-

摘要

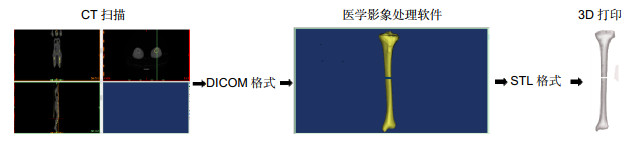

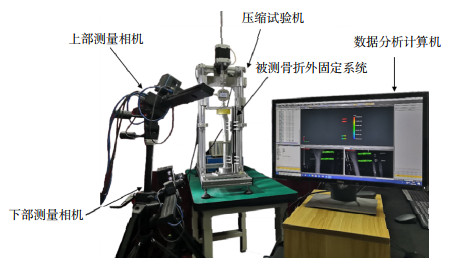

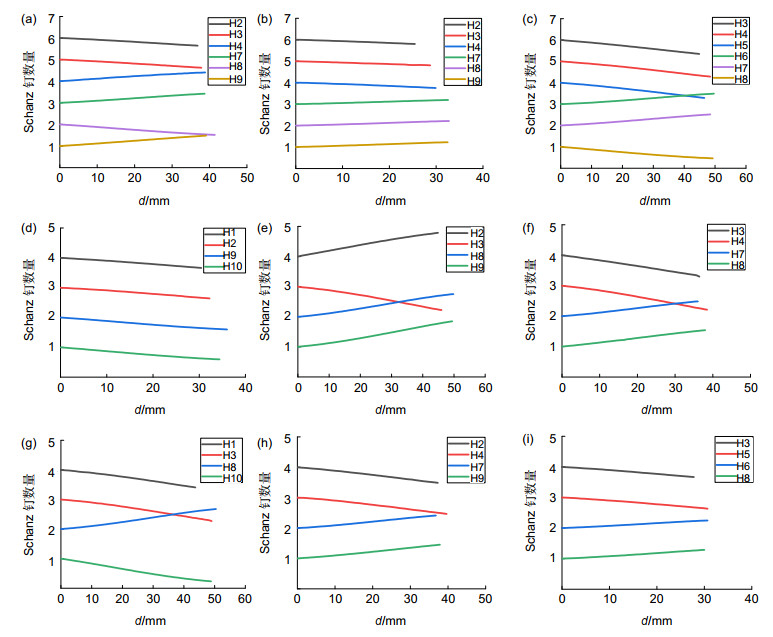

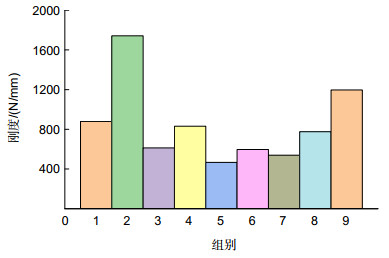

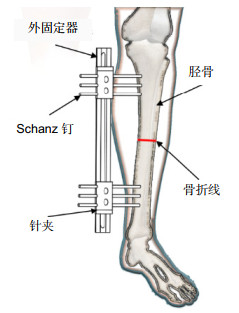

利用逆向工程与3D打印技术定制了患者的胫骨干骨折模型,对Orthofix单边外固定器固定胫骨干骨折方式的生物力学进行了研究。通过设计正交试验方案,采用XTDIC三维全场变形测量系统对Schanz钉在针夹上的分布、最外侧Schanz钉到骨折断端的距离、胫骨到外固定器的距离三种因素对Schanz钉的变形进行了测量。实验结果表明:当Schanz钉数量较少时,在压力载荷作用下会造成Schanz钉的弯曲变形增大,增加了外固定器塑性变形及疲劳断裂的可能性。根据综合九种方案的力学分析结果,外固定器到胫骨的距离对Schanz钉的变形影响最显著。当在针夹上安装6根Schanz钉,外侧Schanz钉到骨折断端的距离为120 mm和外固定器到胫骨的距离为30 mm时的方案综合性能最优。

Abstract

The tibial shaft fracture model was customized by reverse engineering and 3D printing technology, and the biomechanics of the Orthofix Unilateral External Fixator for tibial shaft fracture was studied. Through the design of an orthogonal experiment scheme, the distribution of the Schanz's nails on the clamp, the distance from the lateral the Schanz's nails to the fracture end, and the distance from the tibia to the external fixture were measured by the XTDIC-CONST 3D Full-Field Strain Measurement and Analysis System. The experimental results show that when the number of the Schanz's nails decreased, the bending deformation of the Schanz's nails will increase from pressure load, which increases the possibility of plastic deformation and fatigue fracture of the external fixator. According to the mechanical analysis results of the nine schemes, the distance from the external fixture to the tibia has the most significant effect on the deformation of the Schanz nail. When installing six Schanz pins in the clip, the distance from the lateral Schanz's nail to the fracture end is 120 mm, and the distance from the external fixture to the tibia is 30 mm. The comprehensive performance of the scheme is the best.

-

Key words:

- 3D printing /

- external fixation /

- orthogonal experiment /

- biomechanics

-

Overview

Overview: The combination of 3D printing technology and medical treatment has excellent application prospects in auxiliary surgery, personalized medical devices, tissue engineering, medical education, and basic scientific research, especially in orthopedics, which has received more and more attention and application research. The external fixture is an effective treatment for the fracture. Different patients have different external fixation parameters due to different fracture locations. The implantation effect of external fixations is not ideal, which may bring the risk of the secondary operation. Therefore, a detailed and appropriate preoperative surgical plan is particularly important. With the wide application of 3D printing technology in orthopedics, preoperative biomechanical analysis of customized medicine has become a research hotspot.

Doctors usually choose the type of external fixation, the location of the installation, and the number of Schanz's nails according to their experience. When the fixation scheme is unreasonable, it will cause poor stability of external fixations and even lead to the fracture of Schanz's nail. In this paper, a biomechanical study was conducted on the parameters of external fixation for a patient with a tibial fracture, in order to finding a more reasonable fixation scheme, providing the basis of doctors to formulate the operation plan, reducing the operation time, and relieving the pain of patients.

The 1:1 tibial fracture model of patients with fracture was reconstructed by combining reverse engineering and 3D printing technology, which could be simulated more accurately according to the patient's situation. Through the design of the orthogonal experiment, the external fixation system was loaded with 0 N to 370 N for 5 times on a self-made compression testing machine. The deformation of the external fixture was measured by XTDIC-CONST 3D Full-Field Strain Measurement and Analysis System, including the distribution of Schanz's nail on the pin clamp, the distance from the outermost Schanz's nail to the fracture end, and the distance from the tibia to the external fixture.

According to the mechanical analysis results of the nine schemes, the 3D printing customized tibial fracture model is helpful to formulate a personalized treatment plan according to the patient's condition more accurately. The distance from the external fixture to the tibia has the most significant influence on the deformation of Schanz's nail. When installing six Schanz pins in the clip, the distance from the lateral Schanz's nail to the fracture end is 120 mm, and the distance from the external fixture to the tibia is 30 mm, and the stiffness of the external fixture is the largest.

-

-

表 1 因素与水平表

Table 1. Factor and level table

水平 因素A 因素B/mm 因素C/mm 1 1、2、3 100 40 2 1、2 120 30 3 1、3 140 50 表 2 正交试验表

Table 2. Orthogonal test table

胫骨骨折模型孔的布局示意图 试验编号 因素 H1 H2 H3 H4 H5 H6 H7 H8 H9 H10 A B C

1 A1 B1 C1 ● ● ● ● ● ● 2 A1 B2 C2 ● ● ● ● ● ● 3 A1 B3 C3 ● ● ● ● ● ● 4 A2 B1 C2 ● ● ● ● 5 A2 B2 C3 ● ● ● ●

6 A2 B3 C1 ● ● ● ● 7 A3 B1 C3 ● ● ● ● 8 A3 B2 C1 ● ● ● ● 9 A3 B3 C2 ● ● ● ● 表 3 各试验组Schanz钉的变形量

Table 3. Deformation of Schanz's nail in each experimental group

试验方案 Schanz钉的变形量/mm A1B1C1 0.42±0.03 A1B2C2 0.21±0.02 A1B3C3 0.60±0.06 A2B1C2 0.44±0.01 A2B2C3 0.79±0.11 A2B3C1 0.62±0.07 A3B1C3 0.69±0.21 A3B2C1 0.48±0.05 A3B3C2 0.31±0.06 表 4 变形量直观分析表

Table 4. Intuitive analysis table of deformation

实验结果分析 因素 A B C K1 1.2367 1.5517 1.5171 K2 1.8568 1.4817 0.9667 K3 1.4721 1.5322 2.0818 极差R 0.2067 0.0233 0.3717 因素主次 C A B 最优方案 A1 B2 C2 表 5 实验结果变形量数据方差分析表

Table 5. Analysis of variance table of experimental results deformation data

差异源 Ⅲ型平方和SS 自由度df 均方MS F值 显著性 因素A 0.0653 2 0.0327 5689.2903 0.00018 因素B 0.0009 2 0.0004 75.7741 0.013 因素C 0.2073 2 0.1036 18049.8767 0.00006 误差 1.148E-5 2 5.741E-6 总计 0.2735 8 -

参考文献

[1] 卢秉恒, 李涤尘. 增材制造(3D打印)技术发展[J]. 机械制造与自动化, 2013, 42(4): 1-4. doi: 10.3969/j.issn.1671-5276.2013.04.001

Lu B H, Li D C. Development of the additive manufacturing (3D printing)technology[J]. Mach Build Autom, 2013, 42(4): 1-4. doi: 10.3969/j.issn.1671-5276.2013.04.001

[2] 邓滨, 欧阳汉斌, 黄文华. 3D打印在医学领域的应用进展[J]. 中国医学物理学杂志, 2016, 33(4): 389-392. doi: 10.3969/j.issn.1005-202X.2016.04.014

Deng B, Ouyang H B, Huang W H. Application progress of three-dimensional printing in medical field[J]. Chin J Med Phys, 2016, 33(4): 389-392. doi: 10.3969/j.issn.1005-202X.2016.04.014

[3] 阿依古丽·喀斯木. 3D打印技术在骨科手术辅助中的应用研究[D]. 乌鲁木齐: 新疆大学, 2017.

Application of 3D printing technology in the orthopedic surgery assist[D]. Urumqi: Xinjiang University, 2017.

[4] 蒋明辉, 蔡立宏, 雷青, 等. 3D打印技术在骨科临床的应用研究及展望[J]. 中华损伤与修复杂志(电子版), 2016, 11(4): 288-290. doi: 10.3877/cma.j.issn.1673-9450.2016.04.011

Jiang M H, Cai L H, Lei Q, et al. Application research and prospect of 3D printing technology in department of orthopedics[J]. Chin J Inj Repair Wound Heal (Electron Ed), 2016, 11(4): 288-290. doi: 10.3877/cma.j.issn.1673-9450.2016.04.011

[5] 王燎, 戴尅戎. 骨科个体化治疗与3D打印技术[J]. 医用生物力学, 2014, 29(3): 193-199. https://www.cnki.com.cn/Article/CJFDTOTAL-YISX201403001.htm

Wang L, Dai K R. Individualized treatment of orthopaedics and 3D printing technology[J]. J Med Biomech, 2014, 29(3): 193-199. https://www.cnki.com.cn/Article/CJFDTOTAL-YISX201403001.htm

[6] Lowenberg D W, Githens M, Boone C. Principles of tibial fracture management with circular external fixation[J]. Orthop Clin North Am, 2014, 45(2): 191-206. doi: 10.1016/j.ocl.2013.11.003

[7] Emami A, Mjöberg B, Karlström G, et al. Treatment of closed tibial shaft fractures with unilateral external fixation[J]. Injury, 1995, 26(5): 299-303. doi: 10.1016/0020-1383(95)00037-A

[8] Stoffel K, Dieter U, Stachowiak G, et al. Biomechanical testing of the LCP--how can stability in locked internal fixators be controlled?[J]. Injury, 2003, 34(S2): B11-B19. doi: 10.1016/j.injury.2003.09.021

[9] Kouassi K J E, Cartiaux O, Fonkoué L, et al. Biomechanical study of a low-cost external fixator for diaphyseal fractures of long bones[J]. J Orthop Surg Res, 2020, 15(1): 247. doi: 10.1186/s13018-020-01777-5

[10] Shi D, Liu K Y, Zhang H M, et al. Investigating the biomechanical function of the plate-type external fixator in the treatment of tibial fractures: a biomechanical study[J]. BMC Musculoskelet Disord, 2020, 21(1): 128. doi: 10.1186/s12891-020-3144-5

[11] Moazen M, Calder P, Koroma P, et al. An experimental evaluation of fracture movement in two alternative tibial fracture fixation models using a vibrating platform[J]. Proc Inst Mech Eng Part H, 2019, 233(5): 595-599. doi: 10.1177/0954411919837304

[12] 阿孜古丽·克热木, 乌日开西·艾依提, 滕勇. 接骨板固定股骨干骨折的有限元分析[J]. 机械设计与制造, 2020(9): 172-175. doi: 10.3969/j.issn.1001-3997.2020.09.041

Keremu A, Aiyiti W, Teng Y. Finite element analysis of bone plate fixation for femoral shaft fracture[J]. Mach Des Manuf, 2020(9): 172-175. doi: 10.3969/j.issn.1001-3997.2020.09.041

[13] 张剑锋. 3D打印组配式节段型人工假体重建骨干缺损的实验研究[D]. 天津: 天津医科大学, 2019.

Zhang J F. Experimental study on reconstruction of diaphyseal defect with 3D-printing modular intercalary endoprosthesis[D]. Tianjin: Tianjin Medical University, 2019.

[14] Gao F Y, Wang Q, Liu C X, et al. Individualized 3D printed model-assisted posterior screw fixation for the treatment of craniovertebral junction abnormality: a retrospective study[J]. J Neurosurg: Spine, 2017, 27(1): 29-34. doi: 10.3171/2016.11.SPINE16713

[15] Li L, Yang L F, Yu F, et al. 3D printing individualized heel cup for improving the self-reported pain of plantar fasciitis[J]. J Transl Med, 2018, 16(1): 167. doi: 10.1186/s12967-018-1547-y

[16] 刘豫新. 锁定钢板工作长度对股骨干骨折力学的影响[D]. 天津: 天津医科大学, 2017.

Liu Y X. The effect of working length of locking plate on the mechanics of femoral shaft fracture[D]. Tianjin: Tianjin Medical University, 2017.

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: