Micro/Nano profile measurement by structured illumination microscopy utilizing time-domain phase-shift technique

-

摘要:

针对微纳器件三维形貌快速检测及重构中的高精度和高速度难以兼得的技术难题,本文提出一种基于时域相移技术的结构光检测方法,通过空间光调制器对测量光进行调制,结合时域相移技术实现微纳器件三维形貌检测和重构。相比传统的结构光检测方法,本技术在样片轴向扫描的同时,利用空间光调制器进行相移测量,保证测量精度的同时提高测量的效率。通过对测量数据进行分析,该方法可快速实现三维形貌检测和重构,测量精度可优于10 nm。

Abstract:

Abstract:Aiming at the technical difficulties in the rapid detection and reconstruction of three-dimensional micro-nano devices that are difficult to achieve both high precision and high speed, this paper proposes a structured light detection method based on time-domain phase shift technology. The measured light is modulated by a spatial light modulator, and the time-domain phase shift technology is further employed to realize the detection and reconstruction of three-dimensional micro-nano devices. Compared with the traditional structured light detection method, this technology uses the spatial light modulator to measure the phase shift while the sample is scanned axially, so as to ensure the measurement accuracy and improve the measurement efficiency. By analyzing the measurement data, this method can quickly realize three-dimensional shape detection and reconstruction, and the measurement accuracy can be better than 10 nm.

-

Key words:

- profile measurement /

- micro/nano measurement /

- phase-shift /

- structured illumination

-

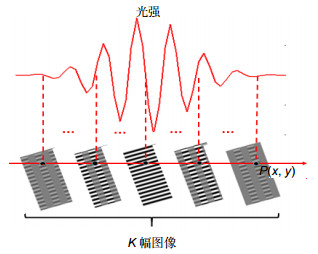

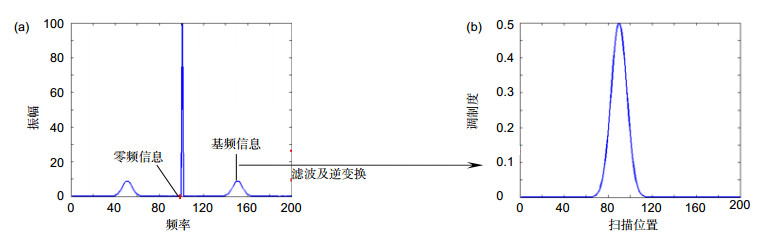

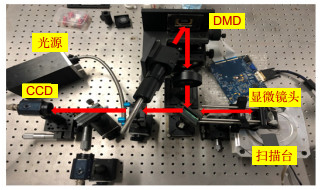

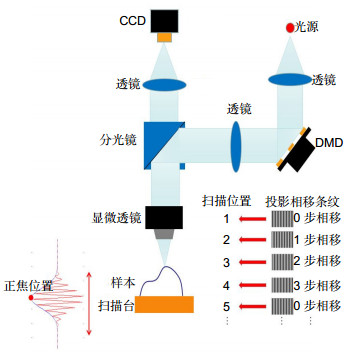

Overview: With the wide application of micro/nanostructures and the rapid development of a micro/nano technique, micro/nano measurement technologies continue to innovate to satisfy increasing needs for a micro/nano optical measurement method, which is widely used in manufacturing, material science, biology, and other fields. The existing micro/nano optical measurement approaches mainly include the laser confocal method, a white light interferometry, and a structured illumination microscopy (SIM). Aiming at the technical difficulties in the rapid detection and reconstruction of three-dimensional micro-nano devices that are difficult to achieve both high precision and high speed, this paper proposes a structured light detection method based on time-domain phase shift technology. The detection and reconstruction of three-dimensional micro-nano devices are realized combined with time-domain phase shift technology. The measurement system is composed of a light source, a digital mirror device (DMD), a microscope and a CCD sensor. The phase of space light from illumination is modulated by the DMD and the special structural light is vertically illuminated onto the micro-nano devices under testing. The reflexed rays from micro-nano devices under testing are detect by the CCD sensor. The innovation of this method is that the micro-nano devices under testing are drive by a piezo transformer (PZT), measuring rays is modulated by DMD and the height information is tested. The basic principle of SIM is to project a set of sinusoidal grating fringes generated by the DMD onto the sample. While the sample is scanned vertically, the modulation of the image keeps changing, which can be extracted by a modulation decoding algorithm. Theoretically, the peak position of the modulation curve coincides with the focus position and the exact peak position can be obtained by Gaussian curve fitting. Afterward, a 3D shape of the object can be restored by acquiring the exact focus position of each pixel. Compared with the traditional structured light detection method, this technology uses the spatial light modulator to measure the phase shift while the sample is scanned axially, so as to ensure the measurement accuracy and improve the measurement efficiency. By analyzing the measurement data, this method can quickly realize three-dimensional shape detection and reconstruction, and the measurement accuracy can be better than 10 nm. After all, this method can enable a simpler measurement system, faster measurement speed, and better adaptability, because only one fringe pattern is projected at each scanning step and a Fourier transform method based on local analysis is applied to extract the modulation curve. To verify the performance of the proposed method, simulations and experiments have been carried out.

-

-

-

[1] Abdel-Aal H A. Functional surfaces for tribological applications: inspiration and design[J]. Surf Topogr Metrol Prop, 2016, 4(4): 043001. doi: 10.1088/2051-672X/4/4/043001

[2] Dan D, Yao B L, Lei M. Structured illumination microscopy for super-resolution and optical sectioning[J]. Chin Sci Bull, 2014, 59(12): 1291-1307. doi: 10.1007/s11434-014-0181-1

[3] 张雨东, 骆清铭. 超高分辨、高灵敏光学检测方法与技术[J]. 中国科学: 信息科学, 2016, 46(8): 1136-1155. https://www.cnki.com.cn/Article/CJFDTOTAL-PZKX201608011.htm

Zhang Y D, Luo Q M. Ultrahigh-resolution and high-sensitive optical detection methods and technologies[J]. Sci China Inf Sci, 2016, 46(8): 1136-1155. https://www.cnki.com.cn/Article/CJFDTOTAL-PZKX201608011.htm

[4] 王华东, 张泰华. 光学材料亚表面损伤的表征与检测技术的研究进展[J]. 激光与光电子学进展, 2017, 54(10): 100003. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201710003.htm

Wang H D, Zhang T H. Research progresses on characterization and detection technology of subsurface damages in optical materials[J]. Laser Optoelectron Prog, 2017, 54(10): 100003. https://www.cnki.com.cn/Article/CJFDTOTAL-JGDJ201710003.htm

[5] Müller F A, Kunz C, Gräf S. Bio-inspired functional surfaces based on laser-induced periodic surface structures[J]. Materials, 2016, 9(6): 476. doi: 10.3390/ma9060476

[6] O'Connor T, Doblas A, Javidi B. Overview of compact and field-portable system for resolution enhanced digital holographic microscopy by structured illumination[C]//OSA Imaging and Applied Optics Congress, 2020.

[7] Manton J D, Ströhl F, Fiolka R, et al. Concepts for structured illumination microscopy with extended axial resolution through mirrored illumination[J]. Biomed Opt Express, 2020, 11(4): 2098-2108. doi: 10.1364/BOE.382398

[8] Chen X Y, Zhanghao K, Li M Q, et al. Enhanced reconstruction of structured illumination microscopy on a polarized specimen[J]. Opt Express, 2020, 28(17): 25642-25654. doi: 10.1364/OE.395092

[9] Xie Z Y, Tang Y, Zhou Y, et al. Surface and thickness measurement of transparent thin-film layers utilizing modulation-based structured-illumination microscopy[J]. Opt Express, 2018, 26(3): 2944-2953. doi: 10.1364/OE.26.002944

[10] Tu S J, Liu Q L, Liu X, et al. Fast reconstruction algorithm for structured illumination microscopy[J]. Opt Lett, 2020, 45(6): 1567-1570. doi: 10.1364/OL.387888

[11] Ling C, Zhang C L, Wang M Q, et al. Fast structured illumination microscopy via deep learning[J]. Photonics Res, 2020, 8(8): 1350-1359. doi: 10.1364/PRJ.396122

[12] Wang Z J, Cai Y N, Qian J, et al. Hybrid multifocal structured illumination microscopy with enhanced lateral resolution and axial localization capability[J]. Biomed Opt Express, 2020, 11(6): 3058-3070. doi: 10.1364/BOE.391024

[13] Zhong M, Su X Y, Chen W J, et al. Modulation measuring profilometry with auto-synchronous phase shifting and vertical scanning[J]. Opt Express, 2014, 22(26): 31620-31634. doi: 10.1364/OE.22.031620

[14] Bezzubik V V, Belashenkov N R, Vasilyev V N, et al. Optimization-based image reconstruction method for super-resolution structured-illumination microscopy[J]. J Opt Technol, 2019, 86(12): 748-757. doi: 10.1364/JOT.86.000748

[15] Zuo C, Feng S J, Huang L, et al. Phase shifting algorithms for fringe projection profilometry: a review[J]. Opt Lasers Eng, 2018, 109: 23-59. doi: 10.1016/j.optlaseng.2018.04.019

[16] Patorski K, Trusiak M, Tkaczyk T. Optically-sectioned two-shot structured illumination microscopy with Hilbert-Huang processing[J]. Opt Express, 2014, 22(8): 9517-9527. doi: 10.1364/OE.22.009517

[17] Zhang W, Yu B, Lin D Y, et al. Optimized approach for optical sectioning enhancement in multifocal structured illumination microscopy[J]. Opt Express, 2020, 28(8): 10919-10927. doi: 10.1364/OE.390831

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: