Highly sensitive gas-pressure sensor based on paralleled optical fiber Fabry-Perot interferometers

-

摘要:

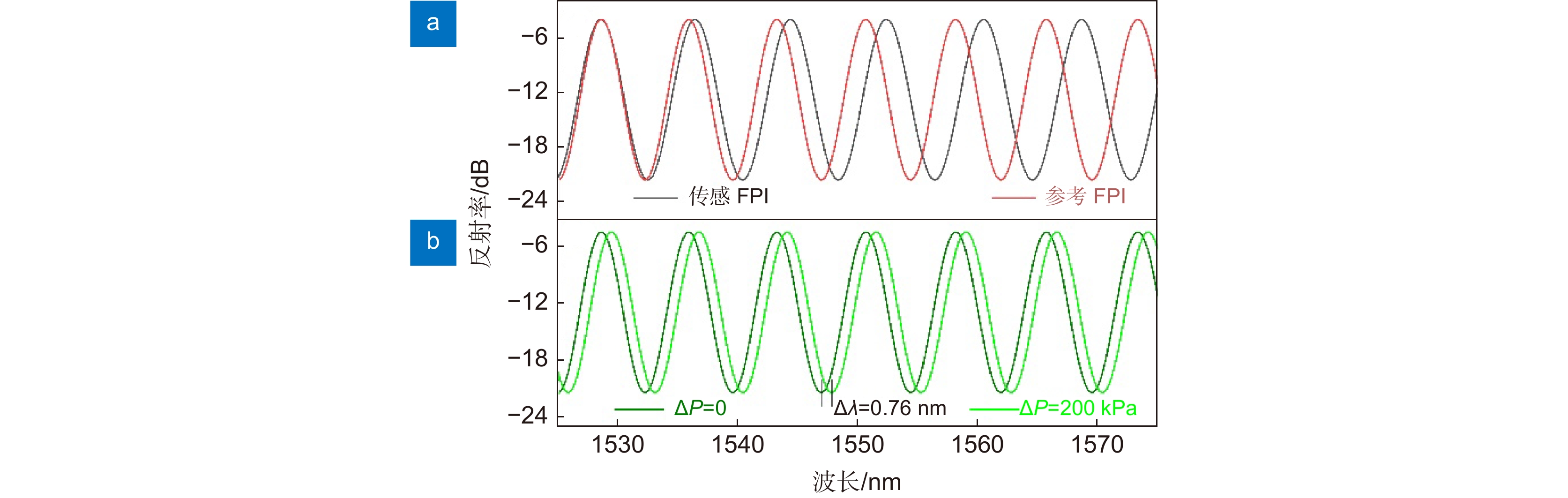

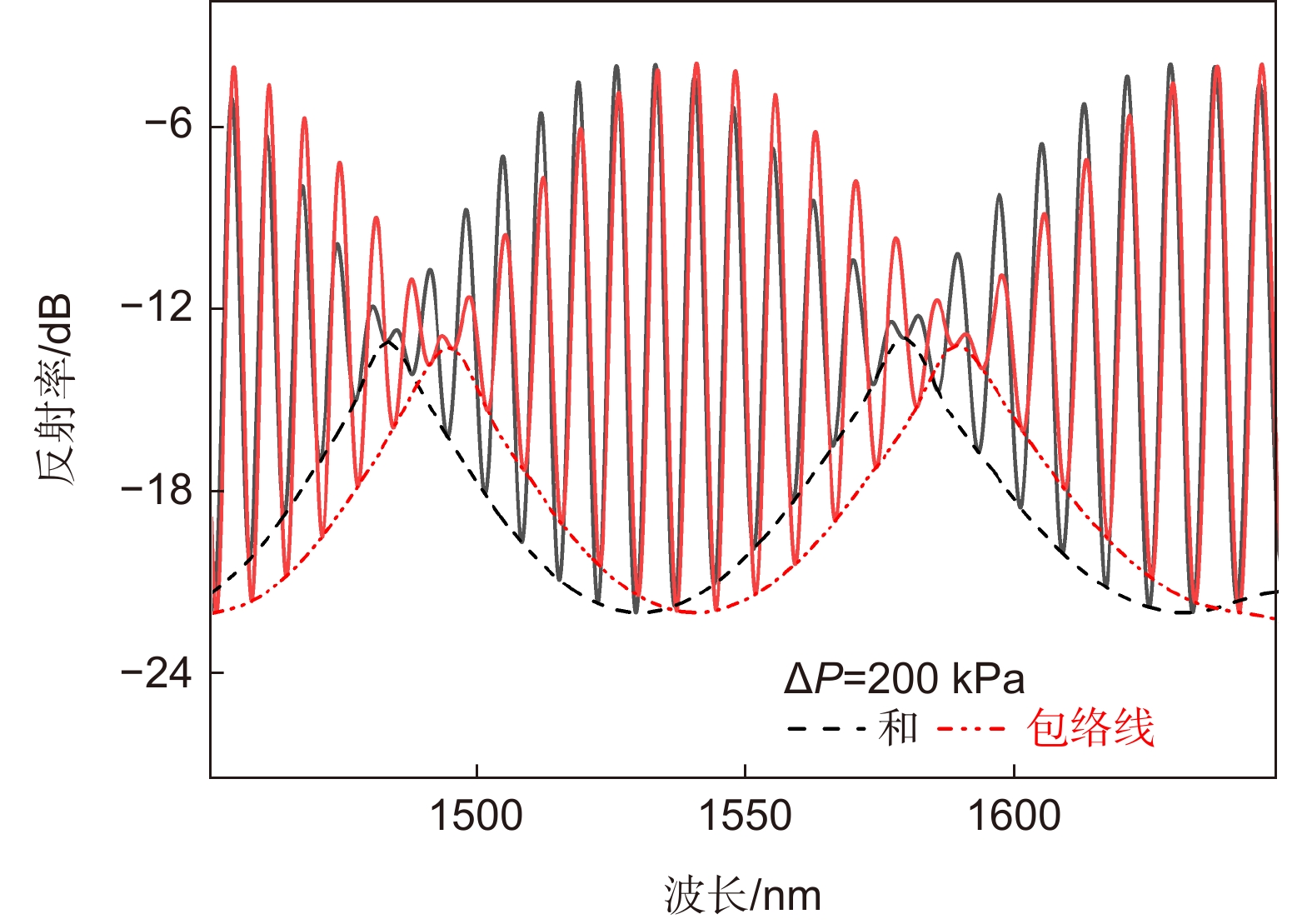

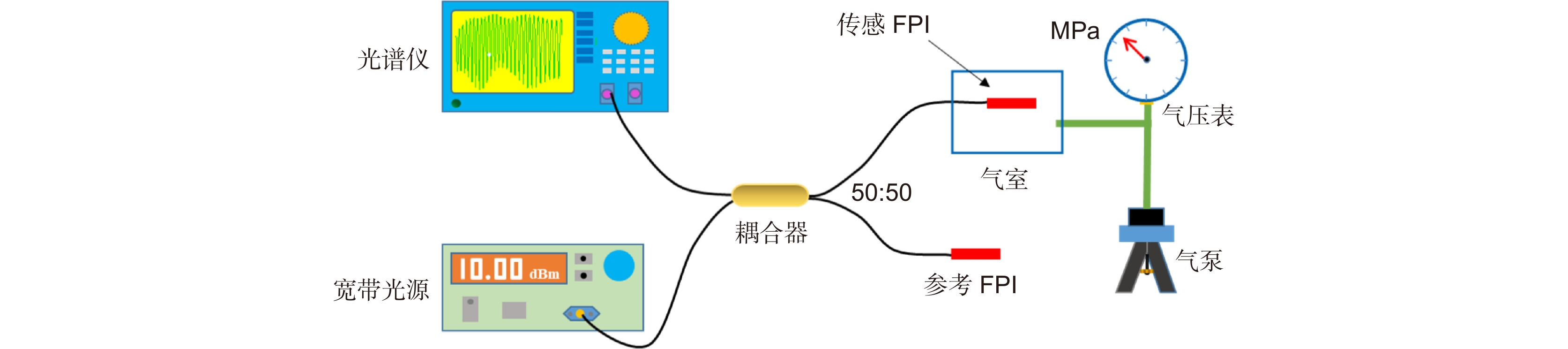

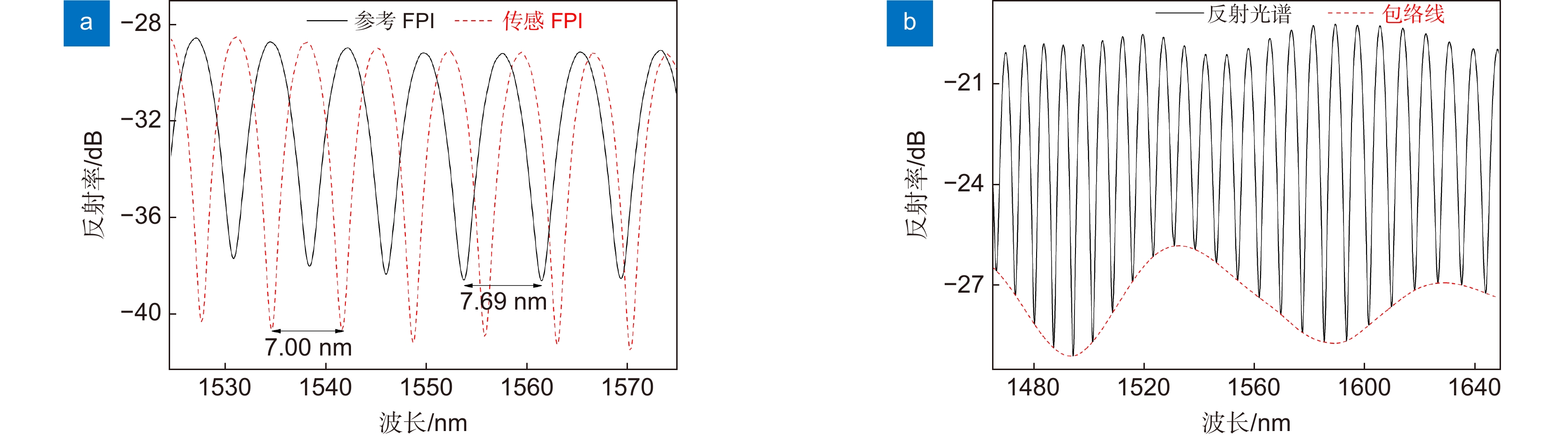

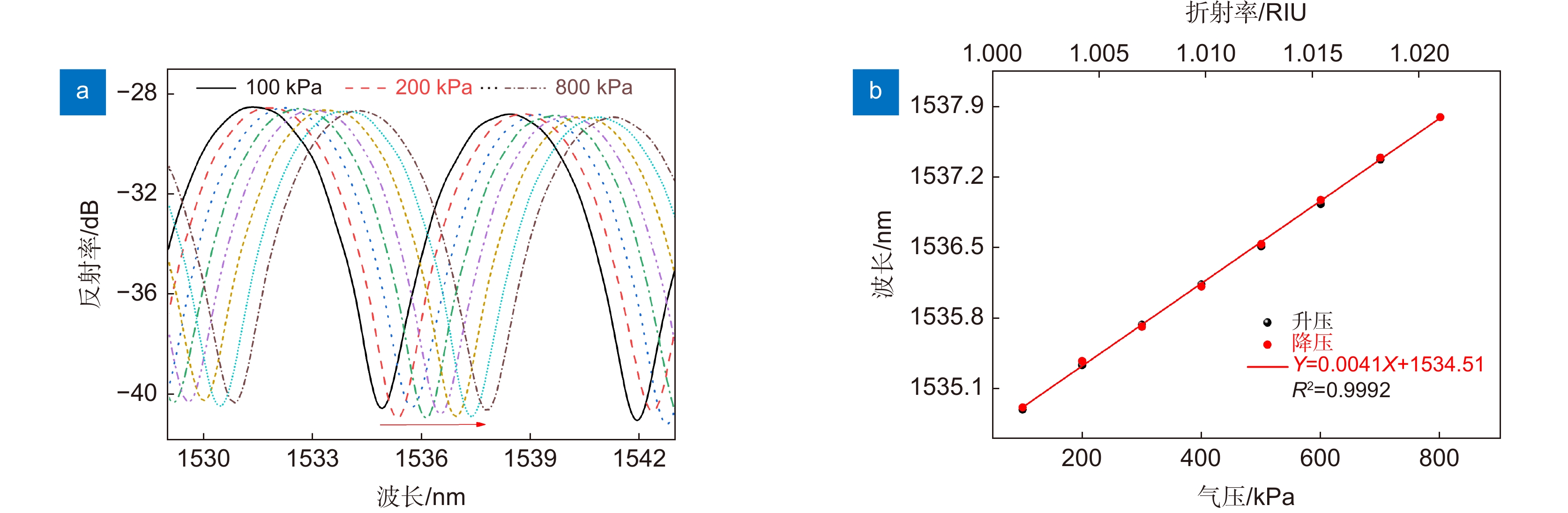

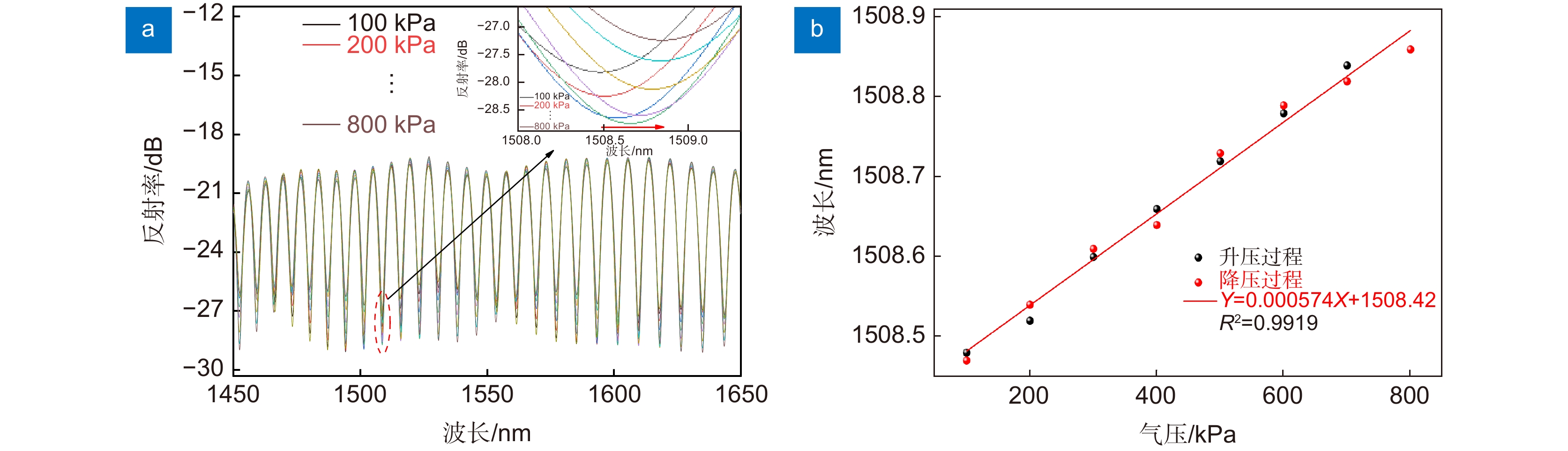

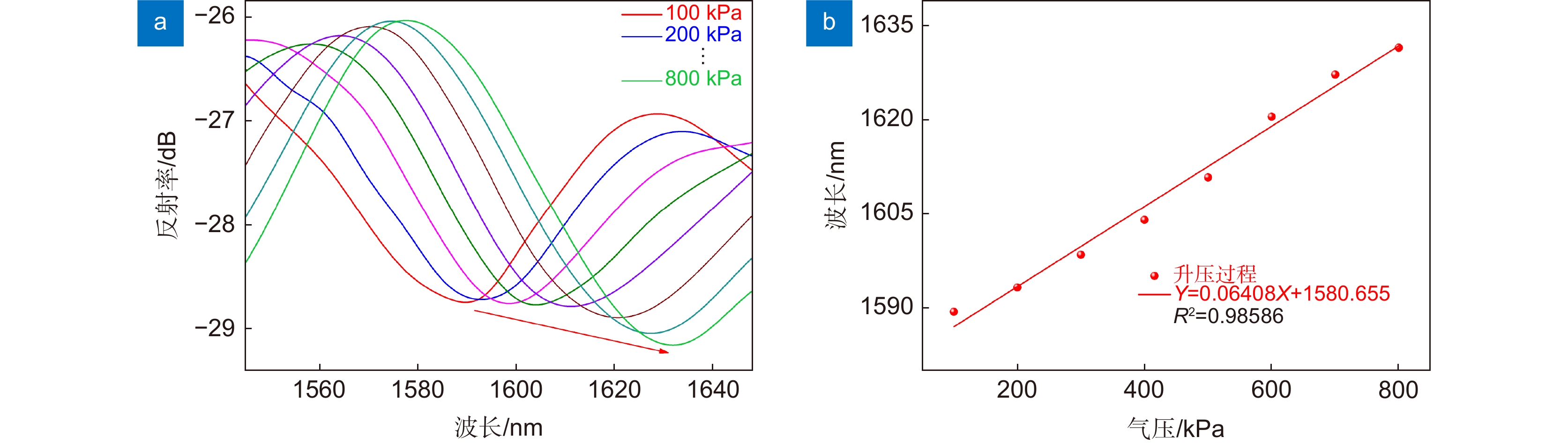

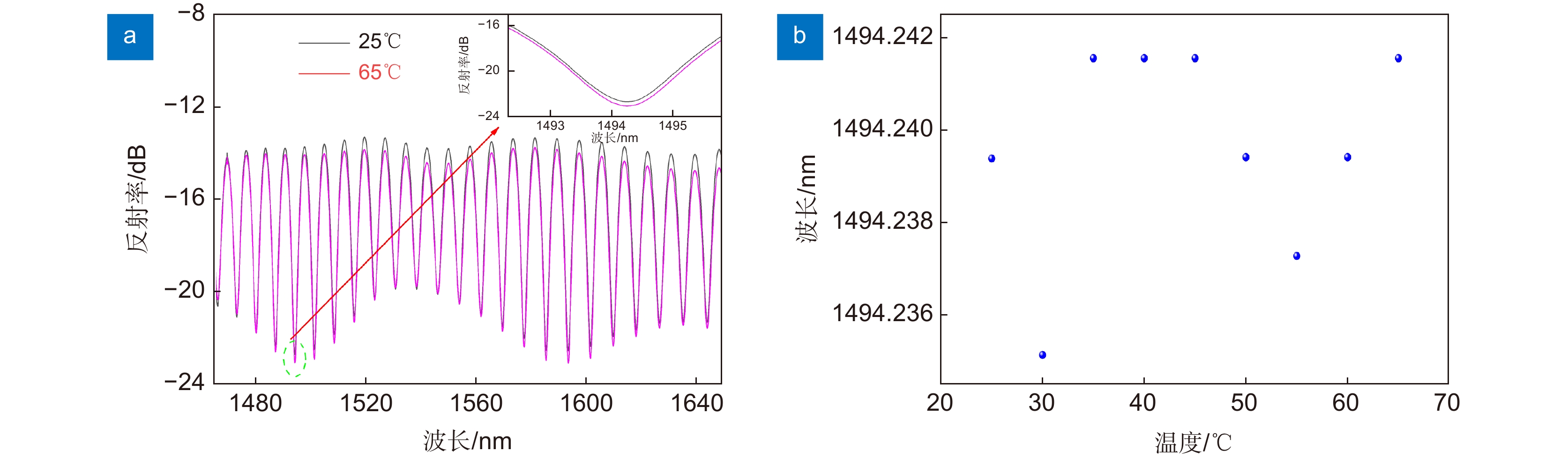

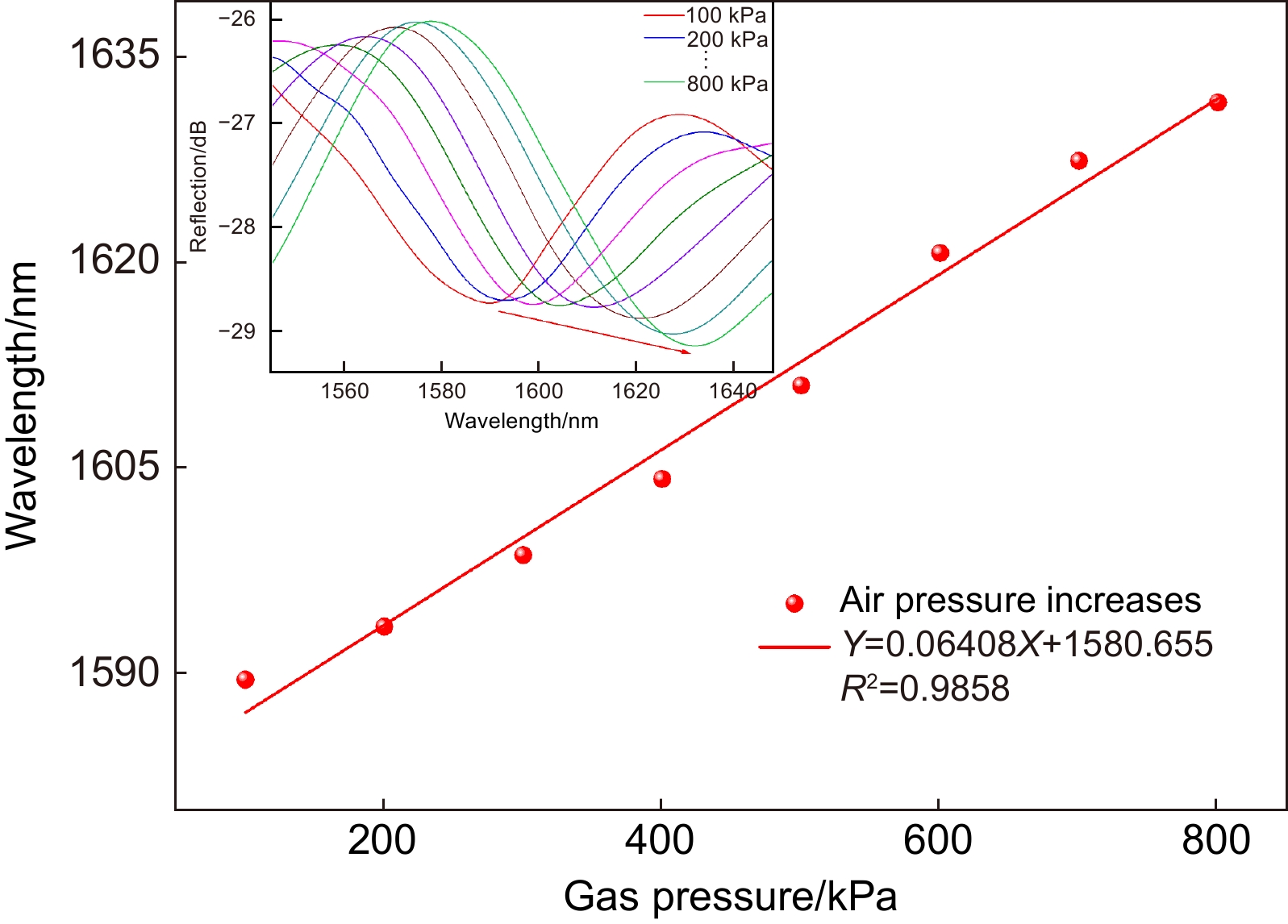

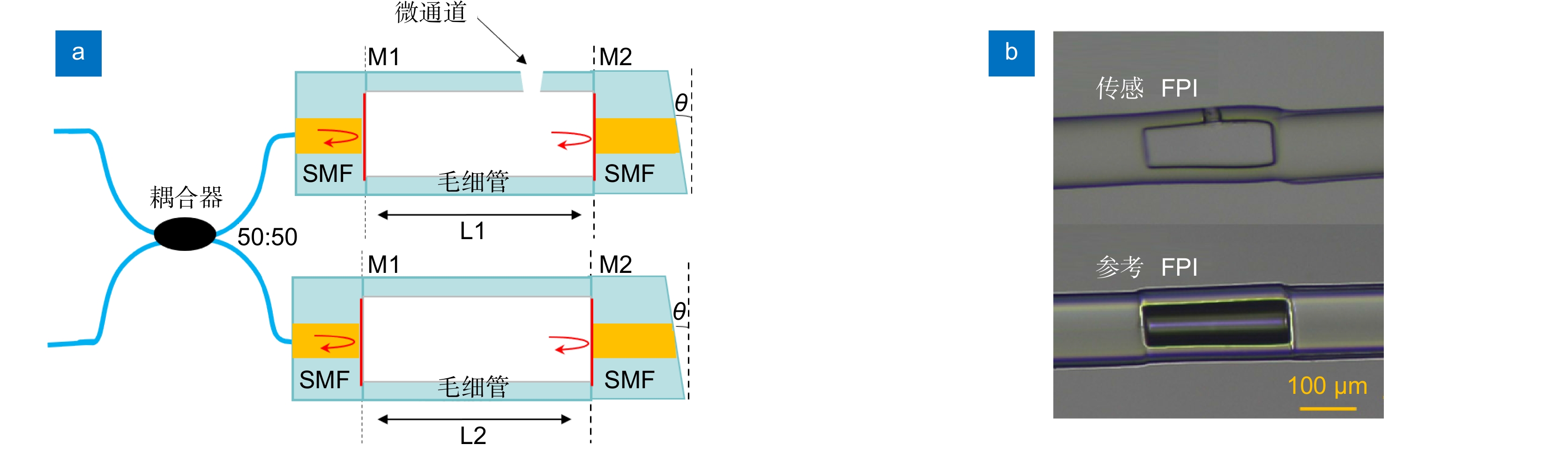

本文提出并制备了一个基于游标效应的高灵敏度光纤气压传感器。该传感器包含两个并联的法布里-珀罗干涉仪(FPI),它们均由单模光纤和一小截毛细管熔接构成,分别作为传感腔和参考腔,且其中传感腔的侧面刻蚀微通道,以便于待测气体进入。俩干涉仪间较小的光程差导致传感器产生具有游标效应的叠加反射光谱,气压灵敏度得到极大的提高,达到~64 pm/kPa,该值是单一FPI的~16倍。另外,实验结果显示,该传感器对温度不敏感,从而减少了环境温度对气压测量结果的影响。结构结实、气压灵敏度高等优点,预示着该传感器在工业生产、气体检测等领域具有广阔的应用前景。

Abstract:A highly sensitive optical fiber sensor based on the Vernier effect is demonstrated for gas pressure sensing. It consists of two paralleled Fabry-Perot interferometers (FPIs), which are both produced by splicing a single-mode fiber to a short segment of capillary tube, acting as sensing cavity and reference cavity, respectively. The lateral wall of the sensing FPI is drilled with a micro-channel allowing gas to flow in. Due to the small optical path difference between the two FPI, the Vernier effect is caused in the reflected spectrum of the sensor. Thus, the gas-pressure sensitivity is significantly enhanced, achieving up to ~64 pm/kPa which is ~16 times higher than that of a single FPI. Additionally, experimental results show that the sensor is insensitive to the surrounding temperature, which reduces the influence of ambient temperature on the measurement of gas pressure. The advantages of robust structure and high sensitivity of gas pressure indicate that the demonstrated sensor has a promising potential in industrial production, gas detection, and other fields.

-

Key words:

- optical fiber sensor /

- Fabry–Perot interferometer /

- vernier effect /

- gas pressure

-

Overview: Precise measurement of the gas pressure is important in a variety of fields, including environmental monitoring, energy management, and vehicle manufacturing. The measuring range is severely limited due to the electronic gas pressure sensor's susceptibility to temperature and electromagnetic interference. Optical fiber pressure sensors have demonstrated significant potential in practical applications due to their unique qualities of compact size, anti-electromagnetic interference, corrosion resistance, and robust resistance, attracting a lot of interest from researchers. Various fiber sensors based on fiber Bragg gratings (FBGs), long-period gratings (LPGs), and interferometers for gas pressure sensing have been presented in recent years. They all have distinct sensing benefits, among those, high sensitivity has always been one of the goals that researchers pursue.

Vernier effect is known for the first time because it was applied to Vernier calipers, consists of two independent scales with slightly different periods so that the overlap of both achieves the high measurement accuracy. Similarly, this effect can also be employed in the field of optical fiber sensing. Normally two interferometers with slightly different free spectral ranges are arranged in series (or cascaded structures), one as a sensor while the other as a stable reference. By tracking the response of the spectral envelope of the two interferometers, the sensitivity can be amplified by several orders of magnitude, realizing high-precision measurements. This sensitivity amplification mechanism has been successfully applied in temperature, pressure, refractive index, and curvature.

In this paper, a highly sensitive optical fiber sensor based on the Vernier effect is demonstrated for gas pressure sensing. It consists of two paralleled Fabry-Perot interferometers (FPIs), which are both produced by splicing a single-mode fiber to a short segment of capillary tube, acting as sensing cavity and reference cavity, respectively. The lateral wall of the sensing FPI is drilled with a micro-channel allowing gas to flow in. Due to the small optical path difference between the two FPI, the Vernier effect is caused in the reflected spectrum of the sensor. Thus, the gas-pressure sensitivity is significantly enhanced, achieving up to ~64 pm/kPa which is ~16 times higher than that of a single FPI. Additionally, experimental results show that the sensor is insensitive to the surrounding temperature, which reduces the influence of ambient temperature on the measurement of gas pressure. The advantages of robust structure and high sensitivity of gas pressure indicate that the demonstrated sensor has a promising potential in industrial production, gas detection, and other fields.

-

-

-

[1] Zhao Z Y, Tang M, Lu C. Distributed multicore fiber sensors[J]. Opto-Electron Adv, 2020, 3(2): 190024.

[2] 王欢, 郑刚, 陈海滨, 等. 调频连续波激光干涉光纤温度传感器[J]. 光电工程, 2019, 46(5): 180506. doi: 10.12086/oee.2019.180506

Wang H, Zheng G, Chen H B, et al. Frequency-modulated continuous-wave laser interferometric optical fiber temperature sensor[J]. Opto-Electron Eng, 2019, 46(5): 180506. doi: 10.12086/oee.2019.180506

[3] Ma L, Qi Y H, Kang Z X, et al. All-fiber strain and curvature sensor based on no-core fiber[J]. IEEE Sens J, 2014, 14(5): 1514−1517. doi: 10.1109/JSEN.2014.2298553

[4] Zhang L C, Jiang Y, Jia J S, et al. Fiber-optic micro vibration sensors fabricated by a femtosecond laser[J]. Opt Lasers Eng, 2018, 110: 207−210. doi: 10.1016/j.optlaseng.2018.06.003

[5] Liu X B, Liang L, Jiang L, et al. Sensitivity-enhanced fiber Bragg grating pressure sensor based on a diaphragm and hinge-lever structure[J]. IEEE Sens J, 2021, 21(7): 9155−9164. doi: 10.1109/JSEN.2020.3045992

[6] Ahmad H, Chong W Y, Thambiratnam K, et al. High sensitivity fiber Bragg grating pressure sensor using thin metal diaphragm[J]. IEEE Sens J, 2009, 9(12): 1654−1659. doi: 10.1109/JSEN.2009.2030388

[7] Tang J, Yin G L, Liu S, et al. Gas pressure sensor based on CO2-laser-induced Long-Period Fiber Grating in air-core photonic bandgap fiber[J]. IEEE Photonics J, 2015, 7(5): 6803107. doi: 10.1109/JPHOT.2015.2475636

[8] Fu D Y, Liu X J, Shang J Y, et al. A simple, highly sensitive fiber sensor for simultaneous measurement of pressure and temperature[J]. IEEE Photonics Technol Lett, 2020, 32(13): 747−750. doi: 10.1109/LPT.2020.2993836

[9] Cui Y, Jiang Y, Liu T M, et al. A dual-cavity Fabry-Perot interferometric fiber-optic sensor for the simultaneous measurement of high-temperature and high-gas-pressure[J]. IEEE Access, 2020, 8: 80582−80587. doi: 10.1109/ACCESS.2020.2991551

[10] Sun W, Zhang X B, Yu Y, et al. Comparative study on transmission Mechanisms in a SMF-Capillary-SMF structure[J]. J Lightwave Technol, 2020, 38(15): 4075−4085. doi: 10.1109/JLT.2020.2983910

[11] Wei X Y, Song X K, Li C, et al. Optical fiber gas pressure sensor based on polydimethylsiloxane microcavity[J]. J Lightwave Technol, 2021, 39(9): 2988−2993. doi: 10.1109/JLT.2021.3054883

[12] Liu S, Wang Y P, Liao C R, et al. Nano silica diaphragm in-fiber cavity for gas pressure measurement[J]. Sci Rep, 2017, 7(1): 787. doi: 10.1038/s41598-017-00931-0

[13] Ma J, Jin W, Ho H L, et al. High-sensitivity fiber-tip pressure sensor with graphene diaphragm[J]. Opt Lett, 2012, 37(13): 2493−2495. doi: 10.1364/OL.37.002493

[14] Wang Q H, Liu X, Wang D N. Ultra-sensitive gas pressure sensor based on Vernier effect with controllable amplification factor[J]. Opt Fiber Technol, 2021, 61: 102404. doi: 10.1016/j.yofte.2020.102404

[15] Yang X M, Li Y Q, Zhang S Y, et al. Comparison of fiber-based gas pressure sensors using hollow-core photonic crystal fibers[J]. IEEE Photonics J, 2021, 13(2): 6800209. doi: 10.1109/JPHOT.2021.3059925

[16] Xu B, Wang C, Wang D N, et al. Fiber-tip gas pressure sensor based on dual capillaries[J]. Opt Express, 2015, 23(18): 23484−23492. doi: 10.1364/OE.23.023484

[17] Xu B, Liu Y M, Wang D N, et al. Fiber Fabry-Pérot interferometer for measurement of gas pressure and temperature[J]. J Lightwave Technol, 2016, 34(21): 4920−4925. doi: 10.1109/JLT.2016.2598573

[18] Yang X M, Wu S, Cheng H H, et al. Simplified highly-sensitive gas pressure sensor based on harmonic Vernier effect[J]. Opt Laser Technol, 2021, 140: 107007. doi: 10.1016/j.optlastec.2021.107007

[19] Zhang Y N, Huang J, Lan X W, et al. Simultaneous measurement of temperature and pressure with cascaded extrinsic Fabry-Perot interferometer and intrinsic Fabry-Perot interferometer sensors[J]. Opt Eng, 2014, 53(6): 067101. doi: 10.1117/1.OE.53.6.067101

[20] Shi J, Wang Y Y, Xu D G, et al. Remote gas pressure sensor based on fiber ring laser embedded with Fabry-Pérot interferometer and Sagnac loop[J]. IEEE Photonics J, 2016, 8(5): 6804408. doi: 10.1109/JPHOT.2016.2605460

[21] Lin H F, Liu F F, Dai Y T, et al. Cascaded fiber Mach-Zehnder interferometers for sensitivity-enhanced gas pressure measurement[J]. IEEE Sens J, 2019, 19(7): 2581−2586. doi: 10.1109/JSEN.2018.2889063

[22] Zhao Y J, Lin H F, Zhou C M, et al. Cascaded Mach-Zehnder interferometers with Vernier effect for gas pressure sensing[J]. IEEE Photonics Technol Lett, 2019, 31(8): 591−594. doi: 10.1109/LPT.2019.2902383

[23] Vargas-Rodriguez E, Guzman-Chavez A D, Cano-Contreras M, et al. Analytical modelling of a refractive index sensor based on an intrinsic micro Fabry-Perot interferometer[J]. Sensors (Basel), 2015, 15(10): 26128−26142. doi: 10.3390/s151026128

[24] Zhang J, Liao H, Lu P, et al. Ultrasensitive temperature sensor with cascaded fiber optic Fabry–Perot interferometers based on Vernier effect[J]. IEEE Photonics J, 2018, 10(5): 6803411. doi: 10.1109/jphot.2018.2865449

[25] Birch K P, Downs M J. An updated Edlén equation for the refractive index of air[J]. Metrologia, 1993, 30(3): 155−162. doi: 10.1088/0026-1394/30/3/004

[26] Han Z, Xin G G, Nan P Y, et al. Hypersensitive high-temperature gas pressure sensor with Vernier effect by two parallel Fabry-Perot interferometers[J]. Optik, 2021, 241: 166956. doi: 10.1016/j.ijleo.2021.166956

[27] Wu Y, Wang S, Meng F Y, et al. Compact Mach-Zehnder interferometer based on processed hollow-core fiber for gas pressure sensing[J]. J Nanophotonics, 2019, 13(3): 036013. doi: 10.1117/1.JNP.13.036013

[28] 胡义慧, 江超, 孙四梅, 等. 毛细石英管构成的高灵敏度光纤气压传感器[J]. 光电子·激光, 2018, 29(1): 39−43. doi: 10.16136/j.joel.2018.01.0140

Hu Y H, Jiang C, Sun S M, et al. High sensitivity capillary structure optical fiber gas pressure sensor[J]. J Optoelectron·Laser, 2018, 29(1): 39−43. doi: 10.16136/j.joel.2018.01.0140

[29] 郭小珊, 王解, 叶文豪, 等. 飞秒激光制备的高灵敏度气压探针传感器[J]. 激光与红外, 2021, 51(11): 1498−1505. doi: 10.3969/j.issn.1001-5078.2021.11.016

Guo X S, Wang J, Ye W H, et al. High sensitivity gas-pressure probe sensor fabricated by femtosecond laser[J]. Laser Infrared, 2021, 51(11): 1498−1505. doi: 10.3969/j.issn.1001-5078.2021.11.016

[30] Huang J, Zhou Z D, Wen X Y, et al. A diaphragm-type fiber Bragg grating pressure sensor with temperature compensation[J]. Measurement, 2013, 46(3): 1041−1046. doi: 10.1016/j.measurement.2012.10.010

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: