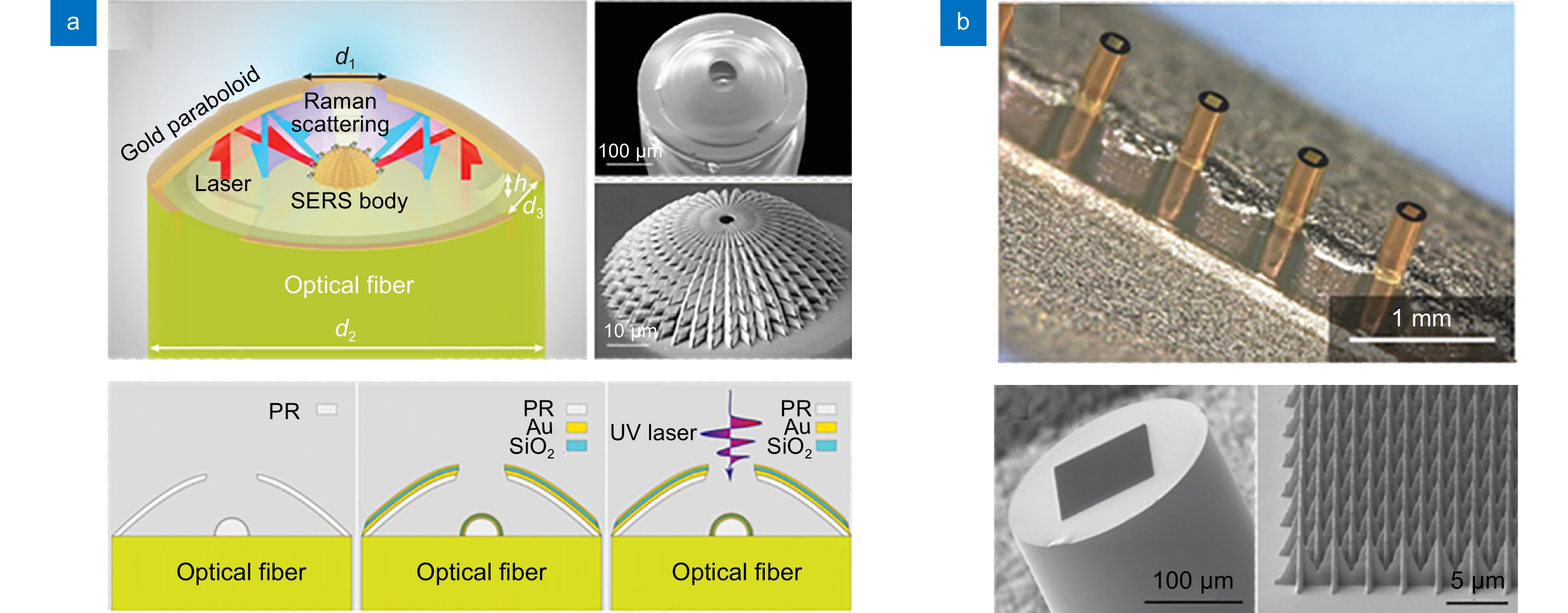

图 8 双光子直写结合金属蒸镀。(a, b) 光纤端面三维SERS结构[121-122]

Figure 8. Two-photon direct writing combined metal evaporation. (a, b) 3D SERS structure of fiber surface [121-122]. Figure reproduced with permission from: (a) ref. [121] © under a Creative Commons Attribution-NonCommercial-No-Derivatives 4.0 International License; (b) ref. [122] © Wiley

图 9 飞秒激光加工毛细力自组装制备SERS基底。(a) 毛细力自组装[126];(b) 基于毛细力自组装微通道的三维SERS结构[7]

Figure 9. Femtosecond laser processing capillary self-assembly to prepare SERS substrate. (a) Capillary force self-assembly[126]; (b) Three-dimensional SERS structure based on capillary force self-assembly microchannels[7]. Figure reproduced with permission from: (a) ref. [126] © American Chemical Society; (b) ref. [7] © Wiley

表 1 四种飞秒激光加工SERS基底各方法对比

Table 1. Comparison of four methods for processing SERS substrates by femtosecond laser

基底类型及维度 微纳结构 分析物 检测浓度下限/mol 增强因子 特殊基底 参考文献 双光子还原金属—-三维 银微花阵列 4-AP 10−10 1×108 封闭微通道 [71] 银钯纳米颗粒 R6G 10−9 2.6×108 封闭微通道 [73] 银纳米颗粒 CV 10−13 / 封闭微通道 [74] 粗糙银纳米结构 R6G 10−9 1×107 光纤端面 [78] 飞秒激光切割金属—二维 金纳米颗粒 R6G 10−9 2.4×108 金板 [94] 铜微粒和粒子团 R6G 10−14 2.09×1014 铜板 [30] 银微粒和粒子团 R6G 10−8 5.3×1014 银板 [92] 钛合金纳米颗粒 R6G 10−11 7.85×105 钛合金 [97] 飞秒激光切割-溅射—二维 金铂纳米颗粒 R6G 10−6 8.46×107 硅 [105] 银纳米颗粒 R6G 10−12 5.6×107 柔性FEP膜 [31] 银纳米颗粒 R6G / 2×105 玻璃 [106] 金纳米颗粒 R6G 10−6 / PTFE [117] 银纳米颗粒 R6G 10−17 5.19×1013 铜箔 [109] 飞秒激光3D打印—三维 金纳米颗粒 水晶紫 10−6 / 光纤端面 [121] 金纳米颗粒 R6G 10−7 3×103 光纤端面 [122] 金纳米颗粒 R6G 10−6 8×107 开放微通道 [7] -

[1] Zong C, Xu M X, Xu L J, et al. Surface-enhanced Raman spectroscopy for Bioanalysis: reliability and challenges[J]. Chem Rev, 2018, 118(10): 4946−4980. doi: 10.1021/acs.chemrev.7b00668

[2] Xu K C, Wang Z Y, Tan C F, et al. Uniaxially stretched flexible surface Plasmon resonance film for versatile surface enhanced Raman scattering diagnostics[J]. ACS Appl Mater Interfaces, 2017, 9(31): 26341−26349. doi: 10.1021/acsami.7b06669

[3] Xu K C, Zhou R, Takei K, Hong M H. Toward flexible surface-enhanced Raman scattering (SERS) sensors for point-of-care diagnostics[J]. Adv Sci (Weinh), 2019, 6(16): 1900925. doi: 10.1002/advs.201900925

[4] Niu R J, Gao F, Wang D, et al. Pattern recognition directed assembly of Plasmonic gap nanostructures for single-molecule SERS[J]. ACS Nano, 2022, 16(9): 14622−14631. doi: 10.1021/acsnano.2c05150

[5] Lee S, Jung I, Son J, et al. Heterogeneous component Au (Outer)-Pt (Middle)-Au (Inner) Nanorings: synthesis and vibrational characterization on middle Pt Nanorings with surface-enhanced Raman scattering[J]. ACS Nano, 2022, 16(7): 11259−11267. doi: 10.1021/acsnano.2c04633

[6] Qin M, Ge M H, Li P, et al. Natural <3 nm interbedded gaps to trap target molecules and provide an enhanced Raman spectroscopy method[J]. Adv Opt Mater, 2022, 10(19): 2200551. doi: 10.1002/adom.202200551

[7] Lao Z X, Zheng Y Y, Dai Y C, et al. Nanogap plasmonic structures fabricated by switchable capillary-force driven self-assembly for localized sensing of anticancer medicines with microfluidic SERS[J]. Adv Funct Mater, 2020, 30(15): 1909467. doi: 10.1002/adfm.201909467

[8] He J, Hua S Y, Zhang D X, et al. SERS/NIR‐II optical nanoprobes for multidimensional tumor imaging from living subjects, pathology, and single cells and guided NIR‐II photothermal therapy[J]. Adv Funct Mater, 2022, 32(46): 2208028. doi: 10.1002/adfm.202208028

[9] Sun J Y, Song Y N, Wang M Y, et al. Quantitative and noninvasive detection of SAH-related MiRNA in cerebrospinal fluids in vivo using SERS sensors based on acupuncture-based technology[J]. ACS Appl Mater Interfaces, 2022, 14(32): 37088−37100. doi: 10.1021/ACSAMI.2C03436

[10] Andreiuk B, Nicolson F, Clark L M, et al. Design and synthesis of gold nanostars-based SERS nanotags for bioimaging applications[J]. Nanotheranostics, 2022, 6(1): 10−30. doi: 10.7150/ntno.61244

[11] Van Der Hoeven J E S, Gurunarayanan H, Bransen M, et al. Silica‐coated gold nanorod supraparticles: a tunable platform for surface enhanced Raman spectroscopy[J]. Adv Funct Mater, 2022, 32(27): 2200148. doi: 10.1002/adfm.202200148

[12] Li C, Li S, Qu A, et al. Directing arrowhead Nanorod dimers for MicroRNA in situ Raman detection in living cells[J]. Adv Funct Mater, 2020, 30(22): 2001451. doi: 10.1002/adfm.202001451

[13] Meyer S M, Murphy C J. Anisotropic silica coating on gold nanorods boosts their potential as SERS sensors[J]. Nanoscale, 2022, 14(13): 5214−5226. doi: 10.1039/D1NR07918B

[14] Lu Y C, Tseng P C, Yang M J, et al. Fabrication of Gyroid‐structured metal/semiconductor nanoscaffolds with ultrasensitive SERS detection via block copolymer Templating[J]. Adv Opt Mater, 2023, 11(2): 2202280. doi: 10.1002/adom.202202280

[15] Zhang H, Duan S, Radjenovic P M, et al. Core-shell nanostructure-enhanced Raman spectroscopy for surface catalysis[J]. Acc Chem Res, 2020, 53(4): 729−739. doi: 10.1021/acs.accounts.9b00545

[16] Zhang Y J, Chen S, Radjenovic P, et al. Probing the location of 3D hot spots in gold nanoparticle films using surface-enhanced Raman spectroscopy[J]. Anal Chem, 2019, 91(8): 5316−5322. doi: 10.1021/acs.analchem.9b00200

[17] Phuong NTT, Dang VQ, Van Hieu L, et al. Functionalized silver nanoparticles for SERS amplification with enhanced reproducibility and for ultrasensitive optical fiber sensing in environmental and biochemical assays[J]. RSC Adv, 2022, 12(48): 31352−31362. doi: 10.1039/D2RA06074D

[18] Wang T J, Barveen N R, Liu Z Y, et al. Transparent, flexible plasmonic Ag NP/PMMA substrates using chemically patterned ferroelectric crystals for detecting pesticides on curved surfaces[J]. ACS Appl Mater Interfaces, 2021, 13(29): 34910−34922. doi: 10.1021/acsami.1c08233

[19] Anh N H, Doan M Q, Dinh N X, et al. Gold nanoparticle-based optical nanosensors for food and health safety monitoring: recent advances and future perspectives[J]. RSC Adv, 2022, 12(18): 10950−10988. doi: 10.1039/D1RA08311B

[20] Wang D, Bao L P, Li H J, et al. Polydopamine stabilizes silver nanoparticles as a SERS substrate for efficient detection of myocardial infarction[J]. Nanoscale, 2022, 14(16): 6212−6219. doi: 10.1039/D2NR00091A

[21] Wang X K, Park S G, Ko J, et al. Sensitive and reproducible immunoassay of multiple mycotoxins using surface-enhanced Raman scattering mapping on 3D plasmonic nanopillar arrays[J]. Small, 2018, 14(39): 1801623. doi: 10.1002/smll.201801623

[22] Liu Y, Guang J Y, Liu C, et al. Simple and low‐cost plasmonic fiber‐optic probe as SERS and biosensing platform[J]. Adv Opt Mater, 2019, 7(19): 1900337. doi: 10.1002/adom.201900337

[23] Mogera U, Guo H, Namkoong M, et al. Wearable plasmonic paper–based microfluidics for continuous sweat analysis[J]. Sci Adv, 2022, 8(12): eabn1736. doi: 10.1126/sciadv.abn1736

[24] Ma Z C, Zhang Y L, Han B, et al. Femtosecond-laser direct writing of metallic micro/nanostructures: from fabrication strategies to future applications[J]. Small Methods, 2018, 2(7): 1700413. doi: 10.1002/smtd.201700413

[25] Sugioka K, Cheng Y. Ultrafast lasers—reliable tools for advanced materials processing[J]. Light Sci Appl, 2014, 3(4): e149. doi: 10.1038/lsa.2014.30

[26] Wu D, Xu J, Niu L G, et al. In-channel integration of designable microoptical devices using flat scaffold-supported femtosecond-laser microfabrication for coupling-free optofluidic cell counting[J]. Light Sci Appl, 2015, 4(1): e228. doi: 10.1038/lsa.2015.1

[27] Kawata S, Sun H B, Tanaka T, et al. Finer features for functional microdevices[J]. Nature, 2001, 412(6848): 697−698. doi: 10.1038/35089130

[28] 周伟平, 白石, 谢祖武, 等. 激光直写制备金属与碳材料微纳结构与器件研究进展[J]. 光电工程, 2022, 49(1): 210330.

Zhou W P, Bai S, Xie Z W, et al. Research progress of laser direct writing fabrication of metal and carbon micro/nano structures and devices[J]. Opto-Electron Eng, 2022, 49(1): 210330.

[29] 廖嘉宁, 张东石, 李铸国. 飞秒激光制备柔性电子器件进展[J]. 光电工程, 2022, 49(2): 210388.

Liao J N, Zhang D S, Li Z G. Advance in femtosecond laser fabrication of flexible electronics[J]. Opto-Electron Eng, 2022, 49(2): 210388.

[30] Luo X, Pan R, Cai M Y, et al. Atto-Molar Raman detection on patterned superhydrophilic-superhydrophobic platform via localizable evaporation enrichment[J]. Sens Actuators B Chem, 2021, 326: 128826. doi: 10.1016/j.snb.2020.128826

[31] Xu L M, Liu H G, Zhou H, et al. One-step fabrication of metal nanoparticles on polymer film by femtosecond LIPAA method for SERS detection[J]. Talanta, 2021, 228: 122204. doi: 10.1016/j.talanta.2021.122204

[32] Xu B B, Ma Z C, Wang L, et al. Localized flexible integration of high-efficiency surface enhanced Raman scattering (SERS) monitors into microfluidic channels[J]. Lab Chip, 2011, 11(19): 3347−3351. doi: 10.1039/c1lc20397e

[33] Langer J, De Aberasturi D J, Aizpurua J, et al. Present and future of surface-enhanced Raman scattering[J]. ACS Nano, 2020, 14(1): 28−117. doi: 10.1021/acsnano.9b04224

[34] Fleischmann M, Hendra P J, McQuillan A J. Raman spectra of pyridine adsorbed at a silver electrode[J]. Chem Phys Lett, 1974, 26(2): 163−166. doi: 10.1016/0009-2614(74)85388-1

[35] Jeanmaire D L, Van Duyne R P. Surface Raman spectroelectrochemistry: Part I. Heterocyclic, aromatic, and aliphatic amines adsorbed on the anodized silver electrode[J]. J Electroanal Chem Interfac Electrochem, 1977, 84(1): 1−20. doi: 10.1016/S0022-0728(77)80224-6

[36] Lee H K, Lee Y H, Koh C S L, et al. Designing surface-enhanced Raman scattering (SERS) platforms beyond hotspot engineering: emerging opportunities in analyte manipulations and hybrid materials[J]. Chem Soc Rev, 2019, 48(3): 731−756. doi: 10.1039/C7CS00786H

[37] Stiles P L, Dieringer J A, Shah N C, et al. Surface-enhanced Raman spectroscopy[J]. Annu Rev Anal Chem, 2008, 1: 601−626. doi: 10.1146/annurev.anchem.1.031207.112814

[38] Ding S Y, You E M, Tian Z Q, et al. Electromagnetic theories of surface-enhanced Raman spectroscopy[J]. Chem Soc Rev, 2017, 46(13): 4042−4076. doi: 10.1039/C7CS00238F

[39] Phan-Quang G C, Lee H K, Phang I Y, et al. Plasmonic colloidosomes as three-dimensional SERS platforms with enhanced surface area for multiphase sub-microliter toxin sensing[J]. Angew Chem Int Ed, 2015, 54(33): 9691−9695. doi: 10.1002/anie.201504027

[40] Cardinal M F, Ende E V, Hackler R A, et al. Expanding applications of SERS through versatile nanomaterials engineering[J]. Chem Soc Rev, 2017, 46(13): 3886−3903. doi: 10.1039/C7CS00207F

[41] Im H, Bantz K C, Lee S H, et al. Self-assembled plasmonic nanoring cavity arrays for SERS and LSPR biosensing[J]. Adv Mater, 2013, 25(19): 2678−2685. doi: 10.1002/adma.201204283

[42] Whitney A V, Elam J W, Zou S L, et al. Localized surface Plasmon resonance Nanosensor: a high-resolution distance-dependence study using atomic layer deposition[J]. J Phys Chem B, 2005, 109(43): 20522−20528. doi: 10.1021/jp0540656

[43] Guselnikova O, Lim H, Kim H J, et al. New trends in nanoarchitectured SERS substrates: nanospaces, 2D materials, and organic heterostructures[J]. Small, 2022, 18(25): 2107182. doi: 10.1002/smll.202107182

[44] Yang X, Ileri N, Larson C C, et al. Nanopillar array on a fiber facet for highly sensitive surface-enhanced Raman scattering[J]. Opt Express, 2012, 20(22): 24819−24826. doi: 10.1364/OE.20.024819

[45] Lin D D, Wu Z L, Li S J, et al. Large-area au-nanoparticle-functionalized Si nanorod arrays for spatially uniform surface-enhanced Raman spectroscopy[J]. ACS Nano, 2017, 11(2): 1478−1487. doi: 10.1021/acsnano.6b06778

[46] Tian Y, Wang H F, Yan L Q, et al. A generalized methodology of designing 3D SERS probes with superior detection limit and uniformity by maximizing multiple coupling effects[J]. Adv Sci (Weinh), 2019, 6(11): 1900177. doi: 10.1002/advs.201900177

[47] Luo X J, Xing Y F, Galvan D D, et al. Plasmonic gold Nanohole array for surface-enhanced Raman scattering detection of DNA methylation[J]. ACS Sens, 2019, 4(6): 1534−1542. doi: 10.1021/acssensors.9b00008

[48] Köker T, Tang N, Tian C, et al. Cellular imaging by targeted assembly of hot-spot SERS and photoacoustic nanoprobes using split-fluorescent protein scaffolds[J]. Nat Commun, 2018, 9(1): 607. doi: 10.1038/s41467-018-03046-w

[49] Tian L, Su M K, Yu F F, et al. Liquid-state quantitative SERS analyzer on self-ordered metal liquid-like plasmonic arrays[J]. Nat Commun, 2018, 9(1): 3642. doi: 10.1038/s41467-018-05920-z

[50] Fan J A, Wu C, Bao K, et al. Self-assembled plasmonic nanoparticle Clusters[J]. Science, 2010, 328(5982): 1135−1138. doi: 10.1126/science.1187949

[51] Ma Y, Sikdar D, Fedosyuk A, et al. Electrotunable nanoplasmonics for amplified surface enhanced raman spectroscopy[J]. ACS Nano, 2020, 14(1): 328−336. doi: 10.1021/acsnano.9b05257

[52] Yap F L, Thoniyot P, Krishnan S, et al. Nanoparticle cluster arrays for high-performance SERS through directed self-assembly on flat substrates and on optical fibers[J]. ACS Nano, 2012, 6(3): 2056−2070. doi: 10.1021/nn203661n

[53] 董子豪, 刘晔, 秦琰琰, 等. 激光诱导液面自组装法制备光纤SERS探针及其农残检测应用[J]. 中国激光, 2018, 45(8): 181−187. doi: 10.3788/CJL201845.0804009

Dong Z H, Liu Y, Qin Y Y, et al. Fabrication of fiber SERS probes by laser-induced self-assembly method in a meniscus and its applications in trace detection of pesticide residues[J]. Chin J Lasers, 2018, 45(8): 181−187. doi: 10.3788/CJL201845.0804009

[54] 李春赫, 马卓晨, 胡昕宇, 等. 微流控拉曼检测芯片的制备与应用[J]. 中国激光, 2021, 48(2): 0202010. doi: 10.3788/CJL202148.0202010

Li C H, Ma Z C, Hu X Y, et al. Preparation and application of microfluidic Raman detection chip[J]. Chin J Lasers, 2021, 48(2): 0202010. doi: 10.3788/CJL202148.0202010

[55] Hu M, Ou F S, Wu W, et al. Gold nanofingers for molecule trapping and detection[J]. J Am Chem Soc, 2010, 132(37): 12820−12822. doi: 10.1021/ja105248h

[56] Liu F X, Song B X, Su G X, et al. Molecule sensing: sculpting extreme electromagnetic field enhancement in free space for molecule sensing[J]. Small, 2018, 14(33): 1870152. doi: 10.1002/smll.201870152

[57] Park S G, Mun C, Xiao X F, et al. Surface energy-controlled SERS substrates for molecular concentration at plasmonic nanogaps[J]. Adv Funct Mater, 2017, 27(41): 1703376. doi: 10.1002/adfm.201703376

[58] Zhu C H, Meng G W, Zheng P, et al. A hierarchically ordered array of silver-nanorod bundles for surface-enhanced Raman scattering detection of phenolic pollutants[J]. Adv Mater, 2016, 28(24): 4871−4876. doi: 10.1002/adma.201506251

[59] Song B X, Jiang Z H, Liu Z R, et al. Probing the mechanisms of strong fluorescence enhancement in plasmonic nanogaps with sub-nanometer precision[J]. ACS Nano, 2020, 14(11): 14769−14778. doi: 10.1021/acsnano.0c01973

[60] Wu K Y, Li T, Schmidt M S, et al. Gold nanoparticles sliding on recyclable nanohoodoos-engineered for surface-enhanced Raman spectroscopy[J]. Adv Funct Mater, 2018, 28(2): 1704818. doi: 10.1002/adfm.201704818

[61] Macias-Montero M, Peláez R J, Rico V J, et al. Laser treatment of Ag@ZnO nanorods as long-life-span SERS surfaces[J]. ACS Appl Mater Interfaces, 2015, 7(4): 2331−2339. doi: 10.1021/am506622x

[62] Xu K C, Yan H P, Tan C F, et al. Hedgehog inspired CuO nanowires/Cu2O composites for broadband visible-light-driven recyclable surface enhanced Raman scattering[J]. Adv Opt Mater, 2018, 6(7): 1701167. doi: 10.1002/adom.201701167

[63] Gurbatov S O, Modin E, Puzikov V, et al. Black Au-decorated TiO2 produced via laser ablation in liquid[J]. ACS Appl Mater Interfaces, 2021, 13(5): 6522−6531. doi: 10.1021/acsami.0c20463

[64] Momma C, Chichkov B N, Nolte S, et al. Short-pulse laser ablation of solid targets[J]. Opt Commun, 1996, 129(1–2): 134−142. doi: 10.1016/0030-4018(96)00250-7

[65] Gattass R R, Mazur E. Femtosecond laser micromachining in transparent materials[J]. Nat Photon, 2008, 2(4): 219−225. doi: 10.1038/nphoton.2008.47

[66] Küper S, Stuke M. Ablation of uv-transparent materials with femtosecond uv excimer laser pulses[J]. Microelectron Eng, 1989, 9(1): 475−480. doi: 10.1016/0167-9317(89)90104-4

[67] Küper S, Stuke M. Ablation of polytetrafluoroethylene (Teflon) with femtosecond UV excimer laser pulses[J]. Appl Phys Lett, 1989, 54(1): 4−6. doi: 10.1063/1.100831

[68] Lim T W, Son Y, Jeong Y J, et al. Three-dimensionally crossing manifold micro-mixer for fast mixing in a short channel length[J]. Lab Chip, 2011, 11(1): 100−103. doi: 10.1039/C005325M

[69] Raimondi M T, Eaton S M, Nava M M, et al. Two-photon laser polymerization: from fundamentals to biomedical application in tissue engineering and regenerative medicine[J]. J Appl Biomater Funct Mater, 2012, 10(1): 56−66. doi: 10.5301/JABFM.2012.9278

[70] Ran P, Jiang L, Li X, et al. Femtosecond photon-mediated plasma enhances photosynthesis of plasmonic nanostructures and their SERS applications[J]. Small, 2019, 15(11): 1804899. doi: 10.1002/smll.201804899

[71] Xu B B, Xia H, Niu L G, et al. Flexible nanowiring of metal on nonplanar substrates by femtosecond-laser-induced electroless plating[J]. Small, 2010, 6(16): 1762−1766. doi: 10.1002/smll.201000511

[72] Xu B B, Zhang R, Liu X Q, et al. On-chip fabrication of silver microflower arrays as a catalytic microreactor for allowing in situ SERS monitoring[J]. Chem Commun (Camb), 2012, 48(11): 1680−1682. doi: 10.1039/C2CC16612G

[73] Ma Z C, Zhang Y L, Han B, et al. Femtosecond laser direct writing of plasmonic Ag/Pd alloy nanostructures enables flexible integration of robust SERS substrates[J]. Adv Mater Technol, 2017, 2(6): 1600270. doi: 10.1002/admt.201600270

[74] Yan W J, Yang L K, Chen J N, et al. In situ two-step photoreduced SERS materials for on-chip single-molecule spectroscopy with high reproducibility[J]. Adv Mater, 2017, 29(36): 1702893. doi: 10.1002/adma.201702893

[75] Luo Z J, Zeng Z H, Liu Z Y, et al. Cluster-enabled patterning of copper nanostructures from aqueous solution using a femtosecond laser[J]. Nanotechnology, 2022, 33(50): 505301. doi: 10.1088/1361-6528/ac8c4a

[76] Bai S, Serien D, Hu A M, et al. 3D microfluidic surface-enhanced Raman spectroscopy (SERS) chips fabricated by all-femtosecond-laser-processing for real-time sensing of toxic substances[J]. Adv Funct Mater, 2018, 28(23): 1706262. doi: 10.1002/adfm.201706262

[77] MacKenzie M, Chi H N, Varma M, et al. Femtosecond laser fabrication of silver nanostructures on glass for surface enhanced Raman spectroscopy[J]. Sci Rep, 2019, 9(1): 17058. doi: 10.1038/s41598-019-53328-6

[78] Geng Y F, Yin Z, Tan X L, et al. Femtosecond laser ablated polymer SERS fiber probe with photoreduced deposition of silver nanoparticles[J]. IEEE Photon J, 2016, 8(5): 1−6. doi: 10.1109/JPHOT.2016.2606640

[79] Xu Y W, Geng Y F, Wang L N, et al. Femtosecond laser ablated pyramidal fiber taper-SERS probe with laser-induced silver nanostructures[J]. J Phys D Appl Phys, 2018, 51(28): 285104. doi: 10.1088/1361-6463/aacab2

[80] Vorobyev A Y, Guo C L. Direct femtosecond laser surface nano/microstructuring and its applications[J]. Laser Photon Rev, 2013, 7(3): 385−407. doi: 10.1002/lpor.201200017

[81] Eesley G L. Observation of nonequilibrium electron heating in copper[J]. Phys Rev Lett, 1983, 51(23): 2140−2143. doi: 10.1103/PhysRevLett.51.2140

[82] Fujimoto J G, Liu J M, Ippen E P, et al. Femtosecond laser interaction with metallic tungsten and nonequilibrium electron and lattice temperatures[J]. Phys Rev Lett, 1984, 53(19): 1837−1840. doi: 10.1103/PhysRevLett.53.1837

[83] Elsayed-Ali H E, Norris T B, Pessot M A, et al. Time-resolved observation of electron-phonon relaxation in copper[J]. Phys Rev Lett, 1987, 58(12): 1212−1215. doi: 10.1103/PhysRevLett.58.1212

[84] Oguri K, Okano Y, Nishikawa T, et al. Dynamics of femtosecond laser ablation studied with time-resolved x-ray absorption fine structure imaging[J]. Phys Rev B, 2009, 79(14): 144106. doi: 10.1103/PhysRevB.79.144106

[85] Glover T E, Ackerman G D, Lee R W, et al. Metal–insulator transitions in an expanding metallic fluid: particle formation during femtosecond laser ablation[J]. Chem Phys, 2004, 299(2–3): 171−181. doi: 10.1016/j.chemphys.2003.11.042

[86] Amoruso S, Bruzzese R, Vitiello M, et al. Experimental and theoretical investigations of femtosecond laser ablation of aluminum in vacuum[J]. J Appl Phys, 2005, 98(4): 044907. doi: 10.1063/1.2032616

[87] Oguri K, Okano Y, Nishikawa T, et al. Dynamical study of femtosecond-laser-ablated liquid-aluminum nanoparticles using spatiotemporally resolved x-ray-absorption fine-structure spectroscopy[J]. Phys Rev Lett, 2007, 99(16): 165003. doi: 10.1103/PhysRevLett.99.165003

[88] Amoruso S, Bruzzese R, Wang X, et al. Femtosecond laser ablation of nickel in vacuum[J]. J Phys D Appl Phys, 2007, 40(2): 331−340. doi: 10.1088/0022-3727/40/2/008

[89] Zavestovskaya I N, Kanavin A P, Men’kova N A. Crystallization of metals under conditions of superfast cooling when materials are processed with ultrashort laser pulses[J]. J Opt Technol, 2008, 75(6): 353−358. doi: 10.1364/JOT.75.000353

[90] Hisey C L, Mitxelena-Iribarren O, Martínez-Calderón M, et al. A versatile cancer cell trapping and 1D migration assay in a microfluidic device[J]. Biomicrofluidics, 2019, 13(4): 044105. doi: 10.1063/1.5103269

[91] Chang H W, Tsai Y C, Cheng C W, et al. Nanostructured Ag surface fabricated by femtosecond laser for surface-enhanced Raman scattering[J]. J Colloid Interface Sci, 2011, 360(1): 305−308. doi: 10.1016/j.jcis.2011.04.005

[92] Luo X B, Liu W J, Chen C H, et al. Femtosecond laser micro-Nano structured Ag SERS substrates with unique sensitivity, uniformity and stability for food safety evaluation[J]. Opt Laser Technol, 2021, 139: 106969. doi: 10.1016/j.optlastec.2021.106969

[93] Lu L B, Zhang J R, Jiao L S, et al. Large-scale fabrication of nanostructure on bio-metallic substrate for surface enhanced Raman and fluorescence scattering[J]. Nanomaterials (Basel), 2019, 9(7): 916. doi: 10.3390/nano9070916

[94] Zhang W D, Li C, Gao K, et al. Surface-enhanced Raman spectroscopy with Au-nanoparticle substrate fabricated by using femtosecond pulse[J]. Nanotechnology, 2018, 29(20): 205301. doi: 10.1088/1361-6528/aab294

[95] Long J Y, Cao Z, Lin C H, et al. Formation mechanism of hierarchical Micro- and nanostructures on copper induced by low-cost nanosecond lasers[J]. Appl Surf Sci, 2019, 464: 412−421. doi: 10.1016/j.apsusc.2018.09.055

[96] Harilal S S, Bindhu C V, Tillack M S, et al. Internal structure and expansion dynamics of laser ablation plumes into ambient gases[J]. J Appl Phys, 2003, 93(5): 2380−2388. doi: 10.1063/1.1544070

[97] Cai M Y, Pan R, Liu W J, et al. Laser-assisted doping and architecture engineering of Fe3O4 nanoparticles for highly enhanced oxygen evolution reaction[J]. ChemSusChem, 2019, 12(15): 3562−3570. doi: 10.1002/cssc.201901020

[98] Dileep M, Majumdar J D. Short and ultrashort laser surface processing of Alpha + Beta titanium alloy (Ti6Al4V): Present status[J]. Trans. Indian Natl Acad Eng, 2022, 7(3): 851−871. doi: 10.1007/s41403-022-00333-3

[99] Aggarwal R L, Farrar L W, Diebold E D, et al. Measurement of the absolute Raman scattering cross section of the 1584-cm-1 band of benzenethiol and the surface-enhanced Raman scattering cross section enhancement factor for femtosecond laser-nanostructured substrates[J]. J Raman Spectrosc, 2009, 40(9): 1331−1333. doi: 10.1002/jrs.2396

[100] Jiang L, Ying D W, Li X, et al. Two-step femtosecond laser pulse train fabrication of nanostructured substrates for highly surface-enhanced Raman scattering[J]. Opt Lett, 2012, 37(17): 3648−3650. doi: 10.1364/OL.37.003648

[101] Han Y K, Lan X W, Wei T, et al. Surface enhanced Raman scattering silica substrate fast fabrication by femtosecond laser pulses[J]. Appl Phys A, 2009, 97(3): 721−724. doi: 10.1007/s00339-009-5306-z

[102] Buividas R, Fahim N, Juodkazytė J, et al. Novel method to determine the actual surface area of a laser-nanotextured sensor[J]. Appl Phys A, 2014, 114(1): 169−175. doi: 10.1007/s00339-013-8129-x

[103] Aleknavičienė I, Pabrėža E, Talaikis M, et al. Low-cost SERS substrate featuring laser-ablated amorphous nanostructure[J]. Appl Surf Sci, 2021, 571: 151248. doi: 10.1016/j.apsusc.2021.151248

[104] Botta R, Eiamchai P, Horprathum M, et al. 3D structured laser engraves decorated with gold nanoparticle SERS chips for paraquat herbicide detection in environments[J]. Sens Actuat B Chem, 2020, 304: 127327. doi: 10.1016/j.snb.2019.127327

[105] Li Z H, Hu J, Jiang L, et al. Shaped femtosecond laser-regulated deposition sites of galvanic replacement for simple preparation of large-area controllable noble metal nanoparticles[J]. Appl Surf Sci, 2022, 579: 152123. doi: 10.1016/j.apsusc.2021.152123

[106] Xu L M, Liu H G, Chua T C, et al. Fabrication of SERS substrates by femtosecond LIPAA for detection of contaminants in foods[J]. Opt Laser Technol, 2022, 151: 107954. doi: 10.1016/j.optlastec.2022.107954

[107] Chu F J, Yan S, Zheng J G, et al. A simple laser ablation-assisted method for fabrication of superhydrophobic SERS substrate on teflon film[J]. Nanoscale Res Lett, 2018, 13(1): 244. doi: 10.1186/s11671-018-2658-3

[108] Yu J, Wu J G, Yang H, et al. Extremely sensitive SERS sensors based on a femtosecond laser-fabricated superhydrophobic/-philic microporous platform[J]. ACS Appl Mater Interfaces, 2022, 14(38): 43877−43885. doi: 10.1021/acsami.2c10381

[109] Li Y, Liu H G, Hong M H. High-quality sapphire microprocessing by dual-beam laser induced plasma assisted ablation[J]. Opt Express, 2020, 28(5): 6242−6250. doi: 10.1364/OE.381268

[110] Rahman T U, Rehman Z U, Ullah S, et al. Laser-induced plasma-assisted ablation (LIPAA) of glass: Effects of the laser fluence on plasma parameters and crater morphology[J]. Opt Technol, 2019, 120: 105768. doi: 10.1016/j.optlastec.2019.105768

[111] Saraeva I N, Kudryashov S I, Lednev V N, et al. Single- and multishot femtosecond laser ablation of silicon and silver in air and liquid environments: Plume dynamics and surface modification[J]. Appl Surf Sci, 2019, 476: 576−586. doi: 10.1016/j.apsusc.2019.01.092

[112] Allahyari E, Nivas J J J, Valadan M, et al. Plume shielding effects in ultrafast laser surface texturing of silicon at high repetition rate in air[J]. Appl Surf Sci, 2019, 488: 128−133. doi: 10.1016/j.apsusc.2019.05.219

[113] Weng Z Y, Ting C S, Lee T K. Mobile spin bags and their interaction in the spin-density-wave background[J]. Phys Rev B, 1990, 41(4): 1990−2002. doi: 10.1103/PhysRevB.41.1990

[114] Zhizhchenko A, Kuchmizhak A, Vitrik O, et al. On-demand concentration of an analyte on laser-printed polytetrafluoroethylene[J]. Nanoscale, 2018, 10(45): 21414−21424. doi: 10.1039/C8NR06119J

[115] Yan Z X, Zhang Y L, Wang W, et al. Superhydrophobic SERS substrates based on silver-coated reduced graphene oxide gratings prepared by two-beam laser interference[J]. ACS Appl Mater Interfaces, 2015, 7(49): 27059−27065. doi: 10.1021/acsami.5b09128

[116] Wang A D, Jiang L, Li X W, et al. Low-adhesive superhydrophobic surface-enhanced Raman spectroscopy substrate fabricated by femtosecond laser ablation for ultratrace molecular detection[J]. J Mater Chem B, 2017, 5(4): 777−784. doi: 10.1039/C6TB02629J

[117] Hu X Y, Pan R, Cai M Y, et al. Ultrafast laser micro-Nano structured superhydrophobic Teflon surfaces for enhanced SERS detection via evaporation concentration[J]. Adv Opt Technol, 2020, 9(1–2): 89−100. doi: 10.1515/aot-2019-0072

[118] Gan Z S, Cao Y Y, Evans R A, et al. Three-dimensional deep sub-diffraction optical beam lithography with 9 nm feature size[J]. Nat Commun, 2013, 4: 2061. doi: 10.1038/ncomms3061

[119] Cox N, Wei J X, Pattanaik H, et al. Nondegenerate two-photon absorption in GaAs/AlGaAs multiple quantum well waveguides[J]. Phys Rev Res, 2020, 2: 013376. doi: 10.1103/PhysRevResearch.2.013376

[120] Wang Z K, Sugioka K, Midorikawa K. Fabrication of integrated microchip for optical sensing by femtosecond laser direct writing of Foturan glass[J]. Appl Phys A, 2008, 93(1): 225−229. doi: 10.1007/s00339-008-4664-2

[121] Xie Z W, Feng S F, Wang P J, et al. Demonstration of a 3D Radar-Like SERS Sensor Micro- and Nanofabricated on an Optical Fiber[J]. Adv Opt Mater, 2015, 3(9): 1232−1239. doi: 10.1002/adom.201500041

[122] Kim J A, Wales D J, Thompson A J, et al. Fiber‐Optic SERS probes fabricated using two‐photon polymerization for rapid detection of bacteria[J]. Adv Opt Mater, 2020, 8(9): 1901934. doi: 10.1002/adom.201901934

[123] Kyeremateng N A, Brousse T, Pech D. Microsupercapacitors as miniaturized energy-storage components for on-chip electronics[J]. Nat Nanotechnol, 2017, 12(1): 7−15. doi: 10.1038/nnano.2016.196

[124] Zhu B W, Wang H, Leow W R, et al. Silk fibroin for flexible electronic devices[J]. Adv Mater, 2016, 28(22): 4250−4265. doi: 10.1002/adma.201504276

[125] Chandra D, Yang S, Soshinsky A A, et al. Biomimetic ultrathin whitening by capillary-force-induced random clustering of hydrogel micropillar arrays[J]. ACS Appl Mater& Interfaces, 2009, 1(8): 1698−1704. doi: 10.1021/am900253z

[126] Lao Z X, Pan D, Yuan H W, et al. Mechanical-tunable capillary-force-driven self-assembled hierarchical structures on soft substrate[J]. ACS Nano, 2018, 12(10): 10142−10150. doi: 10.1021/acsnano.8b05024

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: