-

摘要

随着航空航天、能源动力和石油化工等领域的快速发展,镍基合金薄板焊接技术成为决定核心零部件使用性能的关键因素之一。镍基合金薄板焊接对热输入敏感,易出现元素偏析、脆性相析出导致焊缝性能降低及产生焊接变形等问题。本文介绍了镍基合金薄板激光焊接技术的研究进展,分别总结了镍基合金薄板的激光自熔焊接和激光填丝焊接两种焊接技术下的焊缝微观组织演变、力学性能和耐腐蚀性能变化以及焊接变形规律,提出了未来研究应重点考虑对焊缝微观组织的预测,并结合先进的算法,提出微观组织、力学性能和耐腐蚀性能的自适应调控策略,进而开发出新型智能化焊接工艺。

-

关键词:

- 镍基合金 /

- 激光焊接 /

- 微观组织 /

- 力学性能和耐腐蚀性能 /

- 焊接变形

Abstract

With the rapid development of aerospace, energy power, petrochemical, and other fields, nickel-based alloy sheet welding technology has become one of the key factors determining the performance of core components. The welding of nickel base alloy sheet is sensitive to the heat input, and it is easy to cause element segregation and brittle phase precipitation, which will reduce the weld performance and produce welding deformation. This paper introduces the research progress of laser welding technology of nickel base alloy sheet, and summarizes the evolution of weld microstructure, changes of mechanical properties and corrosion resistance, and the rules of welding deformation under two kinds of welding technologies including laser autogenous welding and laser welding with filler wire of nickel base alloy sheet. It is proposed that the prediction of weld microstructure should be considered in the future research, which should combine with advanced algorithms to propose the adaptive control strategy of microstructure, mechanical properties and corrosion resistance, developing a new intelligent welding process.

-

Overview

Overview: With the rapid development of aerospace, energy power, petrochemical, and other fields, nickel-based alloy sheet welding technology has become one of the key factors determining the performance of core components. The welding of nickel base alloy sheet is sensitive to the heat input, and it is easy to cause element segregation and brittle phase precipitation, which will reduce the weld performance and produce welding deformation. This paper introduces the research progress of laser welding technology of nickel base alloy sheet, and summarizes the evolution of weld microstructure, changes of mechanical properties and corrosion resistance, and the rules of welding deformation under two kinds of welding technologies including laser autogenous welding and laser welding with filler wire of nickel base alloy sheet. The research of the autogenous laser welding process focuses on Ni-Cr and Ni-Cr-Mo alloys. The grain morphology and element segregation are analyzed, including refining microstructure and inhibiting the formation of precipitates, by means of adjusting the process parameters, using ultrasonic vibration, and using a low-temperature cooling process. The microhardness of the two kinds of alloy welds is better than that of base metal, because of the finer grains in the welds. Tensile strength at room temperature can reach about 90% of the base metal, but high-temperature tensile performance is comparable to the base metal. Ni-Cr alloy welded joints show good high-temperature plasticity. The relatively lower tensile strength of the welded joints is relative to the worse morphology of the weld surfaces. The fatigue properties and corrosion resistance of the Ni-Cr-Mo alloy welds are comparable to those of the base metal. The research of laser welding of nickel-based alloy sheets with filler wire focuses on the Ni-Cr-Mo alloy, and the grain morphology, element segregation, and its regulation are still the focuses of the research. The microhardness and room temperature tensile strength of the welded joints with filler wire are better than those of the base metal. The better room temperature tensile strength of the welded joints benefits from both the finer weld grains and the occurrence of the reinforcement. Corrosion tests show that the welded joints have comparable corrosion resistance to the base metal. Welding deformation of nickel-based alloy sheets includes shrinkage deformation, deflection, and angular deformation. Compare with the traditional arc welding process, laser welding shows lower heat input, and thus, it leads to smaller deformation. At present, the research of welding deformation of nickel-based alloy sheet mainly concentrates on the prediction of deformation through the finite element method and reducing deformation through process parameters adjustment, restraint intensity control, and utilizing auxiliary processes. Future research should focus on the prediction of weld microstructure and the propose of various adaptive control strategies for microstructure, mechanical properties and corrosion resistance by combining with advanced algorithms. Besides, developing new types of intelligent welding processes is also an important part.

-

-

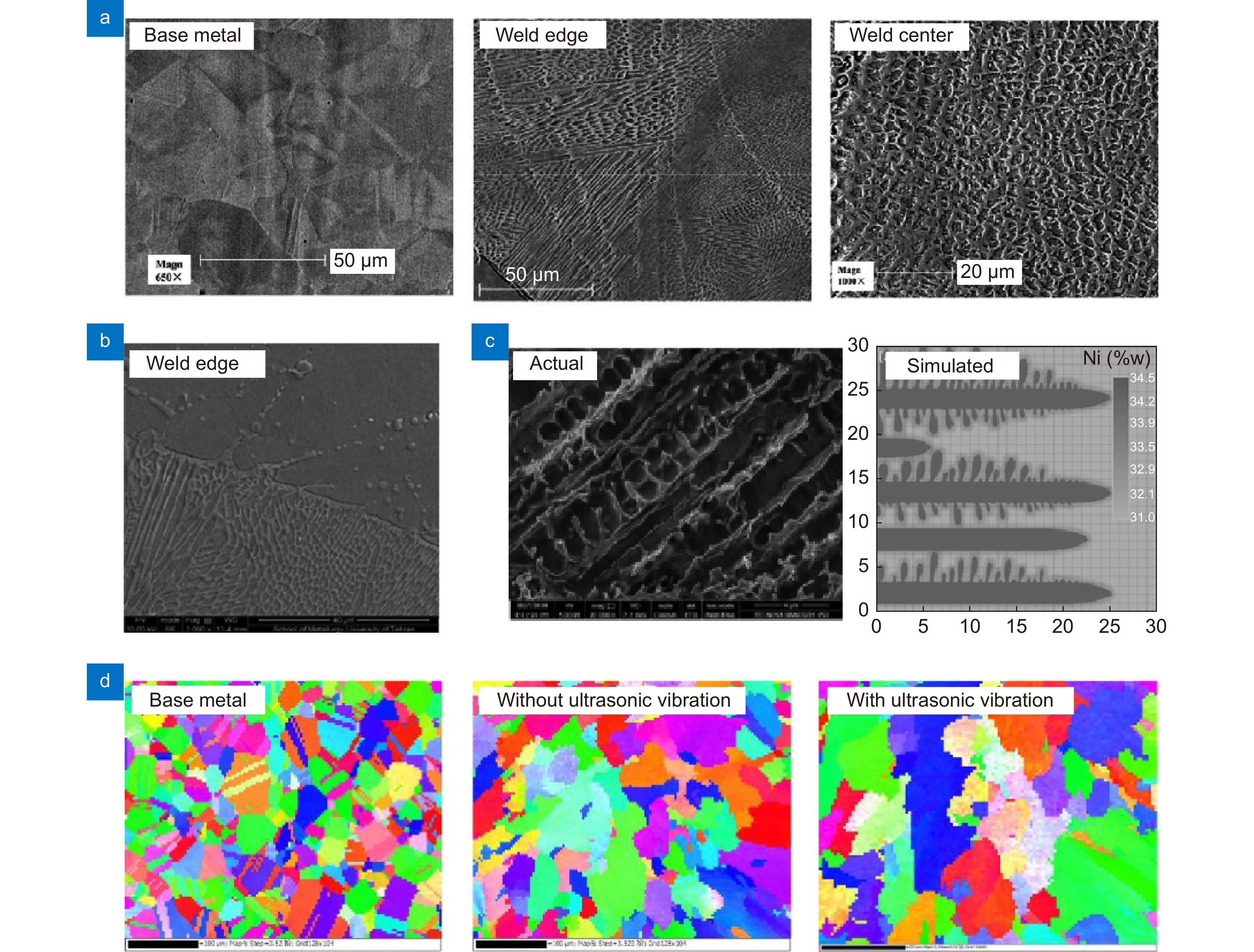

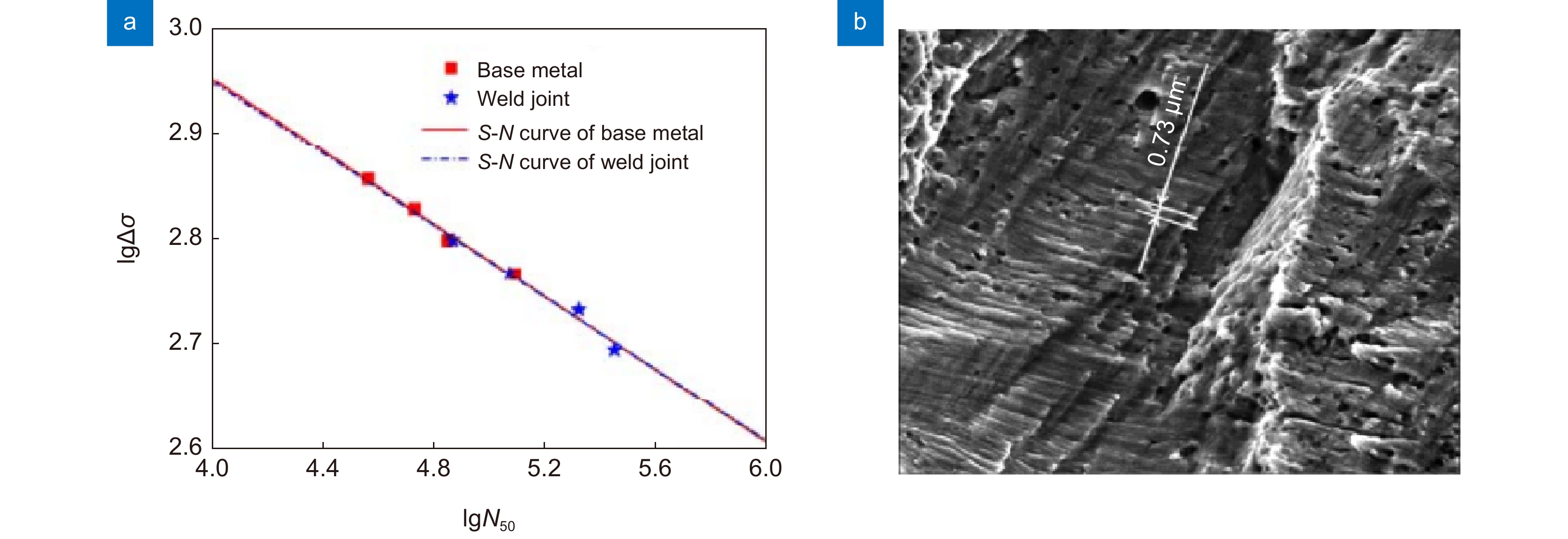

图 1 Ni-Cr合金焊缝微观组织。(a) 熔合线附近和焊缝中心微观组织[19]; (b) 焊接速度对焊缝枝晶的影响[24]; (c) 激光功率对焊缝微观组织的影响[25]; (d) 微观组织预测[26]

Figure 1. Microstructure of Ni-Cr alloy welds. (a) Microstructure near the fusion line and in the weld center[19]; (b) The effect of welding velocity on weld dendrites[24]; (c) The effect of laser power on microstructure of welds[25]; (d) Prediction of microstructure[26]

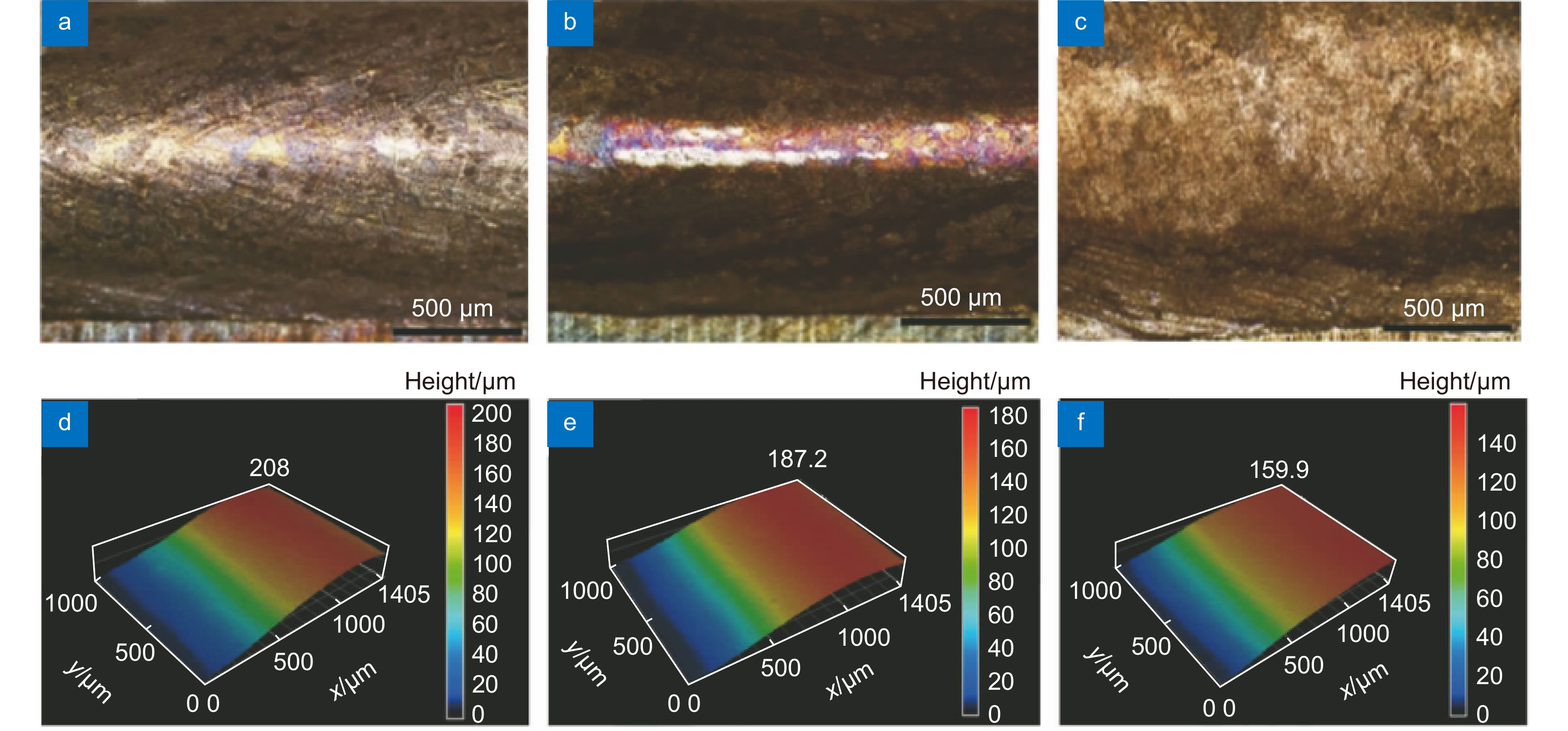

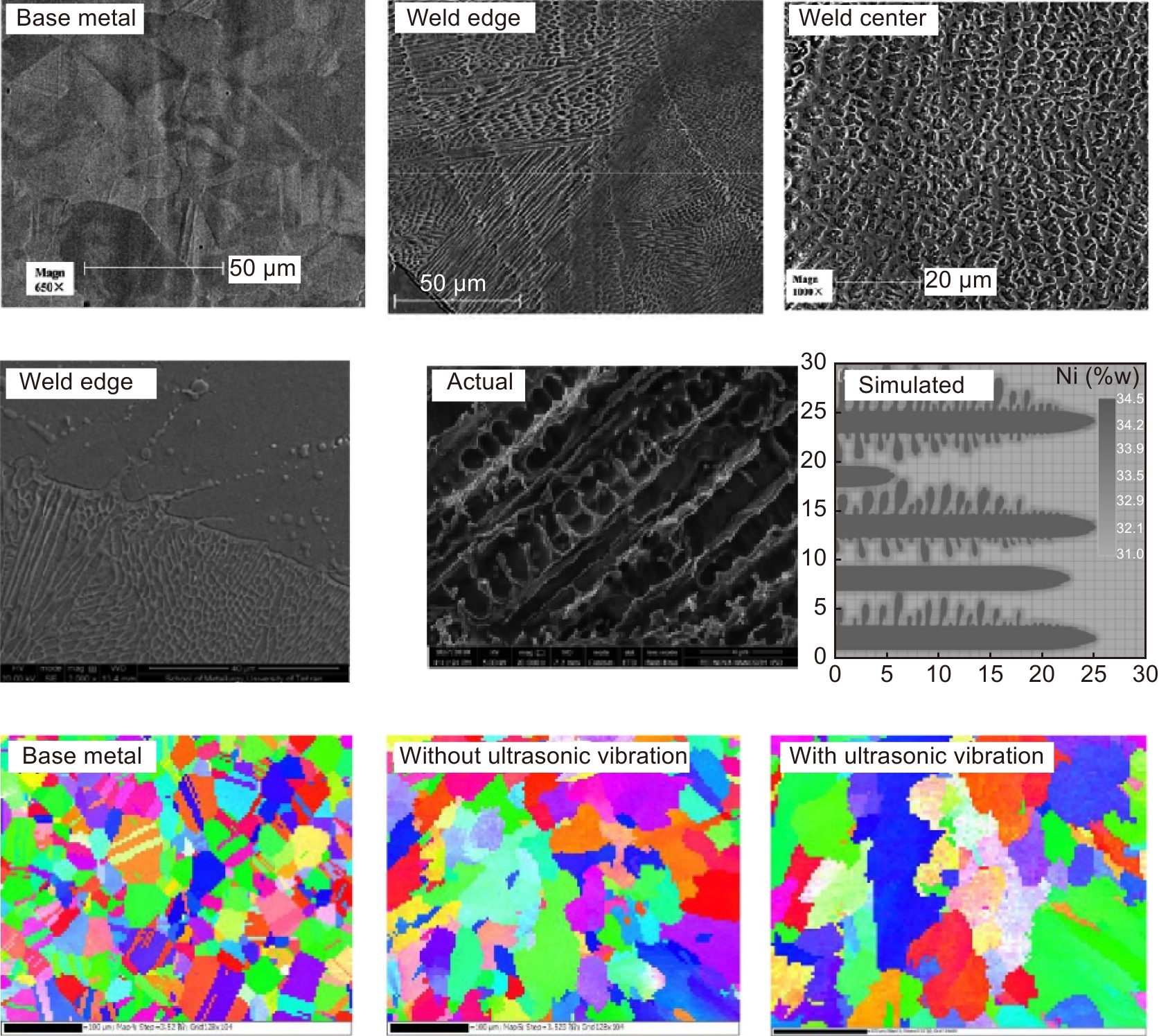

图 2 Ni-Cr-Mo合金焊缝微观组织。(a) Hastelloy C-276母材、热影响区和焊缝中心处的微观组织[27-28]; (b) Hatelloy X焊缝边缘微观组织[29]; (c) 使用相场法模拟焊缝中的柱状晶[30]; (d) 母材及超声作用前后焊缝的微观组织EBSD图[31]

Figure 2. Microstructure of Ni-Cr-Mo alloy welds. (a) Microstructure of Hastelloy C-276 base metal, heat affected zone and weld center[27-28]; (b) Microstructure of Hastelloy X weld edge[29]; (c) The phase field simulation of columnar grains in weld [30]; (d) EBSD microstructure of base metal and the weld with or without ultrasonic vibration[31]

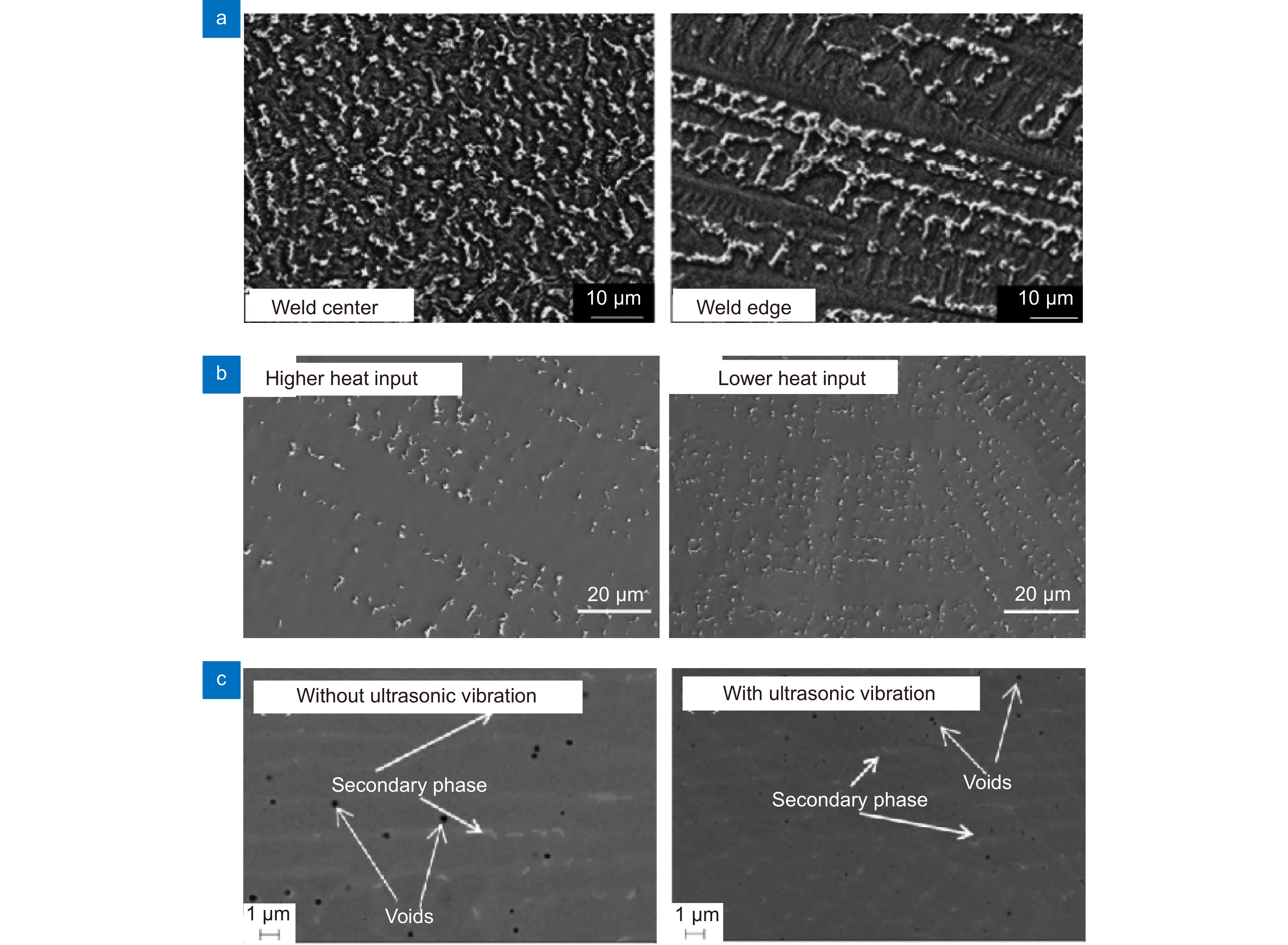

图 3 镍基合金焊缝析出相。(a) Inconel 718焊缝中的Laves相[33]; (b) 热输入变化对Inconel 617焊缝析出相的影响[24];(c) 超声振动对Hastelloy C-276焊缝析出相的影响[31]

Figure 3. The precipitation phase in nickel-based alloy welds. (a) The Laves phase in the Inconel 718 weld[33]; (b) The effect of heat input on the precipitation phase of the Inconel 617 weld[24]; (c) The effect of ultrasonic vibration on the precipitation phase in Hastelloy C-276 welds[31]

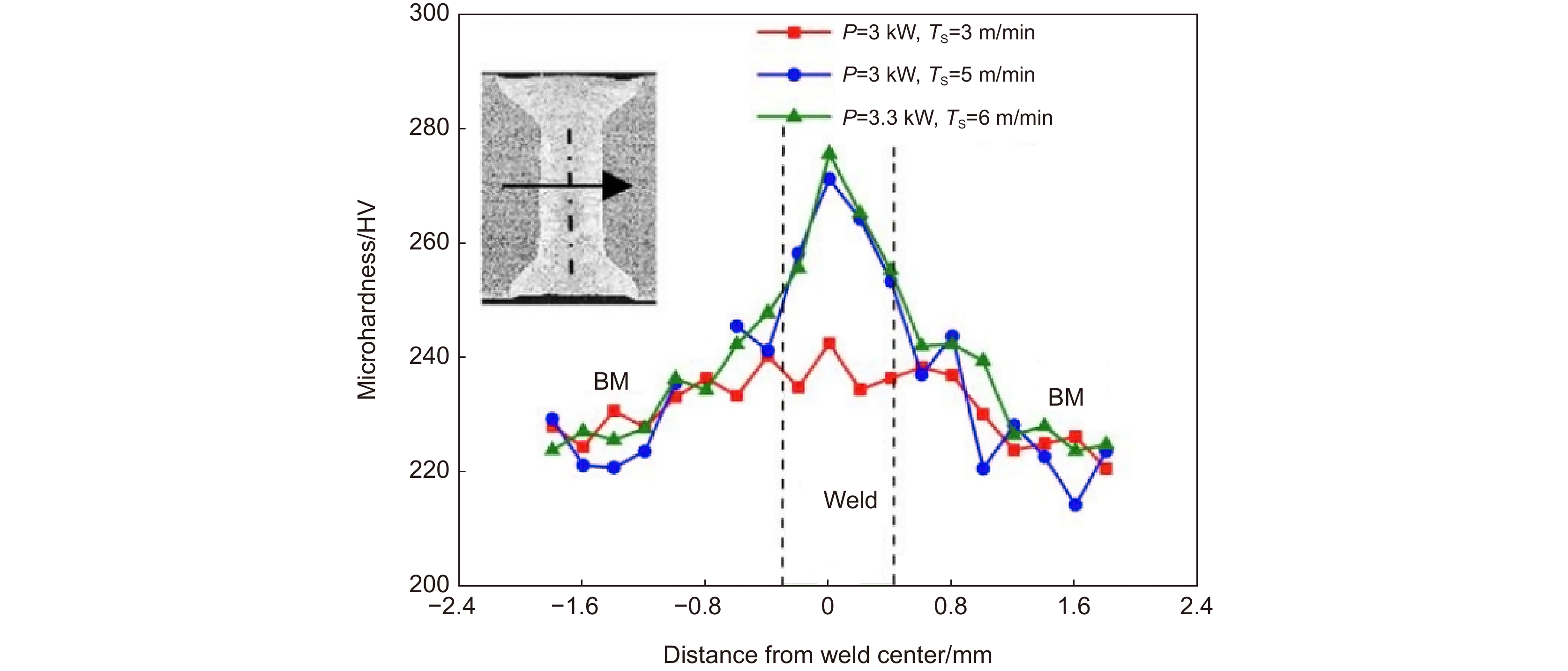

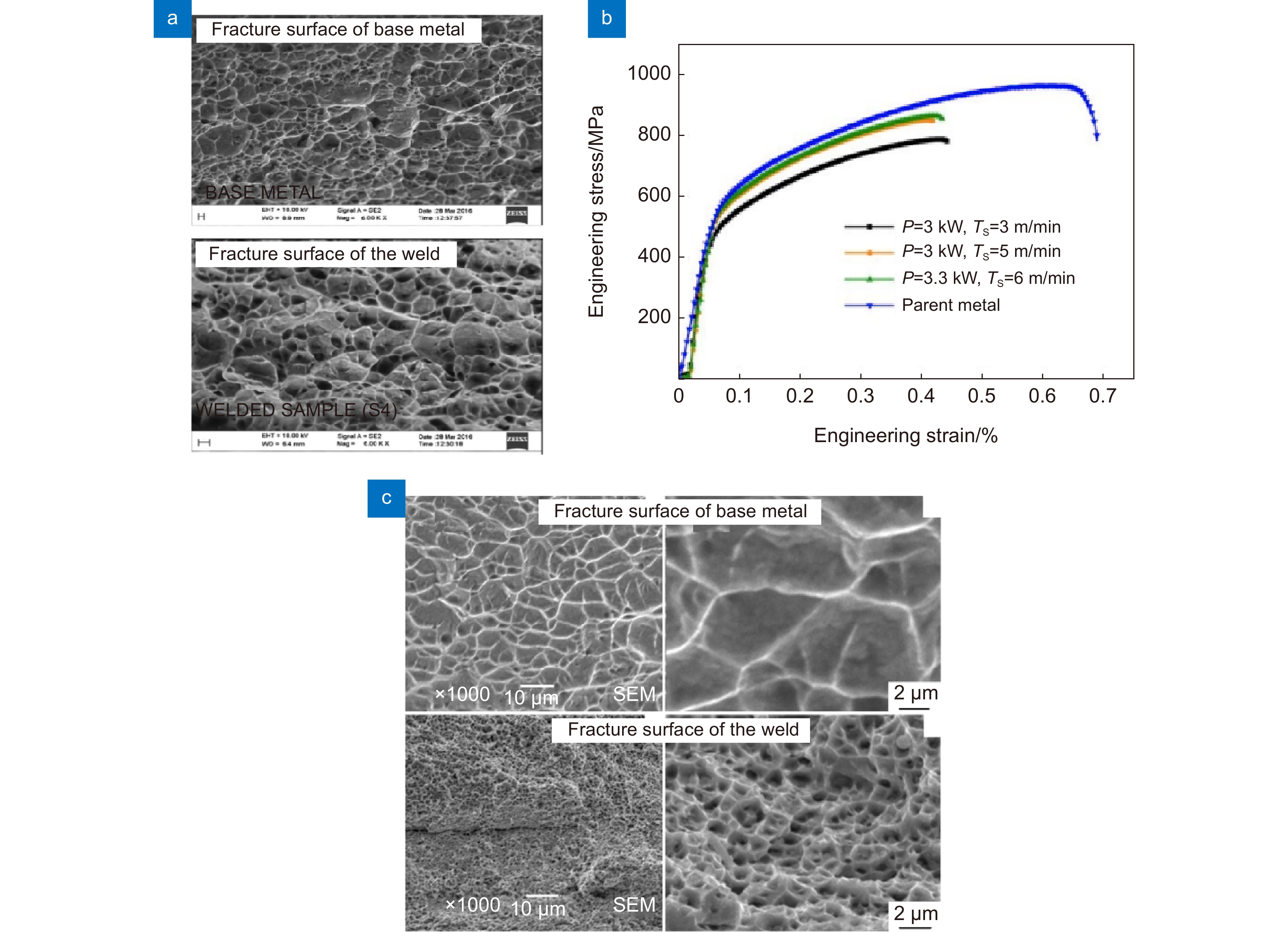

图 5 Ni-Cr-Mo合金焊接接头拉伸性能。(a) Ni-Cr合金的母材与焊缝拉伸断口形貌[46];(b) 通过调整热输入调控抗拉强度[23]; (c) Ni-Cr-Mo合金的母材与焊缝拉伸断口形貌[45]

Figure 5. Tensile properties of Ni-Cr-Mo alloy welded joints. (a) Fracture surfaces of Ni-Cr alloy base metal and weld[46]; (b) Tensile strength with different heat input[23]; (c) Fracture surfaces of Ni-Cr-Mo alloy base metal and weld[45]

图 6 镍基合金高温拉伸性能。(a) Ni-Cr合金高温拉伸前后焊缝中的Laves相[47];(b) Ni-Cr-Mo合金在不同温度下的拉伸曲线[43]; (c) Ni-Cr-Mo合金400 ℃拉伸断口[43]

Figure 6. High temperature tensile properties of nickel-based alloy. (a) The Laves phase in the weld of Ni-Cr alloy before and after high temperature tensile test[47]; (b) Curves of tensile strength of Ni-Cr-Mo alloy welded joints in different temperatures[43]; (c) Fracture surfaces of Ni-Cr-Mo alloy welded joint in 400 °C [43]

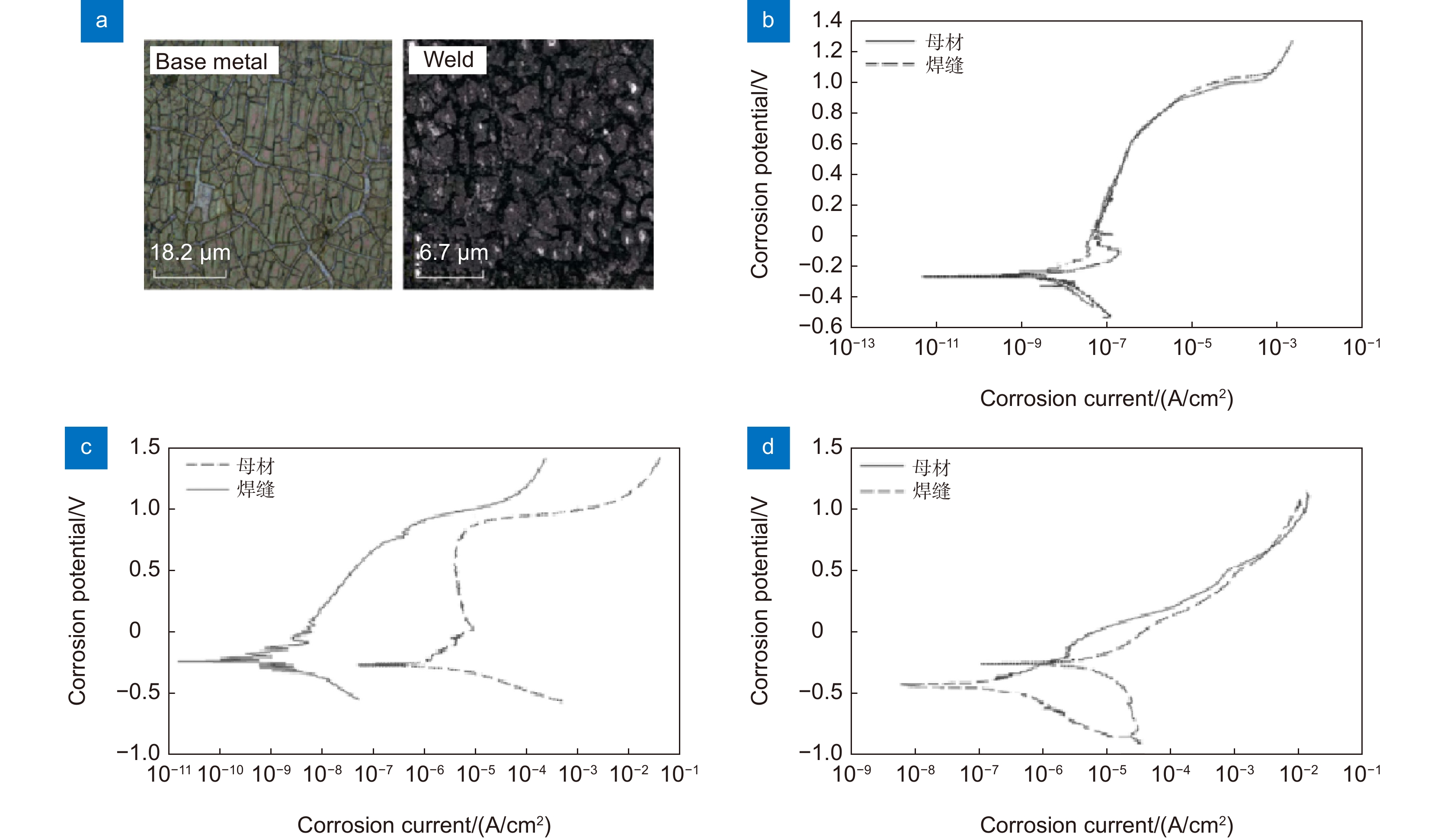

图 8 Ni-Cr-Mo合金腐蚀性能[27]。(a) 腐蚀后的母材和焊缝形貌(NaCl溶液); (b) NaCl溶液电化学极化曲线;(c) 酸性溶液电化学极化曲线; (d) 碱性溶液电化学极化曲线

Figure 8. Corrosion properties of Ni-Cr-Mo alloy[27]. (a) Corrosion morphology of the base metal and the weld (in NaCl solution); (b) Polarization curves in NaCl solution; (c) Polarization curves in acid solution; (d) Polarization curves in alkaline solution

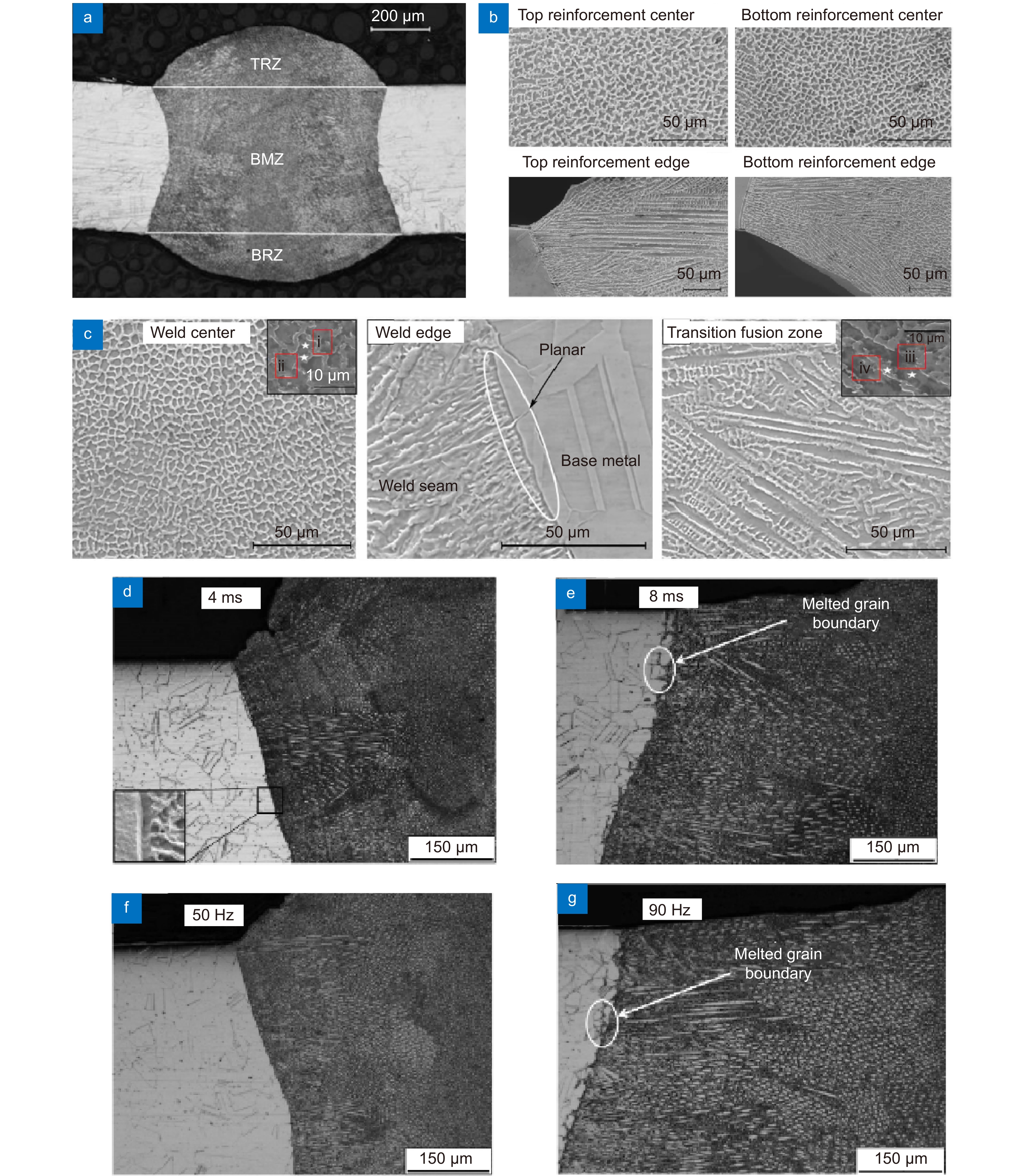

图 9 Ni-Cr-Mo合金激光填丝焊接接头形貌与微观组织。(a) 焊缝整体形貌[57]; (b) 上、下余高边缘及中心处微观组织[57];(c) 焊缝中心、熔合线与过渡熔合区的微观组织[57]; (d) 脉冲宽度为4 ms时微观组织[46]; (e) 脉冲宽度为8 ms时微观组织[46]; (f) 脉冲频率为50 Hz时微观组织[46]; (g) 脉冲频率90 Hz时微观组织[46]

Figure 9. Morphology and microstructure of Ni-Cr-Mo alloy welded joints in laser welding with filler wire. (a) Morphology of the welded joint[57]; (b) Microstructure in edge and center of the reinforcement[57]; (c) Microstructure of the weld center, fusion line and transition fusion zone[57]; (d) Microstructure with the pulse duration of 4 ms[46]; (e) Microstructure with the pulse duration of 8 ms[46]; (f) Microstructure with the pulse frequency of 50 Hz[46]; (g) Microstructure with the pulse frequency of 90 Hz[46]

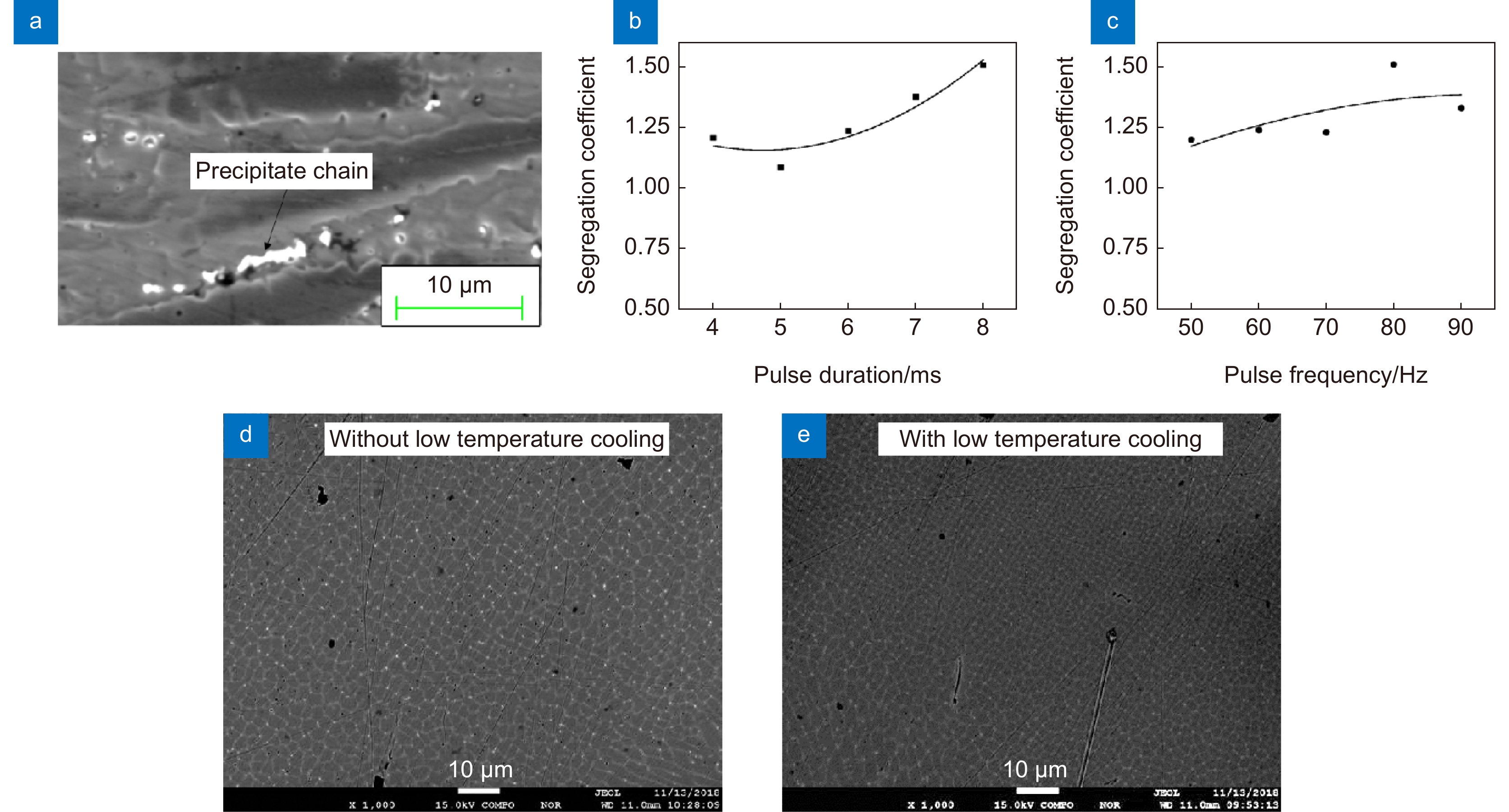

图 10 Ni-Cr-Mo激光填丝焊缝微观组织。(a) 焊缝中的链状析出物[61]; (b) 脉冲宽度对Mo元素偏析影响[61];(c) 脉冲频率对Mo元素偏析影响[61]; (d) 未施加低温冷却的焊缝微观组织[60]; (e) 施加低温冷却后的焊缝微观组织[60]

Figure 10. Microstructure of the Ni-Cr-Mo alloy weld of laser welding with filler wire. (a) Precipitate chain in the weld[61]; (b) The effect of pulse duration on the segregation of Mo[61]; (c) The effect of pulse frequency on segregation of Mo[61]; (d) Microstructure of the weld without low temperature cooling process[60]; (e) Microstructure of the weld with low temperature cooling process[60]

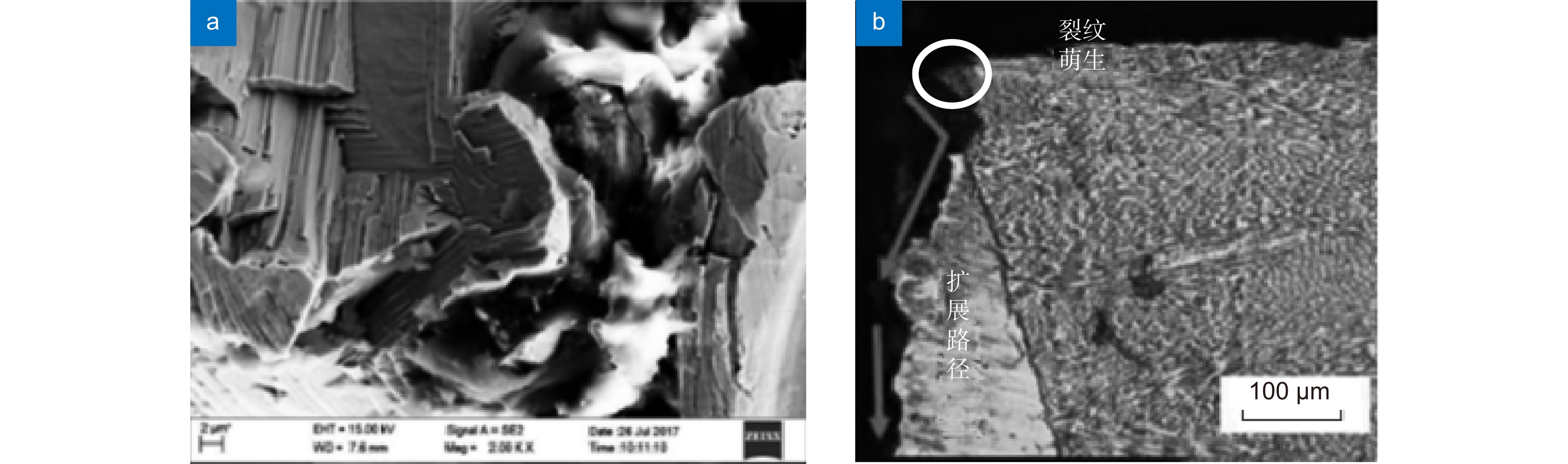

图 13 Ni-Cr-Mo焊接接头空蚀性能[66]。(a) 焊缝空蚀后形貌; (b) 发生空蚀的焊缝晶界; (c) 发生空蚀的母材孪晶界

Figure 13. Cavitation erosion property of Ni-Cr-Mo alloy welded joint [66]. (a) The morphology of the weld after cavitation erosion; (b) Cavitation eroded grain boundary in the weld; (c) Cavitation eroded twin boundary in base metal

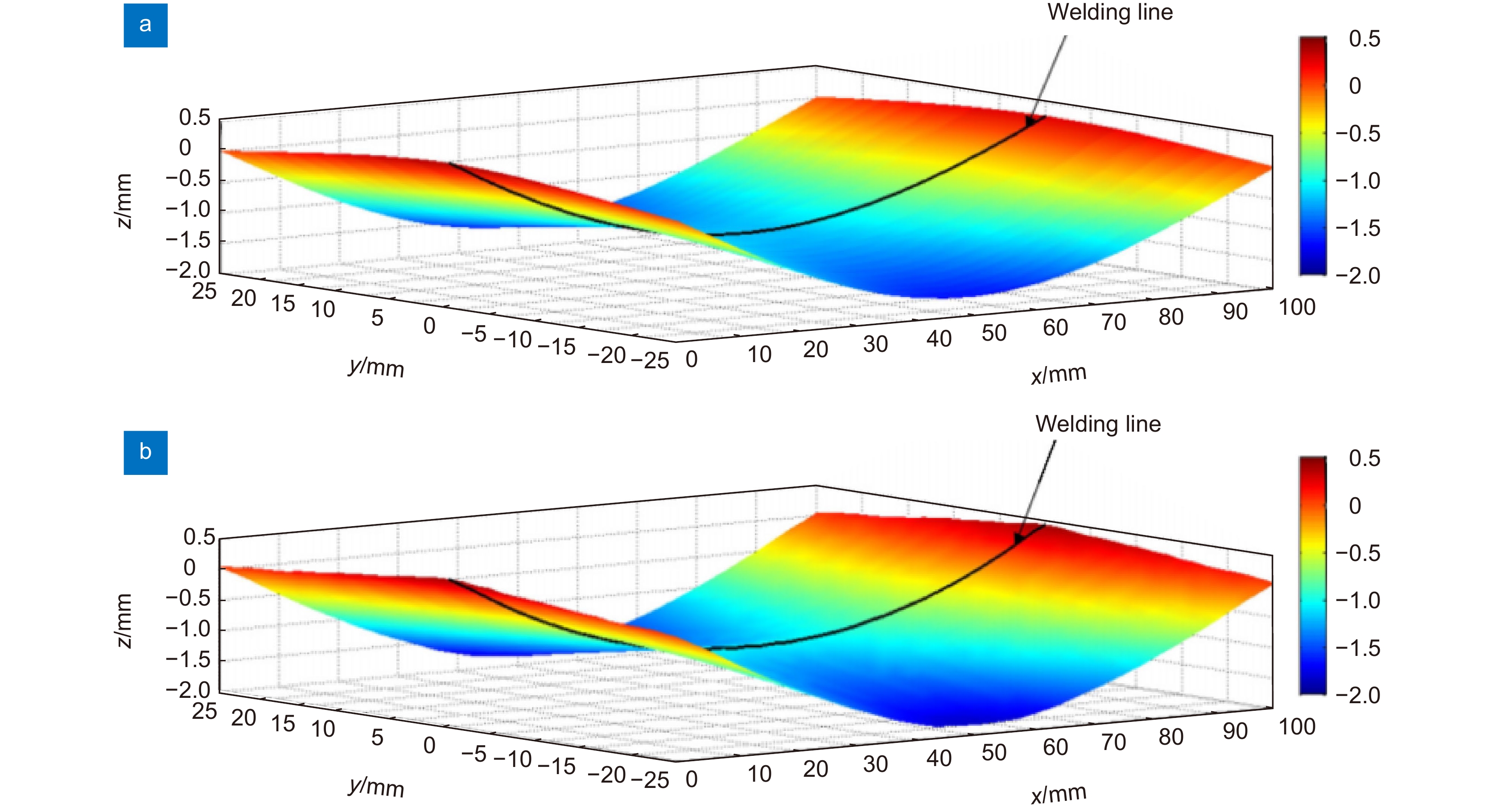

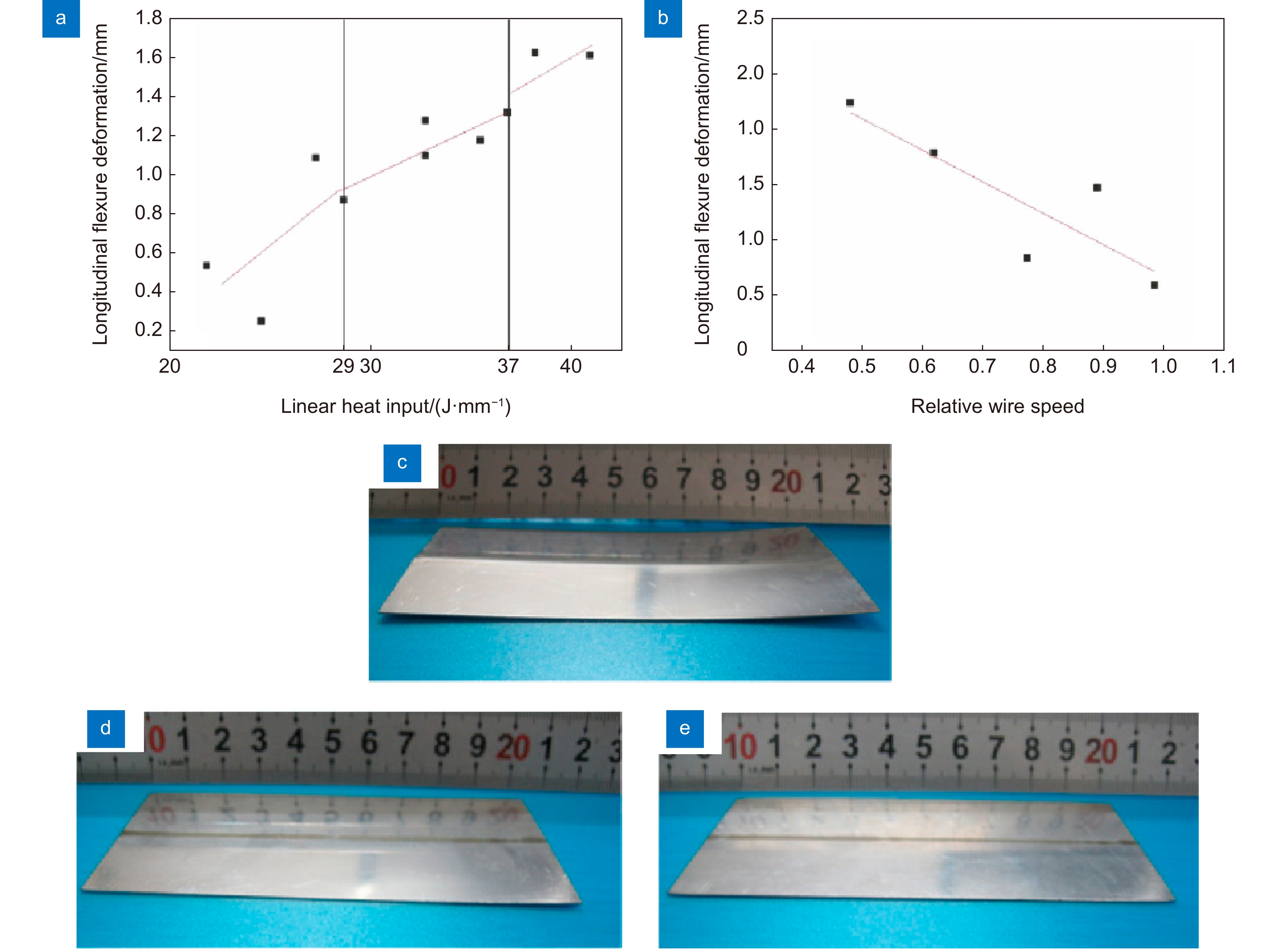

图 16 Hastelloy C-276薄板焊接变形。(a) 线能量密度对挠曲变形的影响[62]; (b) 相对送丝量对挠曲变形的影响[62];(c) 未施加热沉的残余变形[71]; (d) 冷却流量水流量48 mL/min的残余变形[71]; (e) 冷却流量水流量68 mL/min的残余变形[71]

Figure 16. Welding deformation of Hastelloy C-276 sheet. (a) Effect of linear energy density on deflection[62]; (b) Effect of the relative wire speed on the deflection[62]; (c) Residual deformation without heat sink[71]; (d) Residual deformation with the flow rate of 48 mL/min[71]; (e) Residual deformation with the flow rate of 68 mL/min[71]

表 1 自熔焊微观组织研究现状

Table 1. Research status of microstructure of autogenous

材料 微观组织 工艺方法 研究机构 GH 3044 细化焊缝晶粒,减小二次枝晶臂间距 提高焊接速度降低焊接热输入 南昌航空大学[23] Inconel 617 清华大学[24] GH 118 进一步减小焊缝宽度和晶粒尺寸 降低激光功率 北京航空制造工程研究所[25] Hasetlloy C-276 焊缝晶粒显著细化,微观偏析程度降低,脆性相得到抑制 脉冲激光焊接快速凝固 大连理工大学[28] Hasetlloy C-276 减小焊缝晶粒及析出相的尺寸,元素分布更加均匀 施加随焊超声振动调控微观组织 大连理工大学[31] Inconel 617 有效降低了焊缝元素偏析程度,减小脆性相的析出 降低热输入 清华大学[24] Inconel 718 二次枝晶臂间距的预测误差<1.5 μm 数值模型预测焊缝几何形貌和微观组织 巴斯克大学(西班牙)[26] Hatelloy X 初生枝晶臂间距大于3 μm时,会有裂纹产生 德黑兰大学(伊朗)[29] Inconel 718 减少焊缝中的Nb偏析和相应Laves相发展 使用高能量密度的激光焊接 安纳马莱大学(印度)[1] -

参考文献

[1] Sonar T, Balasubramanian V, Malarvizhi S, et al. An overview on welding of Inconel 718 alloy - effect of welding processes on microstructural evolution and mechanical properties of joints[J]. Mater Charact, 2021, 174: 110997. doi: 10.1016/j.matchar.2021.110997

[2] 张明乾, 刘昱, 李承亮. 浅谈压水堆核电站AP1000屏蔽式电动主泵[J]. 水泵技术, 2008(4): 1−5.

Zhang M Q, Liu Y, Li C L. Summary about canned motor type coolant circulating pumps in AP1000 pressurized reactor nuclear power station[J]. Pump Technol, 2008(4): 1−5.

[3] Kuang W J, Song M, Feng X Y. Insight into the acceleration in oxidation kinetics ahead of stress corrosion crack of alloy 690 in simulated PWR primary water[J]. Corros Sci, 2020, 176: 108943. doi: 10.1016/j.corsci.2020.108943

[4] Nowotnik A. Nickel-based superalloys[M]//Reference Module in Materials Science and Materials Engineering. Elsevier, 2016. doi: 10.1016/B978-0-12-803581-8.02574-1.

[5] 熊丽, 王晓南, 张郑辉. Inconel 690镍基合金焊接研究进展[J]. 焊接技术, 2022, 51(3): 12−18,113. doi: 10.13846/j.cnki.cn12-1070/tg.2022.03.003

Xiong L, Wang X N, Zhang Z H. Research progress of Inconel 690 nickel base alloy welding[J]. Weld Technol, 2022, 51(3): 12−18,113. doi: 10.13846/j.cnki.cn12-1070/tg.2022.03.003

[6] Kim J D, Moon J H. C-ring stress corrosion test for Inconel 600 and Inconel 690 sleeve joint welded by Nd: YAG laser[J]. Corros Sci, 2004, 46(4): 807−818. doi: 10.1016/S0010-938X(03)00098-2

[7] 吕志军, 陈玉华, 李树寒, 等. 超薄GH738板材激光微焊接接头的组织性能[J]. 航空科学技术, 2018, 29(7): 73−78. doi: 10.19452/j.issn1007-5453.2018.07.073

Lv Z J, Chen Y H, Li S H, et al. Microstructure and properties of ultrathin GH738 sheet by micro-laser welding[J]. Aeronaut Sci Technol, 2018, 29(7): 73−78. doi: 10.19452/j.issn1007-5453.2018.07.073

[8] 孙佳伟, 陈明和, 梁养民, 等. 超薄Inconel 625激光焊接接头组织与性能[J]. 电焊机, 2016, 46(2): 48−52.

Sun J W, Chen M H, Liang Y M, et al. Microstructure and mechanical properties of thin Inconel 625 by laser beam welding[J]. Elect Weld Mach, 2016, 46(2): 48−52.

[9] 张瑞, 刘鹏, 崔传勇, 等. 国内航空发动机涡轮盘用铸锻难变形高温合金热加工研究现状与展望[J]. 金属学报, 2021, 57(10): 1215−1228. doi: 10.11900/0412.1961.2021.00153

Zhang R, Liu P, Cui C Y, et al. Present research situation and prospect of hot working of cast & wrought superalloys for aero-engine turbine disk in China[J]. Acta Metall Sin, 2021, 57(10): 1215−1228. doi: 10.11900/0412.1961.2021.00153

[10] 李重阳, 龚燚, 刘时兵, 等. 镍基高温合金的发展综述[C]//2020中国铸造活动周论文集, 2020: 170–174.

Li C Y, Gong Y, Liu S B, et al. A review of the development of nickel-based superalloys[C]//2020 China Foundry Week Proceedings, 2020: 170–174.

[11] 李玉龙, 洪智亮. 国外航空发动机火焰筒材料工艺现状与趋势[J]. 航空制造技术, 2021, 64(14): 87−94. doi: 10.16080/j.issn1671-833x.2021.14.087

Li Y L, Hong Z L. Current situation and prospect on material and manufacture process of foreign aero-engine combustion liner[J]. Aeronaut Manuf Technol, 2021, 64(14): 87−94. doi: 10.16080/j.issn1671-833x.2021.14.087

[12] Graneix J, Beguin J D, Alexis J, et al. Weldability of superalloys Hastelloy X by Yb: YAG laser[J]. Adv Mater Res, 2015, 1099: 61−70. doi: 10.4028/www.scientific.net/AMR.1099.61

[13] 伍敏, 熊建坤, 徐健, 等. 燃气轮机用镍基合金焊接技术进展[J]. 电焊机, 2015, 45(5): 59−63.

Wu M, Xiong J K, Xu J, et al. Welding technology development of nickel base alloy for gas turbine[J]. Elect Weld Mach, 2015, 45(5): 59−63.

[14] 罗英, 郑浩, 邱天, 等. 核级主设备焊接技术探讨及展望[J]. 电焊机, 2020, 50(9): 194−201. doi: 10.7512/j.issn.1001-2303.2020.09.20

Luo Y, Zheng H, Qiu T, et al. Discussion and prospect of welding technology for nuclear grade main equipment[J]. Elect Weld Mach, 2020, 50(9): 194−201. doi: 10.7512/j.issn.1001-2303.2020.09.20

[15] 滕彬, 潘士建, 蒋宝, 等. GH536合金激光焊与钨极氩弧焊接头组织性能对比研究[J]. 电焊机, 2022, 52(5): 106−111. doi: 10.7512/j.issn.1001-2303.2022.05.15

Teng B, Pan S J, Jiang B, et al. Comparison of microstructure and mechanical properties between laser welding and TIG welding of GH536 alloy[J]. Elect Weld Mach, 2022, 52(5): 106−111. doi: 10.7512/j.issn.1001-2303.2022.05.15

[16] 刘浩东, 戴京涛. 激光焊接技术的应用研究进展与分析[J]. 电焊机, 2022, 52(1): 95−102. doi: 10.7512/j.issn.1001-2303.2022.01.12

Liu H D, Dai J T. Research review and analysis of laser welding application[J]. Elect Weld Mach, 2022, 52(1): 95−102. doi: 10.7512/j.issn.1001-2303.2022.01.12

[17] 刘春艳, 马瑞, 檀财旺, 等. GH99高温合金环形和C形激光焊接对比研究[J]. 中国激光, 2014, 41(8): 0803002. doi: 10.3788/CJL201441.0803002

Liu C Y, Ma R, Tan C W, et al. Comparison of ring-form and C-form laser welding for GH99 superalloy[J]. Chin J Lasers, 2014, 41(8): 0803002. doi: 10.3788/CJL201441.0803002

[18] 张敏, 宋昊, 高翔, 等. 激光焊接技术在汽车试制及小批量生产中的应用[J]. 金属加工(热加工), 2021(11): 1−4.

Zhang M, Song H, Gao X, et al. Application of laser welding technology in automobile trial manufacture and small batch production[J]. MW Met Form, 2021(11): 1−4.

[19] 孙文君, 王善林, 谭观华, 等. 材料状态对GH4169高温合金激光焊接头组织与性能的影响[J]. 中国激光, 2020, 47(10): 1002006. doi: 10.3788/CJL202047.1002006

Sun W J, Wang S L, Tan G H, et al. Effect of material states on microstructure and properties of GH4169 superalloy laser-welded joint[J]. Chin J Lasers, 2020, 47(10): 1002006. doi: 10.3788/CJL202047.1002006

[20] 龚伟怀, 陈玉华, 吕榛, 等. 0.2mm厚GH4169薄片激光微焊接接头的组织性能[J]. 中国激光, 2011, 38(6): 0603008. doi: 10.3788/CJL201138.0603008

Gong W H, Chen Y H, Lü Z, et al. Microstructure and properties of 0.2 mm thick sheet GH4169 by laser microwelding[J]. Chin J Lasers, 2011, 38(6): 0603008. doi: 10.3788/CJL201138.0603008

[21] Sharma S K, Biswas K, Nath A K, et al. Microstructural change during laser welding of Inconel 718[J]. Optik, 2020, 218: 165029. doi: 10.1016/j.ijleo.2020.165029

[22] Zhang S G, Chen Y H, Cui J H. Microstructure and mechanical properties of laser welding joint of Inconel 718 super thin sheet[J]. Adv Mater Res, 2011, 391–392: 479−483. doi: 10.4028/www.scientific.net/AMR.391-392.479

[23] 王晓光, 刘奋成, 周宝升. GH3044合金激光焊接接头组织和变形均匀性[J]. 中国有色金属学报, 2019, 29(11): 2549−2560. doi: 10.19476/j.ysxb.1004.0609.2019.11.12

Wang X G, Liu F C, Zhou B S. Microstructure and deformation uniformity of GH3044 alloy joints by laser beam welding[J]. Chin J Nonferrous Met, 2019, 29(11): 2549−2560. doi: 10.19476/j.ysxb.1004.0609.2019.11.12

[24] 程昊, 周炼刚, 刘健, 等. 热输入对Inconel 617镍基高温合金激光焊接接头显微组织与力学性能的影响[J]. 材料工程, 2022. doi: 10.11868/j.issn.1001-4381.2021.000790

Cheng H, Zhou L G, Liu J, et al. Effect of heat input on microstructure and mechanical properties of laser welded joint of Inconel 617 nickel-based superalloy[J]. J Mater Eng, 2022. doi: 10.11868/j.issn.1001-4381.2021.000790

[25] 芦伟, 马旭颐, 巩水利, 等. 激光焊接工艺对GH188合金焊缝成形及力学性能的影响[J]. 激光与光电子学进展, 2017, 54(4): 041409. doi: 10.3788/LOP54.041409

Lu W, Ma X Y, Gong S L, et al. Effect of laser welding process on weld formation and mechanical property of GH188 alloy[J]. Laser Optoelectron Prog, 2017, 54(4): 041409. doi: 10.3788/LOP54.041409

[26] Hernando I, Arrizubieta J I, Lamikiz A, et al. Numerical model for predicting bead geometry and microstructure in laser beam welding of Inconel 718 sheets[J]. Metals, 2018, 8(7): 536. doi: 10.3390/met8070536

[27] 马广义, 吴东江, 柴东升, 等. 核主泵屏蔽套近无缺陷激光焊接技术[J]. 机械工程学报, 2015, 51(15): 1−8. doi: 10.3901/JME.2015.15.001

Ma G Y, Wu D J, Chai D S, et al. Near-free-defect laser welding of AP1000 nuclear reactor coolant pump can[J]. J Mech Eng, 2015, 51(15): 1−8. doi: 10.3901/JME.2015.15.001

[28] Ma G Y, Wu D J, Guo D M. Segregation characteristics of pulsed laser butt welding of hastelloy C-276[J]. Metall Mater Trans A, 2011, 42(13): 3853−3857. doi: 10.1007/s11661-011-0978-3

[29] Azimzadegan T, Mousavi S A A A. Investigation of the occurrence of hot cracking in pulsed Nd-YAG laser welding of Hastelloy-X by numerical and microstructure studies[J]. J Manuf Process, 2019, 44: 226−240. doi: 10.1016/j.jmapro.2019.06.005

[30] Azimzadegan T, Mousavi S A A A. Microstructure and solidification cracking analysis of dissimilar pulsed laser welded hastelloy X to 347 stainless steel using phase-field models[J]. Metall Mater Trans B, 2021, 52(4): 2307−2326. doi: 10.1007/s11663-021-02168-9

[31] Zhou S Y, Ma G Y, Wu D J, et al. Ultrasonic vibration assisted laser welding of nickel-based alloy and Austenite stainless steel[J]. J Manuf Process, 2018, 31: 759−767. doi: 10.1016/j.jmapro.2017.12.023

[32] Zhou S Y, Wang B X, Wu D J, et al. Follow-up ultrasonic vibration assisted laser welding dissimilar metals for nuclear reactor pump can end sealing[J]. Nucl Mater Energy, 2021, 27: 100975. doi: 10.1016/j.nme.2021.100975

[33] Janaki Ram G D, Venugopal Reddy A, Prasad Rao K, et al. Microstructure and tensile properties of Inconel 718 pulsed Nd-YAG laser welds[J]. J Mater Process Technol, 2005, 167(1): 73−82. doi: 10.1016/j.jmatprotec.2004.09.081

[34] 蔡祖鹏, 陈玉华, 于大明, 等. GH145薄片脉冲激光微焊接工艺及接头组织性能[J]. 应用激光, 2013, 33(2): 154−157. doi: 10.3788/AL20133302.154

Cai Z P, Chen Y H, Yu D M, et al. The pulse laser micro-welding process of GH145 thin slice and microstructure and properties of welded joints[J]. Appl Laser, 2013, 33(2): 154−157. doi: 10.3788/AL20133302.154

[35] 张子阳, 王善林, 柯黎明, 等. GH3039大功率光纤激光焊接接头组织及力学性能研究[J]. 热加工工艺, 2018, 47(17): 14−19,24. doi: 10.14158/j.cnki.1001-3814.2018.17.004

Zhang Z Y, Wang S L, Ke L M, et al. Microstructure and mechanical properties of GH3039 high power fiber laser welded joints[J]. Hot Work Technol, 2018, 47(17): 14−19,24. doi: 10.14158/j.cnki.1001-3814.2018.17.004

[36] 黄永德, 周兴汶, 龙伟民, 等. 光束偏移量对DD407/GH1140激光焊接头性能的影响[J]. 稀有金属材料与工程, 2018, 47(5): 1620−1624.

Huang Y D, Zhou X W, Long W M, et al. Effect of beam displacement on joint properties of laser welding DD407/GH1140 joint[J]. Rare Met Mater Eng, 2018, 47(5): 1620−1624.

[37] Jelokhani-Niaraki M R, Mostafa Arab N B, Naffakh-Moosavy H, et al. The systematic parameter optimization in the Nd: YAG laser beam welding of Inconel 625[J]. Int J Adv Manuf Technol, 2016, 84(9): 2537−2546. doi: 10.1007/s00170-015-7833-4

[38] Azari M, Rasti E, Dehkordi M H R, et al. Investigation of temperature distribution and melt pool microstructure in laser fusion welding of Inconel 625 superalloy[J]. J Laser Appl, 2021, 33(2): 022015. doi: 10.2351/7.0000376

[39] 吴承隆, 尹浩, 黄泽涵. GH4169镍基高温合金脉冲激光焊工艺参数优化[J]. 工具技术, 2020, 54(10): 38−42. doi: 10.3969/j.issn.1000-7008.2020.10.007

Wu C L, Yin H, Huang Z H. Process parameter optimization of GH4169 pulse laser welding[J]. Tool Eng, 2020, 54(10): 38−42. doi: 10.3969/j.issn.1000-7008.2020.10.007

[40] 彭和思, 陈兵华, 唐景龙, 等. 激光焊接工艺对K418与0Cr18Ni9焊接接头性能的影响[J]. 激光技术, 2018, 42(2): 229−233. doi: 10.7510/jgjs.issn.1001-3806.2018.02.017

Peng H S, Chen B H, Tang J L, et al. Effect of laser welding technology on mechanical properties of K418 and 0Cr18Ni9 weld joints[J]. Laser Technol, 2018, 42(2): 229−233. doi: 10.7510/jgjs.issn.1001-3806.2018.02.017

[41] 沈利霞. 镍基高温合金激光焊接接头组织与力学性能研究[J]. 应用激光, 2015, 35(2): 192−195. doi: 10.14128/j.cnki.al.20153502.192

Shen L X. Research on microstructure and mechanical properties of laser welded joint in nickel-based superalloy[J]. Appl Laser, 2015, 35(2): 192−195. doi: 10.14128/j.cnki.al.20153502.192

[42] 刘丰刚, 成军, 潘海莎, 等. GH3039脉冲激光焊接头组织性能研究[J]. 兵器材料科学与工程, 2010, 33(3): 64−66. doi: 10.3969/j.issn.1004-244X.2010.03.020

Liu F G, Cheng J, Pan H S, et al. Microstructure and properties of the pulse laser welded joint of GH3039[J]. Ordnance Mater Sci Eng, 2010, 33(3): 64−66. doi: 10.3969/j.issn.1004-244X.2010.03.020

[43] Wu D J, Ma G Y, Niu F Y, et al. Pulsed laser welding of hastelloy C-276: high-temperature mechanical properties and microstructure[J]. Mater Manuf Process, 2013, 28(5): 524−528. doi: 10.1080/10426914.2012.736652

[44] 陈玉华, 谢吉林, 黄永德, 等. 稀土对GH4169激光微焊接接头组织性能的影响[J]. 航空制造技术, 2015(11): 80−82. doi: 10.16080/j.issn1671-833x.2015.11.080

Chen Y H, Xie J L, Huang Y D, et al. Effect of rare earth elements on microstructure and properties of GH4169 superalloy joint welded by micro-laser welding[J]. Aeronaut Manuf Technol, 2015(11): 80−82. doi: 10.16080/j.issn1671-833x.2015.11.080

[45] 马广义, 吴东江, 郭玉泉, 等. 超薄Hastelloy C-276脉冲激光焊接接头的拉伸性能[J]. 稀有金属材料与工程, 2013, 42(6): 1241−1245. doi: 10.3969/j.issn.1002-185X.2013.06.030

Ma G Y, Wu D J, Guo Y Q, et al. Tensile properties of weld joint on thin hastelloy C-276 sheet of pulsed laser welding[J]. Rare Met Mater Eng, 2013, 42(6): 1241−1245. doi: 10.3969/j.issn.1002-185X.2013.06.030

[46] Kumar P, Saw K, Kumar U, et al. Effect of laser power and welding speed on microstructure and mechanical properties of fibre laser-welded Inconel 617 thin sheet[J]. J Braz Soc Mech Sci Eng, 2017, 39(11): 4579−4588. doi: 10.1007/s40430-017-0734-8

[47] Qu F S, Liu X G, Xing F, et al. High temperature tensile properties of laser butt-welded plate of Inconel 718 superalloy with ultra-fine grains[J]. Trans Nonferrous Met Soc China, 2012, 22(10): 2379−2388. doi: 10.1016/S1003-6326(11)61474-X

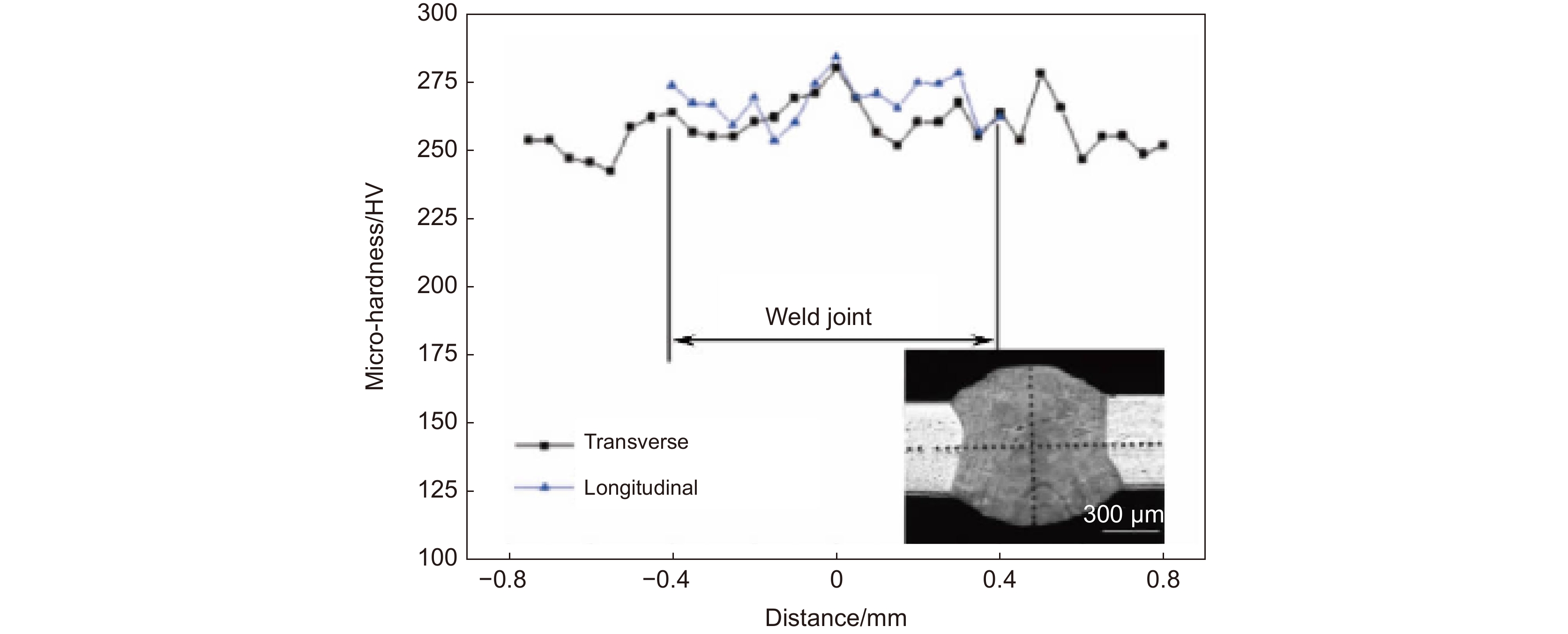

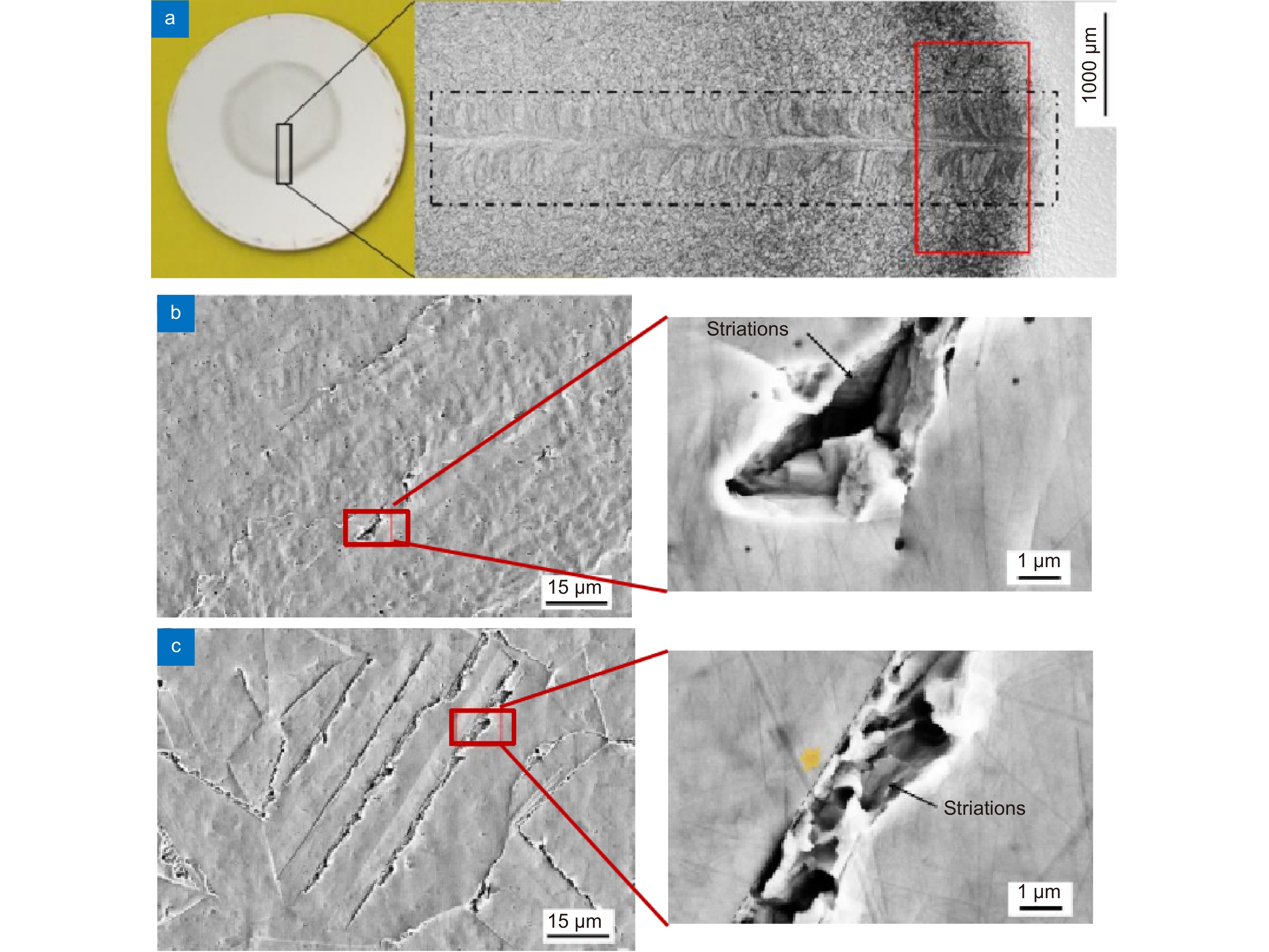

[48] 刘帅, 吴冬冬, 柴东升, 等. Hastelloy C-276薄板激光焊接接头疲劳性能[J]. 中国有色金属学报, 2016, 26(12): 2555−2563. doi: 10.19476/j.ysxb.1004.0609.2016.12.011

Liu S, Wu D D, Chai D S, et al. Fatigue property of laser welded joints of Hastelloy C-276 thin sheet[J]. Chin J Nonferrous Met, 2016, 26(12): 2555−2563. doi: 10.19476/j.ysxb.1004.0609.2016.12.011

[49] Pakniat M, Ghaini F M, Torkamany M J. Hot cracking in laser welding of Hastelloy X with pulsed Nd: YAG and continuous wave fiber lasers[J]. Mater Des, 2016, 106: 177−183. doi: 10.1016/j.matdes.2016.05.124

[50] Lin J, Wang X B, Lei Y P, et al. Study on hot cracking in laser welded joints of Inconel 718 alloy foils[J]. J Manuf Process, 2021, 64: 1024−1035. doi: 10.1016/j.jmapro.2021.02.002

[51] Thejasree P, Krishnamachary P C. Weldability analysis and ANFIS modelling on laser welding of Inconel 718 thin sheets[J]. Mater Manuf Process, 2022, 37(10): 1190−1202. doi: 10.1080/10426914.2022.2039694

[52] Yan F, Wang C M, Wang Y J, et al. A study of the mechanism of laser welding defects in low thermal expansion superalloy GH909[J]. Mater Charact, 2013, 78: 21−30. doi: 10.1016/j.matchar.2013.01.008

[53] Cheng H, Kang L, Wang C, et al. Dynamic behavior of molten pool backside during full-penetration laser welding of Ni-based superalloys[J]. Int J Adv Manuf Technol, 2022, 119(7): 4587−4598. doi: 10.1007/s00170-021-08187-9

[54] Graneix J, Beguin J D, Pardheillan F, et al. Weldability of the superalloys Haynes 188 and Hastelloy X by Nd: YAG[J]. MATEC Web Conf, 2014, 14: 13006. doi: 10.1051/matecconf/20141413006

[55] Kuo T Y. Effects of pulsed and continuous Nd-YAG laser beam waves on welding of Inconel alloy[J]. Sci Technol Weld Join, 2005, 10(5): 557−565. doi: 10.1179/174329305X46709

[56] Aina J O, Ojo O A, Chaturvedi M C. Enhanced laser weldability of an aerospace superalloy by thermal treatment[J]. Sci Technol Weld Join, 2019, 24(3): 225−234. doi: 10.1080/13621718.2018.1518767

[57] 吴冬冬, 柴东升, 马广义, 等. 脉冲激光填丝焊对镍基合金薄板焊缝成形及微观组织的影响[J]. 激光与光电子学进展, 2017, 54(3): 031404. doi: 10.3788/LOP54.031404

Wu D D, Chai D S, Ma G Y, et al. Effect of pulsed laser welding with filler wire on weld forming and microstructures of thin nickel-based alloy sheet[J]. Laser Optoelectron Prog, 2017, 54(3): 031404. doi: 10.3788/LOP54.031404

[58] Chai D S, Wu D D, Ma G Y, et al. The effects of pulse parameters on weld geometry and microstructure of a pulsed laser welding Ni-base alloy thin sheet with filler wire[J]. Metals, 2016, 6(10): 237. doi: 10.3390/met6100237

[59] 吴东江, 柴东升, 程波, 等. 脉冲激光填丝焊接薄板熔池流动行为分析[J]. 中国科学:物理学 力学 天文学, 2020, 50(3): 034208. doi: 10.1360/SSPMA-2019-0203

Wu D J, Chai D S, Cheng B, et al. Flow characteristics of the molten pool in pulsed laser welding of thin sheet with filler wire[J]. Sci Sin Phys Mech Astron, 2020, 50(3): 034208. doi: 10.1360/SSPMA-2019-0203

[60] Wu D J, Cheng B, Liu J, et al. Water cooling assisted laser dissimilar welding with filler wire of nickel-based alloy/austenitic stainless steel[J]. J Manuf Process, 2019, 45: 652−660. doi: 10.1016/j.jmapro.2019.08.003

[61] 柴东升. 哈氏合金C-276薄板脉冲激光填丝焊接成形机理及空蚀性能研究[D]. 大连: 大连理工大学, 2020: 81–116.

Chai D S. Weld formation mechanism and cavitation erosion property of pulsed laser welding Hastelloy C-276 thin sheets with filler wire[D]. Dalian: Dalian University of Technology, 2020: 81–116.

[62] 吴东江, 刘俊, 唐博凯, 等. 工艺参数对哈氏合金薄板激光填丝焊接变形的影响[J]. 激光与光电子学进展, 2020, 57(13): 131404. doi: 10.3788/LOP57.131404

Wu D J, Liu J, Tang B K, et al. Effect of parameters on welding deformation of Laser welding Hastelloy thin sheets with filler wire[J]. Laser Optoelectron Prog, 2020, 57(13): 131404. doi: 10.3788/LOP57.131404

[63] 吴冬冬. 哈氏合金薄板激光填丝焊接基础工艺实验研究[D]. 大连: 大连理工大学, 2017: 37–52.

Wu D D. Experimental study on thin Hastelloy plate laser welding with filler wire[D]. Dalian: Dalian University of Technology, 2017: 37–52.

[64] 于京令, 刘大为, 宋丹, 等. 哈氏合金薄板激光填丝焊接接头高周疲劳性能[J]. 电焊机, 2019, 49(4): 37−42.

Yu J L, Liu D W, Song D, et al. High cycle fatigue strength of laser welding Hastelloy C-276 with filler wire[J]. Elect Weld Mach, 2019, 49(4): 37−42.

[65] Cheng B, Wu D J, Yue K J, et al. Effect of low-temperature cooling on corrosion properties of laser welding Hastelloy C-276/304 stainless steel with filler wire[J]. Opt Laser Technol, 2022, 148: 107755. doi: 10.1016/j.optlastec.2021.107755

[66] Chai D S, Ma G Y, Zhou S Y, et al. Cavitation erosion behavior of HastelloyTM C-276 weld by laser welding[J]. Wear, 2019, 420-421: 226−234. doi: 10.1016/j.wear.2018.10.012

[67] Dieter R D. Welding Thermal Effect: Temperature Field, Residual Stress and Deformation[M]. China Machine Press, 1997: 3–16.

[68] 薛忠明, 曲文卿, 柴鹏, 等. 焊接变形预测技术研究进展[J]. 焊接学报, 2003, 24(3): 87−90. doi: 10.3321/j.issn:0253-360X.2003.03.024

Xue Z M, Qu W Q, Chai P, et al. Review on prediction of welding distortion[J]. Trans China Weld Inst, 2003, 24(3): 87−90. doi: 10.3321/j.issn:0253-360X.2003.03.024

[69] 郭玉泉, 吴东江, 马广义, 等. 夹具拘束距离对Hastelloy C-276薄板脉冲激光焊接变形的影响[J]. 光学 精密工程, 2012, 20(11): 2465−2471. doi: 10.3788/OPE.20122011.2465

Guo Y Q, Wu D J, Ma G Y, et al. Influence of fixture restraint distance on pulsed laser welding distortion of Hastelloy C-276 thin sheet[J]. Opt Precision Eng, 2012, 20(11): 2465−2471. doi: 10.3788/OPE.20122011.2465

[70] 曹政, 姜仁杰, 杜伟哲, 等. 薄壁结构激光焊接随焊高频冲击变形控制[J]. 中国激光, 2020, 47(9): 0902003. doi: 10.3788/CJL202047.0902003

Cao Z, Jiang R J, Du W Z, et al. Distortion control by in-site high frequency peening in laser welding of thin-walled structures[J]. Chin J Lasers, 2020, 47(9): 0902003. doi: 10.3788/CJL202047.0902003

[71] Guo Y Q, Wu D J, Ma G Y, et al. Trailing heat sink effects on residual stress and distortion of pulsed laser welded Hastelloy C-276 thin sheets[J]. J Mater Process Technol, 2014, 214(12): 2891−2899. doi: 10.1016/j.jmatprotec.2014.06.012

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: