The preparation and applications of bio-inspired slippery surface by femtosecond laser micro-nano manufacturing

-

摘要

仿猪笼草的超滑表面由于可以抵抗多种液体的粘附,具有优异的稳定性与自修复性,受到越来越广泛的关注。而飞秒激光由于其对加工材料的普适性、高精度,以及高可控性,成为仿生超滑表面制备的有力手段。本文以仿猪笼草的超滑表面为背景,以飞秒激光微加工技术为手段。从超滑表面的飞秒激光微纳制备和应用两个方面,概述了超滑表面的微纳制造和应用。针对不同材料,通过对飞秒激光进行调控,实现了在聚合物、硬脆透明材料,以及金属上的超滑表面制备。制备的超滑表面可应用于液滴、气泡操控、生物抗凝、防污和防腐等领域。最后总结超滑表面所面临的挑战。

Abstract

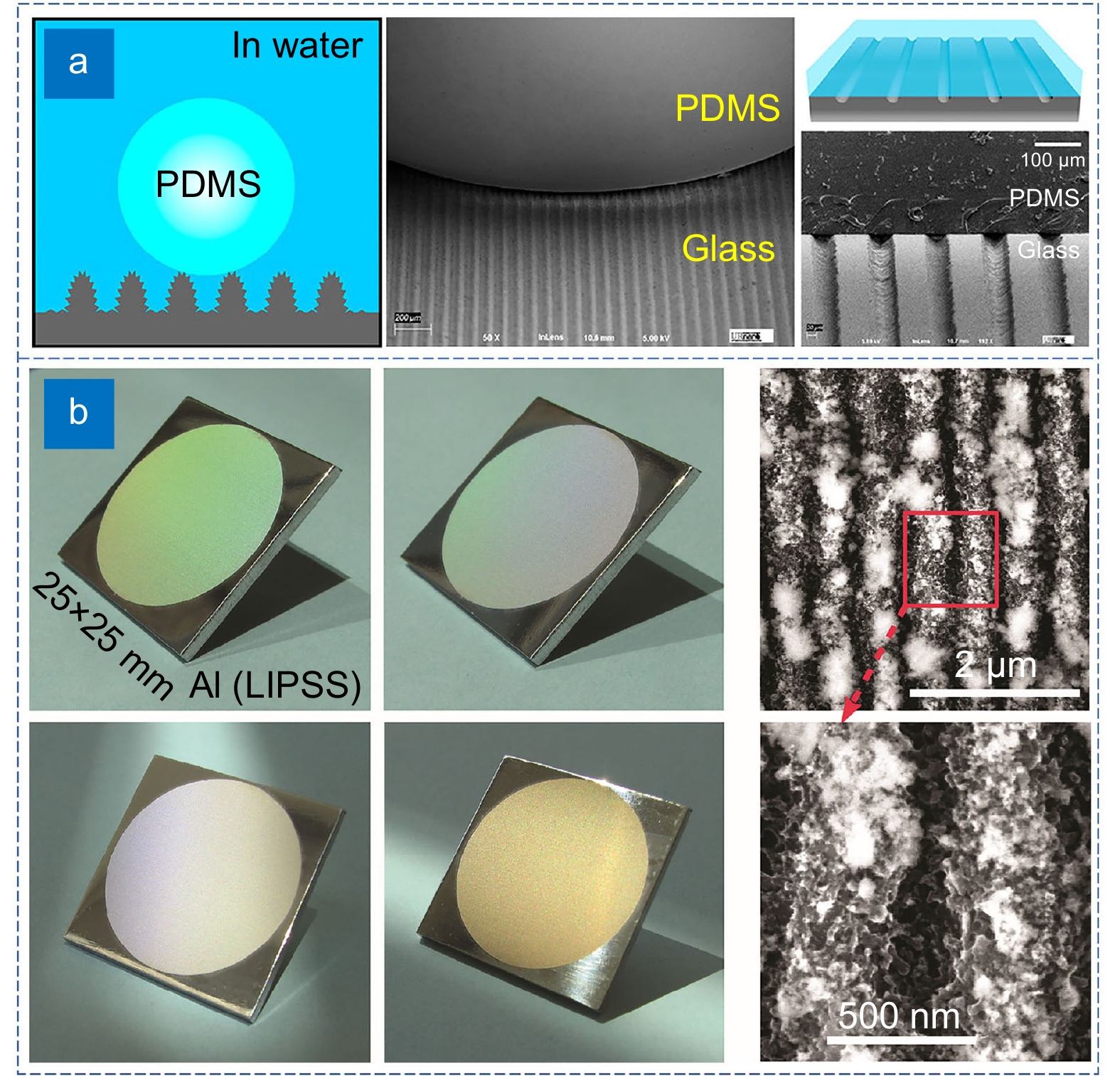

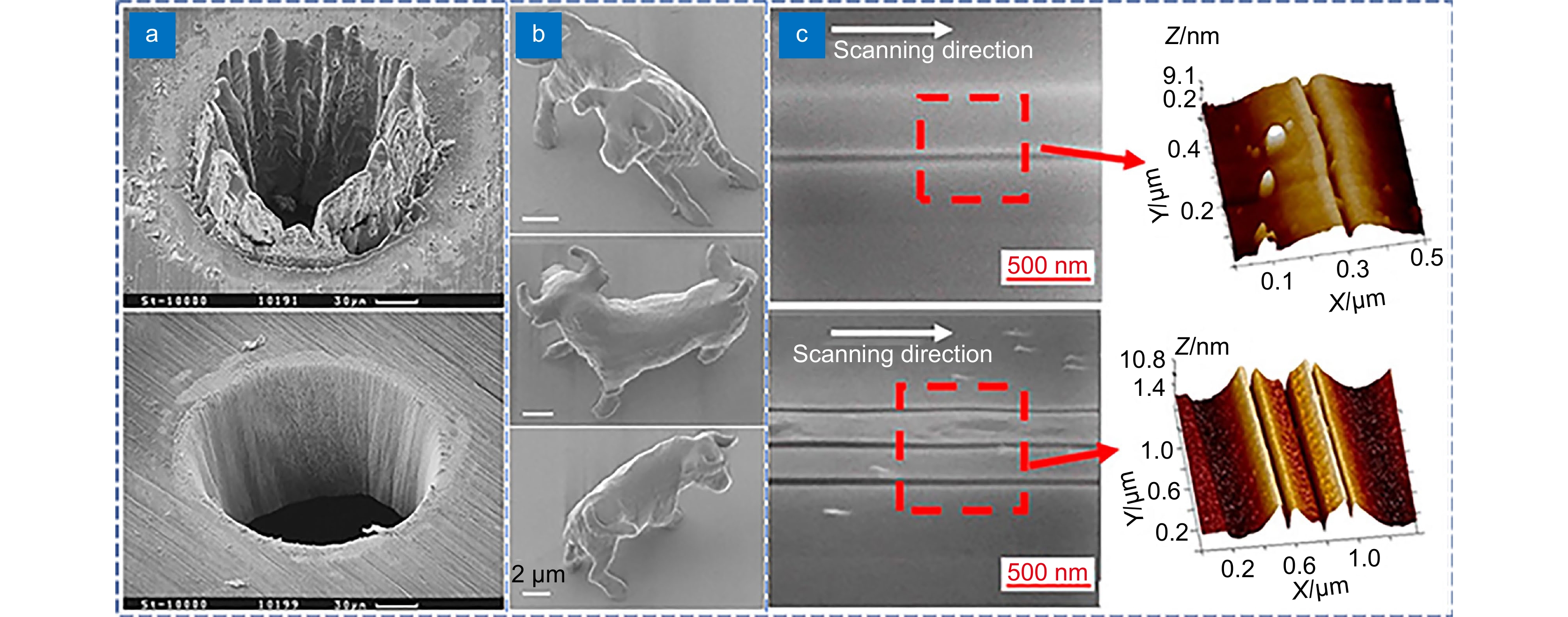

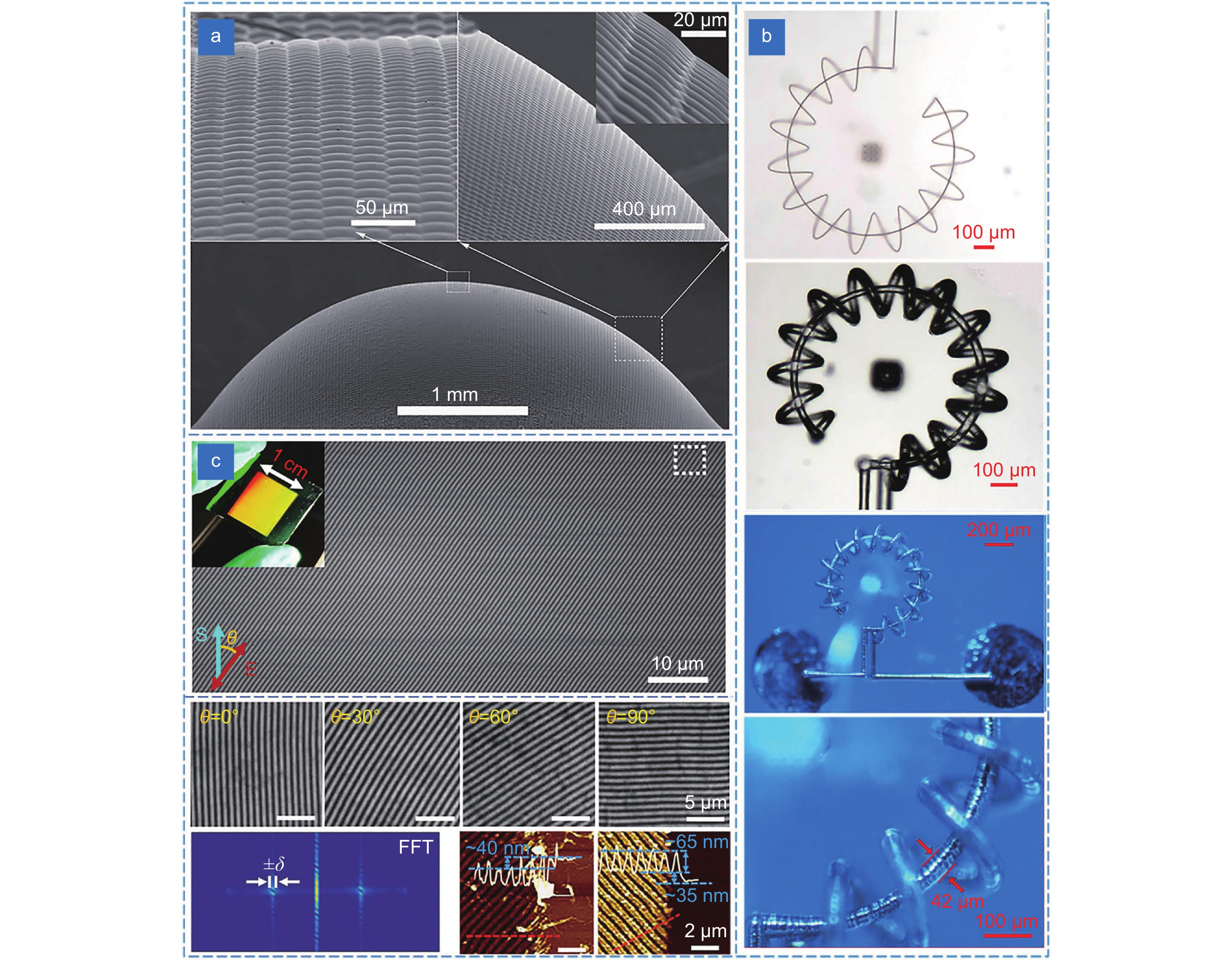

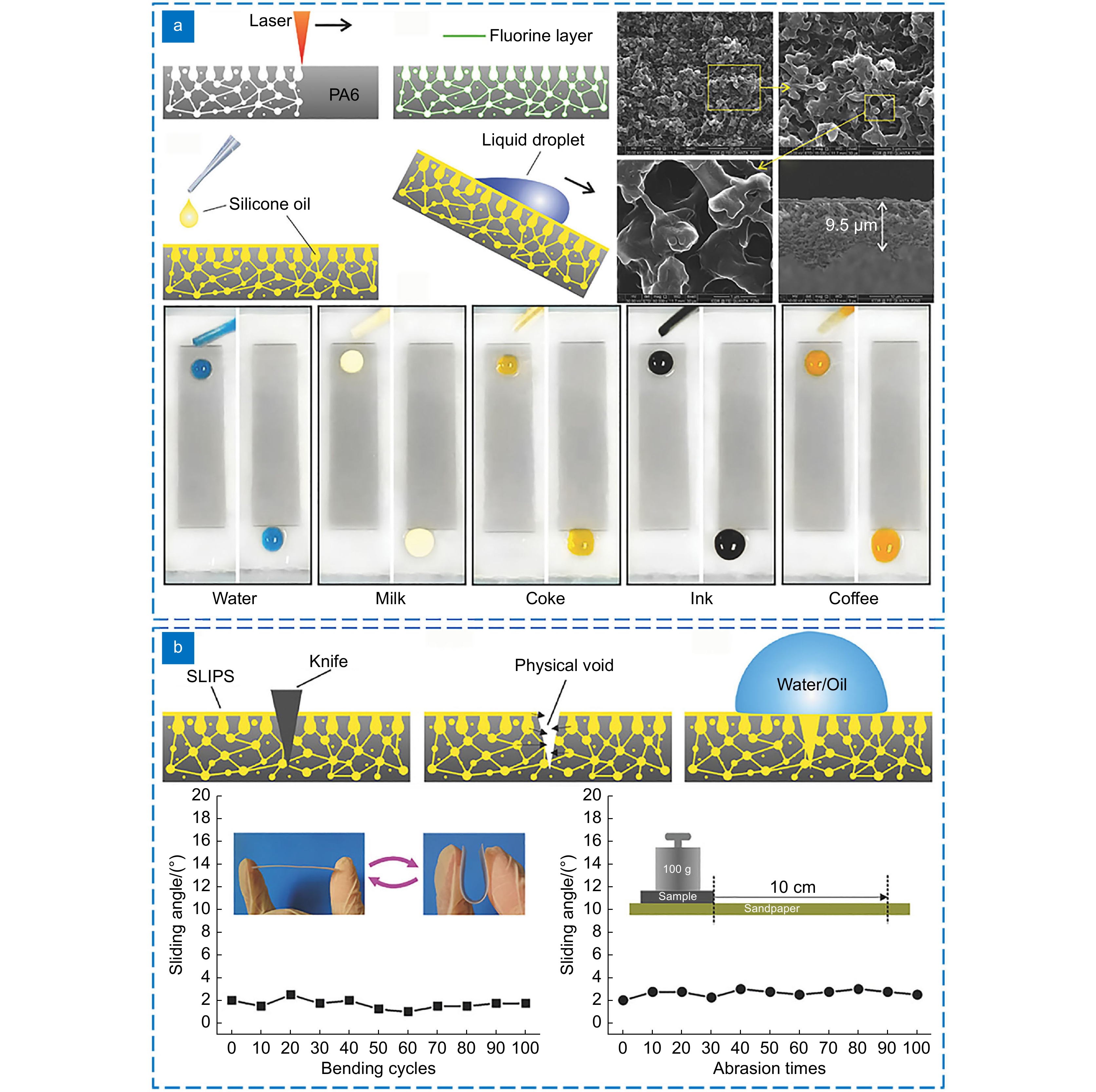

The slippery surface inspired by Nepenthes has received research and industry attentions due to its excellent liquid repellency, stability and self-repair property. The femtosecond laser is a powerful method to prepare the slippery surfaces due to its universality in processing materials with high precision, and high controllability. In this paper, taking the lyophobicity of slippery surfaces as a background, using femtosecond laser mico/nano-manufacturing technology as a method, the development of slippery surfaces by femtosecond laser was summarized from two perspectives, including the femtosecond laser mico/nano-manufacturing and applications of slippery surfaces. By controlling the processing parameters of femtosecond laser, the slippery surfaces could be fabricated on various materials, such as polymers, hard brittle transparent material, and metals. The prepared slippery surface can be applied in the fields of droplet and bubble manipulation, biological anticoagulation, antifouling, and anti-corrosion. Finally, the challenges of slippery surfaces were summarized.

-

Key words:

- slippery surface /

- femtosecond laser /

- micro-nano manufacture /

- hemocompatibility /

- lyophobicity

-

Overview

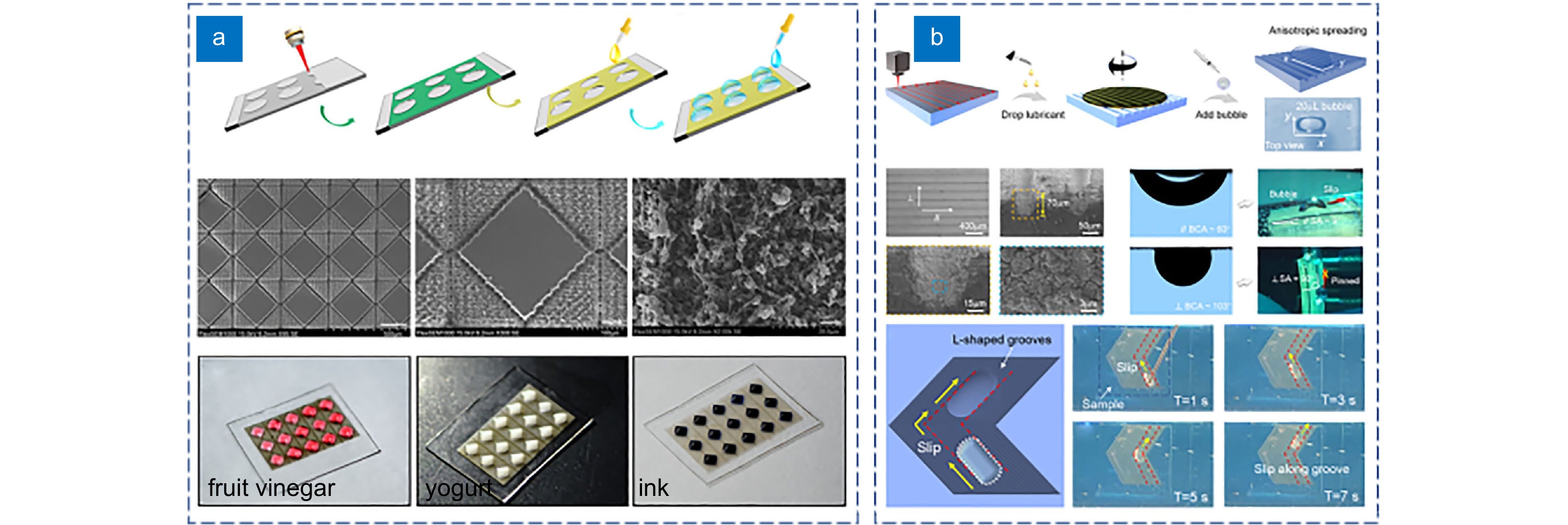

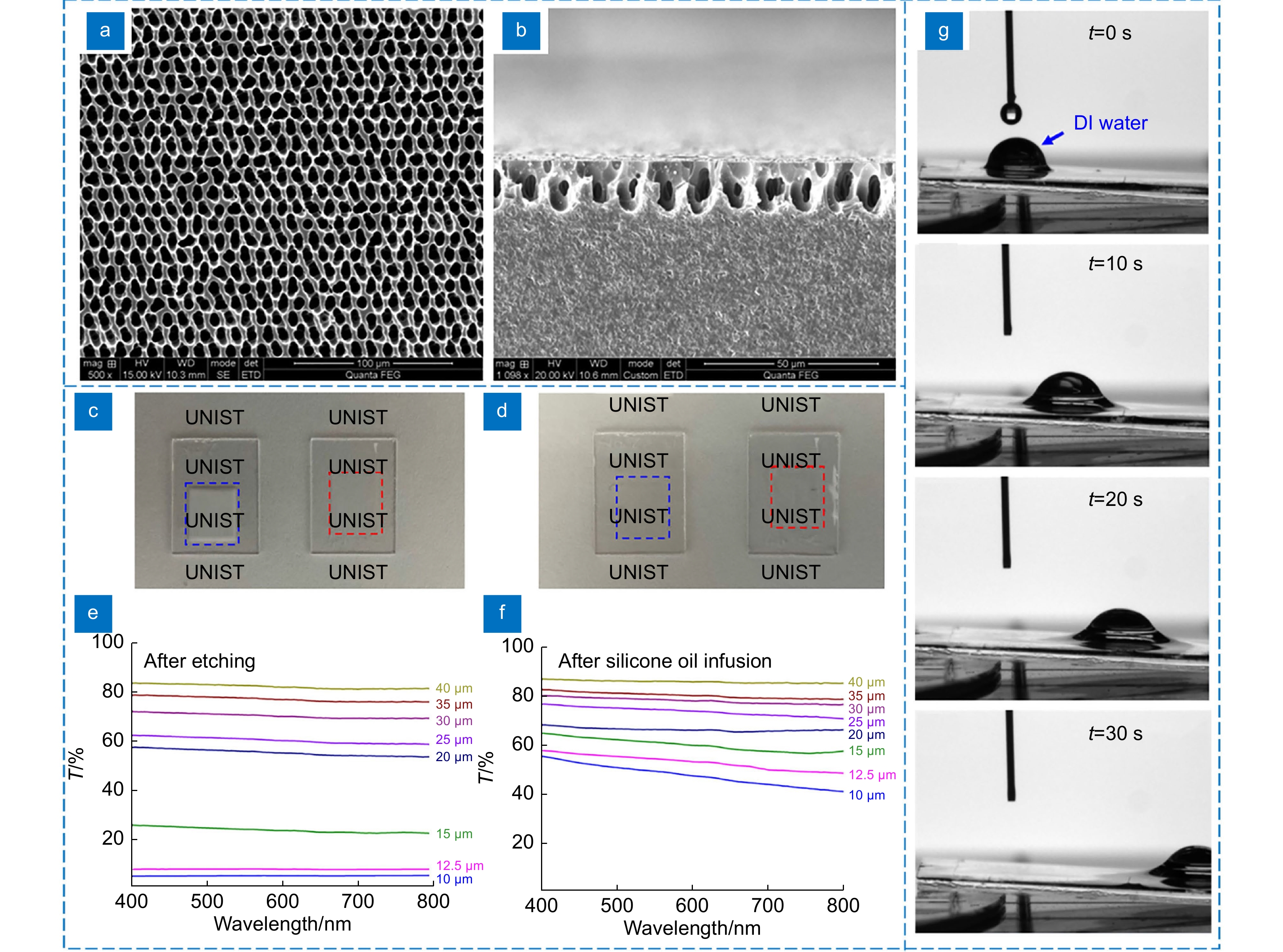

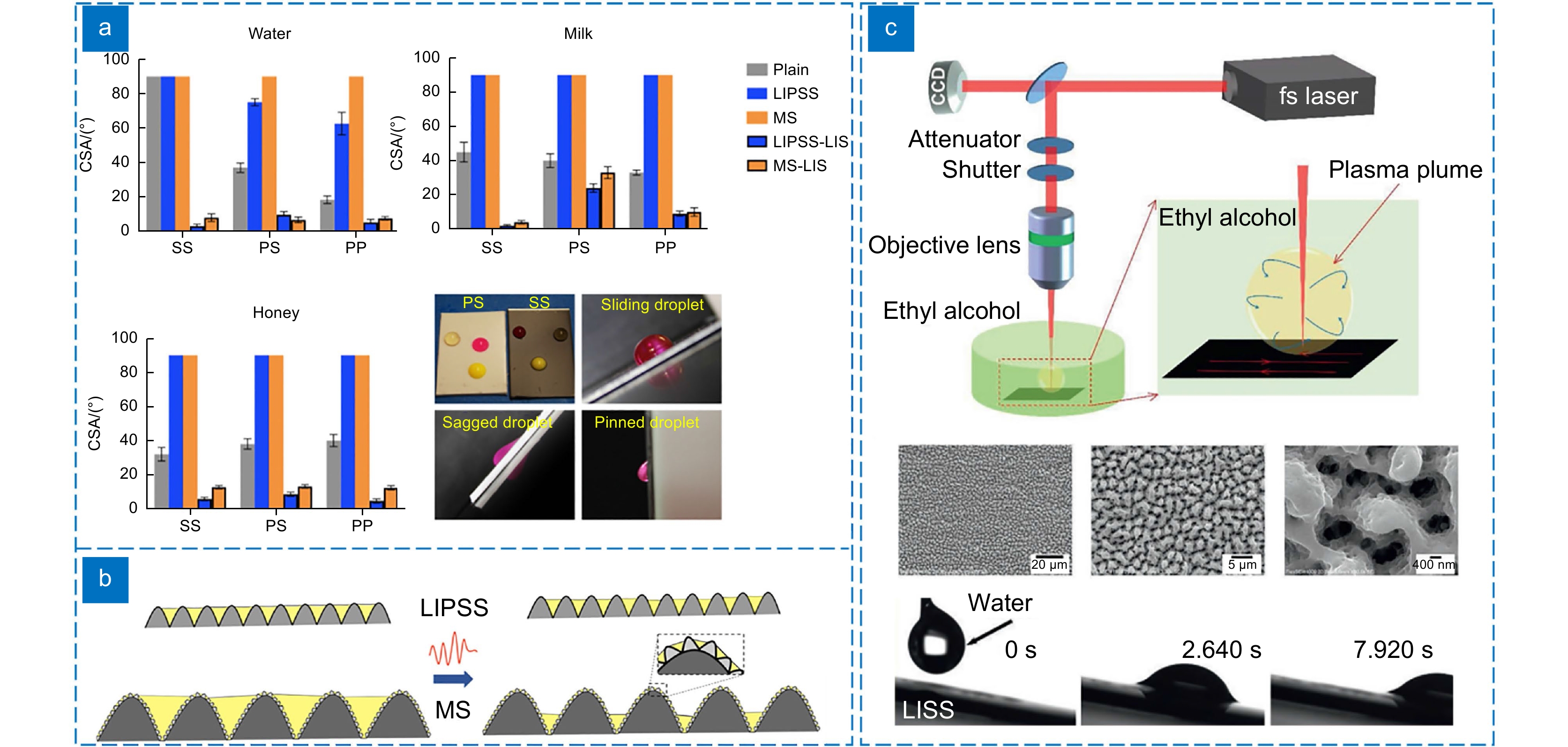

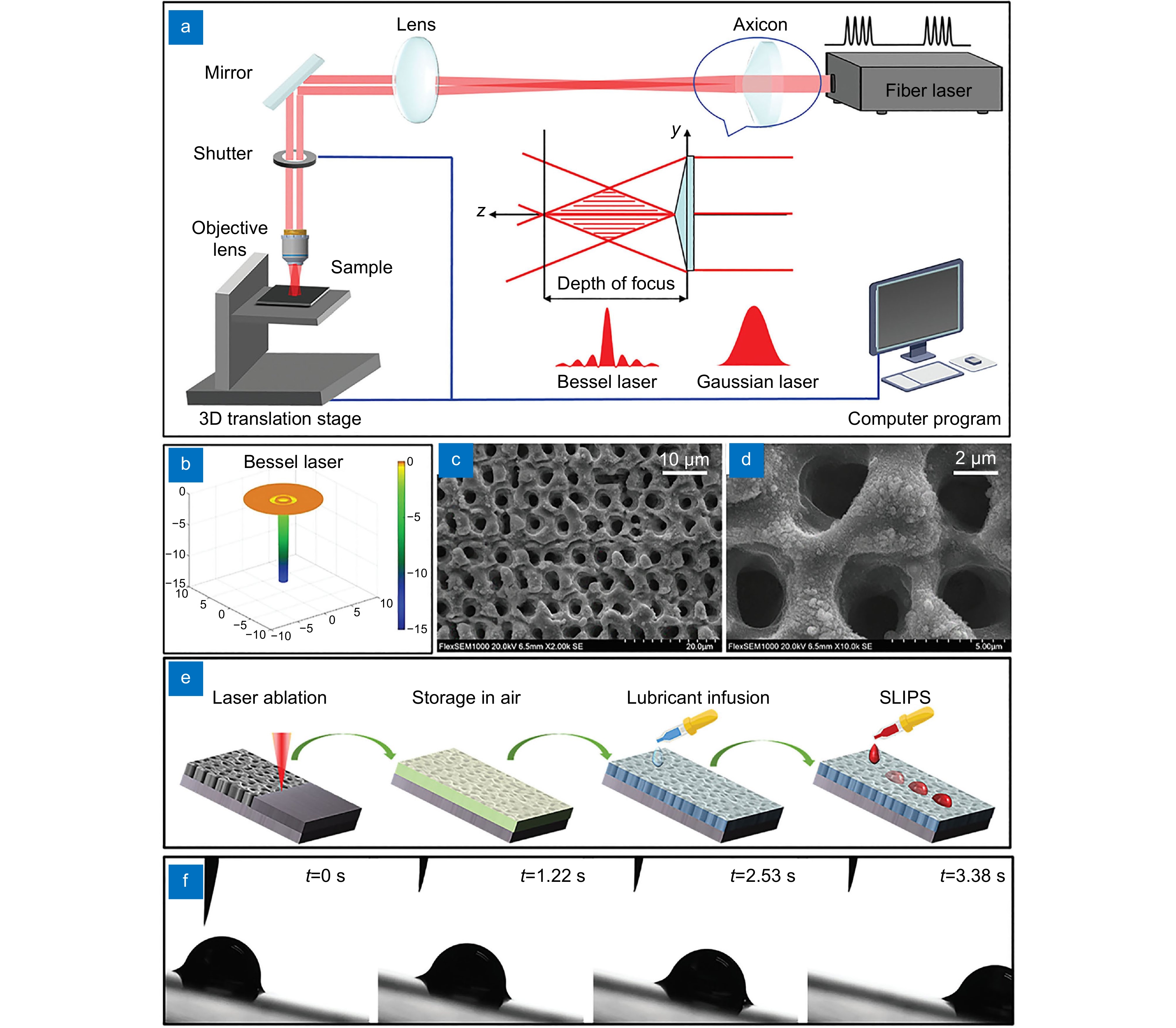

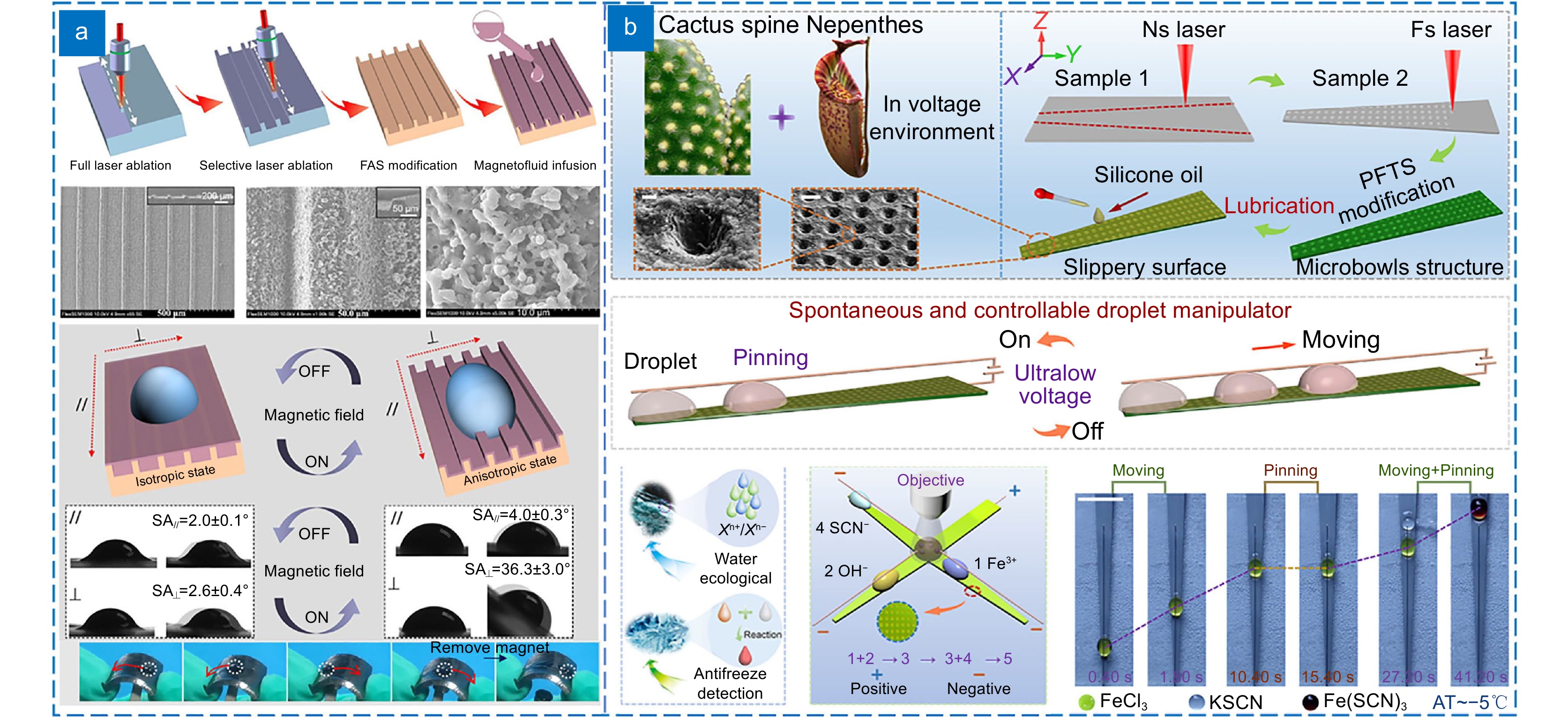

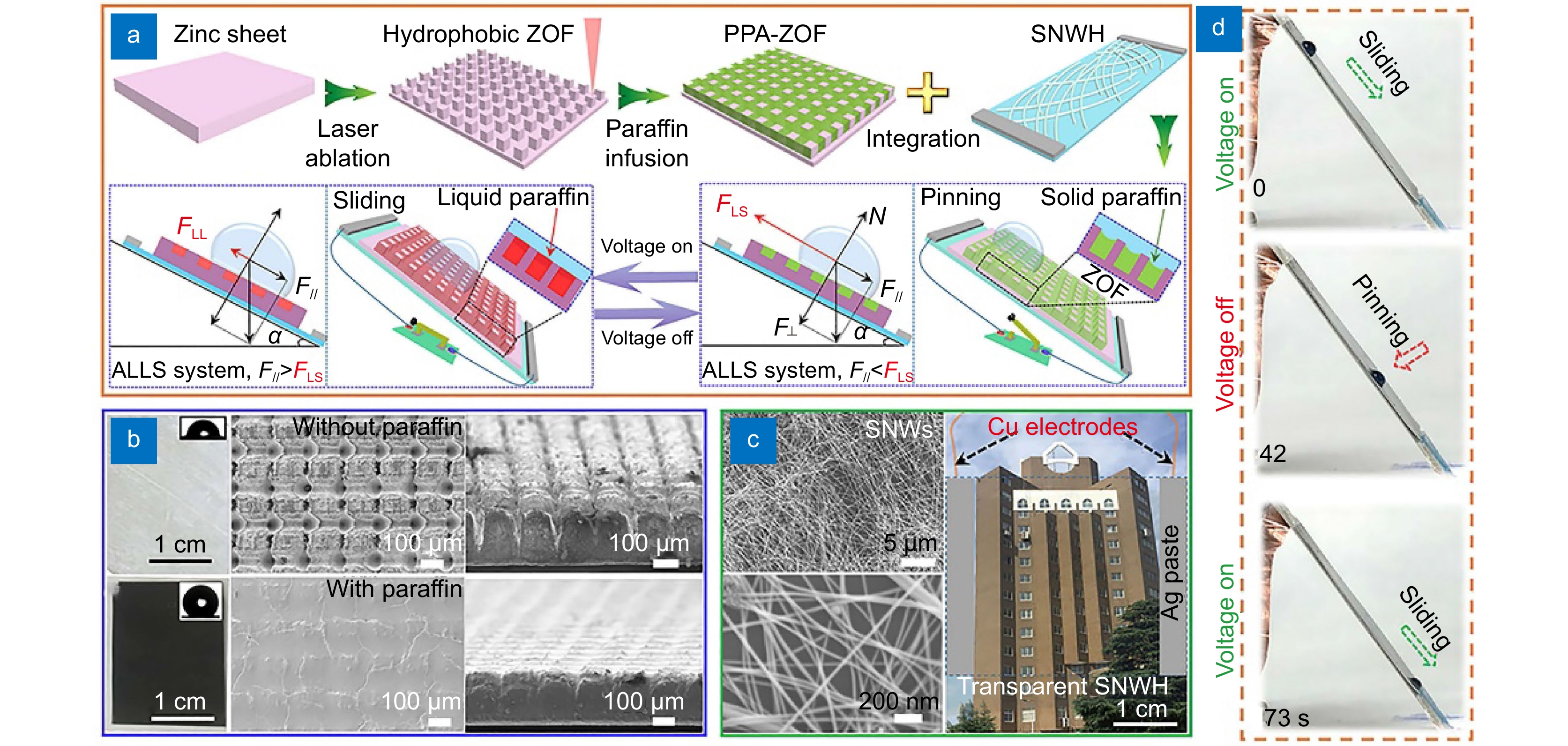

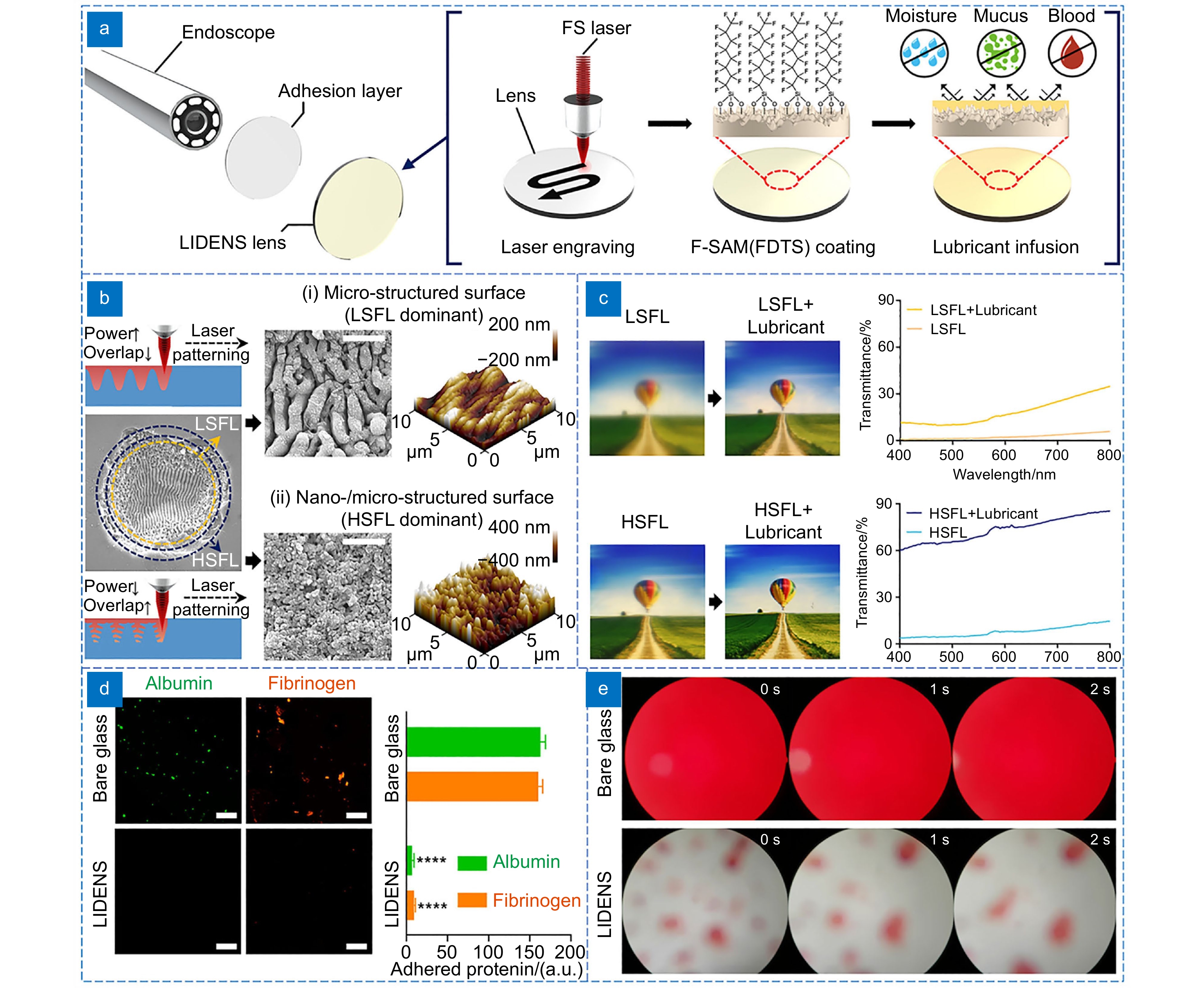

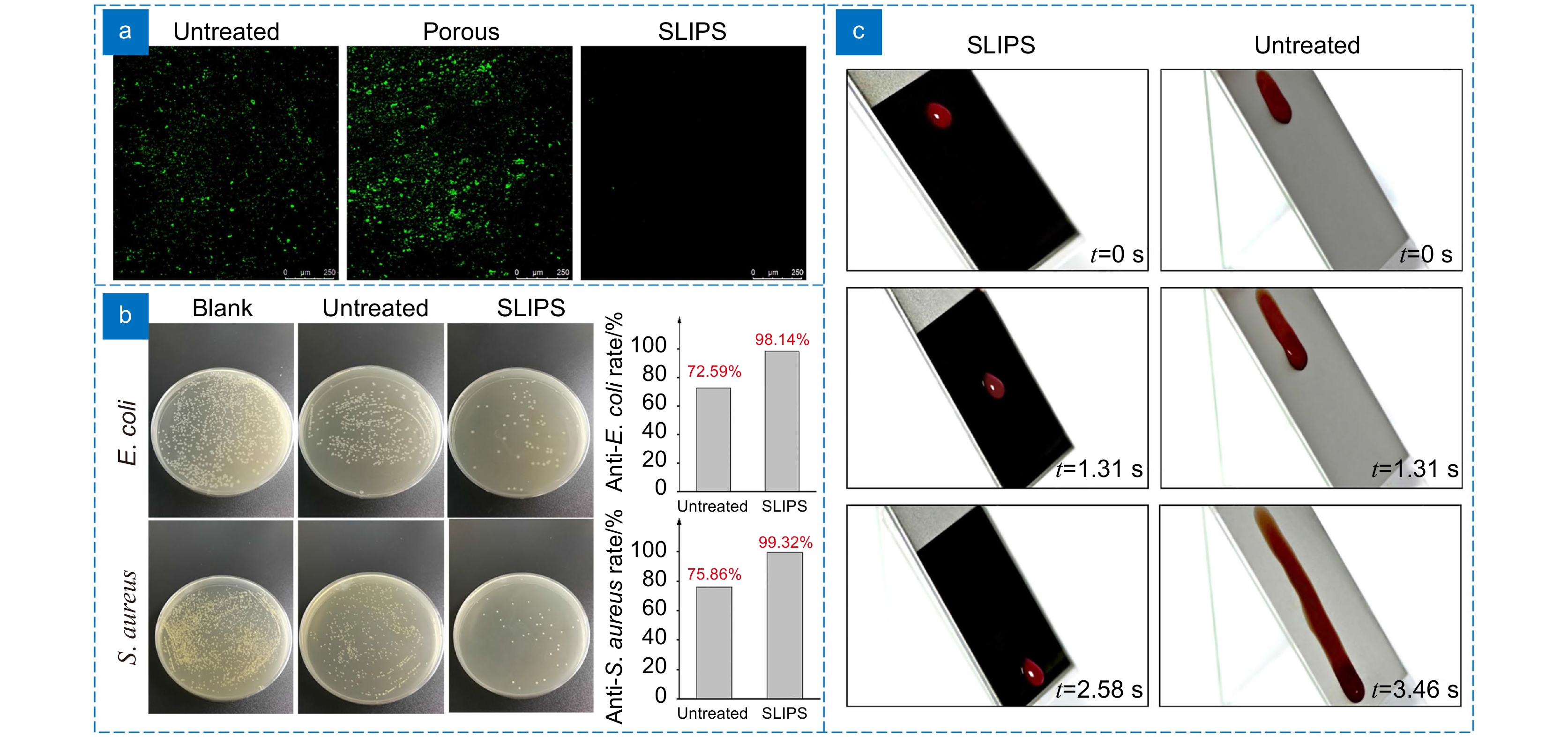

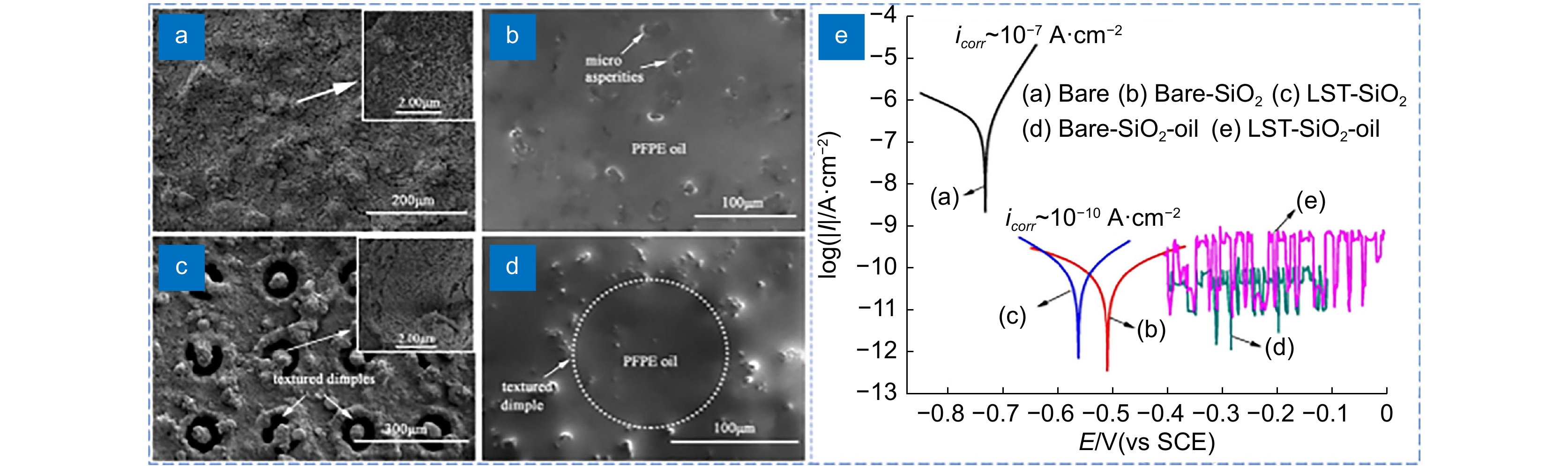

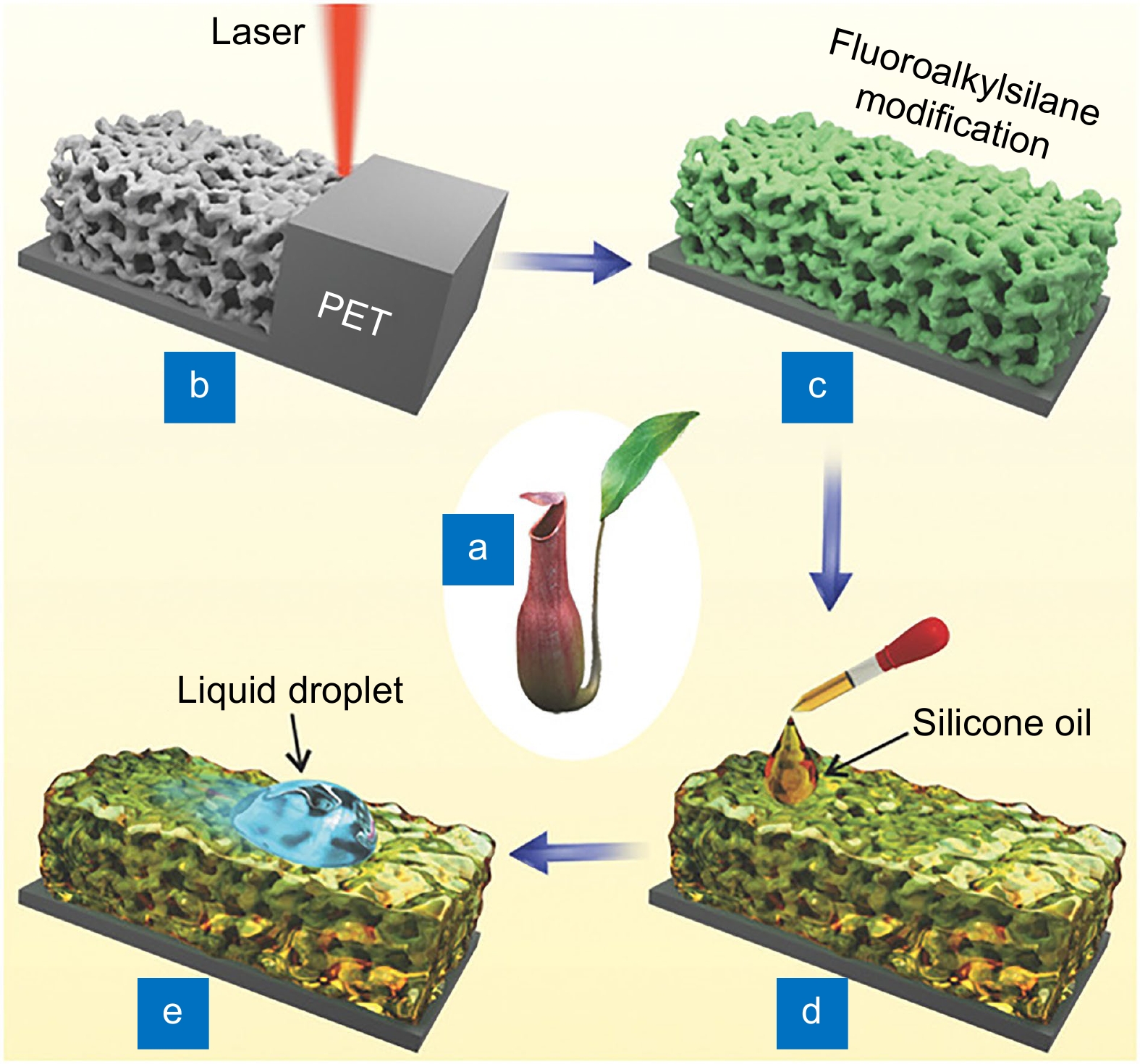

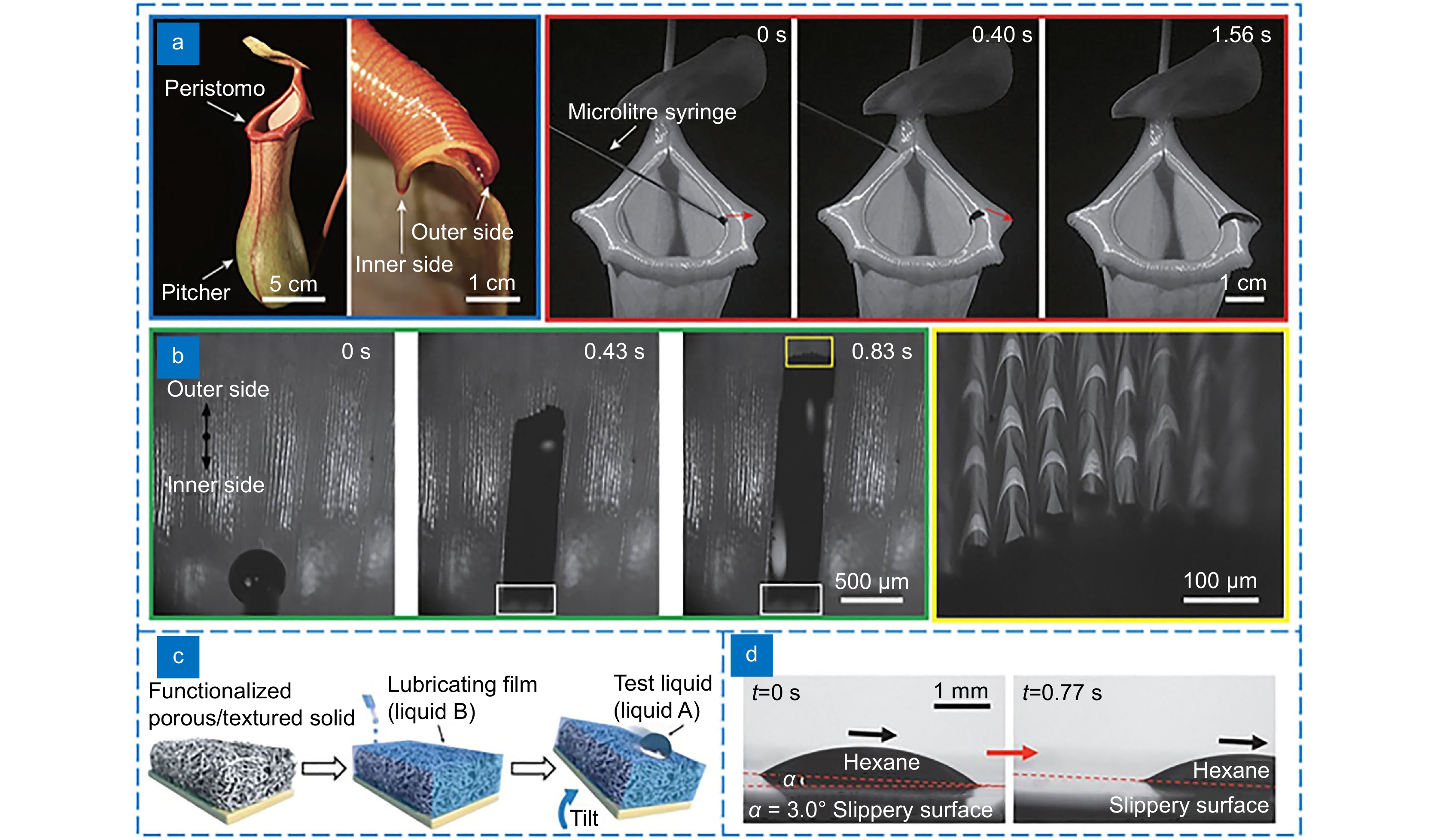

Overview: Nepenthes pitcher plant is a tropical insectivorous plant which is able to trap and digest insects. This unique property is mainly due to the rich micro/nano porous structures on the surfaces filled with a layer of lubricating, thus forming a slippery liquid-infused porous surface (SLIPS). When the insects stand on the mouth of pitch plant, they can easily fall into the pitcher because its inner surface is too smooth and thus digested by the digestive juices. Due to the mechanism of liquid-liquid contact between the lubricant and repelled object, SLIPS shows high stability and versatile liquid-repellency compared with superhydrophobic surfaces inspired by lotus leaves. Due to the fluidity of the lubricant, it can timely flow to the surface defects caused by external force and help recover the favorable slippery property. These excellent liquid repellency, stability and self-healing properties of SLIPS have attracted wide attentions from researchers, who carried out a large number of related studies. Methods to prepare SLIPS are mostly based on the three parts: fabrication of micro/nano-structures, low surface energy treatment and lubricant infusion. The fabrication of rough structure is the essential part during the process. Femtosecond laser has the ultra-short pulse width and ultra-high peak power, so it can process the majority of materials with high processing accuracy and strong controllability. Therefore, femtosecond laser has become a powerful tool for preparing the micro/nano-structure on the SLIPS. In addition, the femtosecond laser processing is directly performed on the material for subtractive manufacturing. It shows more stability compared with chemical treatment. In this paper, we focus on the preparation of SLIPS on different materials by femtosecond laser, including polymers, hard and brittle transparent materials, and metals. Then, the application of SLIPS is summarized in the fields of droplet bubble manipulation, biological anticoagulation, anti-fouling, and corrosion prevention. Finally, challenges of slippery surfaces were summarized.

-

-

-

参考文献

[1] Wong T S, Kang S H, Tang S K Y, et al. Bioinspired self-repairing slippery surfaces with pressure-stable omniphobicity[J]. Nature, 2011, 477(7365): 443−447. doi: 10.1038/nature10447

[2] Chen H W, Zhang P F, Zhang L W, et al. Continuous directional water transport on the peristome surface of Nepenthes alata[J]. Nature, 2016, 532(7597): 85−89. doi: 10.1038/nature17189

[3] Li J S, Ueda E, Paulssen D, et al. Slippery lubricant-infused surfaces: properties and emerging applications[J]. Adv Funct Mater, 2019, 29(4): 1802317. doi: 10.1002/adfm.201802317

[4] Zhao X, Wei J F, Li B C, et al. A self-healing superamphiphobic coating for efficient corrosion protection of magnesium alloy[J]. J Colloid Interface Sci, 2020, 575: 140−149. doi: 10.1016/j.jcis.2020.04.097

[5] Zhao H X, Sun Q Q, Deng X, et al. Earthworm-inspired rough polymer coatings with self-replenishing lubrication for adaptive friction-reduction and antifouling surfaces[J]. Adv Mater, 2018, 30(29): 1802141. doi: 10.1002/adma.201802141

[6] Xiao X, Zhang C H, Ma H Y, et al. Bioinspired slippery cone for controllable manipulation of gas bubbles in low-surface-tension environment[J]. ACS Nano, 2019, 13(4): 4083−4090. doi: 10.1021/acsnano.8b08480

[7] Wei D S, Wang J G, Li S Y, et al. Novel corrosion-resistant behavior and mechanism of a biomimetic surface with switchable wettability on Mg alloy[J]. Chem Eng J, 2021, 425: 130450. doi: 10.1016/j.cej.2021.130450

[8] Wang H J, Zhang Z H, Wang Z K, et al. Improved dynamic stability of superomniphobic surfaces and droplet transport on slippery surfaces by dual-scale re-entrant structures[J]. Chem Eng J, 2020, 394: 124871. doi: 10.1016/j.cej.2020.124871

[9] Liu W J, Pan R, Cai M Y, et al. Oil-triggered switchable wettability on patterned alternating air/lubricant-infused superamphiphobic surfaces[J]. J Mater Chem A, 2020, 8(14): 6647−6660. doi: 10.1039/C9TA14116B

[10] Leslie D C, Waterhouse A, Berthet J B, et al. A bioinspired omniphobic surface coating on medical devices prevents thrombosis and biofouling[J]. Nat Biotechnol, 2014, 32(11): 1134−1140. doi: 10.1038/nbt.3020

[11] Badv M, Imani S M, Weitz J I, et al. Lubricant-infused surfaces with built-in functional biomolecules exhibit simultaneous repellency and tunable cell adhesion[J]. ACS Nano, 2018, 12(11): 10890−10902. doi: 10.1021/acsnano.8b03938

[12] Fang Y, Liang J, Bai X, et al. Magnetically controllable isotropic/anisotropic slippery surface for flexible droplet manipulation[J]. Langmuir, 2020, 36(50): 15403−15409. doi: 10.1021/acs.langmuir.0c03008

[13] Yang J, Li J Y, Jia X H, et al. Fabrication of robust and transparent slippery coating with hot water repellency, antifouling property, and corrosion resistance[J]. ACS Appl Mater Interfaces, 2020, 12(25): 28645−28654. doi: 10.1021/acsami.0c06743

[14] Yang S K, Dai X M, Stogin B B, et al. Ultrasensitive surface-enhanced raman scattering detection in common fluids[J]. Proc Natl Acad Sci USA, 2016, 113(2): 268−273. doi: 10.1073/pnas.1518980113

[15] Deng R, Shen T, Chen H L, et al. Slippery liquid-infused porous surfaces (SLIPSs): a perfect solution to both marine fouling and corrosion?[J]. J Mater Chem A, 2020, 8(16): 7536−7547. doi: 10.1039/D0TA02000A

[16] Zeng X, Guo Z G, Liu W M. Recent advances in slippery liquid-infused surfaces with unique properties inspired by nature[J]. Bio-Des Manuf, 2021, 4(3): 506−525. doi: 10.1007/s42242-021-00133-8

[17] Zhang P F, Liu G, Zhang D Y, et al. Liquid-infused surfaces on electrosurgical instruments with exceptional antiadhesion and low-damage performances[J]. ACS Appl Mater Interfaces, 2018, 10(39): 33713−33720. doi: 10.1021/acsami.8b13373

[18] Chen Y, Guo Z G. An ionic liquid-infused slippery surface for temperature stability, shear resistance and corrosion resistance[J]. J Mater Chem A, 2020, 8(45): 24075−24085. doi: 10.1039/D0TA08717C

[19] Liang Y Z, Wang P, Zhang D. Designing a highly stable slippery organogel on Q235 carbon steel for inhibiting microbiologically influenced corrosion[J]. ACS Appl Bio Mater, 2021, 4(8): 6056−6064. doi: 10.1021/acsabm.1c00357

[20] Anand S, Paxson A T, Dhiman R, et al. Enhanced condensation on lubricant-impregnated nanotextured surfaces[J]. ACS Nano, 2012, 6(11): 10122−10129. doi: 10.1021/nn303867y

[21] Jiang D, Xia X C, Hou J, et al. A novel coating system with self-reparable slippery surface and active corrosion inhibition for reliable protection of Mg alloy[J]. Chem Eng J, 2019, 373: 285−297. doi: 10.1016/j.cej.2019.05.046

[22] Li H, Feng X L, Peng Y J, et al. Durable lubricant-infused coating on a magnesium alloy substrate with anti-biofouling and anti-corrosion properties and excellent thermally assisted healing ability[J]. Nanoscale, 2020, 12(14): 7700−7711. doi: 10.1039/C9NR10699E

[23] Song F, Wu C Q, Chen H L, et al. Water-repellent and corrosion-resistance properties of superhydrophobic and lubricant-infused super slippery surfaces[J]. RSC Adv, 2017, 7(70): 44239−44246. doi: 10.1039/C7RA04816E

[24] Lee J, Jiang Y H, Hizal F, et al. Durable omniphobicity of oil-impregnated anodic aluminum oxide nanostructured surfaces[J]. J Colloid Interface Sci, 2019, 553: 734−745. doi: 10.1016/j.jcis.2019.06.068

[25] Sun J, Wang C, Song J L, et al. Multi-functional application of oil-infused slippery al surface: from anti-icing to corrosion resistance[J]. J Mater Sci, 2018, 53(23): 16099−16109. doi: 10.1007/s10853-018-2760-z

[26] Geraldi N R, Guan J H, Dodd L E, et al. Double-sided slippery liquid-infused porous materials using conformable mesh[J]. Sci Rep, 2019, 9(1): 13280. doi: 10.1038/s41598-019-49887-3

[27] Zhang M L, Chen R R, Liu Q, et al. Long-term stability of a liquid-infused coating with anti-corrosion and anti-icing potentials on al alloy[J]. ChemElectroChem, 2019, 6(15): 3911−3919. doi: 10.1002/celc.201900302

[28] Yong J L, Chen F, Yang Q, et al. Rapid fabrication of large-area concave microlens arrays on pdms by a femtosecond laser[J]. ACS Appl Mater Interfaces, 2013, 5(19): 9382−9385. doi: 10.1021/am402923t

[29] Cheng Y, Yang Q, Fang Y, et al. Underwater anisotropic 3D superoleophobic tracks applied for the directional movement of oil droplets and the microdroplets reaction[J]. Adv Mater Interfaces, 2019, 6(10): 1900067. doi: 10.1002/admi.201900067

[30] Sugioka K, Cheng Y. Femtosecond laser three-dimensional micro- and nanofabrication[J]. Appl Phys Rev, 2014, 1(4): 041303. doi: 10.1063/1.4904320

[31] Kodama N, Takahashi T, Inoue T, et al. Morphological characteristics of nanoholes induced by single-shot femtosecond laser ablation of borates and aluminate silicates[J]. J Laser Appl, 2020, 32(1): 012015. doi: 10.2351/1.5130696

[32] Livakas N, Skoulas E, Stratakis E. Omnidirectional iridescence via cylindrically-polarized femtosecond laser processing[J]. Opto-Electron Adv, 2020, 3(5): 190035. doi: 10.29026/oea.2020.190035

[33] Zhou Y, Chen L W, Du Z R, et al. Tunable optical nonlinearity of silicon nanoparticles in solid state organic matrix[J]. Opt Mater Express, 2015, 5(7): 1606−1612. doi: 10.1364/OME.5.001606

[34] Gattass R R, Mazur E. Femtosecond laser micromachining in transparent materials[J]. Nat Photonics, 2008, 2(4): 219−225. doi: 10.1038/nphoton.2008.47

[35] Chen L W, Yin Y M, Li Y, et al. Multifunctional inverse sensing by spatial distribution characterization of scattering photons[J]. Opto-Electron Adv, 2019, 2(9): 190019. doi: 10.29026/oea.2019.190019

[36] Yong J L, Zhan Z B, Singh S C, et al. Microfluidic channels fabrication based on underwater superpolymphobic microgrooves produced by femtosecond laser direct writing[J]. ACS Appl Polym Mater, 2019, 1(11): 2819−2825. doi: 10.1021/acsapm.9b00269

[37] Vorobyev A Y, Guo C L. Colorizing metals with femtosecond laser pulses[J]. Appl Phys Lett, 2008, 92(4): 041914. doi: 10.1063/1.2834902

[38] Deng Z F, Chen F, Yang Q, et al. Dragonfly-eye-inspired artificial compound eyes with sophisticated imaging[J]. Adv Funct Mater, 2016, 26(12): 1995−2001. doi: 10.1002/adfm.201504941

[39] Sundaram S K, Mazur E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses[J]. Nat Mater, 2002, 1(4): 217−224. doi: 10.1038/nmat767

[40] Momma C, Nolte S, Chichkov B N, et al. Precise laser ablation with ultrashort pulses[J]. Appl Surf Sci, 1997, 109–110: 15−19. doi: 10.1016/S0169-4332(96)00613-7

[41] Kawata S, Sun H B, Tanaka T, et al. Finer features for functional microdevices - micromachines can be created with higher resolution using two-photon absorption[J]. Nature, 2001, 412(6848): 697−698.

[42] Lin Z Y, Liu H G, Ji L F, et al. Realization of ∼10 nm features on semiconductor surfaces via femtosecond laser direct patterning in far field and in ambient air[J]. Nano Lett, 2020, 20(7): 4947−4952. doi: 10.1021/acs.nanolett.0c01013

[43] Kontenis G, Gailevičius D, Jonušauskas L, et al. Dynamic aberration correction via spatial light modulator (SLM) for femtosecond direct laser writing: towards spherical voxels[J]. Opt Express, 2020, 28(19): 27850−27864. doi: 10.1364/OE.397006

[44] Pavlov D, Porfirev A, Khonina S, et al. Coaxial hole array fabricated by ultrafast femtosecond-laser processing with spatially multiplexed vortex beams for surface enhanced infrared absorption[J]. Appl Surf Sci, 2021, 541: 148602. doi: 10.1016/j.apsusc.2020.148602

[45] Yalizay B, Ersoy T, Soylu B, et al. Fabrication of nanometer-size structures in metal thin films using femtosecond laser bessel beams[J]. Appl Phys Lett, 2012, 100(3): 031104. doi: 10.1063/1.3678030

[46] Zhao Y Z, Su Y L, Hou X Y, et al. Directional sliding of water: biomimetic snake scale surfaces[J]. Opto-Electron Adv, 2021, 4(4): 210008. doi: 10.29026/oea.2021.210008

[47] Su Y L, Zhao Y Z, Jiang S Y, et al. Anisotropic superhydrophobic properties of bioinspired surfaces by laser ablation of metal substrate inside water[J]. Adv Mater Interfaces, 2021, 8(16): 2100555. doi: 10.1002/admi.202100555

[48] Bian H, Shan C, Liu K Y, et al. A miniaturized rogowski current transducer with wide bandwidth and fast response[J]. J Micromech Microeng, 2016, 26(11): 115015. doi: 10.1088/0960-1317/26/11/115015

[49] Zou T T, Zhao B, Xin W, et al. High-speed femtosecond laser plasmonic lithography and reduction of graphene oxide for anisotropic photoresponse[J]. Light Sci Appl, 2020, 9: 69. doi: 10.1038/s41377-020-0311-2

[50] Yong J L, Chen F, Yang Q, et al. Nepenthes inspired design of self-repairing omniphobic slippery liquid infused porous surface (SLIPS) by femtosecond laser direct writing[J]. Adv Mater Interfaces, 2017, 4(20): 1700552. doi: 10.1002/admi.201700552

[51] Yong J L, Huo J L, Yang Q, et al. Femtosecond laser direct writing of porous network microstructures for fabricating super-slippery surfaces with excellent liquid repellence and anti-cell proliferation[J]. Adv Mater Interfaces, 2018, 5(7): 1701479. doi: 10.1002/admi.201701479

[52] Liang J, Bian H, Yang Q, et al. Femtosecond laser-patterned slippery surfaces on PET for liquid patterning and blood resistance[J]. Opt Laser Technol, 2020, 132: 106469. doi: 10.1016/j.optlastec.2020.106469

[53] Lv X D, Jiao Y L, Wu S Z, et al. Anisotropic sliding of underwater bubbles on microgrooved slippery surfaces by one-step femtosecond laser scanning[J]. ACS Appl Mater Interfaces, 2019, 11(22): 20574−20580. doi: 10.1021/acsami.9b06849

[54] Deng C, Ki H. Tunable wetting surfaces with interacting cavities via femtosecond laser patterning and wet etching[J]. J Appl Phys, 2020, 128(1): 015306. doi: 10.1063/5.0011885

[55] Gopal V, Manivasagam G. Wear - corrosion synergistic effect on Ti–6Al–4V alloy in H2O2 and albumin environment[J]. J Alloys Compd, 2020, 830: 154539. doi: 10.1016/j.jallcom.2020.154539

[56] Sharma A, Oh M C, Kim J T, et al. Investigation of electrochemical corrosion behavior of additive manufactured Ti–6Al–4V alloy for medical implants in different electrolytes[J]. J Alloys Compd, 2020, 830: 154620. doi: 10.1016/j.jallcom.2020.154620

[57] Zhang Z, Wu X Q, Tan J B. In-situ monitoring of stress corrosion cracking of 304 stainless steel in high-temperature water by analyzing acoustic emission waveform[J]. Corros Sci, 2019, 146: 90−98. doi: 10.1016/j.corsci.2018.10.022

[58] Cheng Y, Yang Q, Lu Y, et al. A femtosecond bessel laser for preparing a nontoxic slippery liquid-infused porous surface (slips) for improving the hemocompatibility of NiTi alloys[J]. Biomater Sci, 2020, 8(23): 6505−6514. doi: 10.1039/D0BM01369B

[59] Karkantonis T, Gaddam A, See T L, et al. Femtosecond laser-induced sub-micron and multi-scale topographies for durable lubricant impregnated surfaces for food packaging applications[J]. Surf Coat Technol, 2020, 399: 126166. doi: 10.1016/j.surfcoat.2020.126166

[60] Fang Y, Yong J L, Cheng Y, et al. Liquid-infused slippery stainless steel surface prepared by alcohol-assisted femtosecond laser ablation[J]. Adv Mater Interfaces, 2021, 8(5): 2001334. doi: 10.1002/admi.202001334

[61] Jiang J K, Gao J, Zhang H D, et al. Directional pumping of water and oil microdroplets on slippery surface[J]. Proc Natl Acad Sci USA, 2019, 116(7): 2482−2487. doi: 10.1073/pnas.1817172116

[62] Tenjimbayashi M, Nishioka S, Kobayashi Y, et al. A lubricant-sandwiched coating with long-term stable anticorrosion performance[J]. Langmuir, 2018, 34(4): 1386−1393. doi: 10.1021/acs.langmuir.7b03913

[63] Urata C, Nagashima H, Hatton B D, et al. Transparent organogel films showing extremely efficient and durable anti-icing performance[J]. ACS Appl Mater Interfaces, 2021, 13(24): 28925−28937. doi: 10.1021/acsami.1c06815

[64] Ware C S, Smith-Palmer T, Peppou-Chapman S, et al. Marine antifouling behavior of lubricant-infused nanowrinkled polymeric surfaces[J]. ACS Appl Mater Interfaces, 2018, 10(4): 4173−4182. doi: 10.1021/acsami.7b14736

[65] Wu D Q, Ma L W, Zhang F, et al. Durable deicing lubricant-infused surface with photothermally switchable hydrophobic/slippery property[J]. Mater Des, 2020, 185: 108236. doi: 10.1016/j.matdes.2019.108236

[66] Yao X, Dunn S S, Kim P, et al. Fluorogel elastomers with tunable transparency, elasticity, shape-memory, and antifouling properties[J]. Angew Chem Int Ed, 2014, 53(17): 4418−4422. doi: 10.1002/anie.201310385

[67] Movafaghi S, Wang W, Bark D L, et al. Hemocompatibility of super-repellent surfaces: current and future[J]. Mater Horiz, 2019, 6(8): 1596−1610. doi: 10.1039/C9MH00051H

[68] Sun L Y, Bian F K, Wang Y, et al. Bioinspired programmable wettability arrays for droplets manipulation[J]. Proc Natl Acad Sci USA, 2020, 117(9): 4527−4532. doi: 10.1073/pnas.1921281117

[69] Sun Q Q, Wang D H, Li Y N, et al. Surface charge printing for programmed droplet transport[J]. Nat Mater, 2019, 18(9): 936−941. doi: 10.1038/s41563-019-0440-2

[70] Huang S L, Li J, Liu L, et al. Lossless fast drop self-transport on anisotropic omniphobic surfaces: origin and elimination of microscopic liquid residue[J]. Adv Mater, 2019, 31(27): 1901417. doi: 10.1002/adma.201901417

[71] Fang J H, Zhang Y B, Xiao L, et al. Self-propelled and electrobraking synergetic liquid manipulator toward microsampling and bioanalysis[J]. ACS Appl Mater Interfaces, 2021, 13(12): 14741−14751. doi: 10.1021/acsami.1c01494

[72] Chen C, Huang Z C, Jiao Y L, et al. In situ reversible control between sliding and pinning for diverse liquids under ultra-low voltage[J]. ACS Nano, 2019, 13(5): 5742−5752. doi: 10.1021/acsnano.9b01180

[73] Chauhan A, Bernardin A, Mussard W, et al. Preventing biofilm formation and associated occlusion by biomimetic glycocalyxlike polymer in central venous catheters[J]. J Infect Dis, 2014, 210(9): 1347−1356. doi: 10.1093/infdis/jiu249

[74] Chen G Q, Wu Q. The application of polyhydroxyalkanoates as tissue engineering materials[J]. Biomaterials, 2005, 26(33): 6565−6578. doi: 10.1016/j.biomaterials.2005.04.036

[75] Huang N, Yang P, Leng Y X, et al. Hemocompatibility of titanium oxide films[J]. Biomaterials, 2003, 24(13): 2177−2187. doi: 10.1016/S0142-9612(03)00046-2

[76] Sun T L, Tan H, Han D, et al. No platelet can adhere-largely improved blood compatibility on nanostructured superhydrophobic surfaces[J]. Small, 2005, 1(10): 959−963. doi: 10.1002/smll.200500095

[77] Fan H L, Chen P P, Qi R M, et al. Greatly improved blood compatibility by microscopic multiscale design of surface architectures[J]. Small, 2009, 5(19): 2144−2148. doi: 10.1002/smll.200900345

[78] Daniello R J, Waterhouse N E, Rothstein J P. Drag reduction in turbulent flows over superhydrophobic surfaces[J]. Phys Fluids, 2009, 21(8): 085103. doi: 10.1063/1.3207885

[79] He W Q, Liu P, Zhang J Q, et al. Emerging applications of bioinspired slippery surfaces in biomedical fields[J]. Chem Eur J, 2018, 24(56): 14864−14877. doi: 10.1002/chem.201801368

[80] Li X Y, Gao P, Tan J Y, et al. Assembly of metal–phenolic/catecholamine networks for synergistically anti-inflammatory, antimicrobial, and anticoagulant coatings[J]. ACS Appl Mater Interfaces, 2018, 10(47): 40844−40853. doi: 10.1021/acsami.8b14409

[81] Manabe K, Kyung K H, Shiratori S. Biocompatible slippery fluid-infused films composed of chitosan and alginate via layer-by-layer self-assembly and their antithrombogenicity[J]. ACS Appl Mater Interfaces, 2015, 7(8): 4763−4771. doi: 10.1021/am508393n

[82] Moradi S, Hadjesfandiari N, Toosi S F, et al. Effect of extreme wettability on platelet adhesion on metallic implants: from superhydrophilicity to superhydrophobicity[J]. ACS Appl Mater Interfaces, 2016, 8(27): 17631−17641. doi: 10.1021/acsami.6b03644

[83] Villegas M, Zhang Y X, Abu Jarad N, et al. Liquid-infused surfaces: a review of theory, design, and applications[J]. ACS Nano, 2019, 13(8): 8517−8536. doi: 10.1021/acsnano.9b04129

[84] Yuan S S, Luan S F, Yan S J, et al. Facile fabrication of lubricant-infused wrinkling surface for preventing thrombus formation and infection[J]. ACS Appl Mater Interfaces, 2015, 7(34): 19466−19473. doi: 10.1021/acsami.5b05865

[85] Doll K, Fadeeva E, Schaeske J, et al. Development of laser-structured liquid-infused titanium with strong biofilm-repellent properties[J]. ACS Appl Mater Interfaces, 2017, 9(11): 9359−9368. doi: 10.1021/acsami.6b16159

[86] Lee Y, Chung Y W, Park J, et al. Lubricant-infused directly engraved nano-microstructures for mechanically durable endoscope lens with anti-biofouling and anti-fogging properties[J]. Sci Rep, 2020, 10(1): 17454. doi: 10.1038/s41598-020-74517-8

[87] Liu X W, Wang L Q, Qiao Y F, et al. Adhesion of liquid food to packaging surfaces: mechanisms, test methods, influencing factors and anti-adhesion methods[J]. J Food Eng, 2018, 228: 102−117. doi: 10.1016/j.jfoodeng.2018.02.002

[88] Schaider L A, Balan S A, Blum A, et al. Fluorinated compounds in U. S. fast food packaging[J]. Environ Sci Technol Lett, 2017, 4(3): 105−111. doi: 10.1021/acs.estlett.6b00435

[89] Williams H, Lindström A, Trischler J, et al. Avoiding food becoming waste in households – the role of packaging in consumers' practices across different food categories[J]. J. Clean Prod, 2020, 265: 121775. doi: 10.1016/j.jclepro.2020.121775

[90] Williams H, Wikström F, Otterbring T, et al. Reasons for household food waste with special attention to packaging[J]. J Clean Prod, 2012, 24: 141−148. doi: 10.1016/j.jclepro.2011.11.044

[91] Wohner B, Pauer E, Heinrich V, et al. Packaging-related food losses and waste: an overview of drivers and issues[J]. Sustainability, 2019, 11(1): 264. doi: 10.3390/su11010264

[92] Zouaghi S, Six T, Bellayer S, et al. Antifouling biomimetic liquid-infused stainless steel: application to dairy industrial processing[J]. ACS Appl Mater Interfaces, 2017, 9(31): 26565−26573. doi: 10.1021/acsami.7b06709

[93] Qin Y K, Li Y, Zhang D, et al. Wettability, durability and corrosion properties of slippery laser-textured aluminum alloy surface under water impact[J]. Surf Coat Technol, 2020, 394: 125856. doi: 10.1016/j.surfcoat.2020.125856

[94] Zhang G Y, Liang B, Zhong Z X, et al. One-step solvent-free strategy for covalently attached, substrate-independent transparent slippery coating[J]. Adv Mater Interfaces, 2018, 5(20): 1800646. doi: 10.1002/admi.201800646

[95] Zhong X M, Hu H F, Yang L, et al. Robust hyperbranched polyester-based anti-smudge coatings for self-cleaning, anti-graffiti, and chemical shielding[J]. ACS Appl Mater Interfaces, 2019, 11(15): 14305−14312. doi: 10.1021/acsami.8b22447

[96] Lei L, Buddingh J, Wang J D, et al. Transparent omniphobic polyurethane coatings containing partially acetylated β–cyclodextrin as the polyol[J]. Chem Eng J, 2020, 380: 122554. doi: 10.1016/j.cej.2019.122554

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: