Elimination method of crosstalk and chromatic aberration between color channels for composite surface measurement

-

摘要:

为实现漫反射表面和镜面复合表面的快速测量,基于条纹投影和条纹反射的复合表面测量系统通过相机的多颜色通道快速获得绝对相位。针对复合表面形貌测量中相机、投影仪、显示屏所引入颜色通道间的串扰和色差,研究了基于矩阵的串扰消除方法和绝对相位对应像素偏差的色差消除方法。基于串扰矩阵,分别建立投影仪和显示屏的串扰矩阵,完成颜色通道间的串扰消除。通过彩色正交条纹获得各颜色通道水平和竖直方向的绝对相位,建立颜色通道间相位差和像素偏差之间的关系,实现每一像素点的像素偏差校正,消除色差的影响。实验结果证明,所提色差和串扰消除方法使复合台阶的测量均方根误差从0.479 mm降至0.030 mm,提高了测量效率和测量精度。

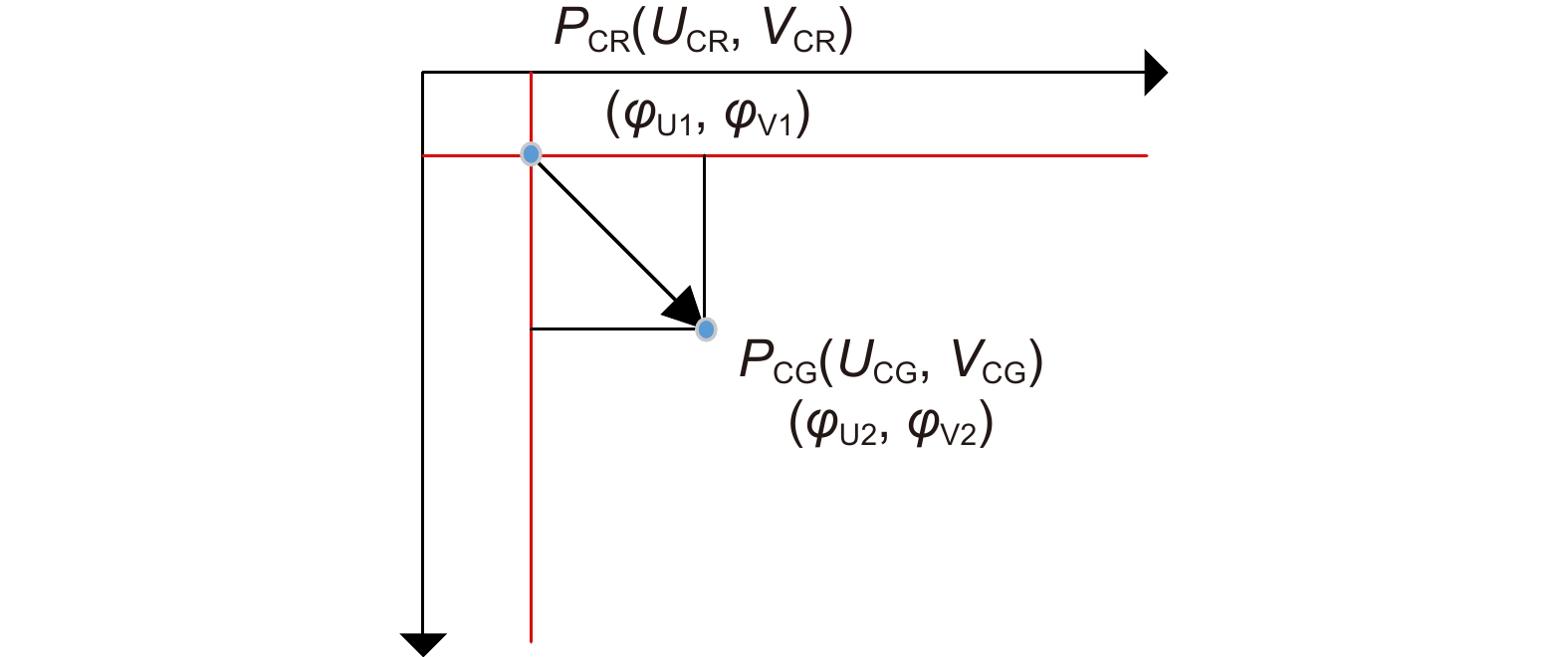

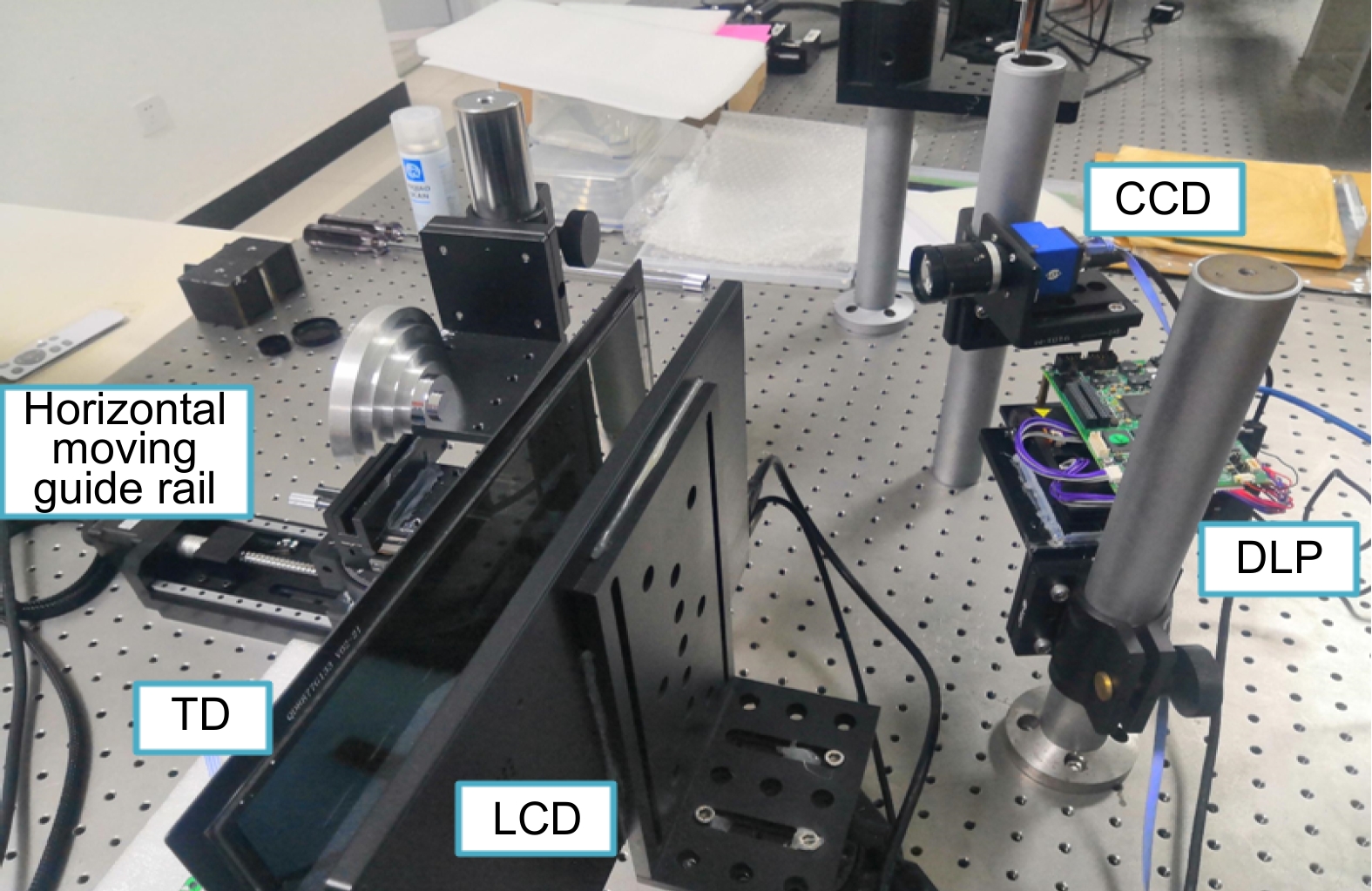

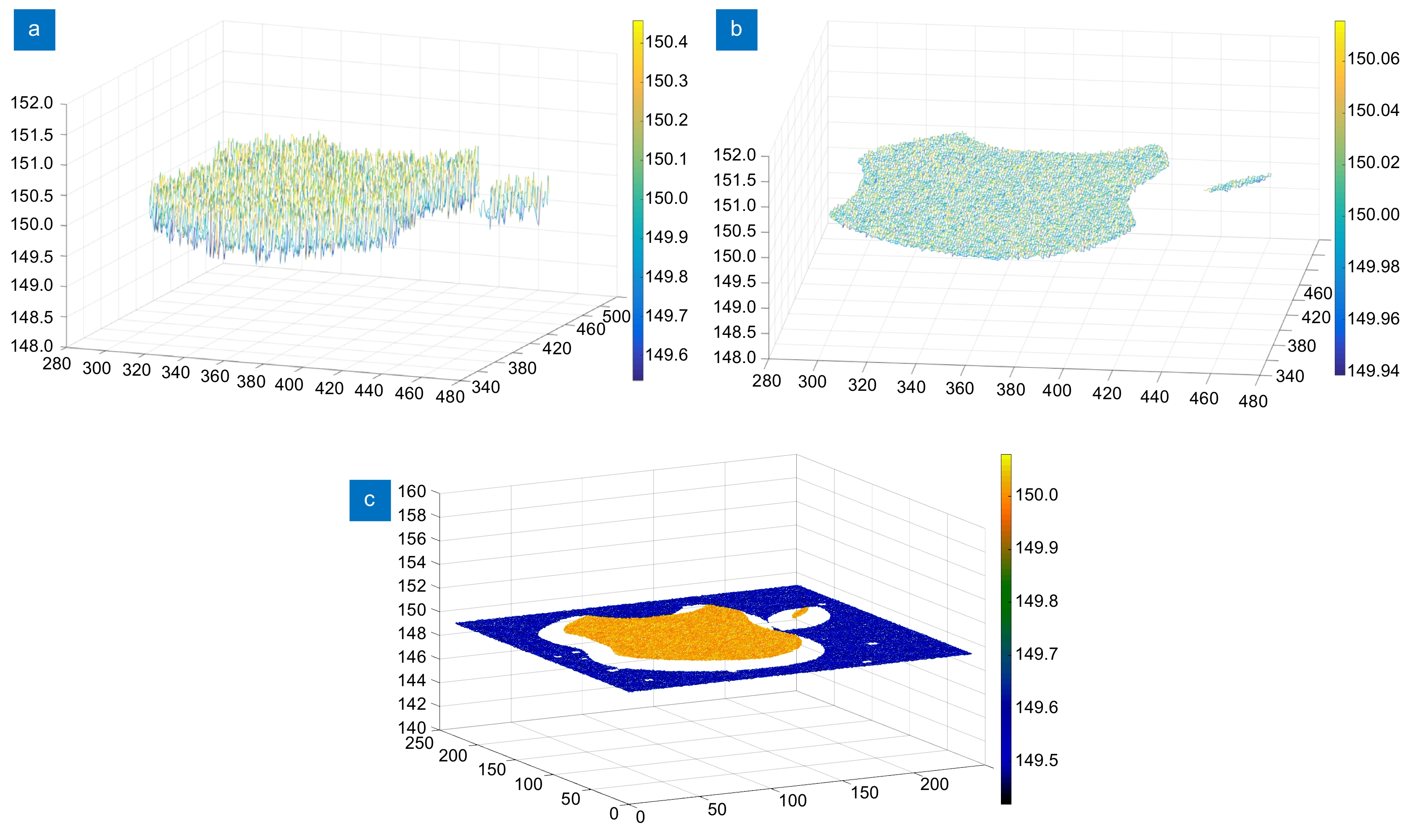

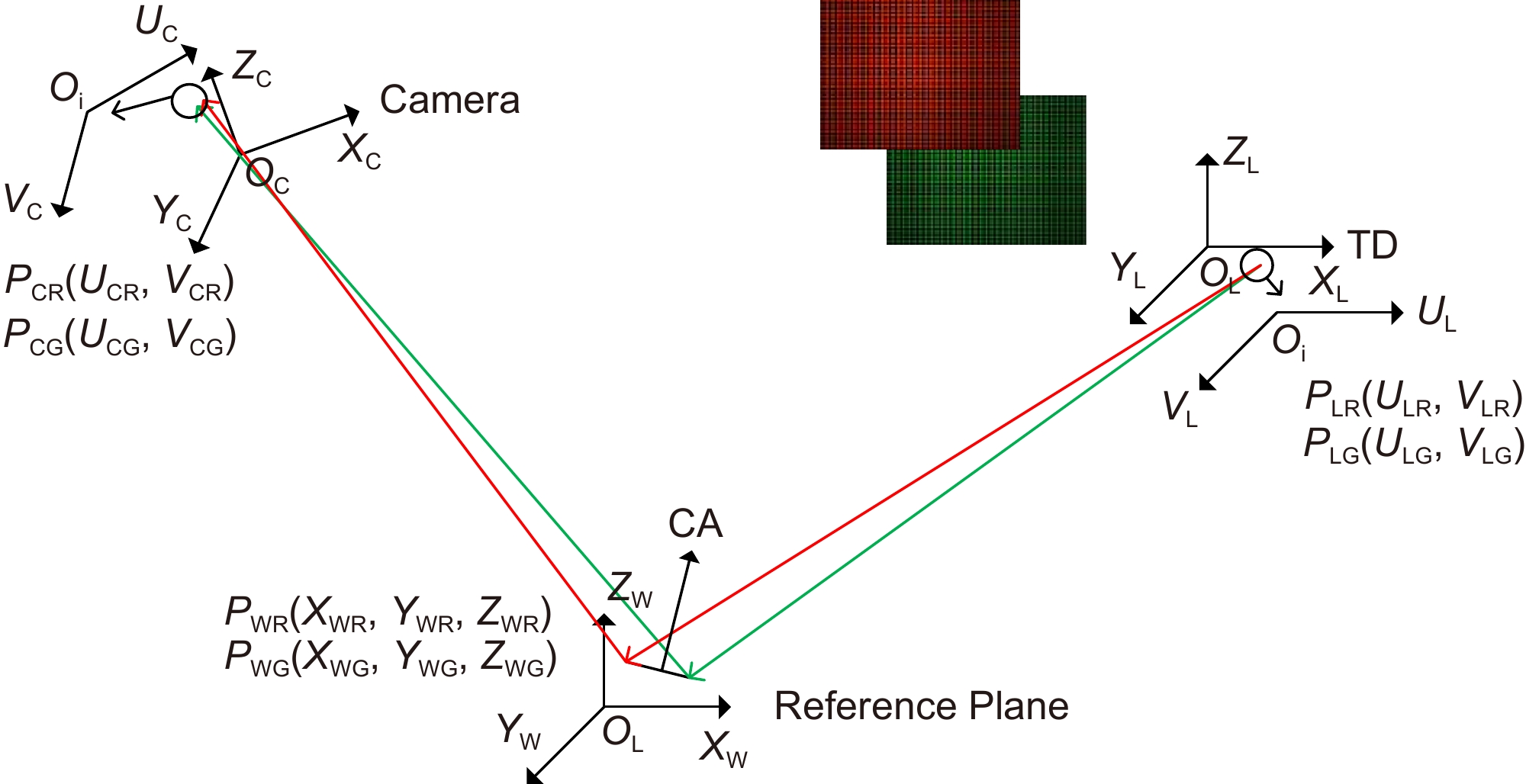

Abstract:In order to realize the rapid measurement of composite surfaces with diffuse and mirror reflection, the composite surface measurement system based on fringe projection and fringe reflection can obtain the absolute phase rapidly through the multi-color channel of the camera. Aiming at the crosstalk and chromatic aberration between the color channels introduced by the camera, projector, and display in the composite surface topography measurement, this paper studies the crosstalk elimination method based on the matrix and the chromatic aberration elimination method of the absolute phase corresponding pixel deviation. Based on the crosstalk matrix, the crosstalk matrix of the projector and display screen is established. The crosstalk intensity from other channels in the desired color channel is eliminated to complete the crosstalk elimination between color channels. The absolute phase in the horizontal and vertical directions of each color channel is obtained by color orthogonal stripes. The relationship between phase difference and pixel deviation is established to realize the pixel deviation correction of each pixel point and eliminate the influence of color difference. The experimental results show that the proposed method reduces the average measurement error of the composite step from 0.479 mm to 0.030 mm, and improves the efficiency and accuracy of measurement.

-

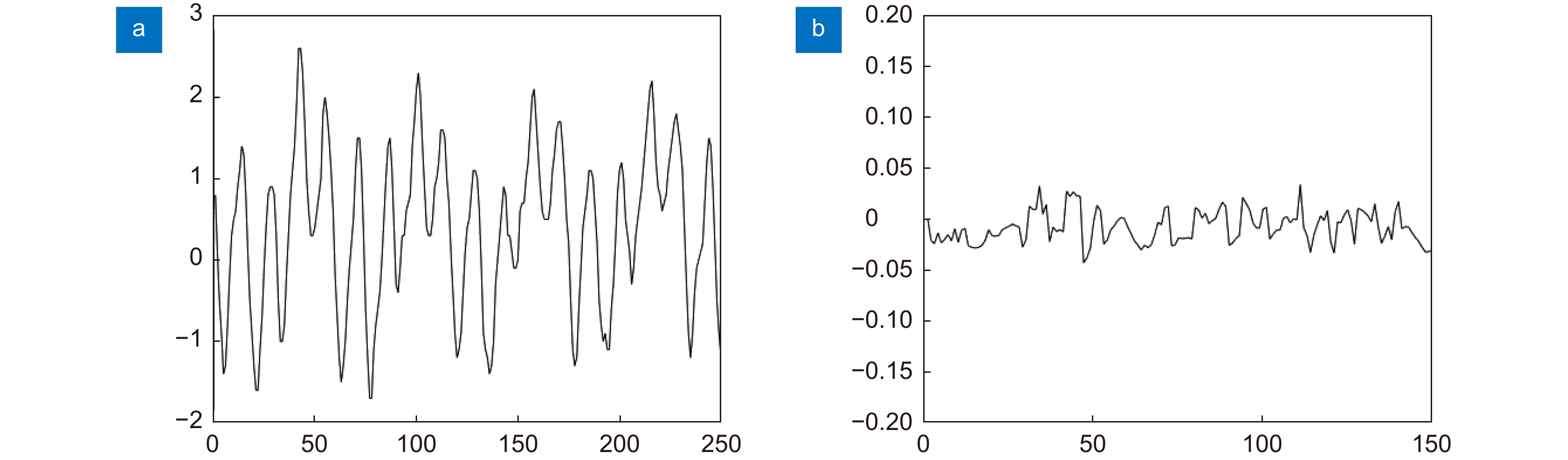

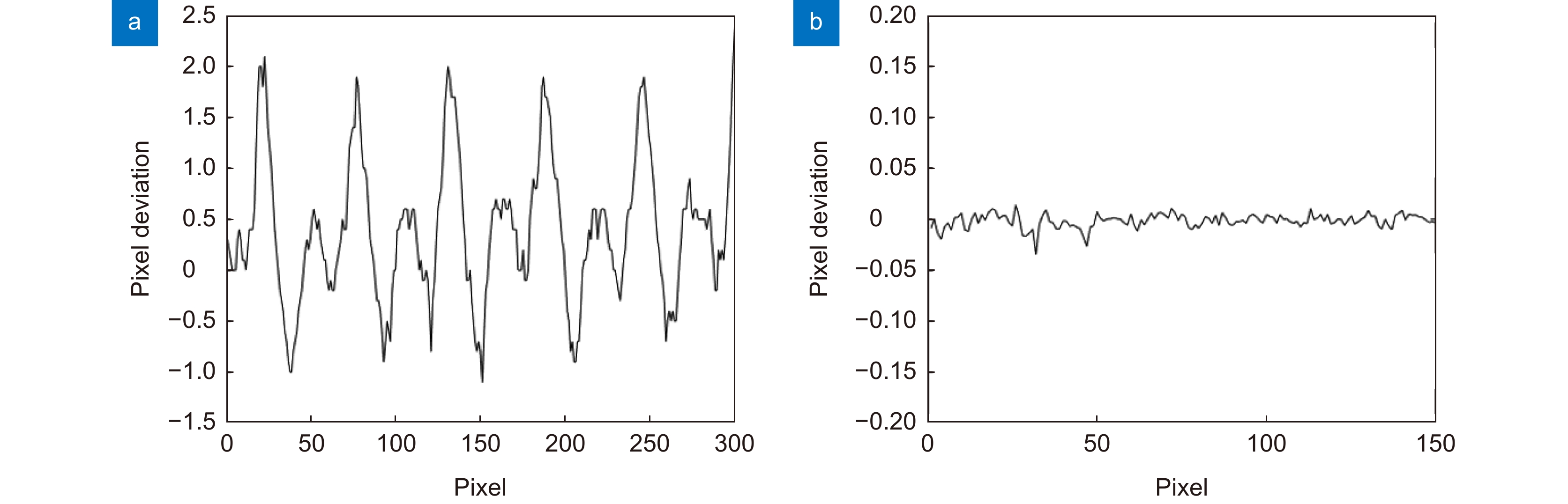

Overview: Due to the large dynamic range and high precision, the optical 3D measurement technology based on phase calculation is widely used in aerospace, automobile manufacturing, biomedicine, cultural relics protection, and other fields to measure a type of surface. For example, fringe projection profilometry and phase measurement deflectometry are used to measure diffuse and specular surfaces, respectively. With the development of advanced manufacturing technology, the measurement of one type of surface cannot meet the current situation. In the existing research on diffuse and specular composite surfaces, 3D topography restoration of large gradient and discontinuous composite surfaces has been achieved. The composite surface measurement system based on fringe projection and fringe reflection can obtain absolute phase rapidly through the multi-color channel of the camera. However, the multi-color channel of the camera not only realizes the rapid measurement but also introduces the errors such as crosstalk and chromatic aberration into the system, which limits the accuracy of 3D topography restoration of composite surface objects. Crosstalk mainly comes from the process of simultaneously shooting different color stripes projected by the projector to the diffuse part of the object and displayed by the transparent display screen on the mirror part of the object. The color difference mainly comes from the different color stripes displayed by the double screen transmission of the mirror part, and there is a phase difference between the absolute phase of the two colors. Therefore, this paper studies the crosstalk elimination method based on the matrix and the color difference elimination method of absolute phase corresponding pixel deviation. Based on the crosstalk matrix, the crosstalk matrix of the projector and the transparent screen is calculated respectively according to the color light intensity relationship between the color camera, projector, and transparent screen. The stripes of different colors projected on the diffuse surface and mirror of the composite object are separated, and the absolute phase of the two parts is obtained. The absolute phase in the horizontal and vertical directions of each color channel was obtained by color orthogonal stripes, and the relationship between phase difference and pixel deviation between color channels was established to complete the pixel matching of different color channels. Finally, the pixel matching points are converted into the matrix obtained by two-dimensional interpolation to realize the pixel deviation correction of each pixel point and eliminate the influence of color difference. The experimental results show that the proposed method reduces the root mean square error of the composite step from 0.479 mm to 0.030 mm, and improves the measurement efficiency and accuracy.

-

-

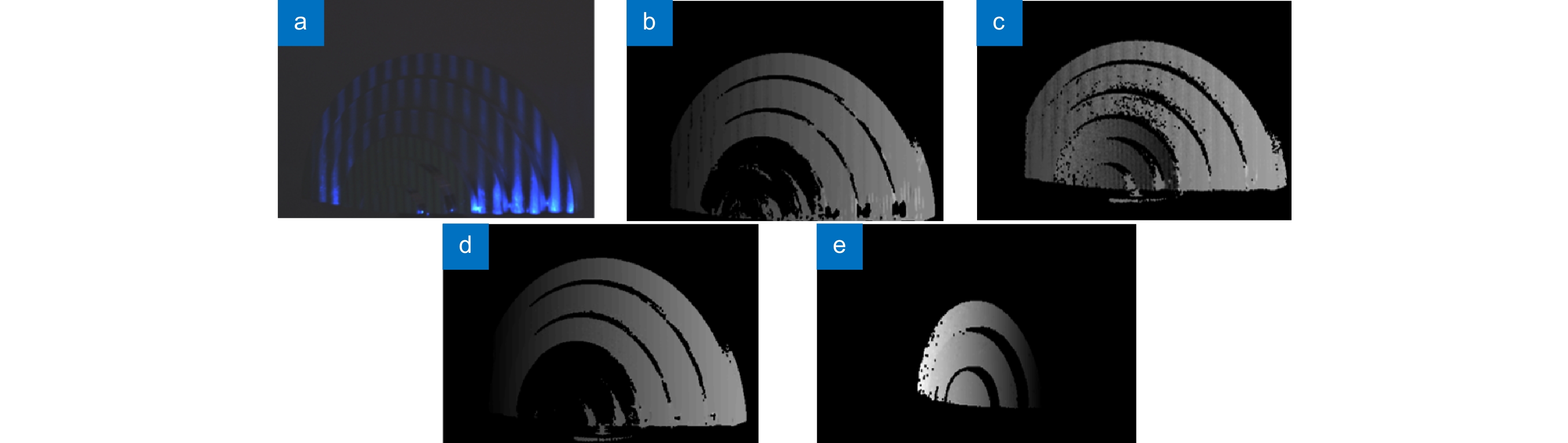

图 5 串扰消除前后的绝对相位图。(a) 同时拍摄的条纹图; (b) 处理前的蓝色通道绝对相位图; (c) 处理前的绿色通道绝对相位图; (d) 处理后的蓝色通道绝对相位图; (e) 处理后的绿色通道绝对相位图

Figure 5. Absolute phase diagram before and after crosstalk elimination. (a) A fringe map taken at the same time; (b) Absolute phase map of the blue channel before processing; (c) Absolute phase diagram of the green channel before processing; (d) Absolute phase diagram of the processed blue channel; (e) Absolute phase diagram of the processed green channel

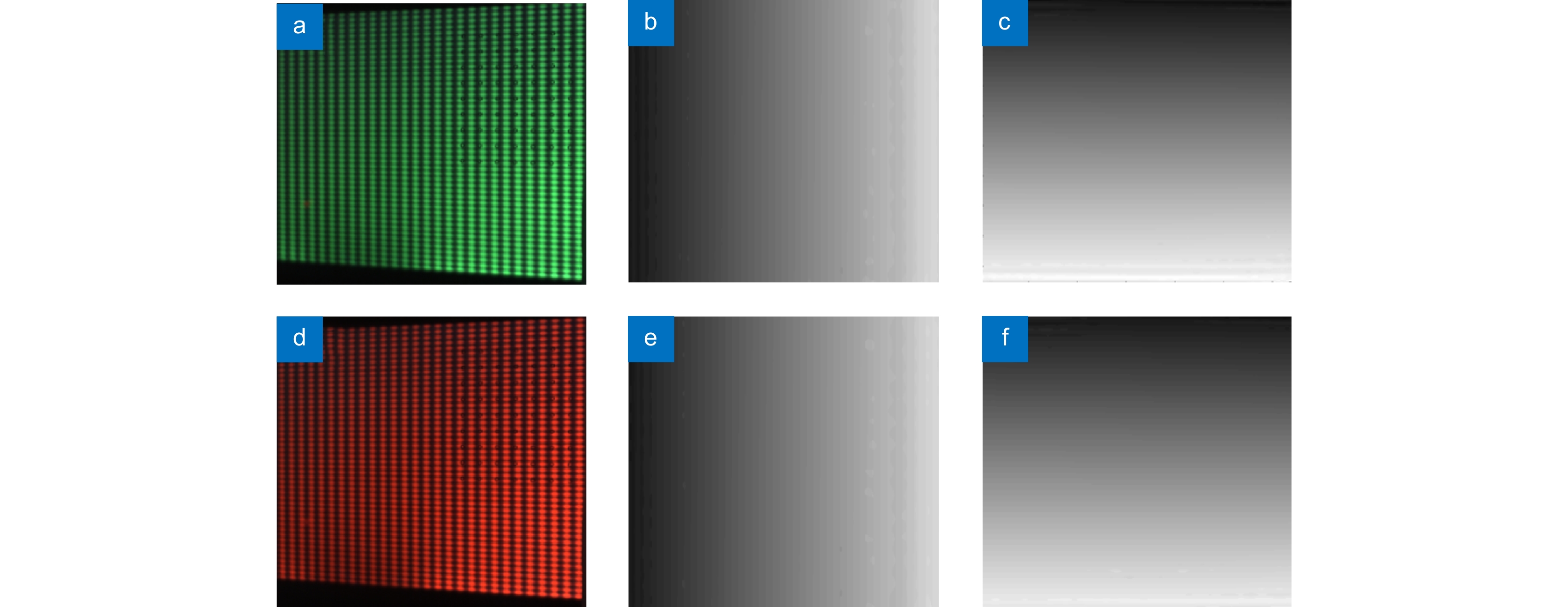

图 7 正交条纹及展开相位图。(a) 绿色正交条纹图; (b) 竖直条纹展开相位; (c) 水平条纹展开相位;(d) 红色正交条纹图; (e) 竖直条纹展开相位; (f) 水平条纹展开相位

Figure 7. Orthogonal fringe and unwrapping phase diagram. (a) Green orthogonal fringe pattern; (b) Vertical stripe unwrapping phase; (c) Horizontal fringe unwrapping phase; (d) Red orthogonal stripe pattern; (e) Vertical stripe unwrapping phase; (f) Horizontal fringe unwrapping phase

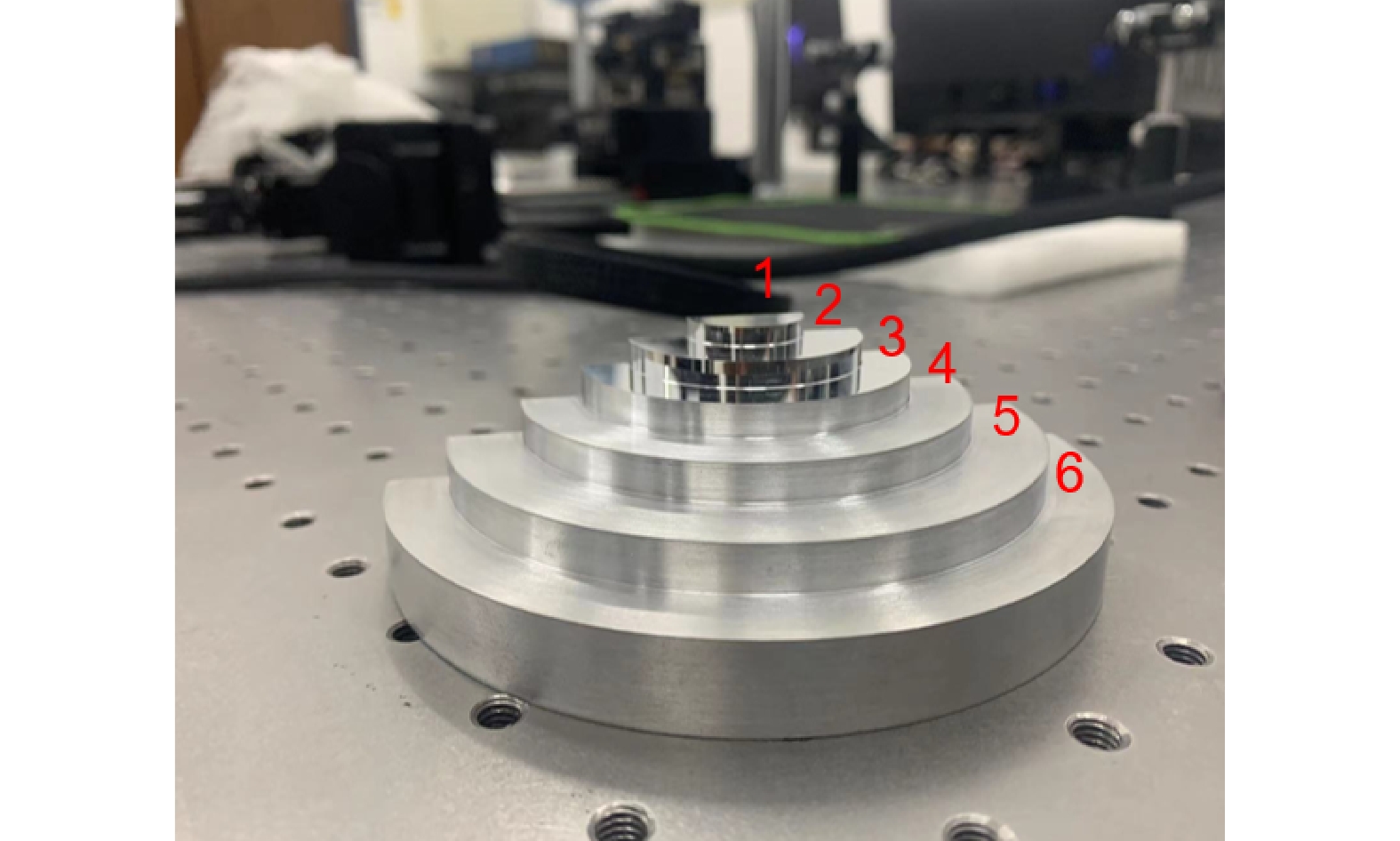

表 1 复合台阶相邻台阶面的测量

Table 1. Measurement results of adjacent step surfaces of composite reflection steps (unit: mm)

Step

surfaceCMM

measurement

resultsMeasurement

results before

correctionCorrected

measurement

resultsAbsolute error

before

correctionCorrected

absolute

error1-2 3.000 2.646 2.975 0.354 0.025 2-3 4.000 4.381 4.021 0.381 0.021 3-4 5.000 4.409 4.961 0.592 0.039 4-5 5.500 5.979 5.523 0.479 0.023 5-6 6.500 5.957 6.463 0.543 0.037 -

[1] Van Der Jeught S, Dirckx J J J. Real-time structured light profilometry: a review[J]. Opt Lasers Eng, 2016, 87: 18−31. doi: 10.1016/j.optlaseng.2016.01.011

[2] 范松如, 范朦, 陈冬晖, 等. 基于时域相移技术的结构光三维微纳形貌检测方法[J]. 光电工程, 2021, 48(4): 200430. doi: 10.12086/oee.2021.200430

Fan S R, Fan M, Chen D H, et al. Micro/Nano profile measurement by structured illumination microscopy utilizing time-domain phase-shift technique[J]. Opto-Electron Eng, 2021, 48(4): 200430. doi: 10.12086/oee.2021.200430

[3] Huang L, Idir M, Zuo C, et al. Review of phase measuring deflectometry[J]. Opt Lasers Eng, 2018, 107: 247−257. doi: 10.1016/j.optlaseng.2018.03.026

[4] 赵涵卓, 高楠, 孟召宗, 等. 双视角三维测量系统同时标定方法[J]. 光电工程, 2021, 48(3): 200127. doi: 10.12086/oee.2021.200127

Zhao H Z, Gao N, Meng Z Z, et al. Method of simultaneous calibration of dual view 3D measurement system[J]. Opto-Electron Eng, 2021, 48(3): 200127. doi: 10.12086/oee.2021.200127

[5] 陈贞屹, 赵文川, 张启灿, 等. 基于立体相位测量偏折术的预应力薄镜面形检测[J]. 光电工程, 2020, 47(8): 190435. doi: 10.12086/oee.2020.190435

Chen Z Y, Zhao W C, Zhang Q C, et al. Shape measurement of stressed mirror based on stereoscopic phase measuring deflectometry[J]. Opto-Electron Eng, 2020, 47(8): 190435. doi: 10.12086/oee.2020.190435

[6] 王月敏, 张宗华, 高楠. 基于全场条纹反射的镜面物体三维面形测量综述[J]. 光学 精密工程, 2018, 26(5): 1014−1027. doi: 10.3788/OPE.20182605.1014

Wang Y M, Zhang Z H, Gao N. Review on three-dimensional surface measurements of specular objects based on full-field fringe reflection[J]. Opt Precis Eng, 2018, 26(5): 1014−1027. doi: 10.3788/OPE.20182605.1014

[7] 郭志南, 刘小红, 张宗华. 复合表面三维形貌测量方法的仿真与验证[J]. 激光与光电子学进展, 2020, 57(19): 191202. doi: 10.3788/LOP57.191202

Guo Z N, Liu X H, Zhang Z H. Simulation and verification of three-dimensional shape measurement method for composite surface[J]. Laser Optoelectron Progr, 2020, 57(19): 191202. doi: 10.3788/LOP57.191202

[8] 岳慧敏, 李绒, 潘志鹏, 等. 一种面结构光三维测量系统及其测量方法: 106197322B[P]. 2019-04-02.

Yue H M, Li R, Pan Z P, et al. Face structure light three-dimensional measuring system: 106197322B[P]. 2019-04-02

[9] Sandner M. Hybrid Reflectometry-3D shape measurement on scattering and reflective surfaces[C]//115th Annual Meeting of the DGaO, 2014.

[10] 张宗华, 刘小红, 郭志南, 等. 基于结构光的镜面/漫反射复合表面形貌测量[J]. 红外与激光工程, 2020, 49(3): 0303015. doi: 10.3378/IRLA202049.0303015

Zhang Z H, Liu X H, Guo Z N, et al. Shape measurement of specular/diffuse complex surface based on structured light[J]. Infrared Laser Eng, 2020, 49(3): 0303015. doi: 10.3378/IRLA202049.0303015

[11] 张宗华, 李月, 高楠, 等. 基于双屏透射显示的镜面物体三维形貌测量方法及装置: 111765851B[P]. 2021-09-28.

Zhang Z H, Li Y, Gao N, et al. Mirror surface object three-dimensional shape measurement method and device based on double-screen transmission display: 111765851B[P]. 2021-09-28

[12] Zhang Z H, Xu Y J, Liu Y. Crosstalk reduction of a color fringe projection system based on multi-frequency heterodyne principle[J]. Proc SPIE, 2013, 9046: 904607. doi: 10.1117/12.2034238

[13] Huang P S, Hu Q, Jin F, et al. Color-encoded digital fringe projection technique for high-speed 3-D surface contouring[J]. Opt Eng, 1999, 38(6): 1065−1071. doi: 10.1117/1.602151

[14] Hu Y S, Xi J T, Li E B, et al. A calibration approach for decoupling colour cross-talk using nonlinear blind signal separation network[C]//Conference on Optoelectronic and Microelectronic Materials and Devices, 2004, Brisbane, 2005: 265–268. https://doi.org/10.1109/COMMAD.2004.1577541.

[15] Sun P P, Xue Q, Ji W Z, et al. Analysis and compensation of lateral chromatic aberration of structured light 3D measurement system[J]. Opt Commun, 2021, 488: 126871. doi: 10.1016/j.optcom.2021.126871

[16] Zhang Z H, Towers C E, Towers D P. Compensating lateral chromatic aberration of a colour fringe projection system for shape metrology[J]. Opt Lasers Eng, 2010, 48(2): 159−165. doi: 10.1016/j.optlaseng.2009.04.010

[17] Liu X H, Huang S J, Zhang Z H, et al. Full-field calibration and compensation of lateral chromatic aberration based on unwrapped phase[J]. Proc SPIE, 2016, 10021: 1002119. doi: 10.1117/12.2245839

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: