Research progress of additive manufacturing of high-performance polymers and the applications

-

摘要

增材制造(AM),通俗称作3D打印,由于其“控形控性”的优点,已在航空航天、光电工程、微电子等领域受到广泛关注和迅速发展。在各领域的实际应用中,开发3D打印材料是直接决定其应用和发展的关键。因此,本文就目前高性能聚合物3D打印材料及先进智造技术进行综述,重点介绍聚合物3D打印技术、3D打印高性能聚合物材料及其相关应用,为其研究及应用发展提供新的方向和思路。

Abstract

Additive manufacturing (AM), also known as 3D printing, has been attracted extensive attention and developed rapidly in aerospace, optoelectronic engineering, microelectronics, and other fields due to its unique characteristic of "shape and performance control". Developing 3D printing materials is critical for the practical applications in various fields. Therefore, this article reviews the current high-performance polymeric materials for 3D printing and the advanced intelligent manufacturing technologies. It focuses on the 3D printing technologies of polymers, the high-performance polymeric materials for 3D printing, and the related applications, which can provide new directions and ideas for its research, development and application.

-

Key words:

- additive manufacturing /

- high-performance polymer /

- 3D printing

-

Overview

Overview: Additive manufacturing (AM) is a technology based on the principle of layer-by-layer manufacturing, which can be freely designed. Through point-by-point, line-by-line, and layer-by-layer manufacturing to construct complex parts such as polymers, metals, and ceramics, it is a new type of precise control of the microstructure of printing materials. Manufacturing technology, which reduces the product manufacturing cycle and cost from the design and manufacturing methods, has been rapidly developed and widely used in aerospace, optoelectronic engineering, microelectronics, and other fields. However, the 3D printed polymer complex products lack the strength and functions required by the bearing part, resulting in 3D printing technology and its polymer materials are still in the conceptual prototype and functional design stage. Therefore, this technology has limitations in the manufacturing technology and application fields of complex parts such as heat resistance and high strength. Then, high-performance 3D printing polymer materials with comprehensive properties such as high temperature resistance (> 100 ℃), high mechanical strength, high hardness, and high modulus at the top of the polymer material pyramid is developed to promote the development and application of 3D printing technology. At present, 3D printing technology can achieve complex intelligent finishing high-performance polymer materials including polyimide (PI), polyetherimide (PEI), polyether ether ketone (PEEK), polyphenylene sulfide (PPS), High-performance epoxy, etc.

Because of their rigid molecular structure, crystallinity, and molecular weight, these high-performance polymers endow them with extremely high heat resistance, high hardness, high mechanical properties, and high modulus, which cannot achieced by traditional processing methods. 3D printing can achieve high-precision, high-complexity, lightweight and miniaturized manufacturing and application of key components. The 3D printing manufacturing technology has "controllability" and the ability to directly form high-precision complex parts in one step, and has the advantages of short molding time, simplified molding equipment, material distribution on demand, and freedom of part design in the manufacture and application of high-precision, high-complexity, miniaturization and lightweight terminal parts. In addition, how to realize the 3D printing preparation and manufacturing of ultra-high-performance polymers has always been a research hotspot in this field and a problem need to be solved. Therefore, with regard to the current polymer 3D printing and application research, this article focuses on the polymer 3D printing technology and the 3D printing research and application of various high-performance polymer materials, and the preparation and application of 3D printing high-performance polymer materials. The development has been prospected, so as to provide new directions and ideas for the research, application and development of 3D printing high-performance polymer (HPP) materials.

-

-

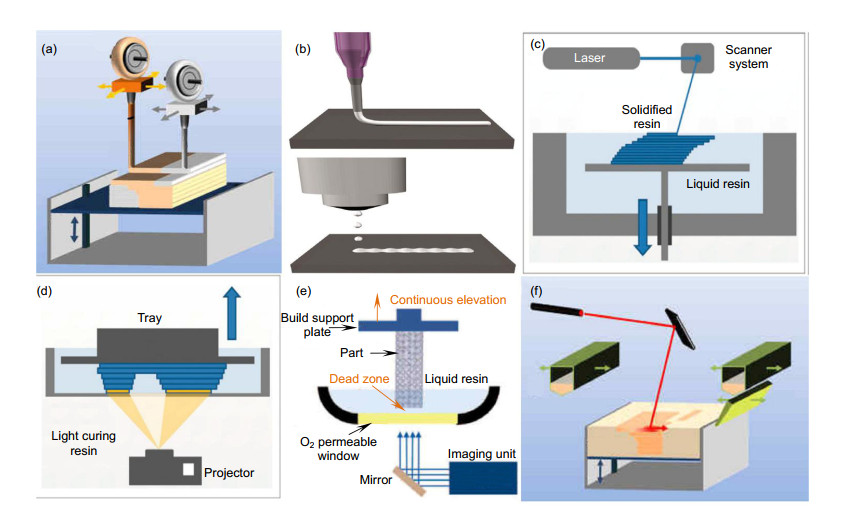

图 1 增材制造技术原理图。(a) 熔融沉积型3D打印(FDM)[12];(b) 墨水直书写(DIW)[17];(c) 立体光刻技术(SLA)[23];(d) 数字光处理技术(DLP)[23];(e) 连续液体界面提取技术(CLIP)[25];(f) 选择性激光烧结技术(SLS)[12]

Figure 1. Schematic diagram of additive manufacturing technology. (a) Fused deposition modeling (FDM)[12]; (b) Direct ink writing (DIW)[17]; (c) Stereo lithography (SLA)[23]; (d) Digital light processing technology (DLP)[23]; (e) Continuous liquid interface production technology (CLIP)[25]; (f) Selective laser sintering (SLS)[12]

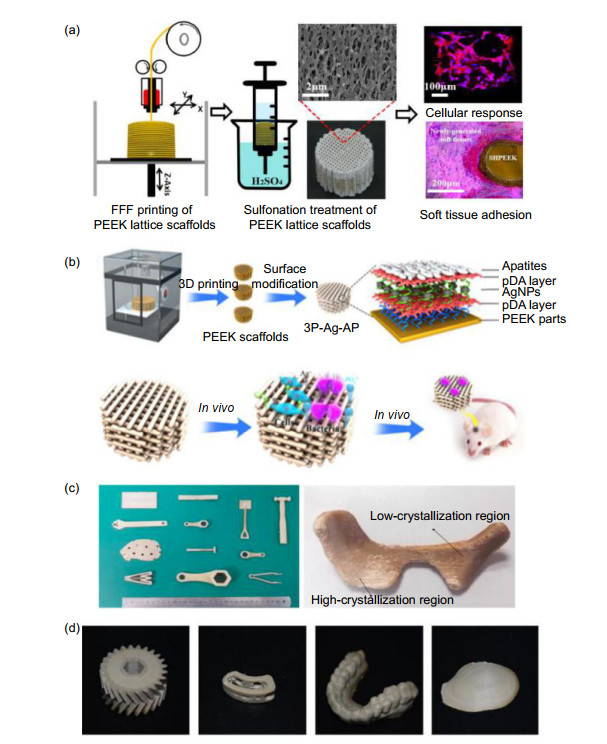

图 2 (a) FFF打印制造PEEK微孔结构晶格支架机制[30];(b) pH触发促骨型3P-Ag-AP-PEEK支架的3D打印制造机理[31];(c) 3D打印制造不同结晶度的可植入骨骼[33];(d) 改进高温FDM 3D打印系统成型的PEEK零件[34]

Figure 2. (a) FFF printing and manufacturing mechanism of PEEK microporous lattice scaffold[30]; (b) pH triggers the 3D printing manufacturing mechanism of the bone-promoting 3P-Ag-AP-PEEK scaffold[31]; (c) 3D printing to manufacture implantable bones with different crystallinity[33]; (d) Improve the PEEK parts formed by the high temperature FDM 3D printing system[34]

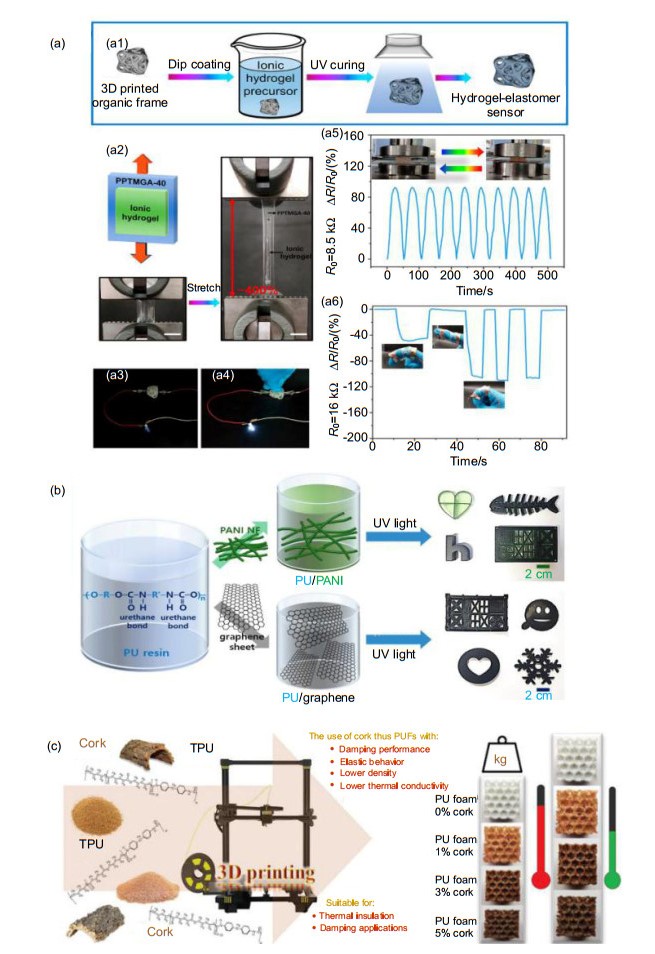

图 5 (a) 压阻应变传感器和可穿戴的手指防护传感器[49];(b) DLP打印具有不同形状的PU复合材料零件[50];(c) 3D打印软木颗粒增强热塑性聚氨酯(TPU)复合材料示意图[51]

Figure 5. (a) Piezoresistive strain sensor and wearable finger protection sensor[49]; (b) DLP printing PU composite parts with different shapes[50]; (c) Schematic diagram of 3D printed cork particle reinforced thermoplastic polyurethane (TPU) composites[51]

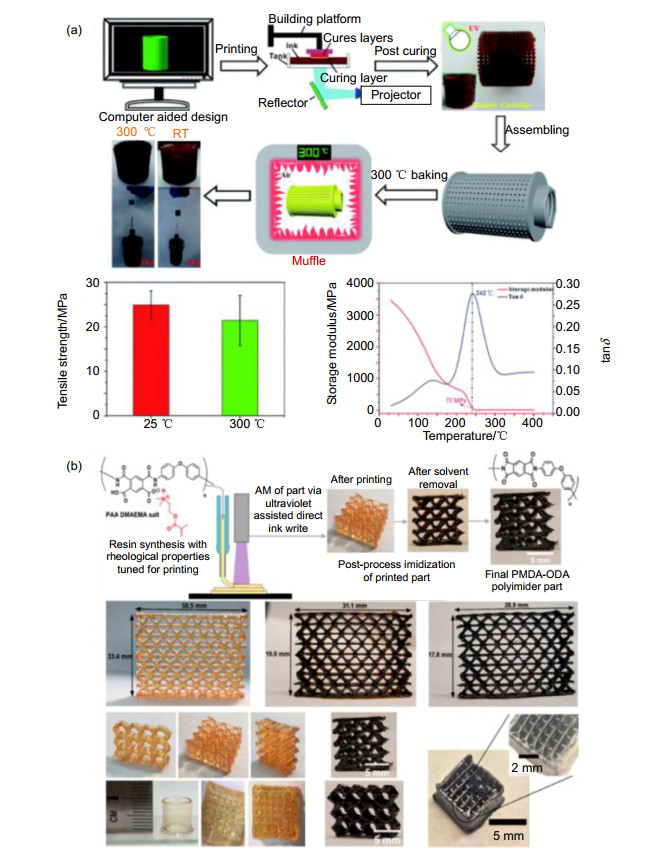

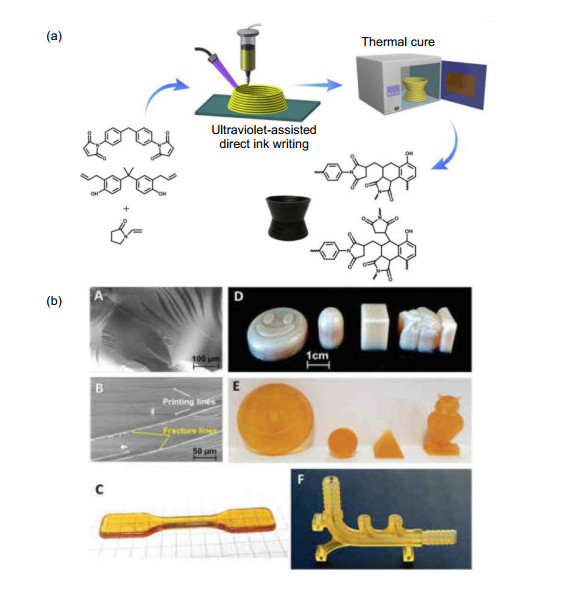

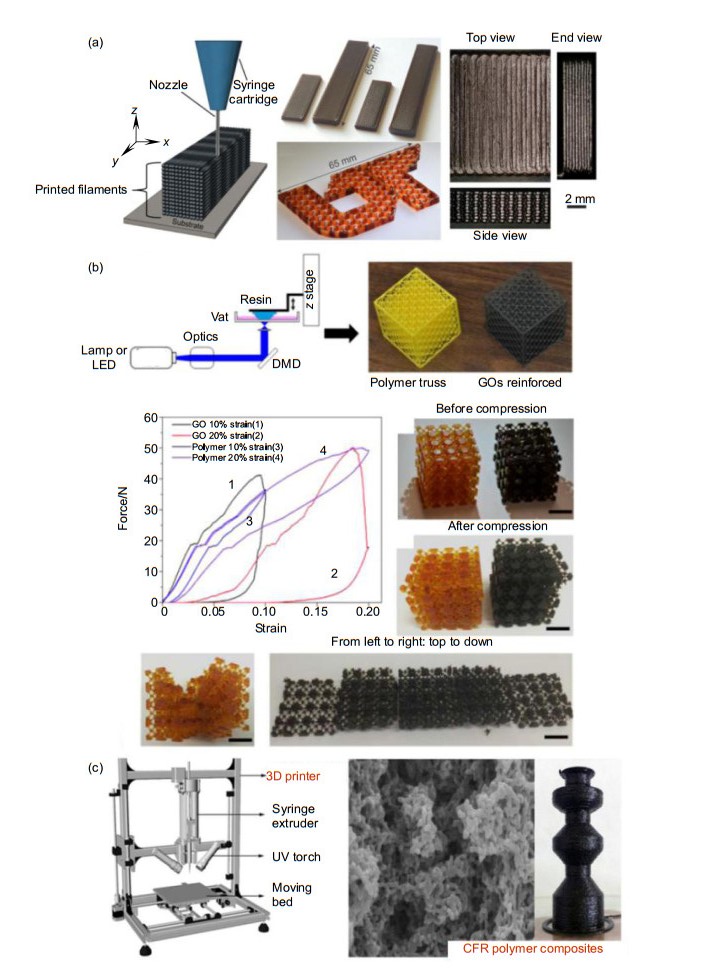

图 6 (a) Piezoresistive strain sensor and wearable finger protection sensor[49]; (b) DLP printing PU composite parts with different shapes[50]; (c) Schematic diagram of 3D printed cork particle reinforced thermoplastic polyurethane (TPU) composites[51]

Figure 6. (a) Schematic diagram of a rectangular sample printed with direct ink and optical micrographs of the horizontally flexed sample printed with a 12.5% by weight nanoclay ink formulation[53]; (b) 3D printing of GO reinforced polymer and compression test of its parts[54]; (c) Schematic diagram of UV-3D printing equipment and its printed sample structure[60]

表 1 各类聚合物3D打印技术优缺点及性能参数对比

Table 1. Comparison of parameters of 3D printing technologies based on polymer

技术类别 成型方式 成型精度/μm 成型尺寸 成型速度 适用材料 优点 缺点 SLA 激光扫描固化下成型技术 50~100 大 慢 光敏聚合物 成型精度高、成型尺寸大、表面质量佳 光敏树脂强度差 DLP 面曝光上成型技术 20~100 小 快 光敏聚合物 成型精度高、无溶剂体系且成型速度快 成型制件综合性能差、材料受限、应用受限 SLS 激光熔覆下成型技术 100~200 中 慢 热熔型聚合物 成型制件强度等综合性能优异,材料多 成型制件表面质量差、成本高、成型速度慢 FDM 热熔挤出堆积成型技术 200~500 小~大 较慢 热熔型聚合物 成熟度高、材料种类多、成型尺寸较灵活 表面精度差、性能不足、高端应用性欠缺 CLIP 连续面曝光上提拉成型技术 50~100 小 较快 光敏聚合物 高精度、高速度、高表面质量 稳定性差、材料受限、应用面窄、设备昂贵 DIW 流变控制直写堆积成型技术 100~500 小~大 中等 聚合物胶料或凝胶 材要求低、性能优异、设备简易 制件表面质量差、处在研究阶段、应用性差 -

参考文献

[1] Herzberger J, Sirrine J M, Williams C B, et al. Polymer design for 3D printing elastomers: recent advances in structure, properties, and printing[J]. Prog Polym Sci, 2019, 97: 101144. doi: 10.1016/j.progpolymsci.2019.101144

[2] Paolini A, Kollmannsberger S, Rank E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods[J]. Addit Manuf, 2019, 30: 100894.

[3] Chandrasekaran S, Duoss E B, Worsley M A, et al. 3D printing of high performance cyanate ester thermoset polymers[J]. J Mater Chem A, 2018, 6(3): 853-858. doi: 10.1039/C7TA09466C

[4] Turner B N, Gold S A. A review of melt extrusion additive manufacturing processes: Ⅱ. Materials, dimensional accuracy, and surface roughness[J]. Rapid Prototyp J, 2015, 21(3): 250-261. doi: 10.1108/RPJ-02-2013-0017

[5] Guo N N, Leu M C. Additive manufacturing: Technology, applications and research needs[J]. Front Mech Eng, 2013, 8(3): 215-243. doi: 10.1007/s11465-013-0248-8

[6] Frazier W E. Metal additive manufacturing: A review[J]. J Mater Eng Perform, 2014, 23(6): 1917-1928. doi: 10.1007/s11665-014-0958-z

[7] Chia H N, Wu B M. Recent advances in 3D printing of biomaterials[J]. J Biol Eng, 2015, 9: 4. doi: 10.1186/s13036-015-0001-4

[8] Melchels F P W, Feijen J, Grijpma D W. A review on stereolithography and its applications in biomedical engineering[J]. Biomaterials, 2010, 31(24): 6121-6130. doi: 10.1016/j.biomaterials.2010.04.050

[9] Gibson I, Shi D P. Material properties and fabrication parameters in selective laser sintering process[J]. Rapid Prototyp J, 1997, 3(4): 129-136. doi: 10.1108/13552549710191836

[10] Stansbury J W, Idacavage M J. 3D printing with polymers: Challenges among expanding options and opportunities[J]. Dent Mater, 2016, 32(1): 54-64. doi: 10.1016/j.dental.2015.09.018

[11] Kruth J P, Wang X, Laoui T, et al. Lasers and materials in selective laser sintering[J]. Assem Autom, 2003, 23(4): 357-371. doi: 10.1108/01445150310698652

[12] Ligon S C, Liska R, Stampfl J, et al. Polymers for 3D printing and customized additive manufacturing[J]. Chem Rev, 2017, 117(15): 10212-10290. doi: 10.1021/acs.chemrev.7b00074

[13] Narupai B, Nelson A. 100th anniversary of macromolecular science viewpoint: Macromolecular materials for additive manufacturing[J]. ACS Macro Lett, 2020, 9(5): 627-638. doi: 10.1021/acsmacrolett.0c00200

[14] Ang T H, Sultana F S A, Hutmacher D W, et al. Fabrication of 3D chitosan-hydroxyapatite scaffolds using a robotic dispensing system[J]. Mater Sci Eng, 2002, 20(1-2): 35-42. doi: 10.1016/S0928-4931(02)00010-3

[15] Landers R, Hübner U, Schmelzeisen R, et al. Rapid prototyping of scaffolds derived from thermoreversible hydrogels and tailored for applications in tissue engineering[J]. Biomaterials, 2002, 23(23): 4437-4447. doi: 10.1016/S0142-9612(02)00139-4

[16] Oh C H, Hong S J, Jeong I, et al. Development of robotic dispensed bioactive scaffolds and human adipose-derived stem cell culturing for bone tissue engineering[J]. Tissue Eng Part C Methods, 2010, 16(4): 561-571. doi: 10.1089/ten.tec.2009.0274

[17] Lewis J A. Direct-write assembly of ceramics from colloidal inks[J]. Curr Opin Solid State Mater Sci, 2002, 6(3): 245-250. doi: 10.1016/S1359-0286(02)00031-1

[18] Raney J R, Compton B G, Mueller J, et al. Rotational 3D printing of damage-tolerant composites with programmable mechanics[J]. Proc Natl Acad Sci USA, 2018, 115(6): 1198-1203. doi: 10.1073/pnas.1715157115

[19] Kotikian A, Truby R L, Boley J W, et al. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order[J]. Adv Mater, 2018, 30(10): 1706164. doi: 10.1002/adma.201706164

[20] Bagheri A, Jin J Y. Photopolymerization in 3D printing[J]. ACS Appl Polym Mater, 2019, 1(4): 593-611. doi: 10.1021/acsapm.8b00165

[21] Chatani S, Kloxin C J, Bowman C N, et al. The power of light in polymer science: Photochemical processes to manipulate polymer formation, structure, and properties[J]. Polym Chem, 2014, 5(7): 2187-2201. doi: 10.1039/C3PY01334K

[22] Jin J, Yang J F, Mao H C, et al. A vibration-assisted method to reduce separation force for stereolithography[J]. J Manuf Process, 2018, 34: 793-801. doi: 10.1016/j.jmapro.2018.03.052

[23] Kim G B, Lee S, Kim H, et al. Three-dimensional printing: Basic principles and applications in medicine and radiology[J]. Korean J Radiol, 2016, 17(2): 182-197. doi: 10.3348/kjr.2016.17.2.182

[24] Gross B C, Erkal J L, Lockwood S Y, et al. Evaluation of 3D printing and its potential impact on biotechnology and the chemical sciences[J]. Anal Chem, 2014, 86(7): 3240-3253. doi: 10.1021/ac403397r

[25] Tumbleston J R, Shirvanyants D, Ermoshkin N, et al. Continuous liquid interface production of 3D objects[J]. Science, 2015, 347(6228): 1349-1352. doi: 10.1126/science.aaa2397

[26] Liska R, Schuster M, Inführ R, et al. Photopolymers for rapid prototyping[J]. J Coat Technol Res, 2007, 4(4): 505-510. doi: 10.1007/s11998-007-9059-3

[27] Fortney A, Fossum E. Soluble, semi-crystalline PEEK analogs based on 3, 5-difluorobenzophenone: Synthesis and characterization[J]. Polymer, 2012, 53(12): 2327-2333. doi: 10.1016/j.polymer.2012.03.056

[28] Elhattab K, Sikder P, Walker J M, et al. Fabrication and evaluation of 3-D printed PEEK scaffolds containing Macropores by design[J]. Mater Lett, 2020, 263: 127227. doi: 10.1016/j.matlet.2019.127227

[29] Feng P, Wu P, Gao C D, et al. A multimaterial scaffold with tunable properties: toward bone tissue repair[J]. Adv Sci, 2018, 5(6): 1700817. doi: 10.1002/advs.201700817

[30] Su Y W, He J K, Jiang N, et al. Additively-manufactured poly-ether-ether-ketone (PEEK) lattice scaffolds with uniform microporous architectures for enhanced cellular response and soft tissue adhesion[J]. Mater Des, 2020, 191: 108671. doi: 10.1016/j.matdes.2020.108671

[31] Deng Y, Shi X Y, Chen Y, et al. Bacteria-triggered pH-responsive osteopotentiating coating on 3D-printed polyetheretherketone scaffolds for infective bone defect repair[J]. Ind Eng Chem Res, 2020, 59(26): 12123-12135. doi: 10.1021/acs.iecr.0c02107

[32] Zalaznik M, Kalin M, Novak S. Influence of the processing temperature on the tribological and mechanical properties of poly-ether-ether-ketone (PEEK) polymer[J]. Tribol Int, 2016, 94: 92-97. doi: 10.1016/j.triboint.2015.08.016

[33] Yang C C, Tian X Y, Li D C, et al. Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of PEEK material[J]. J Mater Process Technol, 2017, 248: 1-7. doi: 10.1016/j.jmatprotec.2017.04.027

[34] Hu B, Duan X B, Xing Z H, et al. Improved design of fused deposition modeling equipment for 3D printing of high-performance PEEK parts[J]. Mech Mater, 2019, 137: 103139. doi: 10.1016/j.mechmat.2019.103139

[35] Zheng J B, Kang J F, Sun C N, et al. Effects of printing path and material components on mechanical properties of 3D-printed polyether-ether-ketone/hydroxyapatite composites[J]. J Mech Behav Biomed Mater, 2021, 118: 104475. doi: 10.1016/j.jmbbm.2021.104475

[36] Yaragalla S, Zahid M, Panda J K, et al. Comprehensive enhancement in thermomechanical performance of melt-extruded PEEK filaments by Graphene incorporation[J]. Polymers, 2021, 13(9): 1425. doi: 10.3390/polym13091425

[37] Guo Y X, Ji Z Y, Zhang Y, et al. Solvent-free and photocurable polyimide inks for 3D printing[J]. J Mater Chem A, 2017, 5(31): 16307-16314. doi: 10.1039/C7TA01952A

[38] Hegde M, Meenakshisundaram V, Chartrain N, et al. 3D printing all-aromatic polyimides using mask-projection stereolithography: processing the nonprocessable[J]. Adv Mater, 2017, 29(31): 1701240. doi: 10.1002/adma.201701240

[39] Zhang F, Tuck C, Hague R, et al. Inkjet printing of polyimide insulators for the 3D printing of dielectric materials for microelectronic applications[J]. J Appl Polym Sci, 2016, 133(18): 43361.

[40] Herzberger J, Meenakshisundaram V, Williams C B, et al. 3D printing all-aromatic polyimides using stereolithographic 3D printing of polyamic acid salts[J]. ACS Macro Lett, 2018, 7(4): 493-497. doi: 10.1021/acsmacrolett.8b00126

[41] Guo Y X, Xu J W, Yan C Y, et al. Direct ink writing of high performance architectured polyimides with low dimensional shrinkage[J]. Adv Eng Mater, 2019, 21(5): 1801314. doi: 10.1002/adem.201801314

[42] Qin S Y, Jiang Y, Ji Z Y, et al. Three-dimensional printing of high-performance polyimide by direct ink writing of hydrogel precursor[J]. J Appl Polym Sci, 2021, 138(27): 50636. doi: 10.1002/app.50636

[43] Wang C Y, Ma S Q, Li D D, et al. 3D printing of lightweight polyimide honeycombs with the high specific strength and temperature resistance[J]. ACS Appl Mater Interfaces, 2021, 13(13): 15690-15700. doi: 10.1021/acsami.1c01992

[44] Jiang S L, Liao G X, Xu D D, et al. Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling[J]. High Perform Polym, 2019, 31(1): 97-106. doi: 10.1177/0954008317752822

[45] Wu T, Jiang P, Zhang X Q, et al. Additively manufacturing high-performance bismaleimide architectures with ultraviolet-assisted direct ink writing[J]. Mater Des, 2019, 180: 107947. doi: 10.1016/j.matdes.2019.107947

[46] Gouzman I, Atar N, Grossman E, et al. 3D printing of bismaleimides: from new ink formulation to printed thermosetting polymer objects[J]. Adv Mater Technol, 2019, 4(10): 1900368. doi: 10.1002/admt.201900368

[47] Gan X P, Wang J Z, Wang Z H, et al. Simultaneous realization of conductive segregation network microstructure and minimal surface porous macrostructure by SLS 3D printing[J]. Mater Des, 2019, 178: 107874. doi: 10.1016/j.matdes.2019.107874

[48] Sun S J, Gan X P, Wang Z H, et al. Dynamic healable polyurethane for selective laser sintering[J]. Addit Manuf, 2020, 33: 101176.

[49] Peng S Q, Li Y W, Wu L X, et al. 3D printing mechanically robust and transparent polyurethane elastomers for stretchable electronic sensors[J]. ACS Appl Mater Interfaces, 2020, 12(5): 6479-6488. doi: 10.1021/acsami.9b20631

[50] Joo H, Cho S. Comparative studies on polyurethane composites filled with polyaniline and graphene for DLP-Type 3D printing[J]. Polymers, 2020, 12(1): 67. doi: 10.3390/polym12010067

[51] Gama N, Ferreira A, Barros-Timmons A. 3D printed cork/polyurethane composite foams[J]. Mater Des, 2019, 179: 107905. doi: 10.1016/j.matdes.2019.107905

[52] Wang R M, Zheng S R, Zheng Y P. 3-Matrix materials[M]//Wang R M, Zheng S R, Zheng Y P. Polymer Matrix Composites and Technology. Cambridge: Woodhead Publishing, 2011: 101-548.

[53] Hmeidat N S, Kemp J W, Compton B G. High-strength epoxy nanocomposites for 3D printing[J]. Compos Sci Technol, 2018, 160: 9-20. doi: 10.1016/j.compscitech.2018.03.008

[54] Lin D, Jin S Y, Zhang F, et al. 3D stereolithography printing of graphene oxide reinforced complex architectures[J]. Nanotechnology, 2015, 26(43): 434003. doi: 10.1088/0957-4484/26/43/434003

[55] Park G T, Lee S J, Kim B G, et al. High thermally conductive epoxy composite inks cured by infrared laser irradiation for two-dimensional/three-dimensional printing technology[J]. J Compos Mater, 2020, 54(29): 4635-4643. doi: 10.1177/0021998320935154

[56] Liu L, Ying G B, Wen D, et al. Aqueous solution-processed MXene (Ti3C2Tx) for non-hydrophilic epoxy resin-based composites with enhanced mechanical and physical properties[J]. Mater Des, 2021, 197: 109276. doi: 10.1016/j.matdes.2020.109276

[57] Jiang Q X, Zhang H G, Rusakov D, et al. Additive manufactured carbon nanotube/epoxy nanocomposites for heavy-duty applications[J]. ACS Appl Polym Mater, 2021, 3(1): 93-97. doi: 10.1021/acsapm.0c01011

[58] Mei H, Ali Z, Yan Y K, et al. Influence of mixed isotropic fiber angles and hot press on the mechanical properties of 3D printed composites[J]. Addit Manuf, 2019, 27: 150-158.

[59] Compton B G, Lewis J A. 3D-printing of lightweight cellular composites[J]. Adv Mater, 2014, 26(34): 5930-5935. doi: 10.1002/adma.201401804

[60] Griffini G, Invernizzi M, Levi M, et al. 3D-printable CFR polymer composites with dual-cure sequential IPNs[J]. Polymer, 2016, 91: 174-179. doi: 10.1016/j.polymer.2016.03.048

[61] Hao W F, Liu Y, Zhou H, et al. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites[J]. Polym Test, 2018, 65: 29-34. doi: 10.1016/j.polymertesting.2017.11.004

[62] Sano Y, Matsuzaki R, Ueda M, et al. 3D printing of discontinuous and continuous fibre composites using stereolithography[J]. Addit Manuf, 2018, 24: 521-527.

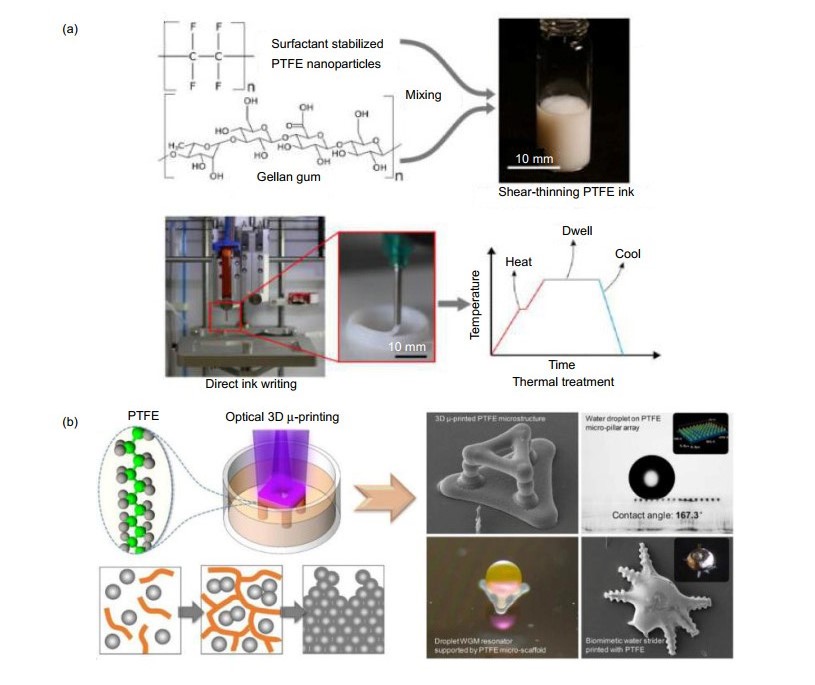

[63] Jiang Z R, Erol O, Chatterjee D, et al. Direct ink writing of Poly(tetrafluoroethylene) (PTFE) with tunable mechanical properties[J]. ACS Appl Mater Interfaces, 2019, 11(31): 28289-28295. doi: 10.1021/acsami.9b07279

[64] Zhang Y X, Yin M J, Ouyang X, et al. 3D μ-printing of polytetrafluoroethylene microstructures: A route to superhydrophobic surfaces and devices[J]. Appl Mater Today, 2020, 19: 100580. doi: 10.1016/j.apmt.2020.100580

[65] Wu T, Jiang P, Ji Z Y, et al. 3D printing of high-performance isocyanate ester thermosets[J]. Macromol Mater Eng, 2020, 305: 2000397. doi: 10.1002/mame.202000397

[66] Lu Y, Ng K W J, Chen H, et al. The molecular design of photo-curable and high-strength benzoxazine for 3D printing[J]. Chem Commun, 2021, 57(27): 3375-3378. doi: 10.1039/D0CC07801H

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: