Perovskite quantum dot color conversion Micro-LEDs: progress in stability and patterning

-

摘要

微型发光二极管 (Micro light-emitting diode,Micro-LED)显示具有优异的显示性能和光电性质,被称为“下一代”终极显示技术。为了满足近眼显示需求,Micro-LED需要进一步微缩与集成化。随着微纳级图案化技术的不断革新,荧光色转换层法表现出低制造成本等显著优势,相较于三色芯片法,更适合应用于对色域、分辨率有更高要求的虚拟/增强现实显示应用。钙钛矿量子点是最有前景的荧光色转换材料,然而自身晶格固有的不稳定性和外界环境因素刺激共同导致的结构降解是一大问题。另外,如何制备与Micro-LED芯片阵列相匹配的微米级荧光阵列图案是至关重要的。为此,本文首先讲述了造成钙钛矿量子点结构不稳定性的原因;其次,总结了配体交换、离子掺杂、表面包覆和化学交联等方案在提升钙钛矿量子点稳定性方面的应用;最后,总结了光刻技术和喷墨打印技术在制备高分辨率钙钛矿量子点荧光阵列的最新研究进展。

Abstract

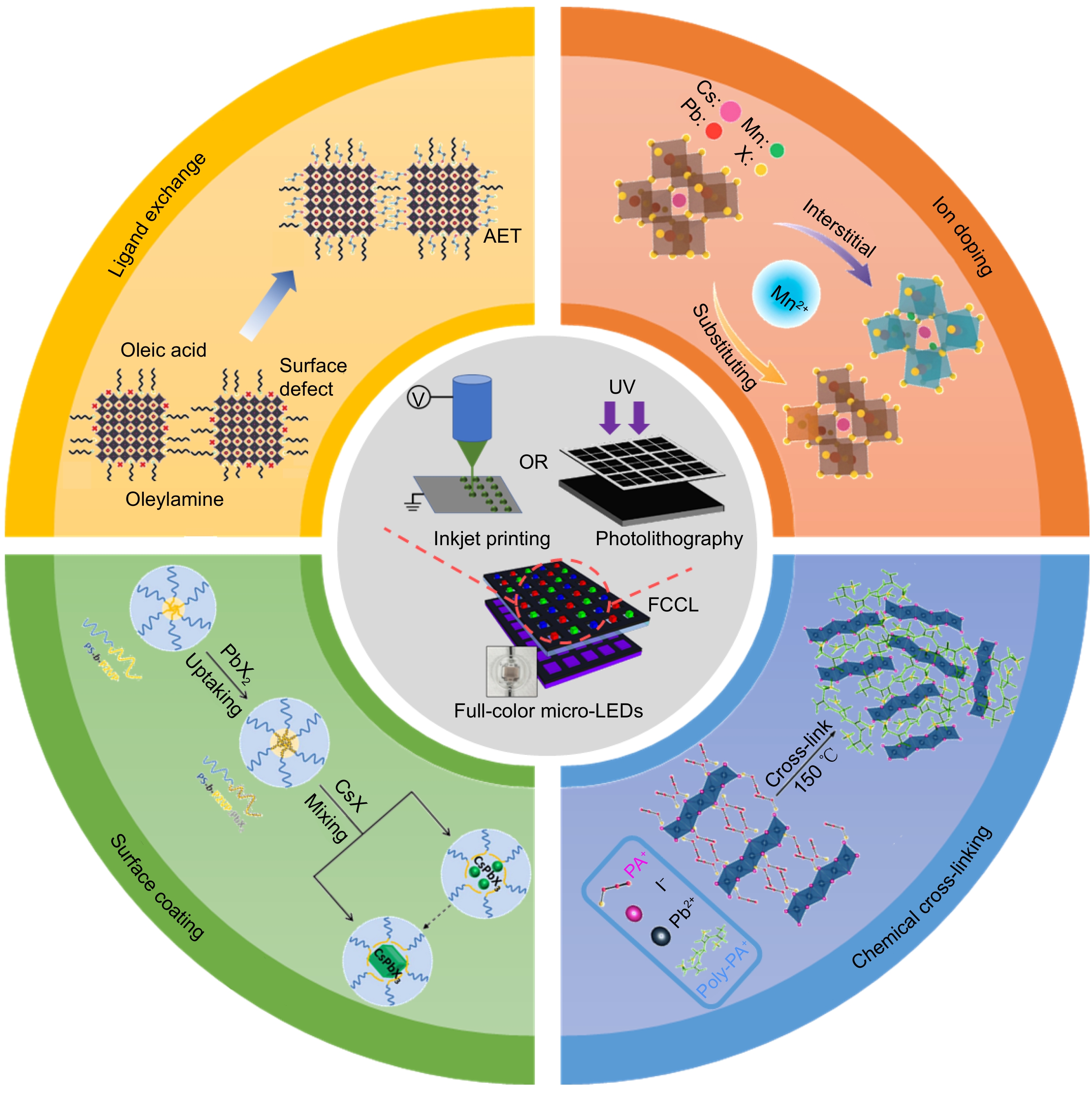

Micro light-emitting diode (Micro-LED) display is considered the "next-generation" ultimate display technology due to its excellent display performance and optoelectronic properties. In order to meet the requirements of near-eye display applications, further miniaturization and integration of Micro-LED are necessary. With the continuous innovation of micro/nanopatterning technology, the fluorescent color conversion layer method has significant advantages such as low manufacturing cost. Compared to the three-color chip method, it is more suitable for virtual/augmented reality display applications that demand higher color gamut and resolution. Perovskite quantum dots (PQDs) are the most promising fluorescent color conversion materials. However, the inherent lattice instability of PQDs and degradation caused by external environmental factors pose significant challenges. Furthermore, it is crucial to develop micro-scale fluorescent array patterns that match the Micro-LED chip array. Therefore, this paper first discusses the factors that affect the structural instability of perovskite quantum dots. Then, it summarizes the applications of strategies such as ligand exchange, ion doping, surface coating, and chemical cross-linking in enhancing the stability of perovskite quantum dots. Finally, the latest research progress for fabricating high-resolution perovskite quantum dot fluorescent arrays using photolithography and inkjet printing techniques is summarized.

-

Overview

Overview: Micro-LEDs, as microscale light-emitting diode displays, are widely regarded as the ultimate choice for next-generation display technology due to their exceptional display performance and optoelectronic properties. Through miniaturization and high integration, Micro-LEDs have surpassed LCD and OLED technologies. Currently, the methods employed to achieve full-color Micro-LEDs primarily involve the use of trichromatic chips and photoluminescent quantum dot (PQD) conversion layers. However, one of the major challenges faced by the trichromatic chip approach is large-scale transfer technology, which affects transfer efficiency, precision, and yield. Moreover, the demand for ultra-high pixel density displays has led to a further reduction in Micro-LED chip size, increasing the difficulty of chip transfer and resulting in high manufacturing costs. Additionally, the impact of sidewall damage during the fabrication process on the performance of small-sized Micro-LEDs cannot be overlooked. In recent years, the fabrication of patterned full-color Micro-LED displays using PQDs conversion layers has garnered significant attention. However, a PQD possess ionic properties and low surface energy, making them highly susceptible to the external environment, including water, oxygen, heat, and light. The high dissociation of long-chain surface ligands leads to increased surface defects and particle aggregation, severely impacting the performance of PQD-based Micro-LED displays. To overcome these challenges, several strategies have been proposed, including ligand exchange, ion doping, surface encapsulation, and chemical cross-linking. These methods effectively passivate surface defects of PQDs, enhance lattice stability, and suppress non-radiative recombination pathways. By employing stability-enhancing techniques such as strong ligand bonding, lattice adjustment, organic/inorganic shell encapsulation, and covalent cross-linking, ion diffusion in PQDs can be inhibited, thereby improving their environmental stability. For achieving exceptional full-color Micro-LEDs, these stability-enhancing approaches can be combined with photolithography and inkjet printing techniques to fabricate PQDs conversion layers with high resolution, stability, and luminance. This review begins by elucidating the causes of structural instability in PQDs. Subsequently, it summarizes the applications of ligand exchange, ion doping, surface encapsulation, and chemical cross-linking in enhancing the stability of perovskite quantum dots. Finally, the latest research advancements in photolithography and inkjet printing techniques for fabricating high-resolution perovskite quantum dot fluorescent arrays are presented. By synthesizing these findings, this comprehensive review specifically emphasizes the strategies employed to enhance the stability and performance of patterned Micro-LED displays with perovskite quantum dot conversion layers.

-

-

图 2 (a)卤化物钙钛矿典型ABX3晶体结构示意图[33]; (b) CsPbI3相变的可能途径[39]; (c) CsPbI3光氧化机制[43]; (d)水与钙钛矿晶体相互作用示意图[47]; (e) CsPbBr3光诱导团聚示意图[45]

Figure 2. (a) Schematic of a typical ABX3 crystal structure of halide perovskite[33] ; (b) Possible pathways for phase transitions of CsPbI3[39] ; (c) Photo-oxidation mechanism of CsPbI3[43]; (d) Schematic of the interaction between water and PNCs[47]; (e) Schematic of photo-induced agglomeration of CsPbBr3[45]

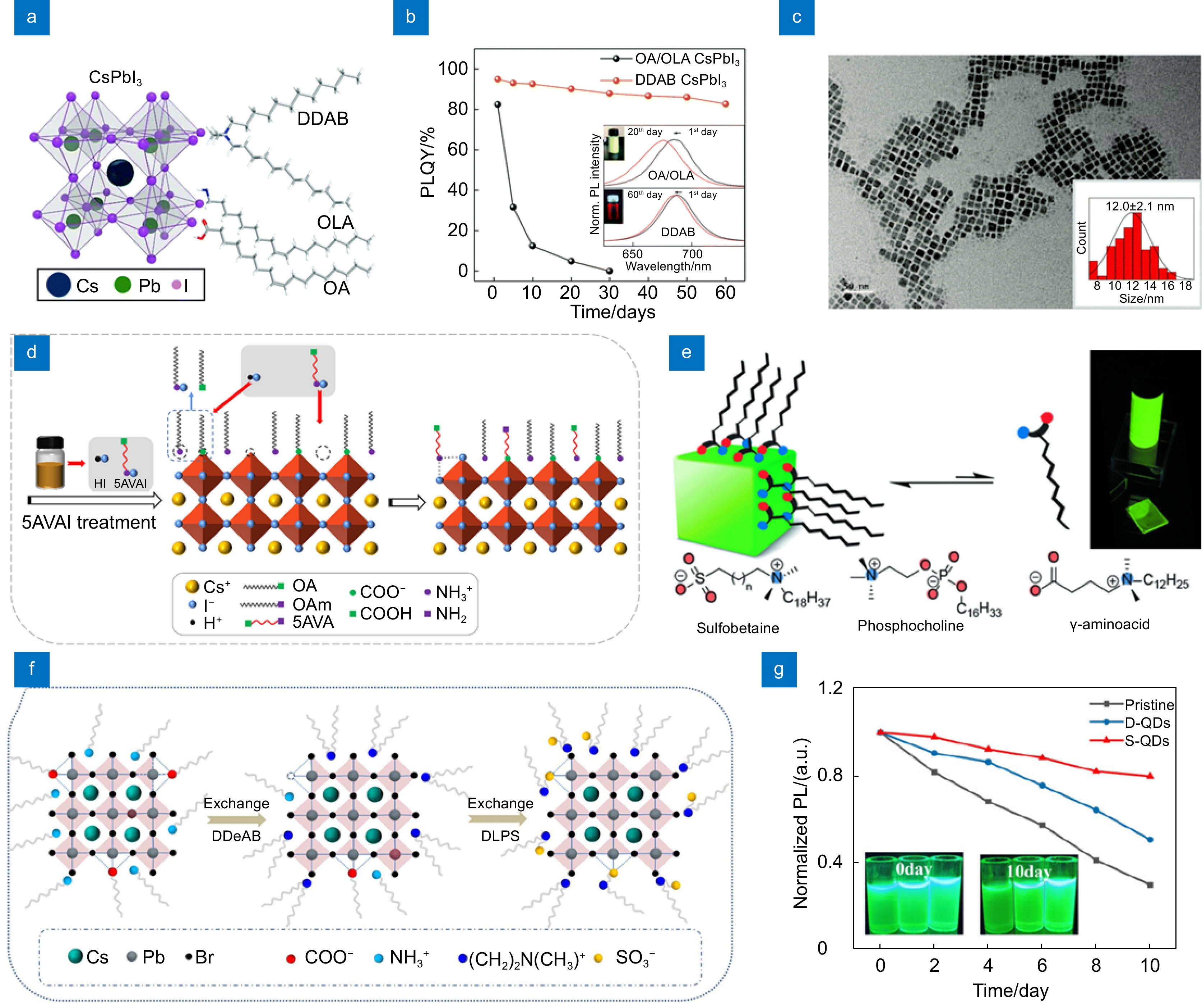

图 3 (a) CsPbI3-DDAB和CsPbI3-OA/OLA结构图[52]; (b) CsPbI3-DDAB和CsPbI3-OA/OLA的PLQY稳定性[52]; (c) CsPbI3-DDAB在黑暗环境中存放60天后的TEM图[52]; (d) HI诱导的5AVA配体与OA/OLA配体原位交换策略图[54]; (e) 两性离子配体 (磺基甜菜碱、磷胆碱和γ-氨基酸)钝化示意图[58]; (f) DDAB和DLPS双配体钝化策略[59]; (g) 三种量子点在自然环境下的PL稳定性[59]

Figure 3. (a) Structure of CsPbI3-DDAB and CsPbI3-OA/OLA[52]; (b) PLQY stability of CsPbI3-DDAB and CsPbI3-OA/OLA[52]; (c) TEM image of CsPbI3-DDAB after 60 days of storage in a dark environment[52]; (d) Strategy of HI-induced in situ exchange strategy of 5AVA ligand with OA/OLA ligand[54]; (e) Schematic of the passivation of amphipathic ionic ligands (sulfobetaine, phosphocholine and γ-aminoacids)[58]; (f) DDAB and DLPS dual ligand passivation strategies[59]; (g) PL stability of three QDs in natural environments[59]

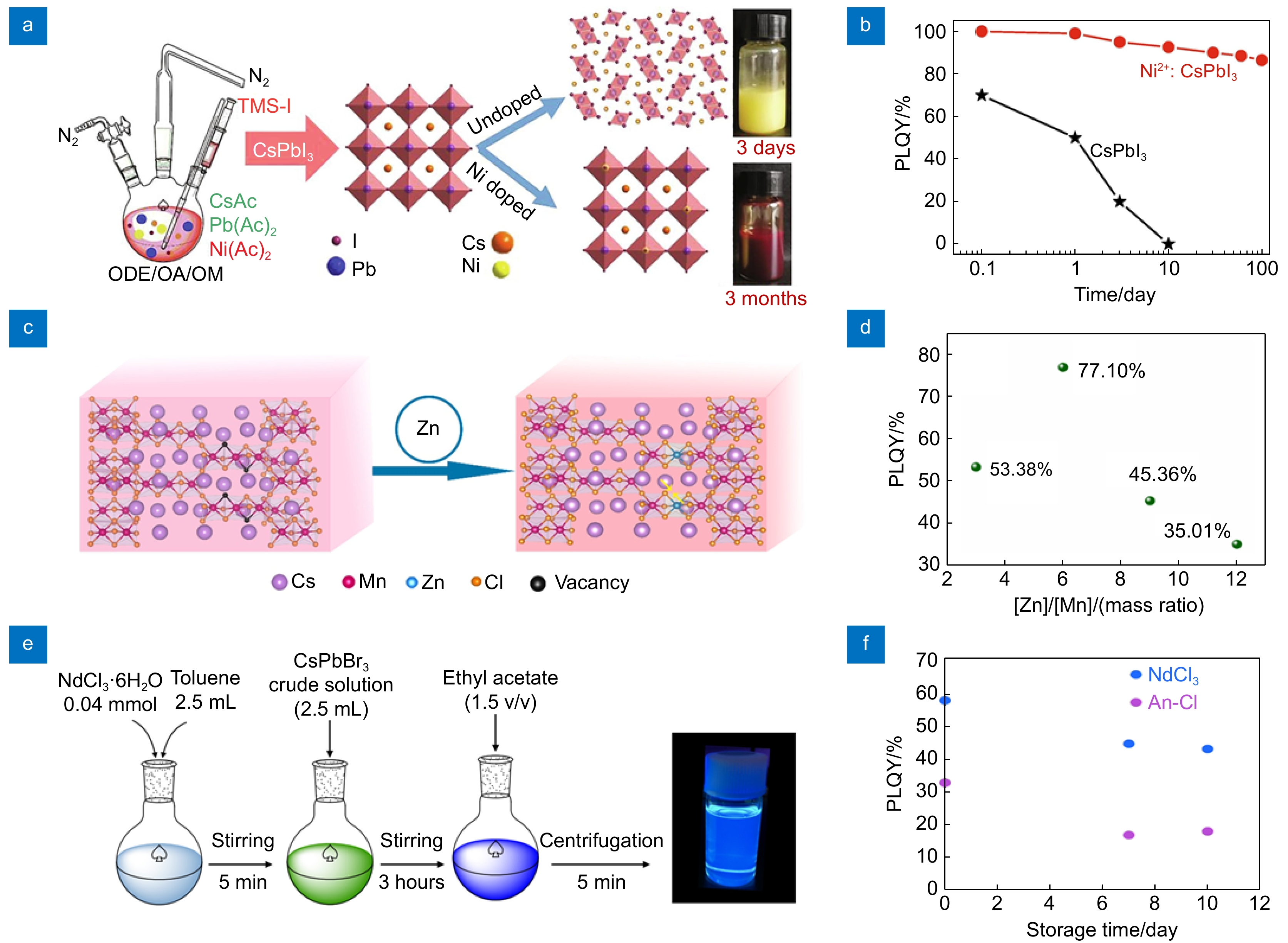

图 4 (a)原位合成Ni2+掺杂的CsPbI3 PQD示意图[75]; (b)未掺杂和掺镍CsPbI3 PQD 的PLQY随存储时间的变化[75]; (c) Zn2+掺杂CsMnCl3 PQD的稳定机制[77]; (d)不同Zn/Mn质量比的PLQY[77]; (e)掺杂NdCl3的CsPbBr3 PQD制备流程图[79]; (f)不同掺杂的CsPbBr3 PQD在自然环境下的PLQY稳定性[79]

Figure 4. (a) Schematic diagram of in-situ synthesized Ni2+ doped CsPbI3 PQD[75]; (b) Variation of PLQY with storage time for undoped and Ni-doped CsPbI3 PQD[75]; (c) Stabilization mechanism of Zn2+ doped CsMnCl3 PQD[77]; (d) PLQY at different Zn/Mn mass ratios[77]; (e) Process flowchart for the preparation of CsPbBr3 PQDs doped with NdCl3[79]; (f) PLQY stability of CsPbBr3 PQDs with different dopants in a natural environment[79]

图 5 (a) CsPbBr3/LLPDE结构示意图[83]; (b) CsPbBr3和CsPbBr3/LLPDE在自然环境下的降解实验[83]; (c) CsPbBr3和CsPbBr3/LLPDE在365 nm光照射下的降解实验[83]; (d) 可聚合CsPbX3 PQD墨水制备流程图[87]; (e) 配体交换与ALD-Al2O3封装流程图[97]; (f) CsPbBr3/CdS和CsPbBr3/Cs4PbBr6封装方法和能量图[103]; (g) 各种QD材料在水环境 (左图)和365 nm光环境 (右图)下的降解实验[103]

Figure 5. (a) Schematic structure of CsPbBr3/LLPDE[83]; (b) Degradation of CsPbBr3 and CsPbBr3/LLPDE in natural environment[83]; (c) Degradation of CsPbBr3 and CsPbBr3/LLPDE under 365 nm light irradiation[83]; (d) Flowchart for preparation of polymerisable CsPbX3 PQD ink[87]; (e) Ligand exchange and ALD-Al2O3 encapsulation flowchart[97]; (f) CsPbBr3/CdS and CsPbBr3/Cs4PbBr6 encapsulation methods and energy maps[103]; (g) Degradation of various QD materials in aqueous environment (left) and 365 nm light environment (right)[103]

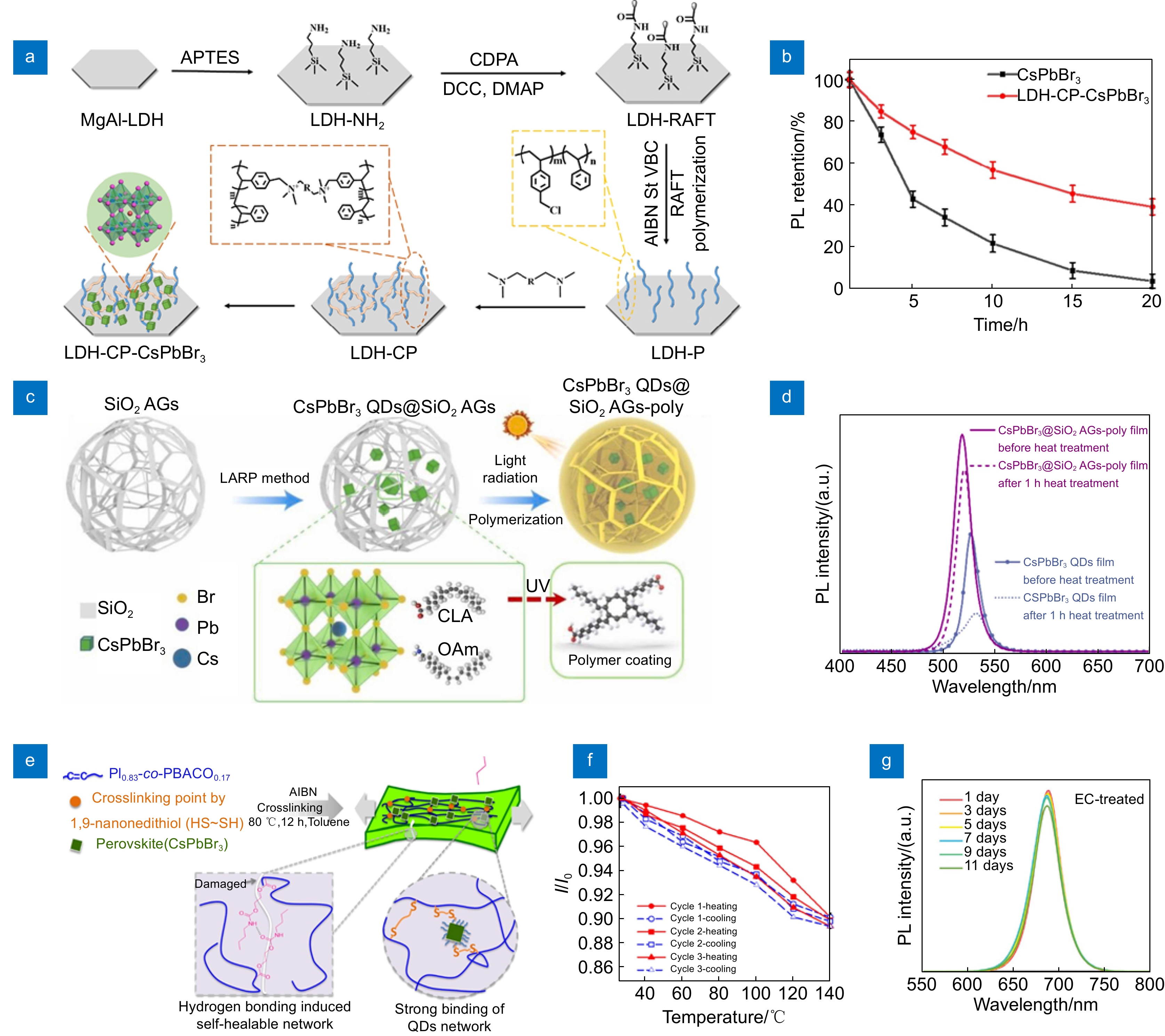

图 6 (a) 层状双金属氢氧化物纳米片中制备CsPbBr3 PQD示意图[107]; (b) CsPbBr3和LDH-CP-CsPbBr3在高温下的PL稳定[107]; (c) 在疏水性二氧化硅气凝胶上原位生长CsPbBr3 QDs示意图[108]; (d) PQD在高温下加热1小时后的PL稳定性[108]; (e) CsPbBr3 PQD复合材料的设计示意图[109]; (f) CsPbBr3 PQD复合材料加热-冷却循环的荧光特性[109]; (g) 添加乙基纤维素的PQD在自然环境下的PL稳定性[110]

Figure 6. (a) Schematic diagram of the preparation of CsPbBr3 perovskite PQD in LHD nanosheets[107]; (b) PL stability of CsPbBr3 and LDH-CP-CsPbBr3 at high temperatures[107]; (c) Schematic diagram of in-situ growth of CsPbBr3 QDs on hydrophobic silica aerogel[108]; (d) PL stability of PQDs after heating at high temperatures for 1 hour[108]; (e) Design schematic of CsPbBr3 PQD composite materials[109]; (f) Fluorescence characteristics of CsPbBr3 PQD composite materials during heating-cooling cycles[109]; (g) PL stability of PQDs with the addition of ethyl cellulose in a natural environment[110]

图 7 (a)光刻掩膜法制备PQD薄膜示意图[113]; (b)特征尺寸小至3 µm的PQD阵列[113]; (c)光刻剥离法制备PQD薄膜示意图[114]; (d)半径尺寸为5 µm的PQD点阵[114]; (e)利用溴化铅配合物原位制造PQD图案示意图[115]; (f)分辨率高达2450 PPI的PQD荧光阵列[115]; (g) PZ配体光图案化机制[116]; (h)线距为4 µm的高分辨率PQD图案[116]

Figure 7. (a) Schematic diagram of PQD thin film preparation using photolithographic masking method[113]; (b) PQD array with feature sizes as small as 3 µm[113]; (c) Schematic diagram of PQD thin film preparation using photolithographic peeling method[114]; (d) PQD dot array with a radius size of 5 µm[114]; (e) Schematic diagram of in-situ fabrication of PQD patterns using lead bromide complex[115]; (f) PQD fluorescence array with a resolution of up to 2450 PPI [115]; (g) Photopatterning mechanism of PZ ligands[116]; (h) High-resolution PQD pattern with a line spacing of 4 µm[116]

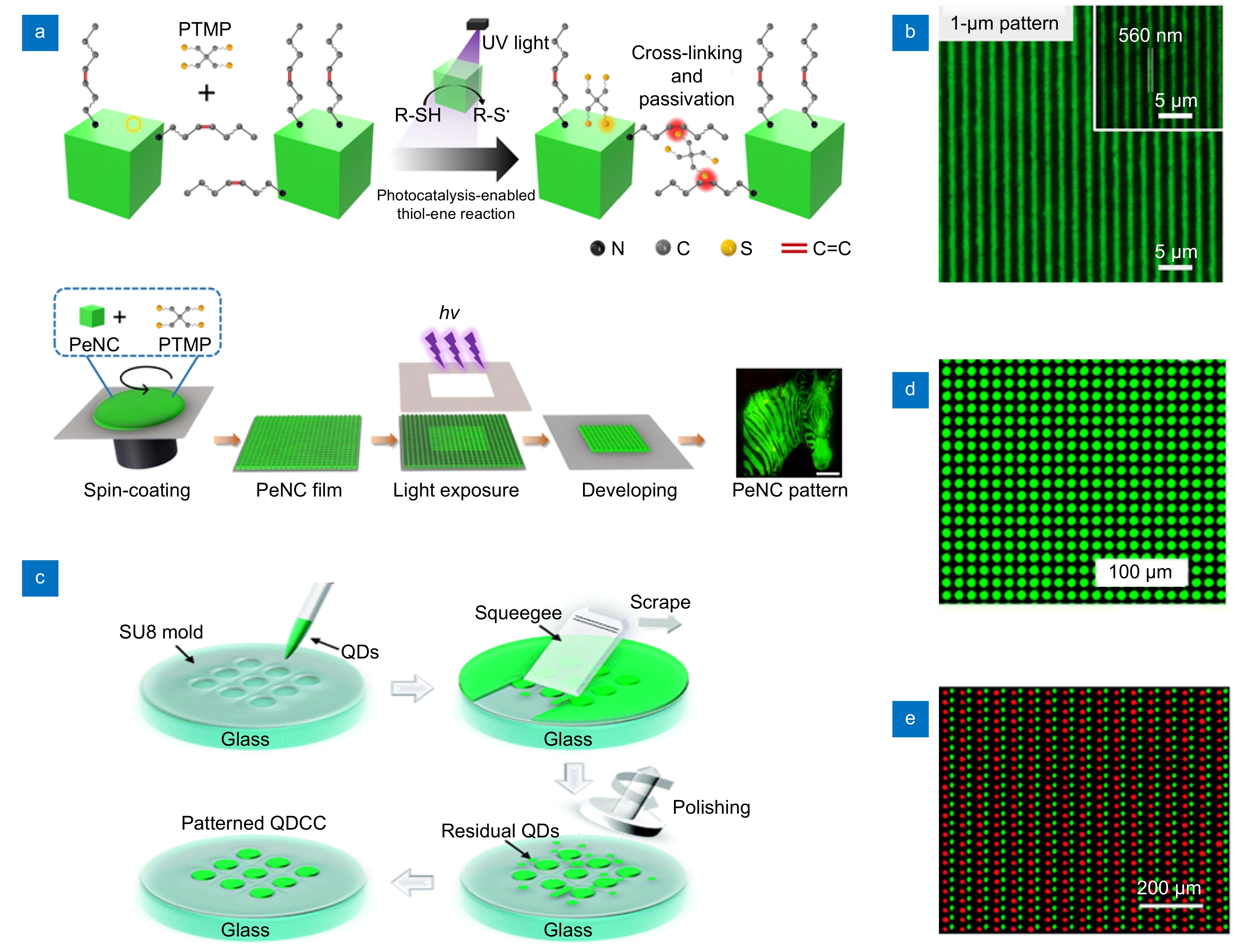

图 8 (a) PTMP与PQD的反应机制 (上图)和直接光刻制备PQD图案示意图 (下图)[119]; (b)分辨率达12700 PPI的PQD荧光阵列[119]; (c)微孔填充法制备PQD荧光阵列示意图[120]; (d)像素尺寸2 µm的高分辨率PQD荧光阵列[120]; (e)高分辨率双色PQD图案[120]

Figure 8. (a) Reaction mechanism between PTMP and PQD (top) and schematic diagram of direct photolithographic fabrication of PQD patterns (bottom)[119]; (b) PQD fluorescence array with a resolution of 12700 PPI[119]; (c) Schematic diagram of PQD fluorescence array prepared by microsphere filling method[120]; (d) High-resolution PQD fluorescence array with pixel size of 2 µm[120]; (e) High-resolution dual-color PQD pattern[120].

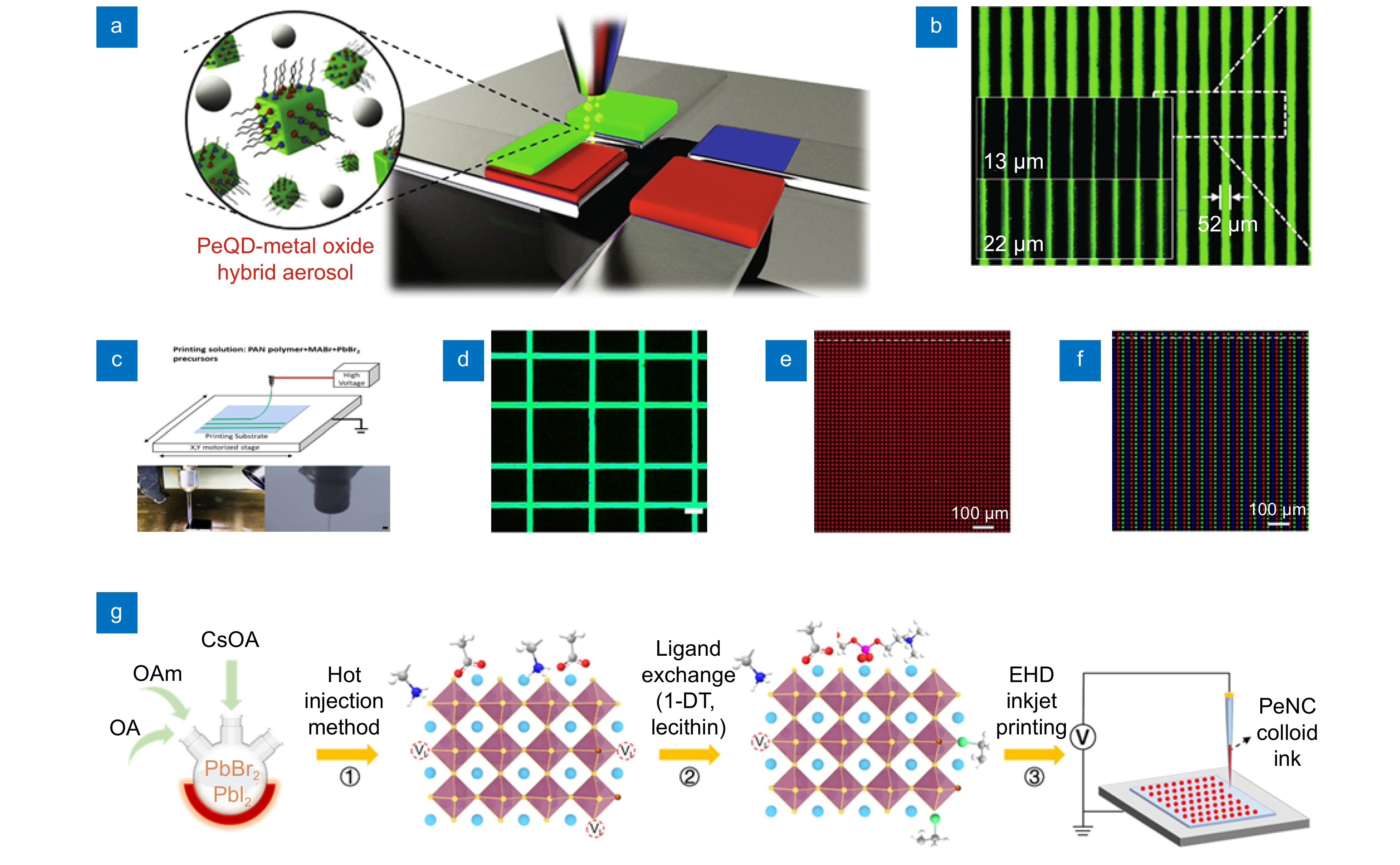

图 9 (a)气溶胶喷墨打印技术制备PQD颜色转换层示意图[125]; (b)线宽为13 µm的PQD图案[125]; (c) EHD喷墨打印示意图[126]; (d)分辨率为10 µm的PQD图案[126]; (e)分辨率为2540 DPI的红色PQD荧光阵列[127]; (f)子像素直径为10 µm的全彩PQD颜色转换层[127]; (g)通过配体交换和EHD喷墨打印工艺制备红色PQD荧光阵列示意图[127]

Figure 9. (a) Schematic diagram of PQD color conversion layer prepared by aerosol inkjet printing technique[125]; (b) PQD pattern with a line width of 13 µm [125]; (c) Schematic diagram of EHD inkjet printing[126]; (d) PQD pattern with a resolution of 10 µm [126]; (e) Red PQD fluorescence array with a resolution of 2540 DPI [127]; (f) Full-color PQD color conversion layer with subpixel diameter of 10 µm [127]; (g) Schematic diagram of red PQD fluorescence array prepared by ligand exchange and EHD inkjet printing process[127]

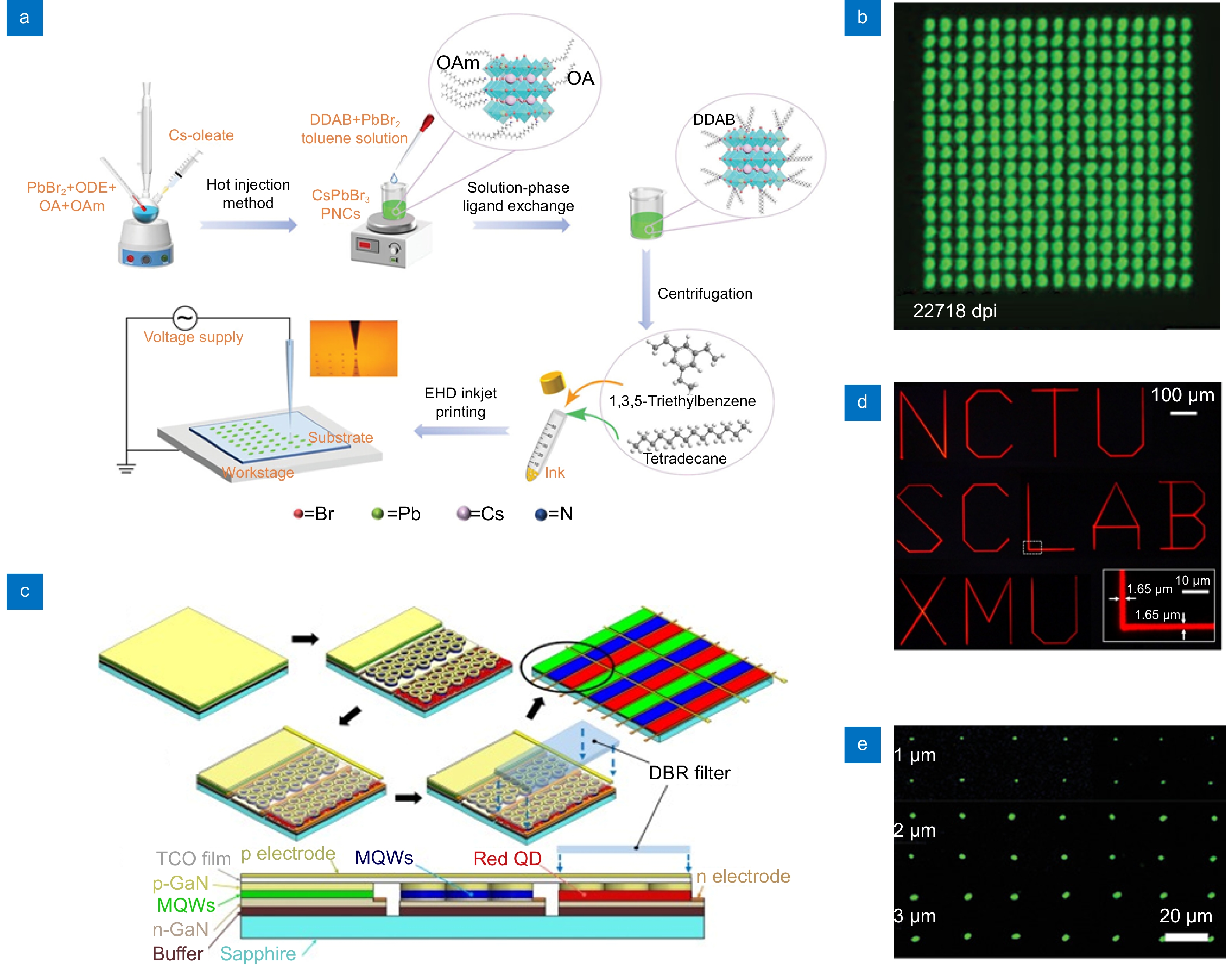

图 10 (a)墨水制备和印刷示意图[129]; (b)分辨率高达22718 DPI的PQD荧光阵列[129]; (c)线宽小于2 µm的混合QD纳米环Micro-LED制备流程[130]; (d)线宽为1.65 µm的QD图案[130]; (e)直径为1 µm、2 µm、3 µm的钙钛矿点阵图案[131]

Figure 10. (a) Schematic diagram of ink preparation and printing[129]; (b) PQD fluorescence array with a resolution of up to 22718 DPI[129]; (c) Fabrication process of mixed QD nanoring Micro-LED with line width less than 2 µm[130]; (d) QD pattern with a line width of 1.65 µm[130]; (e) Patterns of perovskite dot arrays with diameters of 1 µm, 2 µm, and 3 µm[131]

-

参考文献

[1] Xiong J H, Hsiang E L, He Z Q, et al. Augmented reality and virtual reality displays: emerging technologies and future perspectives[J]. Light Sci Appl, 2021, 10(1): 216. doi: 10.1038/s41377-021-00658-8

[2] Yin K, Hsiang E L, Zou J Y, et al. Advanced liquid crystal devices for augmented reality and virtual reality displays: principles and applications[J]. Light Sci Appl, 2022, 11(1): 161. doi: 10.1038/s41377-022-00851-3

[3] Jin S X, Li J, Li J Z, et al. Gan microdisk light emitting diodes[J]. Appl Phys Lett, 2000, 76(5): 631−633. doi: 10.1063/1.125841

[4] Wu T Z, Sher C W, Lin Y, et al. Mini-LED and micro-LED: promising candidates for the next generation display technology[J]. Appl Sci, 2018, 8(9): 1557. doi: 10.3390/app8091557

[5] Lu T W, Lin Y, Zhang T Q, et al. Self-polarized RGB device realized by semipolar micro-LEDs and perovskite-in-polymer films for backlight applications[J]. Opto-Electron Adv, 2024, 7(3): 230210. doi: 10.29026/oea.2024.230210

[6] Miao W C, Hsiao F H, Sheng Y J, et al. Microdisplays: mini-LED, micro-OLED, and micro-LED[J]. Adv Opt Mater, 2024, 12(7): 2300112. doi: 10.1002/adom.202300112

[7] Micro-LED: global strategic business report[EB/OL]. (2024). https://www.researchandmarkets.com/reports/4845811/micro-led-global-strategic-business-report.

[8] Huang Y G, Tan G J, Gou F W, et al. Prospects and challenges of mini-LED and micro-LED displays[J]. J Soc Inf Disp, 2019, 27(7): 387−401. doi: 10.1002/jsid.760

[9] Lai S Q, Liu S B, Li Z L, et al. Applications of lasers: a promising route toward low-cost fabrication of high-efficiency full-color micro-LED displays[J]. Opto-Electron Sci, 2023, 2(10): 230028. doi: 10.29026/oes.2023.230028

[10] Yang F, Xu Y, Li L, et al. Optical and microstructural characterization of micro-LED with sidewall treatment[J]. J Phys D Appl Phys, 2022, 55(43): 435103. doi: 10.1088/1361-6463/ac8bdf

[11] Park J, Baek W, Geum D M, et al. Understanding the sidewall passivation effects in AlGaInP/GaInP micro-LED[J]. Nanoscale Res Lett, 2022, 17(1): 29. doi: 10.1186/s11671-022-03669-5

[12] Karpov S Y. Carrier localization in InGaN by composition fluctuations: implication to the "green gap"[J]. Photonics Res, 2017, 5(2): A7−A12. doi: 10.1364/PRJ.5.0000A7

[13] Yan Z J, Liu S Y, Sun Y, et al. Atomic layer deposition technology for the development of high-quality, full-colour micro-LED displays[J]. Next Nanotechnol, 2024, 5: 100051. doi: 10.1016/j.nxnano.2024.100051

[14] Lu T W, Lin X S, Guo W A, et al. High-speed visible light communication based on micro-LED: a technology with wide applications in next generation communication[J]. Opto-Electron Sci, 2022, 1(12): 220020. doi: 10.29026/oes.2022.220020

[15] Lee T Y, Huang Y M, Chiang H, et al. Increase in the efficiency of III-nitride micro LEDs by atomic layer deposition[J]. Opt Express, 2022, 30(11): 18552−18561. doi: 10.1364/OE.455726

[16] Wong M S, Kearns J A, Lee C, et al. Improved performance of AlGaInP red micro-light-emitting diodes with sidewall treatments[J]. Opt Express, 2020, 28(4): 5787−5793. doi: 10.1364/OE.384127

[17] Zhao Y Z, Liang J Q, Zeng Q H, et al. 2000 ppi silicon-based AlGaInP red micro-LED arrays fabricated via wafer bonding and epilayer lift-off[J]. Opt Express, 2021, 29(13): 20217−20228. doi: 10.1364/OE.428482

[18] Yang X, Lin Y, Wu T Z, et al. An overview on the principle of inkjet printing technique and its application in micro-display for augmented/virtual realities[J]. Opto-Electron Adv, 2022, 5(6): 210123. doi: 10.29026/oea.2022.210123

[19] Chaudhary B, Kshetri Y K, Kim H S, et al. Current status on synthesis, properties and applications of CsPbX3 (X = Cl, Br, I) perovskite quantum dots/nanocrystals[J]. Nanotechnology, 2021, 32(50): 502007. doi: 10.1088/1361-6528/ac2537

[20] Wu Y, Li X M, Zeng H B. Highly luminescent and stable halide perovskite nanocrystals[J]. ACS Energy Lett, 2019, 4(3): 673−681. doi: 10.1021/acsenergylett.8b02100

[21] Yan Z J, Ye F S, Xu L Y, et al. Optimum temperature of atomic layer deposition of alumina on CsPbBr3 quantum-dot for optical performance and environmental stability[J]. J Lumin, 2023, 261: 119905. doi: 10.1016/j.jlumin.2023.119905

[22] Shen J H, Wang Y, Zhu Y H, et al. A polymer-coated template-confinement CsPbBr3 perovskite quantum dot composite[J]. Nanoscale, 2021, 13(13): 6586−6591. doi: 10.1039/D1NR00201E

[23] Ho S J, Hsu H C, Yeh C W, et al. Inkjet-printed salt-encapsulated quantum dot film for UV-based RGB color-converted micro-light emitting diode displays[J]. ACS Appl Mater Interfaces, 2020, 12(29): 33346−33351. doi: 10.1021/acsami.0c05646

[24] Bi C H, Kershaw S V, Rogach A L, et al. Improved stability and photodetector performance of CsPbI3 perovskite quantum dots by ligand exchange with aminoethanethiol[J]. Adv Funct Mater, 2019, 29(29): 1902446. doi: 10.1002/adfm.201902446

[25] Bai D L, Zhang J R, Jin Z W, et al. Interstitial Mn2+-driven high-aspect-ratio grain growth for low-trap-density microcrystalline films for record efficiency CsPbI2Br solar cells[J]. ACS Energy Lett, 2018, 3(4): 970−978. doi: 10.1021/acsenergylett.8b00270

[26] Hou S C, Guo Y Z, Tang Y G, et al. Synthesis and stabilization of colloidal perovskite nanocrystals by multidentate polymer micelles[J]. ACS Appl Mater Interfaces, 2017, 9(22): 18417−18422. doi: 10.1021/acsami.7b03445

[27] Yang N, Zhu C, Chen Y H, et al. An in situ cross-linked 1D/3D perovskite heterostructure improves the stability of hybrid perovskite solar cells for over 3000 h operation[J]. Energy Environ Sci, 2020, 13(11): 4344−4352. doi: 10.1039/D0EE01736A

[28] Ma T, Chen J, Chen Z Y, et al. Progress in color conversion technology for micro-LED[J]. Adv Mater Technol, 2023, 8(1): 2200632. doi: 10.1002/admt.202200632

[29] Liang S Y, Liu Y F, Ji Z K, et al. High-resolution patterning of perovskite quantum dots via femtosecond laser-induced forward transfer[J]. Nano Lett, 2023, 23(9): 3769−3774. doi: 10.1021/acs.nanolett.3c00006

[30] Zhu L C, Tao J, Li P Y, et al. Microfluidic static droplet generated quantum dot arrays as color conversion layers for full-color micro-LED displays[J]. Nanoscale Adv, 2023, 5(10): 2743−2747. doi: 10.1039/D2NA00765G

[31] Zhao J Y, Chen L X, Li D Z, et al. Large-area patterning of full-color quantum dot arrays beyond 1000 pixels per inch by selective electrophoretic deposition[J]. Nat Commun, 2021, 12(1): 4603. doi: 10.1038/s41467-021-24931-x

[32] Ju M G, Chen M, Zhou Y Y, et al. Toward eco-friendly and stable perovskite materials for photovoltaics[J]. Joule, 2018, 2(7): 1231−1241. doi: 10.1016/j.joule.2018.04.026

[33] Zhou Y Y, Zhao Y X. Chemical stability and instability of inorganic halide perovskites[J]. Energy Environ Sci, 2019, 12(5): 1495−1511. doi: 10.1039/C8EE03559H

[34] Wei Y, Cheng Z Y, Lin J. An overview on enhancing the stability of lead halide perovskite quantum dots and their applications in phosphor-converted LEDs[J]. Chem Soc Rev, 2019, 48(1): 310−350. doi: 10.1039/C8CS00740C

[35] Nagabhushana G P, Shivaramaiah R, Navrotsky A. Direct calorimetric verification of thermodynamic instability of lead halide hybrid perovskites[J]. Proc Natl Acad Sci USA, 2016, 113(28): 7717−7721. doi: 10.1073/pnas.1607850113

[36] Wu C, Zou Y T, Wu T, et al. Improved performance and stability of all-inorganic perovskite light-emitting diodes by antisolvent vapor treatment[J]. Adv Funct Mater, 2017, 27(28): 1700338. doi: 10.1002/adfm.201700338

[37] Guo J, Lu M, Zhang X Y, et al. Highly stable and efficient light-emitting diodes based on orthorhombic γ-CsPbI3 nanocrystals[J]. ACS Nano, 2023, 17(10): 9290−9301. doi: 10.1021/acsnano.3c00789

[38] Sutton R J, Filip M R, Haghighirad A A, et al. Cubic or orthorhombic? Revealing the crystal structure of metastable black-phase CsPbI3 by theory and experiment[J]. ACS Energy Lett, 2018, 3(8): 1787−1794. doi: 10.1021/acsenergylett.8b00672

[39] Lin Y, Fan X T, Yang X, et al. Remarkable black-phase robustness of CsPbI3 nanocrystals sealed in solid SiO2/AlOx sub-micron particles[J]. Small, 2021, 17(50): 2103510. doi: 10.1002/smll.202103510

[40] Ke F, Wang C X, Jia C J, et al. Preserving a robust CsPbI3 perovskite phase via pressure-directed octahedral tilt[J]. Nat Commun, 2021, 12(1): 461. doi: 10.1038/s41467-020-20745-5

[41] Ma S, Kim S H, Jeong B, et al. Strain-mediated phase stabilization: a new strategy for ultrastable α-CsPbI3 perovskite by nanoconfined growth[J]. Small, 2019, 15(21): 1900219. doi: 10.1002/smll.201900219

[42] Steele J A, Jin H D, Dovgaliuk I, et al. Thermal unequilibrium of strained black CsPbI3 thin films[J]. Science, 2019, 365(6454): 679−684. doi: 10.1126/science.aax3878

[43] Moot T, Dikova D R, Hazarika A, et al. Beyond strain: controlling the surface chemistry of CsPbI3 nanocrystal films for improved stability against ambient reactive oxygen species[J]. Chem Mater, 2020, 32(18): 7850−7860. doi: 10.1021/acs.chemmater.0c02543

[44] Hayyan M, Hashim M A, AlNashef I M. Superoxide ion: generation and chemical implications[J]. Chem Rev, 2016, 116(5): 3029−3085. doi: 10.1021/acs.chemrev.5b00407

[45] Chen J S, Liu D Z, Al-Marri M J, et al. Photo-stability of CsPbBr3 perovskite quantum dots for optoelectronic application[J]. Sci China-Mater, 2016, 59(9): 719−727. doi: 10.1007/s40843-016-5123-1

[46] Shwetharani R, Nayak V, Jyothi M S, et al. Review on recent advances of core-shell structured lead halide perovskites quantum dots[J]. J Alloys Compd, 2020, 834, 155246. doi: 10.1016/j.jallcom.2020.155246

[47] Gao Y J, Lin D X, Liu P Y, et al. Interaction mechanism between water molecules and perovskites[J]. Mater Chem Front, 2024, 8(3): 785−799. doi: 10.1039/D3QM00969F

[48] Calvin J J, Brewer A S, Alivisatos A P. The role of organic ligand shell structures in colloidal nanocrystal synthesis[J]. Nat Synth, 2022, 1(2): 127−137. doi: 10.1038/s44160-022-00025-4

[49] He X H, Yin Y L, Tang G, et al. Role of trioctylphosphine in the synthesis of quantum dots: a modulator of nucleation, growth, and solubility[J]. J Phys Chem C, 2023, 127(10): 5021−5028. doi: 10.1021/acs.jpcc.2c08346

[50] Liu M, Tang G, Liu Y, et al. Ligand exchange of quantum dots: a thermodynamic perspective[J]. J Phys Chem Lett, 2024, 15(7): 1975−1984. doi: 10.1021/acs.jpclett.3c03413

[51] Pan J, Quan L N, Zhao Y B, et al. Highly efficient perovskite-quantum-dot light-emitting diodes by surface engineering[J]. Adv Mater, 2016, 28(39): 8718−8725. doi: 10.1002/adma.201600784

[52] Huang Y H, Luan W L, Liu M K, et al. DDAB-assisted synthesis of iodine-rich CsPbI3 perovskite nanocrystals with improved stability in multiple environments[J]. J Mater Chem C, 2020, 8(7): 2381−2387. doi: 10.1039/C9TC06566K

[53] Cho S, Kim J, Jeong S M, et al. High-voltage and green-emitting perovskite quantum dot solar cells via solvent miscibility-induced solid-state ligand exchange[J]. Chem Mater, 2020, 32(20): 8808−8818. doi: 10.1021/acs.chemmater.0c02102

[54] Li Y M, Deng M, Zhang X Y, et al. Proton-prompted ligand exchange to achieve high-efficiency CsPbI3 quantum dot light-emitting diodes[J]. Nano-Micro Lett, 2024, 16(1): 105. doi: 10.1007/s40820-024-01321-8

[55] Tyagi P, Srivastava R, Giri L I, et al. Degradation of organic light emitting diode: heat related issues and solutions[J]. Synth Met, 2016, 216: 40−50. doi: 10.1016/j.synthmet.2015.10.016

[56] Wang Y K, Yuan F L, Dong Y T, et al. All-inorganic quantum-dot LEDs based on a phase-stabilized α-CsPbI3 perovskite[J]. Angew Chem Int Ed, 2021, 60(29): 16164−16170. doi: 10.1002/anie.202104812

[57] Chiba T, Hayashi Y, Ebe H, et al. Anion-exchange red perovskite quantum dots with ammonium iodine salts for highly efficient light-emitting devices[J]. Nat Photonics, 2018, 12(11): 681−687. doi: 10.1038/s41566-018-0260-y

[58] Krieg F, Ochsenbein S T, Yakunin S, et al. Colloidal CsPbX3 (X = Cl, Br, I) nanocrystals 2.0: zwitterionic capping ligands for improved durability and stability[J]. ACS Energy Lett, 2018, 3(3): 641−646. doi: 10.1021/acsenergylett.8b00035

[59] Zeng Z W, Meng Y H, Yang Z X, et al. Efficient CsPbBr3 perovskite light-emitting diodes via novel multi-step ligand exchange strategy based on zwitterionic molecules[J]. ACS Appl Mater Interfaces, 2024, 16(8): 10389−10397. doi: 10.1021/acsami.3c17324

[60] Ding N, Xu W, Zhou D L, et al. Extremely efficient quantum-cutting Cr3+, Ce3+, Yb3+ tridoped perovskite quantum dots for highly enhancing the ultraviolet response of silicon photodetectors with external quantum efficiency exceeding 70%[J]. Nano Energy, 2020, 78: 105278. doi: 10.1016/j.nanoen.2020.105278

[61] Gao Y, Yan C, Peng X D, et al. The metal doping strategy in all inorganic lead halide perovskites: synthesis, physicochemical properties, and optoelectronic applications[J]. Nanoscale, 2021, 13(43): 18010−18031. doi: 10.1039/D1NR04706J

[62] Goldschmidt V M. Die gesetze der krystallochemie[J]. Naturwissenschaften, 1926, 14(21): 477−485. doi: 10.1007/BF01507527

[63] Dunlap-Shohl W A, Zhou Y Y, Padture N P, et al. Synthetic approaches for halide perovskite thin films[J]. Chem Rev, 2019, 119(5): 3193−3295. doi: 10.1021/acs.chemrev.8b00318

[64] Ju M G, Dai J, Ma L, et al. Lead-free mixed tin and germanium perovskites for photovoltaic application[J]. J Am Chem Soc, 2017, 139(23): 8038−8043. doi: 10.1021/jacs.7b04219

[65] Travis W, Glover E N K, Bronstein H, et al. On the application of the tolerance factor to inorganic and hybrid halide perovskites: a revised system[J]. Chem Sci, 2016, 7(7): 4548−4556. doi: 10.1039/C5SC04845A

[66] Yao Z, Zhao W G, Chen S J, et al. Mn doping of CsPbI3 film towards high-efficiency solar cell[J]. ACS Appl Energy Mater, 2020, 3(6): 5190−5197. doi: 10.1021/acsaem.9b02468

[67] Linaburg M R, McClure E T, Majher J D, et al. Cs1– xRb xPbCl3 and Cs1– xRb xPbBr3 solid solutions: understanding octahedral tilting in lead halide perovskites[J]. Chem Mater, 2017, 29(8): 3507−3514. doi: 10.1021/acs.chemmater.6b05372

[68] Wu H, Yang Y, Zhou D C, et al. Rb+ cations enable the change of luminescence properties in perovskite (Rb xCs1− xPbBr3) quantum dots[J]. Nanoscale, 2018, 10(7): 3429−3437. doi: 10.1039/C7NR07776A

[69] Bi C H, Wang S X, Li Q, et al. Thermally stable copper(Ⅱ)-doped cesium lead halide perovskite quantum dots with strong blue emission[J]. J Phys Chem Lett, 2019, 10(5): 943−952. doi: 10.1021/acs.jpclett.9b00290

[70] Mondal N, De A, Samanta A. Achieving near-unity photoluminescence efficiency for blue-violet-emitting perovskite nanocrystals[J]. ACS Energy Lett, 2019, 4(1): 32−39. doi: 10.1021/acsenergylett.8b01909

[71] Zhang Y Q, Tu D T, Wang L P, et al. Transition metal ion-doped cesium lead halide perovskite nanocrystals: doping strategies and luminescence design[J]. Mater Chem Front, 2024, 8(1): 192−209. doi: 10.1039/D3QM00691C

[72] Litvin A P, Margaryan I V, Yin W X, et al. B-site doping of metal halide perovskite nanoplatelets influences their optical properties[J]. Adv Opt Mater, 2024, 12(8): 2301001. doi: 10.1002/adom.202301001

[73] Dutta A, Pradhan N. Phase-stable red-emitting CsPbI3 nanocrystals: successes and challenges[J]. ACS Energy Lett, 2019, 4(3): 709−719. doi: 10.1021/acsenergylett.9b00138

[74] Behera R K, Dutta A, Ghosh D, et al. Doping the smallest shannon radii transition metal ion Ni(Ⅱ) for stabilizing α-CsPbI3 perovskite nanocrystals[J]. J Phys Chem Lett, 2019, 10(24): 7916−7921. doi: 10.1021/acs.jpclett.9b03306

[75] Liu M L, Jiang N Z, Huang H, et al. Ni2+-doped CsPbI3 perovskite nanocrystals with near-unity photoluminescence quantum yield and superior structure stability for red light-emitting devices[J]. Chem Eng J, 2021, 413: 127547. doi: 10.1016/j.cej.2020.127547

[76] Yang J N, Song Y, Yao J S, et al. Potassium bromide surface passivation on CsPbI3-xBr x nanocrystals for efficient and stable pure red perovskite light-emitting diodes[J]. J Am Chem Soc, 2020, 142(6): 2956−2967. doi: 10.1021/jacs.9b11719

[77] Hao X R, Liu H L, Ding W G, et al. Zn2+-doped lead-free CsMnCl3 nanocrystals enable efficient red emission with a high photoluminescence quantum yield[J]. J Phys Chem Lett, 2022, 13(21): 4688−4694. doi: 10.1021/acs.jpclett.2c01199

[78] Van Der Stam W, Geuchies J J, Altantzis T, et al. Highly emissive divalent-ion-doped colloidal CsPb1– xM xBr3 perovskite nanocrystals through cation exchange[J]. J Am Chem Soc, 2017, 139(11): 4087−4097. doi: 10.1021/jacs.6b13079

[79] Chiba T, Sato J, Ishikawa S, et al. Neodymium chloride-doped perovskite nanocrystals for efficient blue light-emitting devices[J]. ACS Appl Mater Interfaces, 2020, 12(48): 53891−53898. doi: 10.1021/acsami.0c11736

[80] Zhang H H, Wang X, Liao Q, et al. Embedding perovskite nanocrystals into a polymer matrix for tunable luminescence probes in cell imaging[J]. Adv Funct Mater, 2017, 27(7): 1604382. doi: 10.1002/adfm.201604382

[81] Liang P T, Zhang P, Pan A Z, et al. Unusual stability and temperature-dependent properties of highly emissive CsPbBr3 perovskite nanocrystals obtained from in situ crystallization in poly(vinylidene difluoride)[J]. ACS Appl Mater Interfaces, 2019, 11(25): 22786−22793. doi: 10.1021/acsami.9b06811

[82] Yang L, Fu B W, Li X, et al. Poly(vinylidene fluoride)-passivated CsPbBr3 perovskite quantum dots with near-unity photoluminescence quantum yield and superior stability[J]. J Mater Chem C, 2021, 9(6): 1983−1991. doi: 10.1039/D0TC05103A

[83] Dong H R, Zhao H Y, Xuan T T, et al. Constructing perovskite/polymer core/shell nanocrystals with simultaneous high efficiency and stability for mini-LED backlights[J]. ACS Appl Mater Interfaces, 2023, 15(24): 29297−29307. doi: 10.1021/acsami.3c04337

[84] Xiao G J, Wang Y N, Han D, et al. Pressure-induced large emission enhancements of cadmium selenide nanocrystals[J]. J Am Chem Soc, 2018, 140(42): 13970−13975. doi: 10.1021/jacs.8b09416

[85] Zhou Q C, Bai Z L, Lu W G, et al. In situ fabrication of halide perovskite nanocrystal-embedded polymer composite films with enhanced photoluminescence for display backlights[J]. Adv Mater, 2016, 28(41): 9163−9168. doi: 10.1002/adma.201602651

[86] Wang Y N, He J, Chen H, et al. Ultrastable, highly luminescent organic–inorganic perovskite–polymer composite films[J]. Adv Mater, 2016, 28(48): 10710−10717. doi: 10.1002/adma.201603964

[87] Yang X, Valenzuela C, Zhang X, et al. Robust integration of polymerizable perovskite quantum dots with responsive polymers enables 4D-printed self-deployable information display[J]. Matter, 2023, 6(4): 1278−1294. doi: 10.1016/j.matt.2023.02.003

[88] Trinh C K, Ahmad Z. SiO2-coated lead halide perovskites core-shell and their applications: a mini-review[J]. R Soc Open Sci, 2024, 11(1): 230892. doi: 10.1098/rsos.230892

[89] Yang Y F, Zhang Y J, Li R, et al. Low-temperature atomic layer deposition of double-layer water vapor barrier for high humidity stable perovskite solar cells[J]. Adv Opt Mater, 2023, 11(14): 2300148. doi: 10.1002/adom.202300148

[90] He M D, Zhang Q G, Carulli F, et al. Ultra-stable, solution-processable CsPbBr3-SiO2 nanospheres for highly efficient color conversion in micro light-emitting diodes[J]. ACS Energy Lett, 2023, 8(1): 151−158. doi: 10.1021/acsenergylett.2c02062

[91] Zhou B Z, Liu M J, Wen Y W, et al. Atomic layer deposition for quantum dots based devices[J]. Opto-Electron Adv, 2020, 3(9): 190043. doi: 10.29026/oea.2020.190043

[92] Jing Y, Cao K, Zhou B Z, et al. Two-step hybrid passivation strategy for ultrastable photoluminescence perovskite nanocrystals[J]. Chem Mater, 2020, 32(24): 10653−10662. doi: 10.1021/acs.chemmater.0c03831

[93] Fang F, Liu M J, Chen W, et al. Atomic layer deposition assisted encapsulation of quantum dot luminescent microspheres toward display applications[J]. Adv Opt Mater, 2020, 8(12): 1902118. doi: 10.1002/adom.201902118

[94] Valdesueiro D, Prabhu M K, Guerra-Nunez C, et al. Deposition mechanism of aluminum oxide on quantum dot films at atmospheric pressure and room temperature[J]. J Phys Chem C, 2016, 120(8): 4266−4275. doi: 10.1021/acs.jpcc.5b11653

[95] Xiang Q Y, Zhou B Z, Cao K, et al. Bottom up stabilization of CsPbBr3 quantum dots-silica sphere with selective surface passivation via atomic layer deposition[J]. Chem Mater, 2018, 30(23): 8486−8494. doi: 10.1021/acs.chemmater.8b03096

[96] Bose R, Zheng Y Z, Guo T L, et al. Interface matters: enhanced photoluminescence and long-term stability of zero-dimensional cesium lead bromide nanocrystals via gas-phase aluminum oxide encapsulation[J]. ACS Appl Mater Interfaces, 2020, 12(31): 35598−35605. doi: 10.1021/acsami.0c07694

[97] Wang M, Lei Z Y, Du C, et al. Stabilization of CsPbBr3 nanocrystals via defect passivation and alumina encapsulation for high-power light-emitting diodes[J]. ACS Appl Nano Mater, 2023, 6(8): 6480−6487. doi: 10.1021/acsanm.2c04974

[98] Dong H Y, Zhang C H, Nie W J, et al. Interfacial chemistry triggers ultrafast radiative recombination in metal halide perovskites[J]. Angew Chem Int Ed, 2022, 61(13): e202115875. doi: 10.1002/anie.202115875

[99] Ravi V K, Saikia S, Yadav S, et al. CsPbBr3/ZnS core/shell type nanocrystals for enhancing luminescence lifetime and water stability[J]. ACS Energy Lett, 2020, 5(6): 1794−1796. doi: 10.1021/acsenergylett.0c00858

[100] Chen X M, Zhang F, Ge Y, et al. Centimeter-sized Cs4PbBr6 crystals with embedded CsPbBr3 nanocrystals showing superior photoluminescence: nonstoichiometry induced transformation and light-emitting applications[J]. Adv Funct Mater, 2018, 28(16): 1706567. doi: 10.1002/adfm.201706567

[101] Dutta S K, Bera S, Pradhan N. Why is making epitaxially grown all inorganic perovskite–chalcogenide nanocrystal heterostructures challenging? Some facts and some strategies[J]. Chem Mater, 2021, 33(11): 3868−3877. doi: 10.1021/acs.chemmater.1c01000

[102] Bera S, Pradhan N. Perovskite nanocrystal heterostructures: synthesis, optical properties, and applications[J]. ACS Energy Lett, 2020, 5(9): 2858−2872. doi: 10.1021/acsenergylett.0c01449

[103] Shi J D, Ge W Y, Zhu J F, et al. Core–shell CsPbBr3@CdS quantum dots with enhanced stability and photoluminescence quantum yields for optoelectronic devices[J]. ACS Appl Nano Mater, 2020, 3(8): 7563−7571. doi: 10.1021/acsanm.0c01204

[104] Wu L Z, Hu H C, Xu Y, et al. From nonluminescent Cs4PbX6 (X = Cl, Br, I) nanocrystals to highly luminescent CsPbX3 nanocrystals: water-triggered transformation through a CsX-stripping mechanism[J]. Nano Lett, 2017, 17(9): 5799−5804. doi: 10.1021/acs.nanolett.7b02896

[105] Wang X R, Ding Z W, Huang X Z, et al. Cross-linking strategies for efficient and highly stable perovskite solar cells[J]. J Mater Chem C, 2024, 12(2): 351−387. doi: 10.1039/D3TC03183G

[106] Yin X, Wang Z Y, Zhao Y J, et al. Cross-linking polymerization boosts the performance of perovskite solar cells: from material design to performance regulation[J]. Energy Environ Sci, 2023, 16(10): 4251−4279. doi: 10.1039/D3EE01546G

[107] Liu Y, Sun W S, Xiao J, et al. Cross-linked polymer modified layered double hydroxide nanosheet stabilized CsPbBr3 perovskite quantum dots for white light-emitting diode[J]. Appl Clay Sci, 2022, 229: 106662. doi: 10.1016/j.clay.2022.106662

[108] Xiong P, Gong Y Q, Yang X L, et al. Effect of hydrophobic silica aerogels in-situ on encapsulation the stability of CsPbBr3 quantum dots for white light-emitting diodes[J]. J Alloys Compd, 2023, 938: 168541. doi: 10.1016/j.jallcom.2022.168541

[109] Hsu Y C, You Y H, Au-Duong A N, et al. Fabrication of intrinsic, elastic, self-healing, and luminescent CsPbBr3 quantum dot-polymer composites via thiol–ene cross-linking[J]. ACS Appl Polym Mater, 2022, 4(12): 8987−8995. doi: 10.1021/acsapm.2c01352

[110] Sun S Q, Jia P, Lu M, et al. Enhanced flexibility and stability of emissive layer enable high-performance flexible light-emitting diodes by cross-linking of biomass material[J]. Adv Funct Mater, 2022, 32(33): 2204286. doi: 10.1002/adfm.202204286

[111] Park S Y, Lee S, Yang J, et al. Patterning quantum dots via photolithography: a review[J]. Adv Mater, 2023, 35(41): 2300546. doi: 10.1002/adma.202300546

[112] Lee J, Jo H, Choi M, et al. Recent progress on quantum dot patterning technologies for commercialization of QD-LEDs: current status, future prospects, and exploratory approaches[J]. Small Methods, 2024, 8, 2301224. doi: 10.1002/smtd.202301224

[113] Harwell J, Burch J, Fikouras A, et al. Patterning multicolor hybrid perovskite films via top-down lithography[J]. ACS Nano, 2019, 13(4): 3823−3829. doi: 10.1021/acsnano.8b09592

[114] Jeon S, Lee S Y, Kim S K, et al. All-solution processed multicolor patterning technique of perovskite nanocrystal for color pixel array and flexible optoelectronic devices[J]. Adv Opt Mater, 2020, 8(17): 2000501. doi: 10.1002/adom.202000501

[115] Zhang P P, Yang G L, Li F, et al. Direct in situ photolithography of perovskite quantum dots based on photocatalysis of lead bromide complexes[J]. Nat Commun, 2022, 13(1): 6713. doi: 10.1038/s41467-022-34453-9

[116] Noh S H, Jeong W, Lee K H, et al. Photocrosslinkable zwitterionic ligands for perovskite nanocrystals: self-assembly and high-resolution direct patterning[J]. Adv Funct Mater, 2023, 33(41): 2304004. doi: 10.1002/adfm.202304004

[117] Lin C H, Zeng Q J, Lafalce E, et al. Large-area lasing and multicolor perovskite quantum dot patterns[J]. Adv Opt Mater, 2018, 6(16): 1800474. doi: 10.1002/adom.201800474

[118] Guo W S, Chen J, Ma T, et al. Direct photolithography patterning of quantum dot-polymer[J]. Adv Funct Mater, 2024, 34(10): 2310338. doi: 10.1002/adfm.202310338

[119] Maeng S, Park S J, Lee J, et al. Direct photocatalytic patterning of colloidal emissive nanomaterials[J]. Sci Adv, 2023, 9(33): eadi6950. doi: 10.1126/sciadv.adi6950

[120] Sun W C, Li F, Tao J, et al. Micropore filling fabrication of high resolution patterned PQDs with a pixel size less than 5 μm[J]. Nanoscale, 2022, 14(16): 5994−5998. doi: 10.1039/D2NR01115H

[121] Xuan T T, Shi S C, Wang L, et al. Inkjet-printed quantum dot color conversion films for high-resolution and full-color micro light-emitting diode displays[J]. J Phys Chem Lett, 2020, 11(13): 5184−5191. doi: 10.1021/acs.jpclett.0c01451

[122] Wilkinson N J, Smith M A A, Kay R W, et al. A review of aerosol jet printing–a non-traditional hybrid process for micro-manufacturing[J]. Int J Adv Manuf Technol, 2019, 105(11): 4599−4619. doi: 10.1007/s00170-019-03438-2

[123] Oakley C, Chahal P. Aerosol jet printed quasi-optical terahertz components[J]. IEEE Trans Terahertz Sci Technol, 2018, 8(6): 765−772. doi: 10.1109/TTHZ.2018.2873915

[124] Chen G, Gu Y, Tsang H, et al. The effect of droplet sizes on overspray in aerosol-jet printing[J]. Adv Eng Mater, 2018, 20(8): 1701084. doi: 10.1002/adem.201701084

[125] Kim S, Kang S, Baek S, et al. Highly thin film with aerosol-deposited perovskite quantum dot/metal oxide composite for perfect color conversion and luminance enhancement[J]. Chem Eng J, 2022, 441: 135991. doi: 10.1016/j.cej.2022.135991

[126] Kang G, Lee H, Moon J, et al. Electrohydrodynamic jet-printed MAPbBr3 perovskite/polyacrylonitrile nanostructures for water-stable, flexible, and transparent displays[J]. ACS Appl Nano Mater, 2022, 5(5): 6726−6735. doi: 10.1021/acsanm.2c00753

[127] Yang X, Wang S L, Hou Y Q, et al. Dual-ligand red perovskite ink for electrohydrodynamic printing color conversion arrays over 2540 dpi in near-eye micro-LED display[J]. Nano Lett, 2024, 24(12): 3661−3669. doi: 10.1021/acs.nanolett.3c04927

[128] Laurila M M. Super inkjet printed redistribution layer for a mems device[D]. Tampere: Tampere University of Technology, 2015: 73.

[129] Yang X, Yan Z J, Zhong C M, et al. Electrohydrodynamically printed high-resolution arrays based on stabilized CsPbBr3 quantum dot inks[J]. Adv Opt Mater, 2023, 11(9): 2202673. doi: 10.1002/adom.202202673

[130] Chen S W H, Shen C C, Wu T Z, et al. Full-color monolithic hybrid quantum dot nanoring micro light-emitting diodes with improved efficiency using atomic layer deposition and nonradiative resonant energy transfer[J]. Photonics Res, 2019, 7(4): 416−422. doi: 10.1364/PRJ.7.000416

[131] Wang Q L, Zhang G N, Zhang H Y, et al. High-resolution, flexible, and full-color perovskite image photodetector via electrohydrodynamic printing of ionic-liquid-based ink[J]. Adv Funct Mater, 2021, 31(28): 2100857. doi: 10.1002/adfm.202100857

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: