Solution processed organic light-emitting devices: structure, device physics and fabrication process

-

摘要:

有机电致发光器件(OLED)在照明领域的产业化发展仍然受到高成本的制约,而湿法OLED可显著降低制造成本。但是,相比于热蒸镀OLED,湿法OLED在构建多层薄膜体系上面临更大的挑战。鉴于已有相关综述从材料工程角度对湿法OLED进行了总结,本文将主要从器件物理和制备工艺方面对湿法OLED进行概述。首先从器件载流子动力学和光物理角度分析各功能层的必要性。接着介绍常用的湿法薄膜制备工艺,并讨论制备多层湿法薄膜所涉及的问题。最后对湿法OLED的发展进行了展望。

-

关键词:

- 湿法有机电致发光器件 /

- 多层结构 /

- 湿法制备工艺 /

- 电流平衡性 /

- 金属-电介质界面表面等离子体共振吸收

Abstract:The industrialization of organic light-emitting devices (OLEDs) in the field of lighting still faces the challenge of high costs, while solution-processed OLEDs can dramatically reduce their manufacturing cost. However, compared with thermally evaporated OLEDs, solution-processed OLEDs encounter difficulty in building multilayer systems. As the relevant reviews on solution-processed OLED from the perspective of material engineering have been proposed, this paper will mainly summarize multilayer structures of solution-processed OLED from the aspects of device physics and preparation processes. First, we will analyze the necessity of each functional layer based on the carrier/exciton dynamics and optical physics. Next, we will introduce the commonly used solution-processing techniques and discuss the problems involved in the preparation of multilayer films. Finally, we will present the future prospects of solution-processed OLEDs.

-

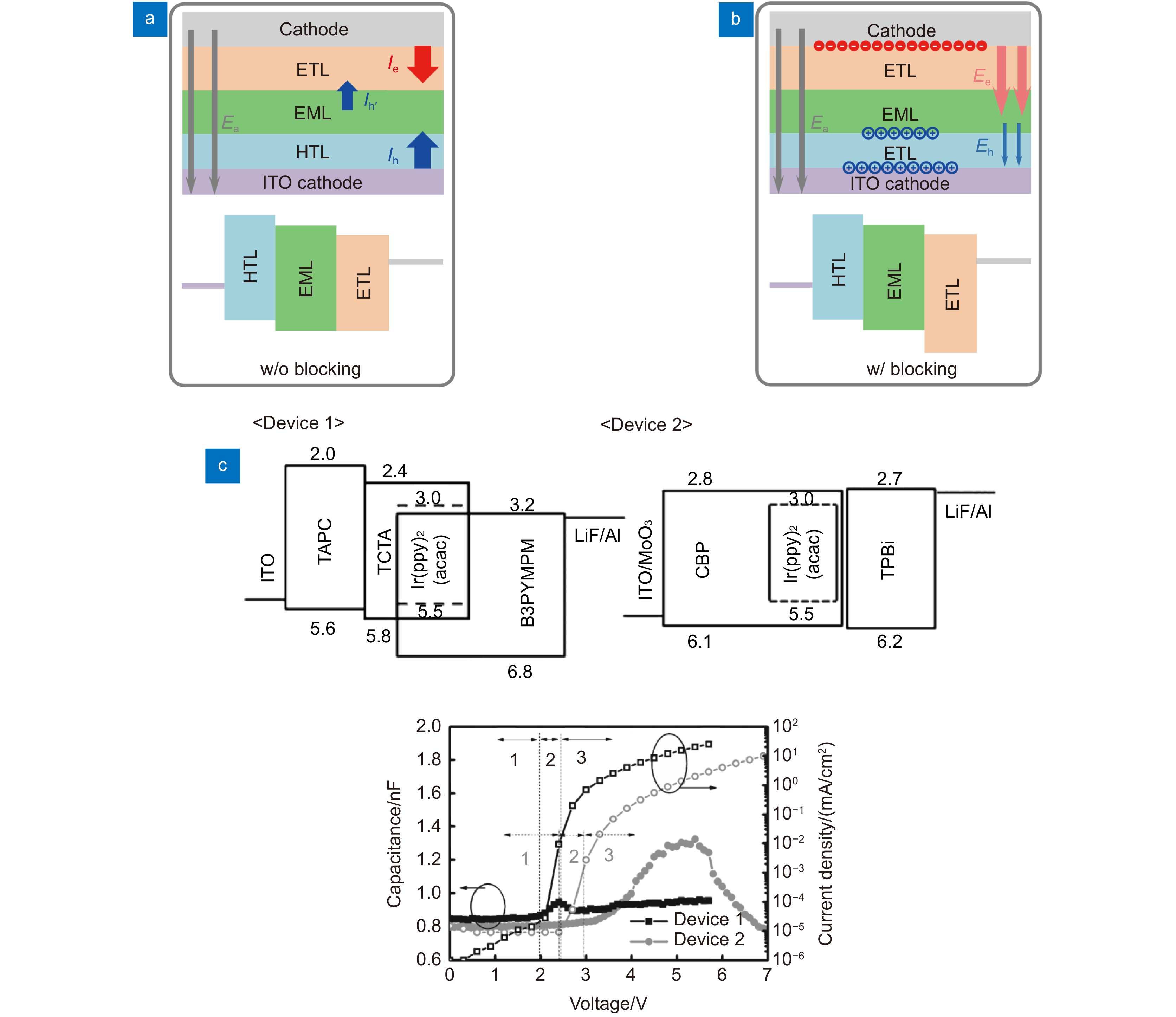

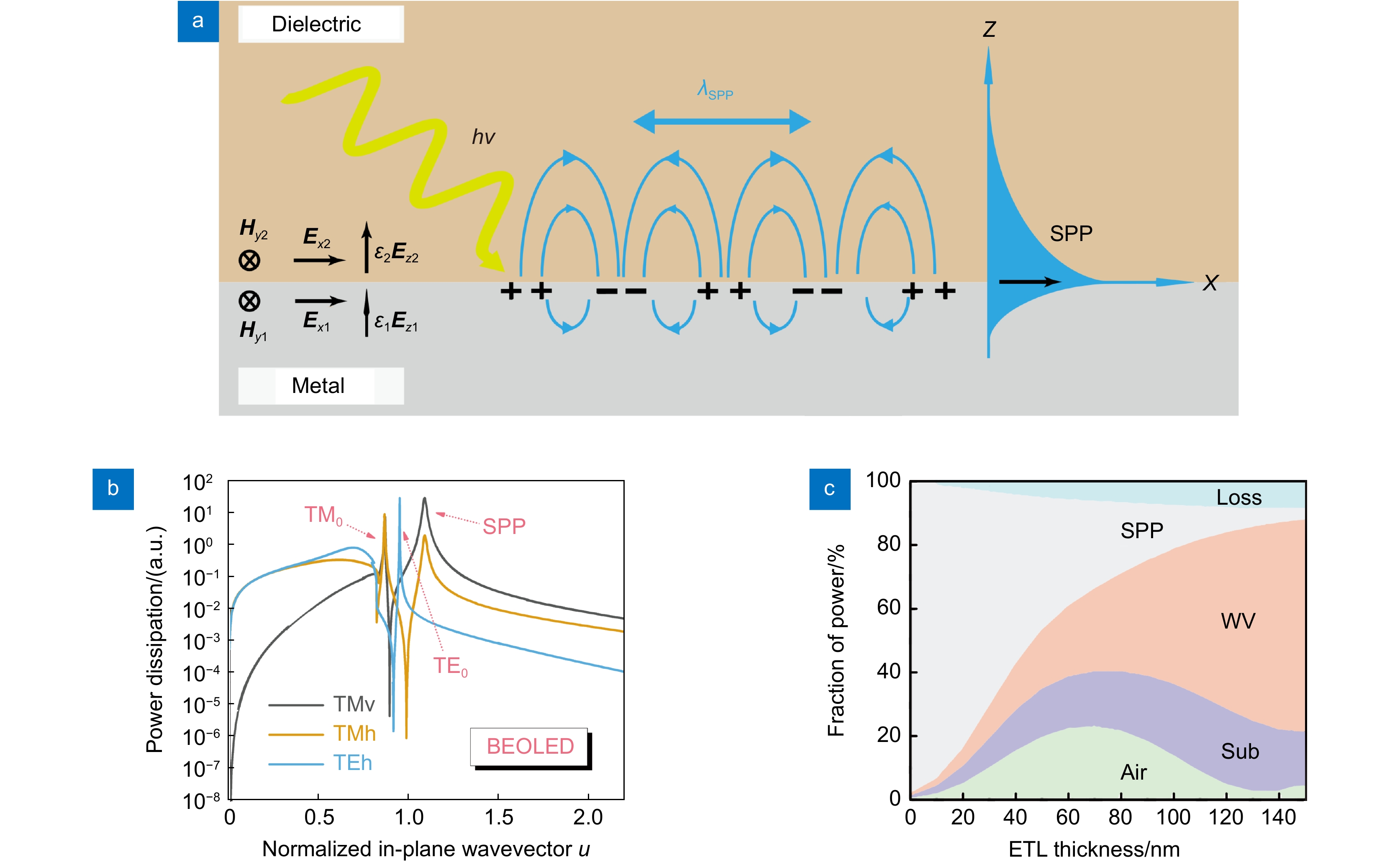

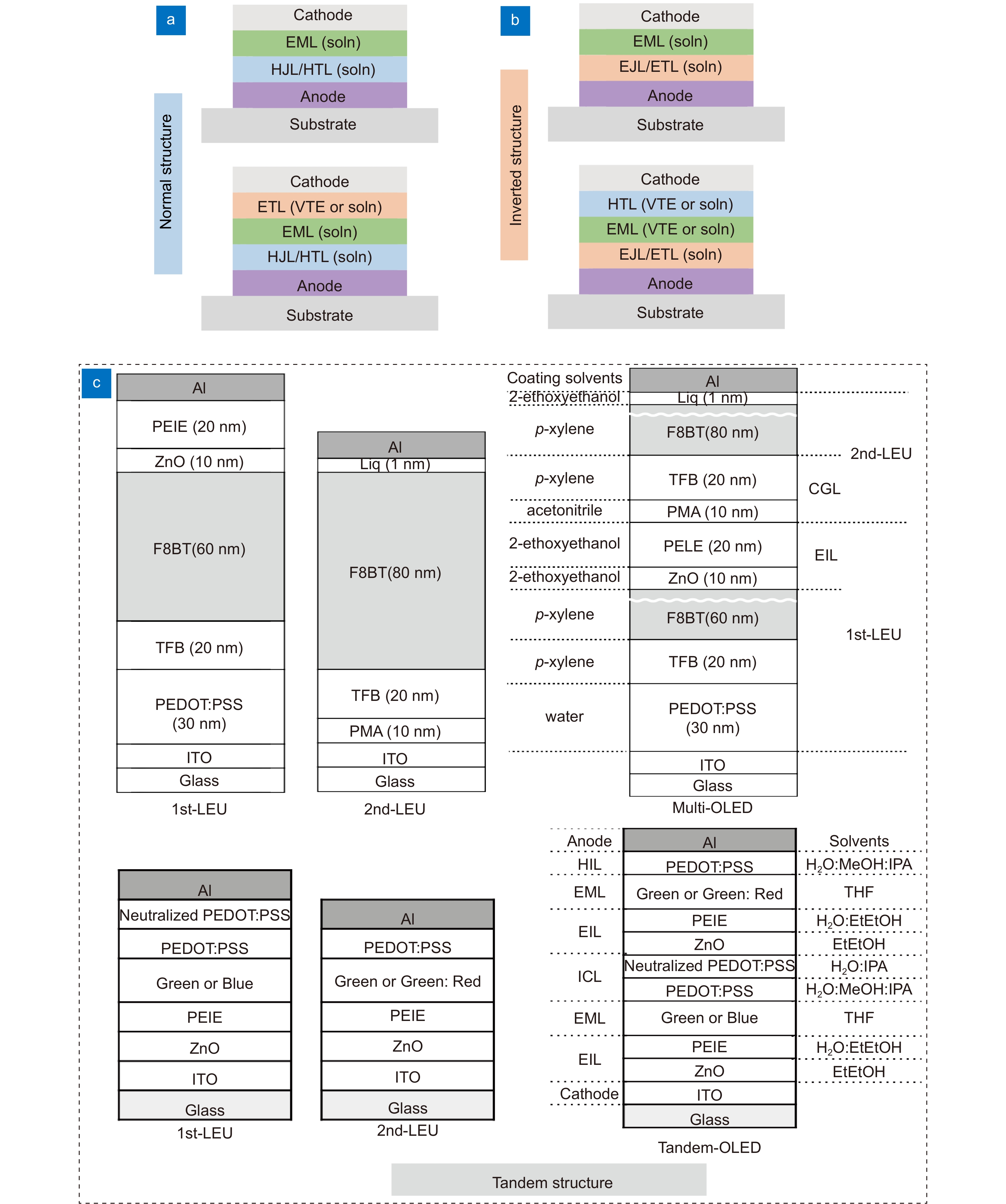

Overview: In this paper, we reviewed multilayer structures of the solution-processed organic light-emitting devices (OLEDs), including normal structure, inverted structure, and tandem structure. From a physical point of view, we discussed and summarized that those multilayer structures are important to improve current balance. The improved current balance can reduce internal accumulations of carriers or current leakages, both of which are detrimental to the device's efficiency and lifetime. We also discussed that multilayer structures are necessary to avoid coupling between dipole sources and surface plasmon polariton (SPP) at the metal-dielectric interface. Thus, we concluded that multilayer structures actually play a key role in achieving solution-processed OLEDs with high performances.

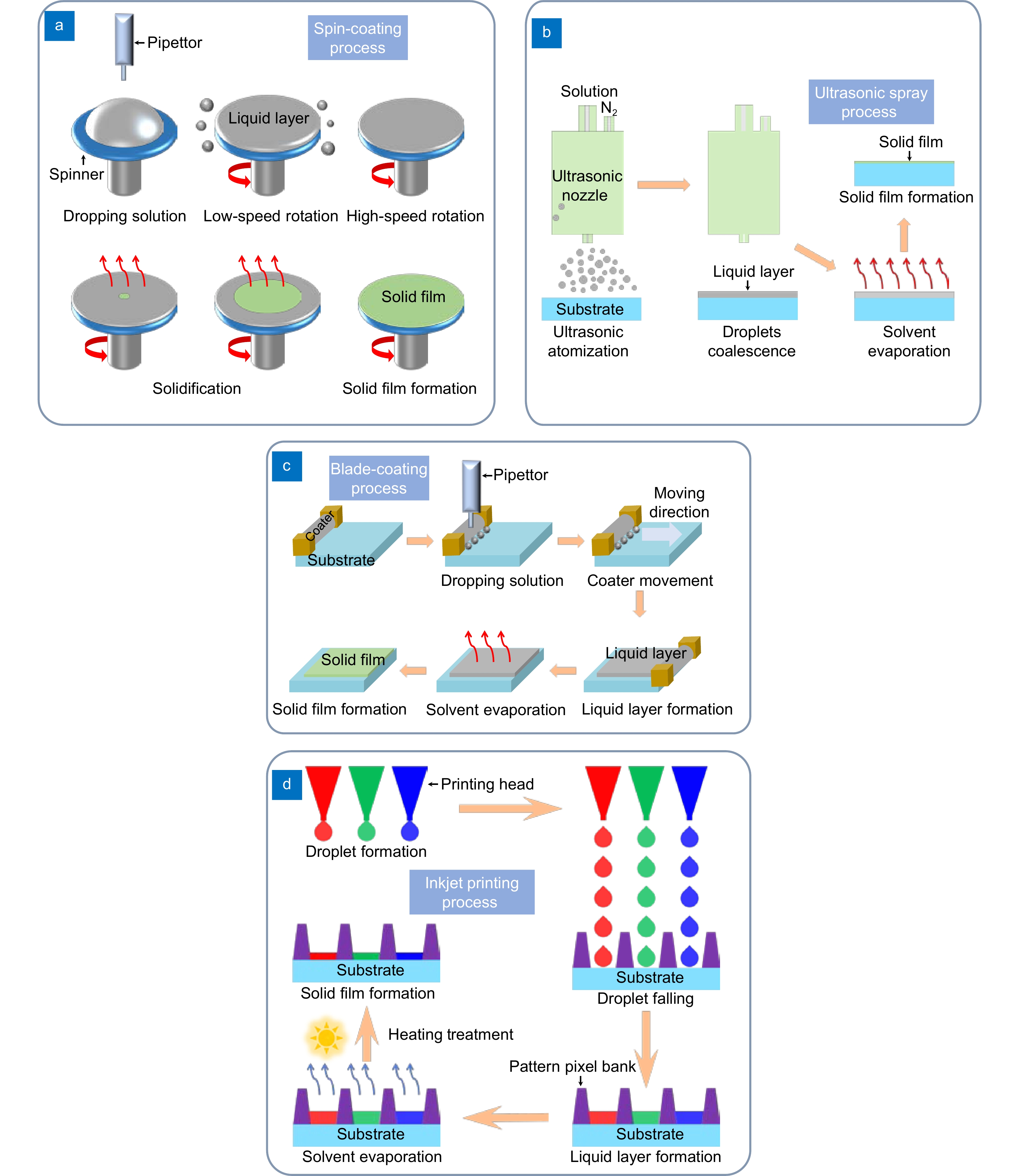

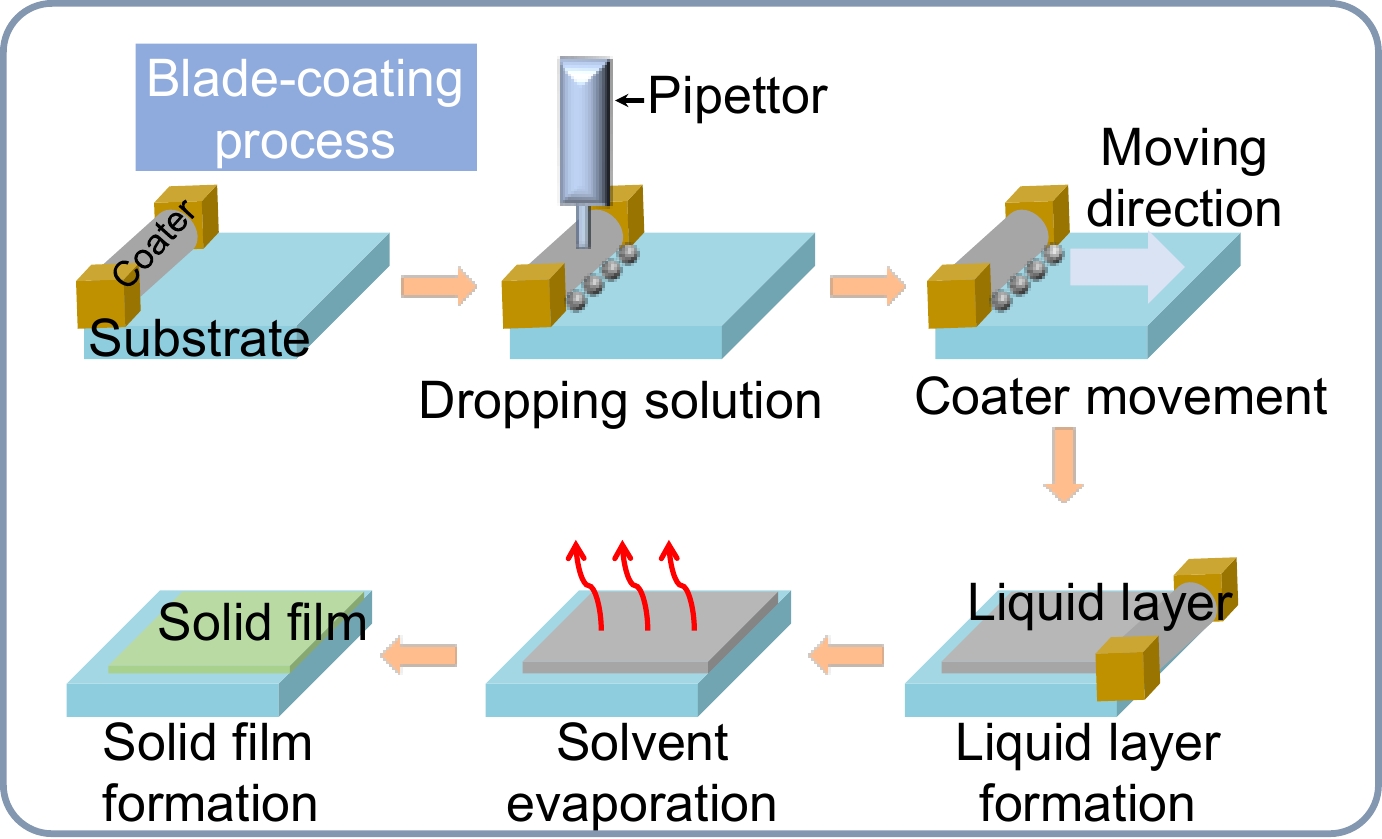

Next, we summarized four solution-processing technologies for OLEDs: spin coating process, spray coating process, blade coating process, and inkjet printing process, as well as their problems involved in preparing multilayer structures. Due to self-leveling under centrifugal force, spin-coated films have a huge advantage in film uniformity. With the aid of the orthogonal solvent system and cross-linked material strategy, the spin coating process can prepare multilayer structures. But the two strategies may cause the problems such as carrier trap and accumulation, which would degrade the device's performances. Besides, due to the capillary flow and Marangoni flow, spray coating process, blade coating process, and inkjet printing process require the add of a surfactant or dual solvent systems to prepare uniform films. In addition, the amount of liquid film and its drying rate can be precisely controlled by the blade coating process and inkjet printing process. As a result, solution-processed multilayer structures can be achieved by the two fabrication processes without using the orthogonal solvent system and crosslinking material strategy. But they are still limited by equipment precision and solvent characteristics.

In conclusion, multilayer structures are necessary to achieve high-performance for solution-processed OLEDs. It is demonstrated that the existing solution-processing technologies can prepare multilayer structures for OLEDs. However, due to similar polarities of organic molecules, the existing solution-processing technologies still have problems with the universality of multilayer structures. The advantage of the existing solution-processing technologies with low costs is that it does not rely on high vacuum, and their problems are mainly caused by the use of solvent. In the field of perovskite, Professor Han Liyuan's team developed a new solvent-free and non-vacuum deposition process for the preparation of methyl ammonium halide lead perovskite film, namely, soft pressure processing. This process can not only retain the low-cost advantages of the existing solution-processing technologies, but also avoid the problems caused by the introduction of solvents. Thus, this process could have great potential in the preparation of low-cost multi-layer OLEDs.

-

-

图 3 (a) 电介质-金属界面的表面等离子体激元示意图; (b) OLED中偶极子辐射的功率耗散谱, TMv、TMh及TEh分别对应于纵向偶极子的TM模,水平偶极子的TM模和TE模[14];(c) 不同ETL厚度OLED的光功率模态分析。Air、Sub、WV、SPP和Loss分别对应于空气模、衬底模、波导模、SPP模和金属吸收模[56]

Figure 3. (a) Schematic diagram of SPP at metal-dielectric surface; (b) Power dissipation spectra of dipole radiation. TMv, TMh and TEh respectively represent TM mode from vertical dipole, TM mode and TE mode from horizontal dipole[14]; (c) Optical power modal analysis vs ETL thickness of a conventional OLED. The power is distributed into air (Air), substrate (Sub), waveguide (WV), surface plasmon polariton (SPP) and lossy metal (Loss) modes [56]

-

[1] Pattison M, Hansen M, Bardsley N, et al. 2019 lighting R&D opportunities[R]. Santa Barbara: Solid State Lighting Solutions (SSLS) Inc. , 2020. doi: 10.2172/1618035.

[2] Tang C W, VanSlyke S A. Organic electroluminescent diodes[J]. Appl Phys Lett, 1987, 51(12): 913−915. doi: 10.1063/1.98799

[3] Liao L S, Klubek K P, Tang C W. High-efficiency tandem organic light-emitting diodes[J]. Appl Phys Lett, 2004, 84(2): 167−169. doi: 10.1063/1.1638624

[4] Uoyama H, Goushi K, Shizu K, et al. Highly efficient organic light-emitting diodes from delayed fluorescence[J]. Nature, 2012, 492(7428): 234−238. doi: 10.1038/nature11687

[5] Gather M C, Köhnen A, Meerholz K. White organic light-emitting diodes[J]. Adv Mater, 2011, 23(2): 233−248. doi: 10.1002/adma.201002636

[6] Wen X M, Bi Y G, Yi F S, et al. Tunable surface plasmon-polariton resonance in organic light-emitting devices based on corrugated alloy electrodes[J]. Opto-Electron Adv, 2021, 4(8): 200024. doi: 10.29026/oea.2021.200024

[7] Liu S H, Liu W B, Yu J, et al. Silver/germanium/silver: an effective transparent electrode for flexible organic light-emitting devices[J]. J Mater Chem C, 2014, 2(5): 835−840. doi: 10.1039/C3TC31927J

[8] Li Z T, Cao K, Li J S, et al. Review of blue perovskite light emitting diodes with optimization strategies for perovskite film and device structure[J]. Opto-Electron Adv, 2021, 4(2): 200019. doi: 10.29026/oea.2021.200019

[9] Wang Y, Liu S H, Dang F Y, et al. An efficient flexible white organic light-emitting device with a screen-printed conducting polymer anode[J]. J Phys D Appl Phys, 2012, 45(40): 402002. doi: 10.1088/0022-3727/45/40/402002

[10] Zhang X, Liu S H, Zhang L T, et al. In-planar-electrodes organic light-emitting devices for smart lighting applications[J]. Adv Opt Mater, 2019, 7(3): 1800857. doi: 10.1002/adom.201800857

[11] Liu S H, Zhang X, Wang S R, et al. Hybrid organic light-emitting device based on ultrasonic spray-coating molybdenum trioxide transport layer with low turn-on voltage, improved efficiency & stability[J]. Org Electron, 2018, 52: 264−271. doi: 10.1016/j.orgel.2017.10.041

[12] Liu S H, Zhang X, Feng H W, et al. Two-dimensional-growth small molecular hole-transporting layer by ultrasonic spray coating for organic light-emitting devices[J]. Org Electron, 2017, 47: 181−188. doi: 10.1016/j.orgel.2017.05.024

[13] Liu W B, Liu S H, Zhang W, et al. Angle-stable inverted top-emitting white organic light-emitting devices based on gradient-doping electron injection interlayer[J]. Org Electron, 2015, 25: 335−339. doi: 10.1016/j.orgel.2015.07.012

[14] Zang C X, Liu S H, Xu M X, et al. Top-emitting thermally activated delayed fluorescence organic light-emitting devices with weak light-matter coupling[J]. Light Sci Appl, 2021, 10(1): 116. doi: 10.1038/s41377-021-00559-w

[15] Zhang X, Pan T, Zhang J X, et al. Color-tunable, spectra-stable flexible white top-emitting organic light-emitting devices based on alternating current driven and dual-microcavity technology[J]. ACS Photonics, 2019, 6(9): 2350−2357. doi: 10.1021/acsphotonics.9b00900

[16] Yin M J, Pan T, Yu Z W, et al. Color-stable WRGB emission from blue OLEDs with quantum dots-based patterned down-conversion layer[J]. Org Electron, 2018, 62: 407−411. doi: 10.1016/j.orgel.2018.08.036

[17] Liu S H, Wen X M, Liu W B, et al. Angle-stable top-emitting white organic light-emitting devices employing a down-conversion layer[J]. Curr Appl Phys, 2014, 14(11): 1451−1454. doi: 10.1016/j.cap.2014.08.003

[18] Yu Z W, Feng H W, Zhang J X, et al. Carrier transport manipulation for efficiency enhancement in blue phosphorescent organic light-emitting devices with a 4, 4′-bis (N-carbazolyl)-2, 2′-biphenyl host[J]. J Mater Chem C, 2019, 7(30): 9301−9307. doi: 10.1039/C8TC06265J

[19] Zhang X, Liu S H, Zhang Y Q, et al. Efficiently alternating current driven tandem organic light-emitting devices with (Ag/4, 7-diphenyl-1, 10-phenanthroline)n interconnecting layers[J]. Appl Phys Lett, 2017, 111(10): 103301. doi: 10.1063/1.5001842

[20] Zang C X, Xu M X, Zhang L T, et al. Organic-inorganic hybrid thin film light-emitting devices: interfacial engineering and device physics[J]. J Mater Chem C, 2021, 9(5): 1484−1519. doi: 10.1039/D0TC05059H

[21] Peng J H, Xu X J, Feng X J, et al. Fabrication of solution-processed pure blue fluorescent OLED using exciplex host[J]. J Lumin, 2018, 198: 19−23. doi: 10.1016/j.jlumin.2018.02.010

[22] He Z Y, Wang C Y, Zhao J W, et al. Blue and white solution-processed TADF-OLEDs with over 20% EQE, low driving voltages and moderate efficiency decrease based on interfacial exciplex hosts[J]. J Mater Chem C, 2019, 7(38): 11806−11812. doi: 10.1039/C9TC03468D

[23] Park S Y, Choi S, Park G E, et al. Unconventional three-armed luminogens exhibiting both aggregation-induced emission and thermally activated delayed fluorescence resulting in high-performing solution-processed organic light-emitting diodes[J]. ACS Appl Mater Interfaces, 2018, 10(17): 14966−14977. doi: 10.1021/acsami.7b19681

[24] Tang C, Yang T, Cao X D, et al. Tuning a weak emissive blue host to highly efficient green dopant by a CN in tetracarbazolepyridines for solution-processed thermally activated delayed fluorescence devices[J]. Adv Opt Mater, 2015, 3(6): 786−790. doi: 10.1002/adom.201500016

[25] Kim Y H, Wolf C, Cho H, et al. Highly efficient, simplified, solution-processed thermally activated delayed-fluorescence organic light-emitting diodes[J]. Adv Mater, 2016, 28(4): 734−741. doi: 10.1002/adma.201504490

[26] Li B, Yang Z, Gong W Q, et al. Intramolecular through-space charge transfer based TADF-active multifunctional emitters for high efficiency solution-processed OLED[J]. Adv Opt Mater, 2021, 9(15): 2100180. doi: 10.1002/adom.202100180

[27] Sun K Y, Liu D, Tian W W, et al. Manipulation of the sterically hindering effect to realize AIE and TADF for high-performing nondoped solution-processed OLEDs with extremely low efficiency roll-off[J]. J Mater Chem C, 2020, 8(34): 11850−11859. doi: 10.1039/D0TC02577A

[28] Usta H, Alimli D, Ozdemir R, et al. A hybridized local and charge transfer excited state for solution-processed non-doped green electroluminescence based on oligo (p-phenyleneethynylene)[J]. J Mater Chem C, 2020, 8(24): 8047−8060. doi: 10.1039/D0TC01266A

[29] Aizawa N, Pu Y J, Watanabe M, et al. Solution-processed multilayer small-molecule light-emitting devices with high-efficiency white-light emission[J]. Nat Commun, 2014, 5(1): 5756. doi: 10.1038/ncomms6756

[30] Pu Y J, Chiba T, Ideta K, et al. Fabrication of organic light-emitting devices comprising stacked light-emitting units by solution-based processes[J]. Adv Mater, 2015, 27(8): 1327−1332. doi: 10.1002/adma.201403973

[31] Chiba T, Pu Y J, Kido J. Solution-processed white phosphorescent tandem organic light-emitting devices[J]. Adv Mater, 2015, 27(32): 4681−4687. doi: 10.1002/adma.201501866

[32] Ho S, Liu S Y, Chen Y, et al. Review of recent progress in multilayer solution-processed organic light-emitting diodes[J]. J Photonics Energy, 2015, 5(1): 057611. doi: 10.1117/1.JPE.5.057611

[33] Zhong C M, Duan C H, Huang F, et al. Materials and devices toward fully solution processable organic light-emitting diodes[J]. Chem Mater, 2011, 23(3): 326−340. doi: 10.1021/cm101937p

[34] Li Y, Zhang D Q, Duan L, et al. Elucidation of the electron injection mechanism of evaporated cesium carbonate cathode interlayer for organic light-emitting diodes[J]. Appl Phys Lett, 2007, 90(1): 012119. doi: 10.1063/1.2429920

[35] Liu W B, Liu S H, Yu J, et al. Efficient inverted organic light-emitting devices with self or intentionally Ag-doped interlayer modified cathode[J]. Appl Phys Lett, 2014, 104(9): 093305. doi: 10.1063/1.4868031

[36] Tokito S, Suzuki M, Sato F, et al. High-efficiency phosphorescent polymer light-emitting devices[J]. Org Electron, 2003, 4(2-3): 105−111. doi: 10.1016/j.orgel.2003.08.005

[37] Burns S, MacLeod J, Do T T, et al. Effect of thermal annealing Super Yellow emissive layer on efficiency of OLEDs[J]. Sci Rep, 2017, 7(1): 40805. doi: 10.1038/srep40805

[38] Al-Attar H A, Griffiths G C, Moore T N, et al. Highly efficient, solution-processed, single-layer, electrophosphorescent diodes and the effect of molecular dipole moment[J]. Adv Funct Mater, 2011, 21(12): 2376−2382. doi: 10.1002/adfm.201100324

[39] Cai M, Xiao T, Hellerich E, et al. High-efficiency solution-processed small molecule electrophosphorescent organic light-emitting diodes[J]. Adv Mater, 2011, 23(31): 3590−3596. doi: 10.1002/adma.201101154

[40] Hwang J, Lee C, Jeong J E, et al. Rational design of carbazole-and carboline-based polymeric host materials for realizing high-efficiency solution-processed thermally activated delayed fluorescence organic light-emitting diode[J]. ACS Appl Mater Interfaces, 2020, 12(7): 8485−8494. doi: 10.1021/acsami.9b20279

[41] Fukagawa H, Sasaki T, Tsuzuki T, et al. Long-lived flexible displays employing efficient and stable inverted organic light-emitting diodes[J]. Adv Mater, 2018, 30(28): 1706768. doi: 10.1002/adma.201706768

[42] Kwon S J, Han T H, Kim Y H, et al. Solution-processed n-type graphene doping for cathode in inverted polymer light-emitting diodes[J]. ACS Appl Mater Interfaces, 2018, 10(5): 4874−4881. doi: 10.1021/acsami.7b15307

[43] Chen J S, Shi C S, Fu Q, et al. Solution-processable small molecules as efficient universal bipolar host for blue, green and red phosphorescent inverted OLEDs[J]. J Mater Chem, 2012, 22(11): 5164−5170. doi: 10.1039/C2JM16463A

[44] Zhang J X, Zhang X, Feng H W, et al. An efficient and stable hybrid organic light-emitting device based on an inorganic metal oxide hole transport layer and an electron transport layer[J]. J Mater Chem C, 2019, 7(7): 1991−1998. doi: 10.1039/C8TC06135A

[45] Zang C X, Wang H, Liu S H, et al. Efficiency enhancement in an inverted organic light-emitting device with a TiO2 electron injection layer through interfacial engineering[J]. J Mater Chem C, 2020, 8(24): 8206−8212. doi: 10.1039/D0TC01040E

[46] Ohisa S, Takahashi T, Igarashi M, et al. An indolocarbazole-based thermally activated delayed fluorescence host for solution-processed phosphorescent tandem organic light-emitting devices exhibiting extremely small efficiency roll-off[J]. Adv Funct Mater, 2019, 29(16): 1808022. doi: 10.1002/adfm.201808022

[47] Höfle S, Bernhard C, Bruns M, et al. Charge generation layers for solution processed tandem organic light emitting diodes with regular device architecture[J]. ACS Appl Mater Interfaces, 2015, 7(15): 8132−8137. doi: 10.1021/acsami.5b00883

[48] Khramtchenkov D V, Bässler H, Arkhipov V I. A model of electroluminescence in organic double-layer light-emitting diodes[J]. J Appl Phys, 1996, 79(12): 9283−9290. doi: 10.1063/1.362604

[49] Nikitenko V R, Arkhipov V I, Tak Y H, et al. The overshoot effect in transient electroluminescence from organic bilayer light emitting diodes: Experiment and theory[J]. J Appl Phys, 1997, 81(11): 7514−7525. doi: 10.1063/1.365293

[50] Hassine L, Bouchriha H, Roussel J, et al. Transient response of a bilayer organic electroluminescent diode: experimental and theoretical study of electroluminescence onset[J]. Appl Phys Lett, 2001, 78(8): 1053−1055. doi: 10.1063/1.1350419

[51] Hassine L, Bouchriha H, Roussel J, et al. Transient response of a bilayer organic light emitting diode: Building-up of external and recombination currents[J]. J Appl Phys, 2002, 91(8): 5170−5175. doi: 10.1063/1.1464212

[52] Lee J H, Lee S, Yoo S J, et al. Langevin and trap-assisted recombination in phosphorescent organic light emitting diodes[J]. Adv Funct Mater, 2014, 24(29): 4681−4688. doi: 10.1002/adfm.201303453

[53] Wang B Q, Kou Z Q, Tang Y, et al. High CRI and stable spectra white organic light-emitting diodes with double doped blue emission layers and multiple ultrathin phosphorescent emission layers by adjusting the thickness of spacer layer[J]. Org Electron, 2019, 70: 149−154. doi: 10.1016/j.orgel.2019.04.013

[54] Park Y S, Lee S, Kim K H, et al. Exciplex-forming co-host for organic light-emitting diodes with ultimate efficiency[J]. Adv Funct Mater, 2013, 23(39): 4914−4920. doi: 10.1002/adfm.201300547

[55] Xu H W, Lin J Y, Jiang X X, et al. Study on the difference in exciton generation processes for a single host and exciplex-type co-host[J]. Opt Lett, 2021, 46(19): 4840−4843. doi: 10.1364/OL.439516

[56] Qu Y, Kim J, Coburn C, et al. Efficient, nonintrusive outcoupling in organic light emitting devices using embedded microlens arrays[J]. ACS Photonics, 2018, 5(6): 2453−2458. doi: 10.1021/acsphotonics.8b00255

[57] Sahu N, Parija B, Panigrahi S. Fundamental understanding and modeling of spin coating process: a review[J]. Indian J Phys, 2009, 83(4): 493−502. doi: 10.1007/s12648-009-0009-z

[58] Liu S H, Wang Y C, Chang C M, et al. Solution-processed organometallic quasi-two-dimensional nanosheets as a hole buffer layer for organic light-emitting devices[J]. Nanoscale, 2020, 12(13): 6983−6990. doi: 10.1039/D0NR00240B

[59] Guan Z Q, Li Y, Zhu Z H, et al. Efficient perovskite white light-emitting diode based on an interfacial charge-confinement structure[J]. ACS Appl Mater Interfaces, 2021, 13(37): 44991−45000. doi: 10.1021/acsami.1c09715

[60] Feng H W, Liu S H, Tang G, et al. Highly efficient and stable quantum dot light-emitting devices with a low-temperature tin oxide electron transport layer[J]. J Mater Chem C, 2021, 9(39): 13748−13754. doi: 10.1039/D1TC03073F

[61] Bangsund J S, Van Sambeek J R, Concannon N M, et al. Sub-turn-on exciton quenching due to molecular orientation and polarization in organic light-emitting devices[J]. Sci Adv, 2020, 6(32): eabb2659. doi: 10.1126/sciadv.abb2659

[62] Liu S H, Yu H W, Zhang Q Y, et al. Efficient ITO-free organic light-emitting devices with dual-functional PSS-rich PEDOT: PSS electrode by enhancing carrier balance[J]. J Mater Chem C, 2019, 7(18): 5426−5432. doi: 10.1039/C9TC00648F

[63] Girotto C, Moia D, Rand B P, et al. High-performance organic solar cells with spray-coated hole-transport and active layers[J]. Adv Funct Mater, 2011, 21(1): 64−72. doi: 10.1002/adfm.201001562

[64] Liu S H, Zhang X, Zhang L T, et al. Ultrasonic spray coating polymer and small molecular organic film for organic light-emitting devices[J]. Sci Rep, 2016, 6(1): 37042. doi: 10.1038/srep37042

[65] Liu S H, Zhang X, Yin M J, et al. Coffee-ring-free ultrasonic spray coating single-emission layers for white organic light-emitting devices and their energy-transfer mechanism[J]. ACS Appl Energy Mater, 2018, 1(1): 103−112. doi: 10.1021/acsaem.7b00011

[66] Yeh H C, Meng H F, Lin H W, et al. All-small-molecule efficient white organic light-emitting diodes by multi-layer blade coating[J]. Org Electron, 2012, 13(5): 914−918. doi: 10.1016/j.orgel.2012.02.001

[67] Deng Y H, Zheng X P, Bai Y, et al. Surfactant-controlled ink drying enables high-speed deposition of perovskite films for efficient photovoltaic modules[J]. Nat Energy, 2018, 3(7): 560−566. doi: 10.1038/s41560-018-0153-9

[68] Yu H W, Zhang J M, Long T, et al. Efficient all-blade-coated quantum dot light-emitting diodes through solvent engineering[J]. J Phys Chem Lett, 2020, 11(21): 9019−9025. doi: 10.1021/acs.jpclett.0c02419

[69] Han D, Khan Y, Ting J, et al. Flexible blade-coated multicolor polymer light-emitting diodes for optoelectronic sensors[J]. Adv Mater, 2017, 29(22): 1606206. doi: 10.1002/adma.201606206

[70] Amruth C, Szymański M Z, Łuszczyńska B, et al. Inkjet printing of super yellow: ink formulation, film optimization, OLEDs fabrication, and transient electroluminescence[J]. Sci Rep, 2019, 9(1): 8493. doi: 10.1038/s41598-019-44824-w

[71] Kang Y J, Bail R, Lee C W, et al. Inkjet printing of mixed-host emitting layer for electrophosphorescent organic light-emitting diodes[J]. ACS Appl Mater Interfaces, 2019, 11(24): 21784−21794. doi: 10.1021/acsami.9b04675

[72] Du Z Z, Liu Y K, Xing X, et al. Inkjet printing multilayer OLEDs with high efficiency based on the blurred interface[J]. J Phys D Appl Phys, 2020, 53(35): 355105. doi: 10.1088/1361-6463/ab86e1

[73] Yang P H, Zhang L, Kang D J, et al. High-resolution inkjet printing of quantum dot light-emitting microdiode arrays[J]. Adv Opt Mater, 2020, 8(1): 1901429. doi: 10.1002/adom.201901429

[74] Chen Z X, Li F S, Zeng Q Y, et al. Inkjet-printed pixelated light-emitting electrochemical cells based on cationic Ir(III) complexes[J]. Org Electron, 2019, 69: 336−342. doi: 10.1016/j.orgel.2019.03.046

[75] Yin Y M, Hu Z P, Ali M U, et al. Full-color micro-LED display with CsPbBr3 perovskite and CdSe quantum dots as color conversion layers[J]. Adv Mater Technol, 2020, 5(8): 2000251. doi: 10.1002/admt.202000251

[76] Chen H, Ye F, Tang W T, et al. A solvent-and vacuum-free route to large-area perovskite films for efficient solar modules[J]. Nature, 2017, 550(7674): 92−95. doi: 10.1038/nature23877

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: