Design and performance analysis of high efficiency non-imaging concentrated optical system

-

摘要

针对菲涅尔透镜存在实际光学效率偏低的问题,本文设计了一种由非球面透镜和棒锥镜组成的高效非成像聚光光学系统。在光学设计软件Zemax的序列模式下对非球面透镜进行了优化设计,通过最大程度地减小球差,像面光斑的几何半径从42 mm降到了1.7 mm。基于此,在Zemax的非序列模式下,完成了非球面透镜和棒锥镜的建模和优化,通过蒙特卡罗光线追迹分析实现了光学效率为87%、接收角为0.9°的非成像聚光光学系统。最后,基于非球面透镜阵列和棒锥镜样品,实现了高倍聚光型光伏模组的封装与测试。测试结果表明,该模组的光电转换效率达30.03%,与菲涅尔透镜构成的高倍聚光型光伏模组相比有显著提升。

Abstract

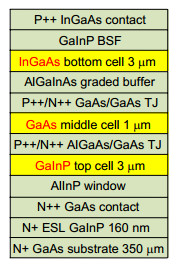

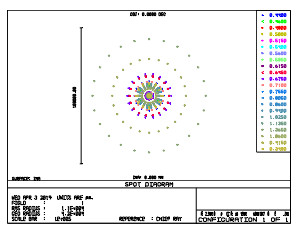

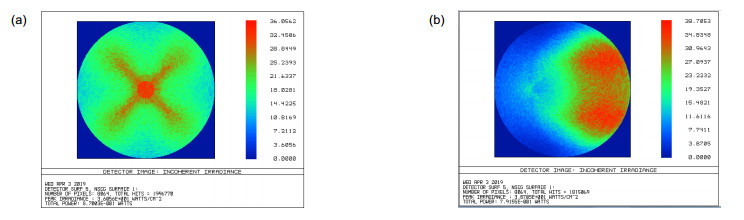

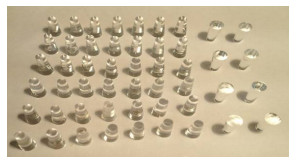

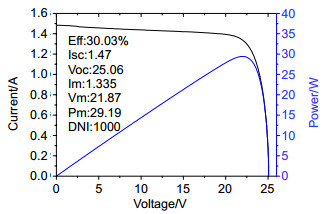

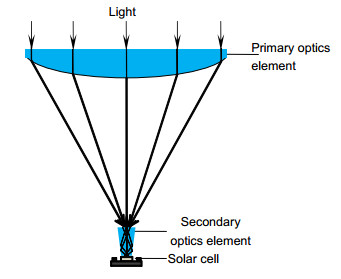

Aiming at the low optical efficiency of Fresnel lens, a high-efficiency non-imaging concentrated optical (NICO) system composed of an aspheric lens and a trumpet lens was designed. The aspheric lens was optimized in sequential mode of Zemax, and the geometric radius of its image spot was reduced from 42 mm to 1.7 mm by minimizing the spherical aberration. The aspheric lens and trumpet lens were modeled and optimized in non-sequential mode of Zemax, and the NICO system with 87% optical efficiency and 0.9° received angle was achieved by Monte Carlo ray tracing analysis. Finally, the packaging and testing of the high concentrated photovoltaic (HCPV) module were completed based on samples of an aspheric lens array and 48 trumpet lenses. The test results showed that the photoelectric conversion efficiency of the module reached 30.03%, which was significantly improved compared with the HCPV module composed of the Fresnel lens.

-

Overview

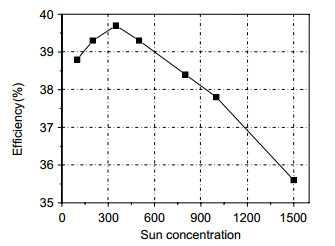

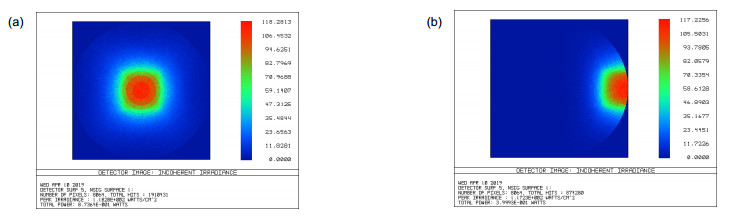

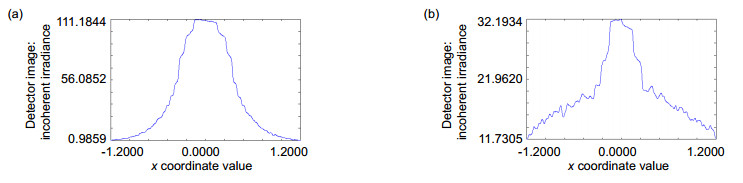

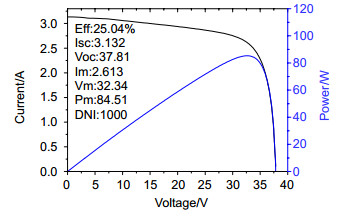

Overview: Nowadays, Fresnel lens was widely used as the primary optics element in high concentrated photovoltaic module. In principle, the optical efficiency of Fresnel lens could be high. However, it will decrease sharply due to the limitation of processing technology, for example, scattering of angle of chamfer, the deformation of demoulding, the shading of tooth root, and so on. These issues influence the further improvement of photoelectric conversion efficiency of high concentrated photovoltaic module. Consequently, the idea of replacing Fresnel lens with aspheric lens was proposed innovatively and a high-efficiency non-imaging concentrated optical system composed of an aspheric lens array and 48 trumpet lenses was designed. Firstly, the initial structure parameters of the aspheric lens were determined according to the characteristics of micro-scale three-junction GaAs solar cell. The aspheric lens was optimized in sequential mode of Zemax on the basis of aberration analysis of the initial structure, and the geometric radius of its image spot was reduced from 42 mm to 1.7 mm and the value of SPHA was reduced from 34.26 to 0.1 by minimizing the spherical aberration. The standard light source, detector, aspheric lens and trumpet lens were modeled in non-sequential mode of Zemax, and the trumpet were optimized by altering the radius of upper surface and the height. The high-efficiency non-imaging concentrated optical system with 87% optical efficiency and 0.9° received angle was achieved by Monte Carlo ray tracing analysis. On the basis, the high-efficiency non-imaging concentrated optical system and single aspheric lens were analyzed comparatively. The analysis results showed that the efficiency of single aspheric lens reduced from 87.4% to 40% when the incident angle increased from 0 to 0.9 degrees, and yet the efficiency of the high-efficiency non-imaging concentrated optical system still reached 79.2%. In addition, the irradiance distribution uniformity of the focal spot of the single aspheric lens was 1.77%, and the value of the high-efficiency non-imaging concentrated optical system was up to 53.42%. Finally, the packaging and test of high concentrated photovoltaic modules based on the high-efficiency non-imaging concentrated optical system and Fresnel lens were completed separately. The results of test comparatively showed that the photoelectric conversion efficiency of the module based on Fresnel lens was 25.04%, and the photoelectric conversion efficiency of the module based on the high-efficiency non-imaging concentrated optical system was up to 30.03%, which was significantly improved compared with the high concentrated photovoltaic module composed of the Fresnel lens.

-

-

表 1 球面透镜的初始结构参数

Table 1. Initial structural parameters of spherical lens

表面 曲率/mm 厚度/mm 材料 半口径/mm 物面 ∞ ∞ – ∞ 光阑面 ∞ 25 BK7 32 后表面 -33.218 64 – 32 像面 ∞ – – 2 表 2 初始结构的塞德尔像差系数

Table 2. Seidel aberration coefficient of initial structure

Surf SPHA S1 COMA S2 ASTI S3 FCUR S4 DIST S5 CLA(CL) CTR(CT) STO 0.000000 0.000000 0.000000 0.000000 0.000012 0.000000 -0.007913 2 34.260829 -0.050551 0.000075 0.000802 -0.000001 -1.326855 0.001958 IMA 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 TOT 34.260829 -0.050551 0.000075 0.000802 0.000011 -1.326855 -0.005955 表 3 非球面透镜的塞德尔像差系数

Table 3. Seidel aberration coefficient of aspheric lens

Surf SPHA S1 COMA S2 ASTI S3 FCUR S4 DIST S5 CLA(CL) CTR(CT) STO 0.000000 0.000000 0.000000 0.000000 0.000012 0.000000 -0.007913 2 0.082364 -0.201918 0.000171 0.000792 -0.000005 -1.310230 0.004510 IMA 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 0.000000 TOT 0.082364 -0.201918 0.000171 0.000792 0.000007 -1.310230 -0.003403 表 4 非球面透镜结构参数

Table 4. Structural parameters of aspheric lens

表面 曲率/mm 厚度/mm 非球面系数 非球面高阶系数 物面 ∞ ∞ – – 光阑面 ∞ 14.47 – A2=-2.161×10-4 偶次非球面 -33.64 63.88 -2.34 A4=-1.554×10-8 像面 ∞ – – A6=-1.769×10-11 表 5 标准光源参数

Table 5. The parameters of standard light source

类型 能量/W 分析光线/条 边长/mm 发散半角/(°) Source two angle 1 2×106 45 0.27 表 6 探测器参数

Table 6. The parameters of detector

类型 半口径/mm 径向分辨率 切向分辨率 Detector sur 1.25 128 32 表 7 棒锥镜初始结构参数

Table 7. Initial structural parameters of trumpet lens

上端面半径/mm 下端面半径/mm 高度/mm 材料 3 1.2 10 BK7 表 8 棒锥镜最优结构参数

Table 8. Optimization structural parameters of trumpet lens

上端面半径/mm 下端面半径/mm 高度/mm 材料 2 1.2 9 BK7 -

参考文献

[1] Burhan M, Chua K J E, Ng K C. Simulation and development of a multi-leg homogeniser concentrating assembly for concentrated photovoltaic (CPV) system with electrical rating analysis[J]. Energy Conversion and Management, 2016, 116: 58–71. doi: 10.1016/j.enconman.2016.02.060

[2] Rajaee M, Ghorashi S M B. Experimental measurements of a prototype high-concentration Fresnel lens and sun-tracking method for photovoltaic panel's efficiency enhancement[J]. Journal of Theoretical and Applied Physics, 2015, 9(4): 251–259. doi: 10.1007/s40094-015-0180-x

[3] 付蕊. Fresnel聚光器的优化设计及其在聚光光伏中的应用研究[D].北京: 华北电力大学, 2017.

Fu R. Optimization design of Fresnel concentrator and application research in concentrator photovoltaic technology[D]. Beijing: North China Electric Power University, 2017.

http://cdmd.cnki.com.cn/Article/CDMD-11412-1017210650.htm [4] Ferrer-Rodríguez J P, Fernández E F, Baig H, et al. Development, indoor characterisation and comparison to optical modelling of four Fresnel-based high-CPV units equipped with refractive secondary optics[J]. Solar Energy Materials and Solar Cells, 2018, 186: 273–283. doi: 10.1016/j.solmat.2018.06.050

[5] 海大鹏.菲涅尔透镜的加工工艺研究[D].哈尔滨: 哈尔滨工业大学, 2007.

Hai D P. Research on fabricating process of Fresnel lens[D]. Harbin: Harbin Institute of Technology, 2007.

http://cdmd.cnki.com.cn/Article/CDMD-10213-2008194351.htm [6] Roy A C, Yadav M, Khanna A, et al. Bi-convex aspheric optical lenses[J]. Applied Physics Letters, 2017, 110(10): 103701. doi: 10.1063/1.4978353

[7] Wang Z M, Qu W J, Asundi A. A simplified expression for aspheric surface fitting[J]. Optik, 2017, 140: 291–298. doi: 10.1016/j.ijleo.2017.02.094

[8] 冯科, 李劲松.高斯光束非球面镜整形系统的设计[J].光电工程, 2013, 40(5): 127–132. doi: 10.3969/j.issn.1003-501X.2013.05.018

Feng K, Li J S. Design of aspherics lenses shaping system on Gaussian beam[J]. Opto-Electronic Engineering, 2013, 40(5): 127–132. doi: 10.3969/j.issn.1003-501X.2013.05.018

[9] 莫卫东, 傅振堂, 范琦, 等.确定非球面最佳参考球面及非球面度的一种新方法[J].光电工程, 2012, 39(12): 7–11. doi: 10.3969/j.issn.1003-501X.2012.12.002

Mo W D, Fu Z T, Fan Q, et al. Determining the best-fit spherical surface and asphericity of aspheric surface by calculating the fringe density[J]. Opto-Electronic Engineering, 2012, 39(12): 7–11. doi: 10.3969/j.issn.1003-501X.2012.12.002

[10] Yeh N. Illumination uniformity issue explored via two-stage solar concentrator system based on Fresnel lens and compound flat concentrator[J]. Energy, 2016, 95: 542–549. doi: 10.1016/j.energy.2015.12.035

[11] Obara S, Matsumura K, Aizawa S, et al. Development of a solar tracking system of a nonelectric power source by using a metal hydride actuator[J]. Solar Energy, 2017, 158: 1016–1025. doi: 10.1016/j.solener.2017.08.056

[12] Yang C K, Cheng T C, Cheng C H, et al. Open-loop altitude-azimuth concentrated solar tracking system for solar-thermal applications[J]. Solar Energy, 2017, 147: 52–60. doi: 10.1016/j.solener.2017.03.014

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: