-

摘要

激光化学气相沉积技术(LCVD)相较于传统化学气相沉积技术具有低沉积温度、高膜层纯度、高沉积效率等特点,在各类功能薄膜材料制备上有着巨大的应用前景。围绕激光化学气相沉积技术,本文详细阐述了激光热解离、激光光解离与激光共振激发解离作用机制,同时介绍了各类LCVD的常用设备,着重总结了LCVD在金属材料、碳基材料、氧化物材料以及半导体材料等各类材料制备应用上的最新研究进展,特别介绍了LCVD制备过程中常用的检测与分析方法,最后讨论了激光化学气相沉积技术目前所面临的挑战与机遇,并展望了该技术的发展前景。

Abstract

Laser chemical vapor deposition (LCVD) technology has its unique advantages in reducing deposition temperatures, enhancing film purity and directly writing complex thin film patterns compared with conventional chemical vapor deposition (CVD). This technology has been widely applied in thin film deposition and attracted growing attention from both research and industries. This review categorizes the LCVD technology into three types according to the laser-matter interaction mechanisms, including laser pyrolysis, laser photolysis, and laser resonance excitation sensitization. We illustrate the deposition principles governed by the three different mechanisms in detail, and briefly introduce the commonly used equipment, and summarize the latest research progress of LCVD technology in synthesis and applications of metals, carbon-based materials, oxides and semiconductors. The detection and analysis methods used in LCVD are specially introduced, and the challenges and prospects of LCVD in material synthesis are discussed.

-

Overview

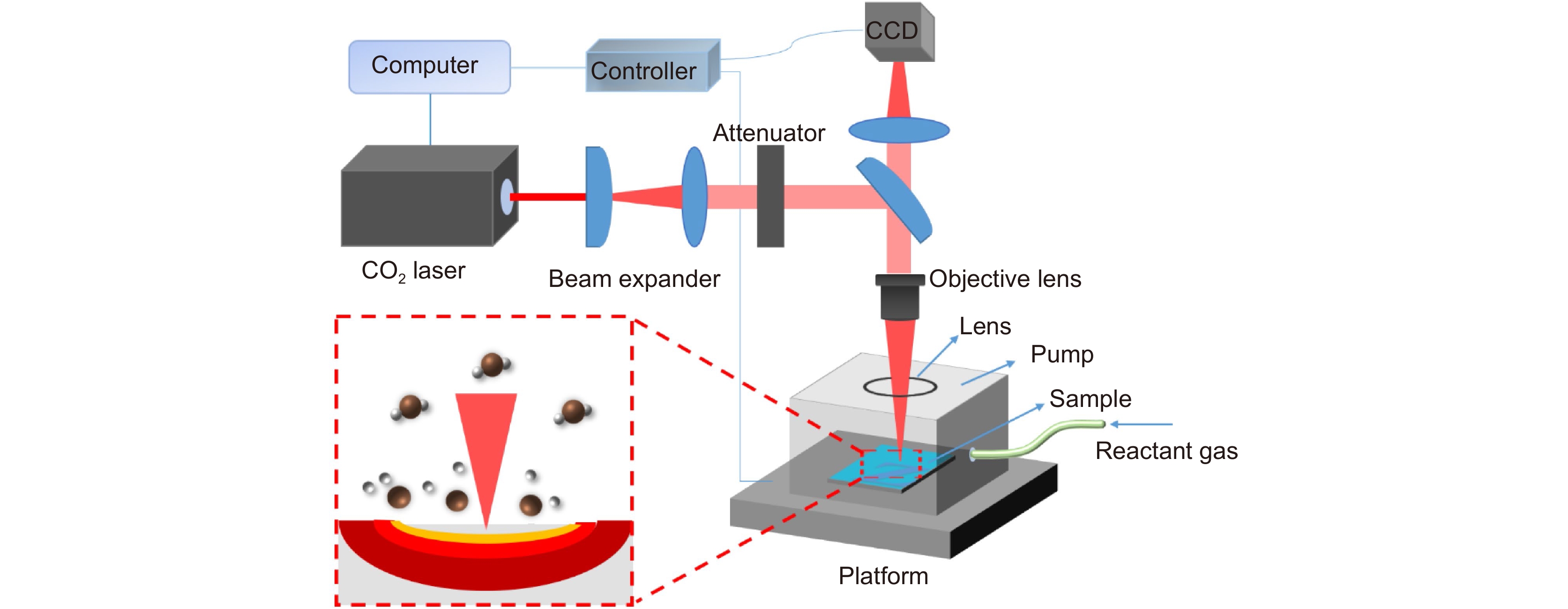

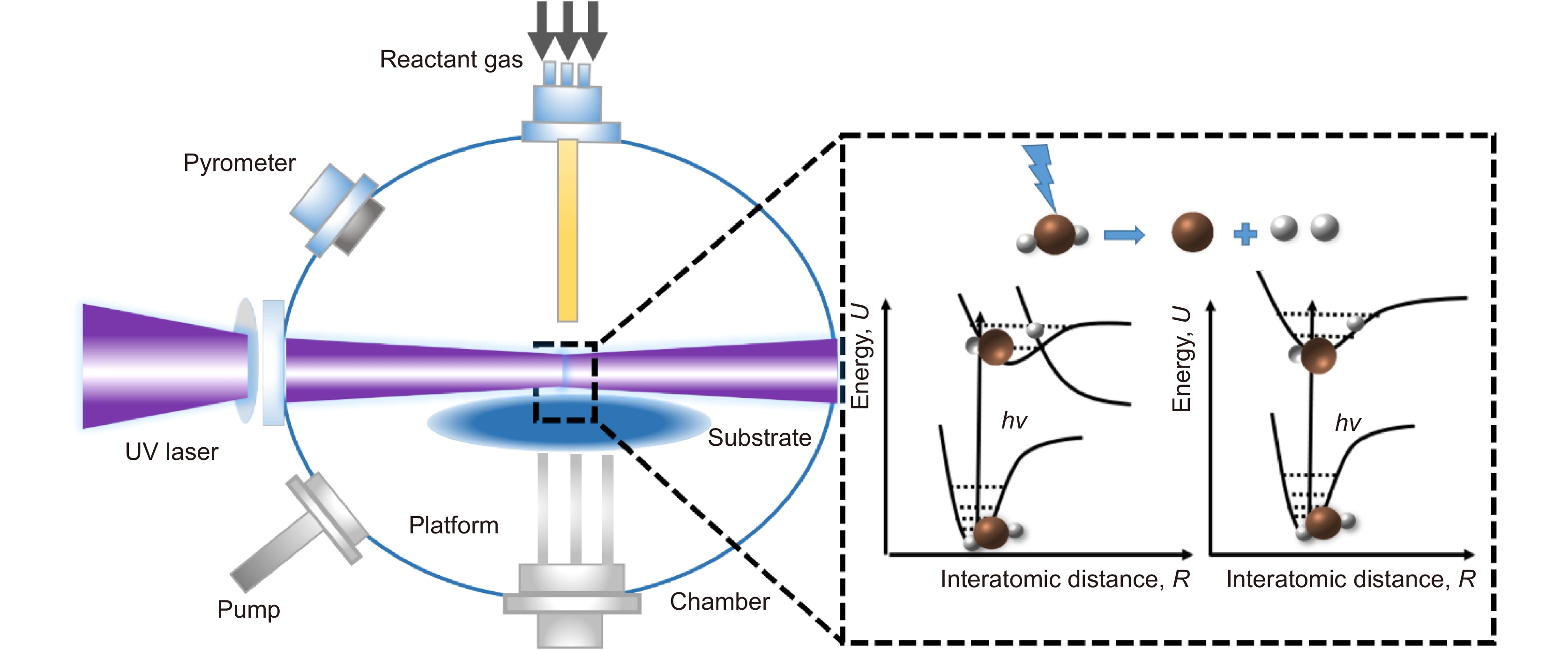

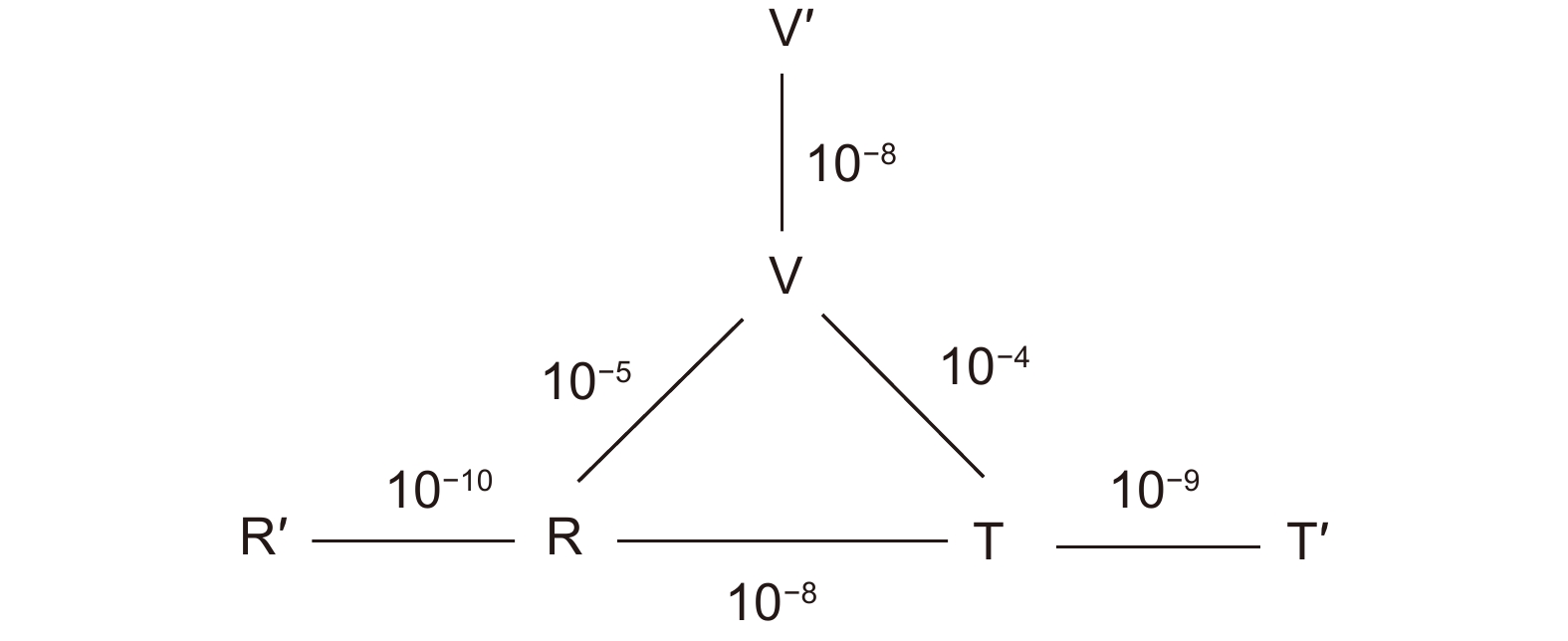

Overview: Laser chemical vapor deposition (LCVD) is a promising method for selective deposition of solid materials via localized chemical vapor reaction driven by a laser beam. It has several advantages over traditional CVD processes including decreased deposition temperature, increased deposition rate, higher crystallization quality, superior spatial resolution, site-selective deposition characteristics and the ability to produce a wide range of complex 3D micro- and nanostructures. In this review, LCVD is divided into three types based on the interaction mechanisms of laser and gaseous precursor, i.e., pyrolytic LCVD, photolytic LCVD and vibrational excitation LCVD. In pyrolytic LCVD processes, a focused laser beam triggered by a continues CO2 laser or Nd:YAG laser is used to locally heat the surface of the substrate and material deposition occurs when the temperature near the irradiated area reaches the decomposition threshold of the gaseous precursor. This approach is often used to deposit small regions of 2D films with complex and fine patterns. Photolytic LCVD processes use photons from focused laser beams (typically generated by short-wavelength ultraviolet laser light source, such as excimer laser and high frequency output of Nd:YAG laser) to reactant gases, resulting in precise deposition of solid material in either 2D films or 3D structures. Photolytic LCVD processes rely on the photochemical action of the laser beam and the chemical reactants. The precursor gas molecules are directly dissociated by the high-energy photons and subsequently form a solid deposit on the surface of the substrate through recombination/re-decomposition. Photolytic LCVD typically utilizes pulsed lasers as their high peak power levels more effectively to drive the chemical reactions. This method is suitable for large-area film formation. Vibrational excitation LCVD often uses laser sources with adjustable wavelengths, such as infrared CO2 lasers and OPO lasers. By precisely modulating the laser wavelength, the laser energy is directionally coupled to selected gas molecules to induce efficient dissociation of key reaction molecules, resulting in deposition of solid material in a low ambient temperature. Vibrational excitation LCVD typically offers a higher deposition rate and a better film quality compared to the photolysis of the precursors with a UV laser. In this article, we first introduce the deposition principles and commonly used equipment of the three LCVD processes, and then a comprehensive survey of recent material deposition applications using this three LCVD approaches is presented. Finally, the challenges and opportunities in the application of LCVD for material preparation are summarized, and the development prospects of this technology are prospected.

-

-

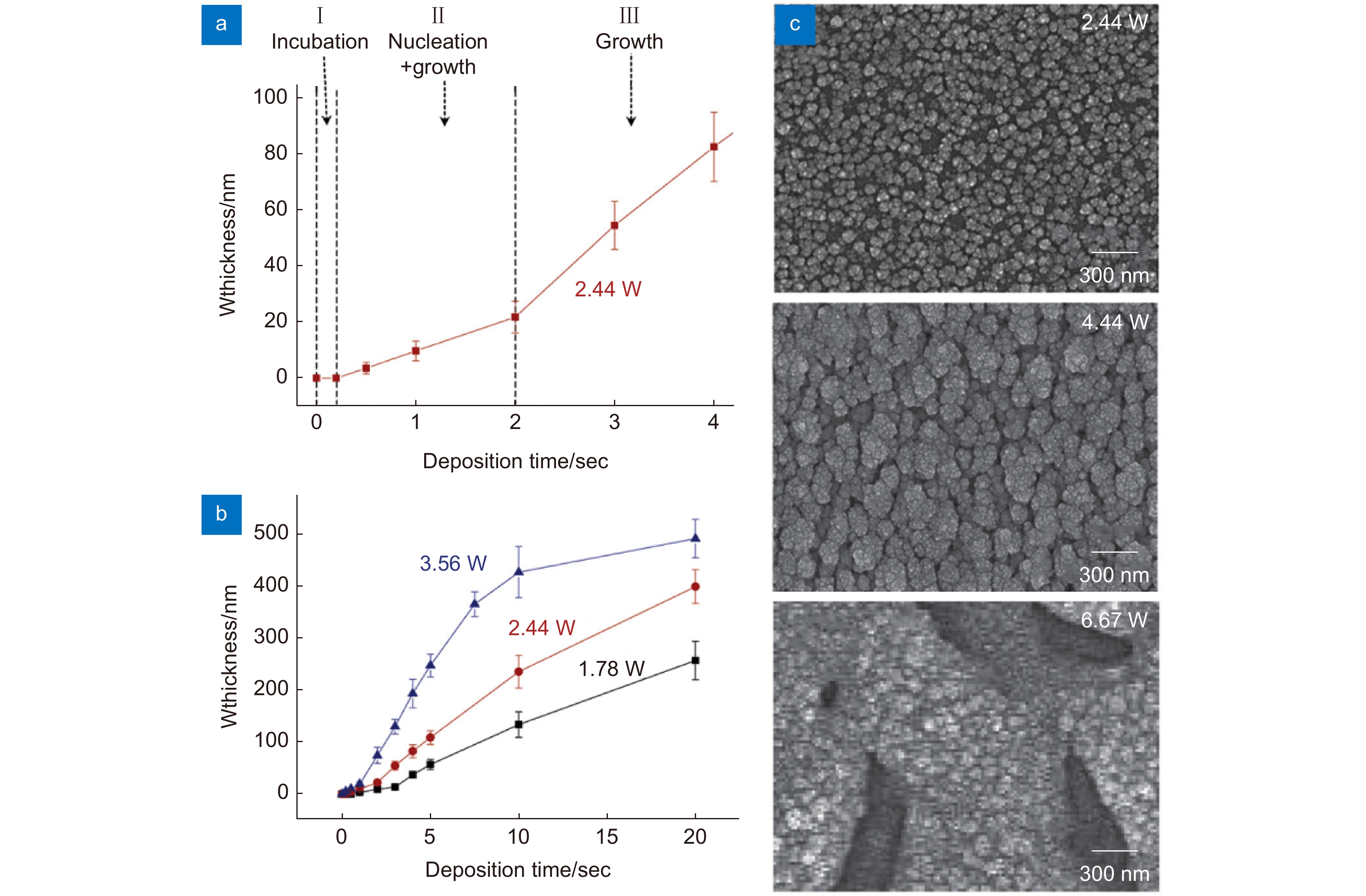

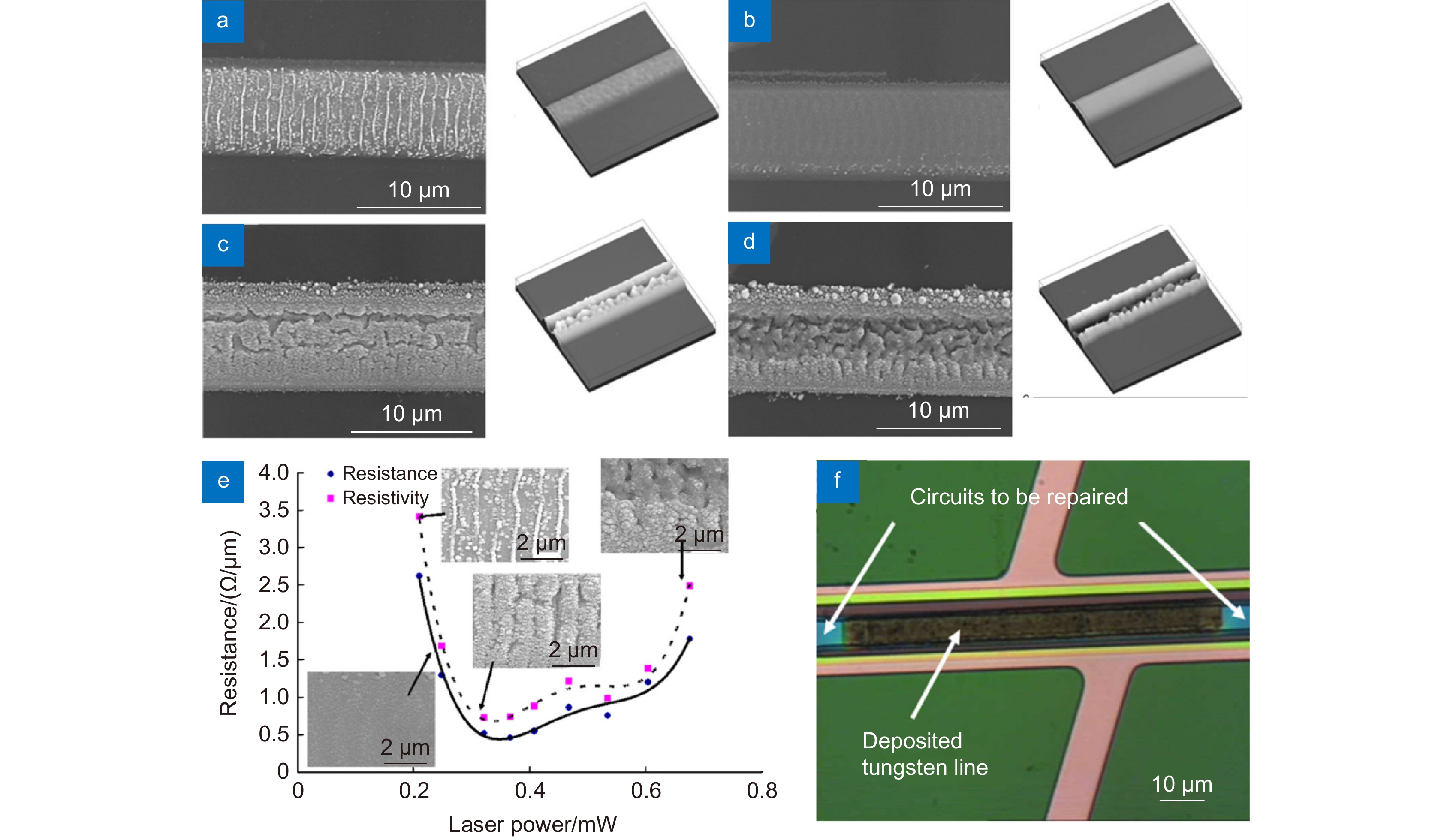

图 3 (a) 2.44 W沉积的W膜孕育、成核和聚结三阶段图;(b) 沉积时间对W膜沉积厚度的影响;(c) 激光功率对W薄膜表面形貌的影响[81]

Figure 3. (a) Plot of three regimes for incubation, nucleation and coalescence of W deposited at 2.44 W; (b) Thickness of W films deposited on glass substrates plotted as a function of deposition time; (c) Surface morphology of deposited W films deposited at different laser power[81]

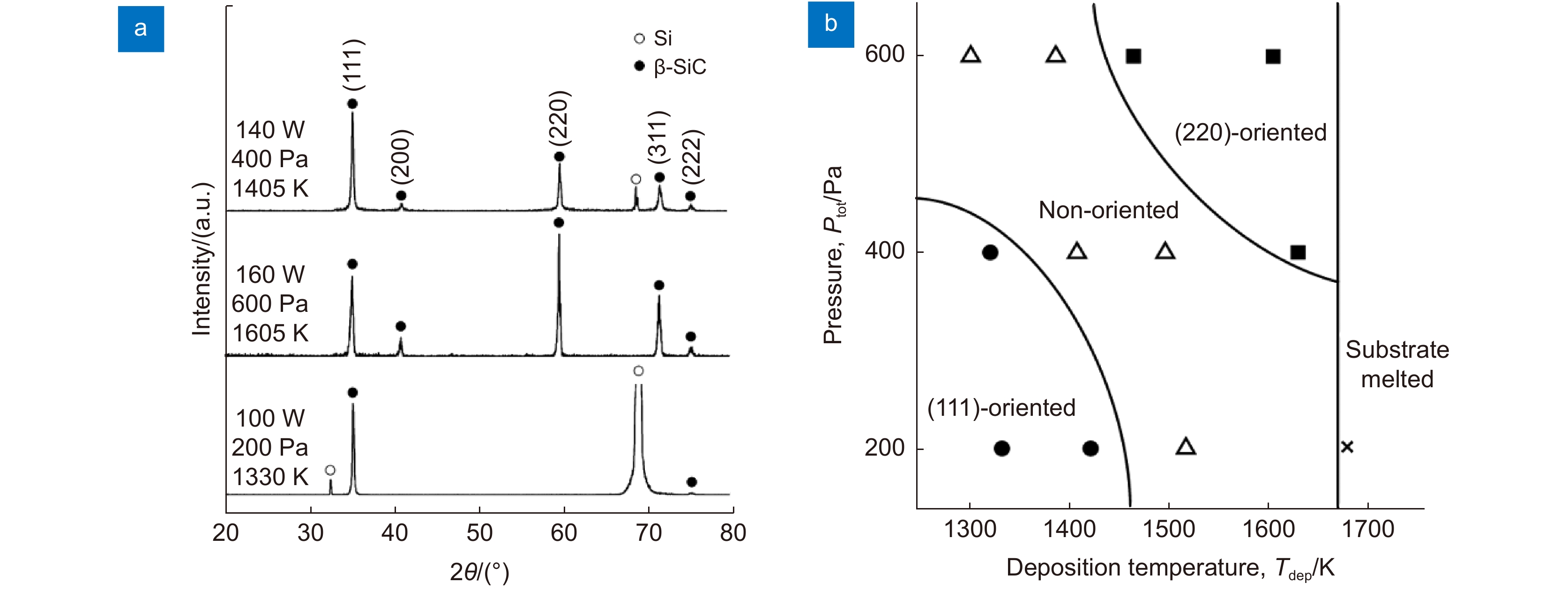

图 5 (a) 在不同激光功率、沉积压力和沉积温度下制备的β-SiC薄膜XRD图;(b) 激光功率和沉积压力对 β-SiC 薄膜择优取向的影响[97]

Figure 5. (a) XRD patterns of the β-SiC films prepared at different laser power, deposition pressure and deposition temperature; (b) Effects of laser power and deposition pressure on preferred crystalline orientations of β-SiC films[97]

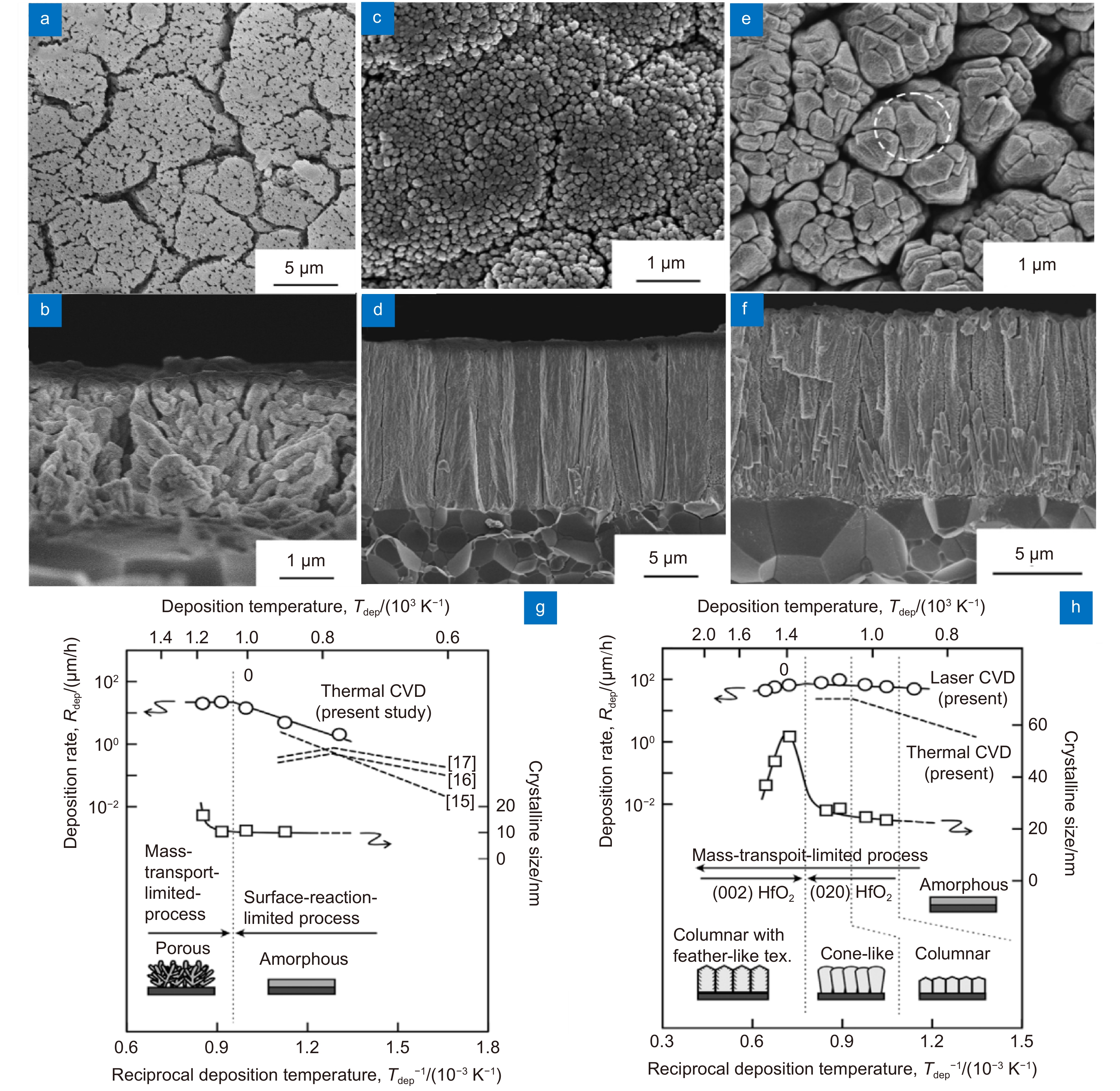

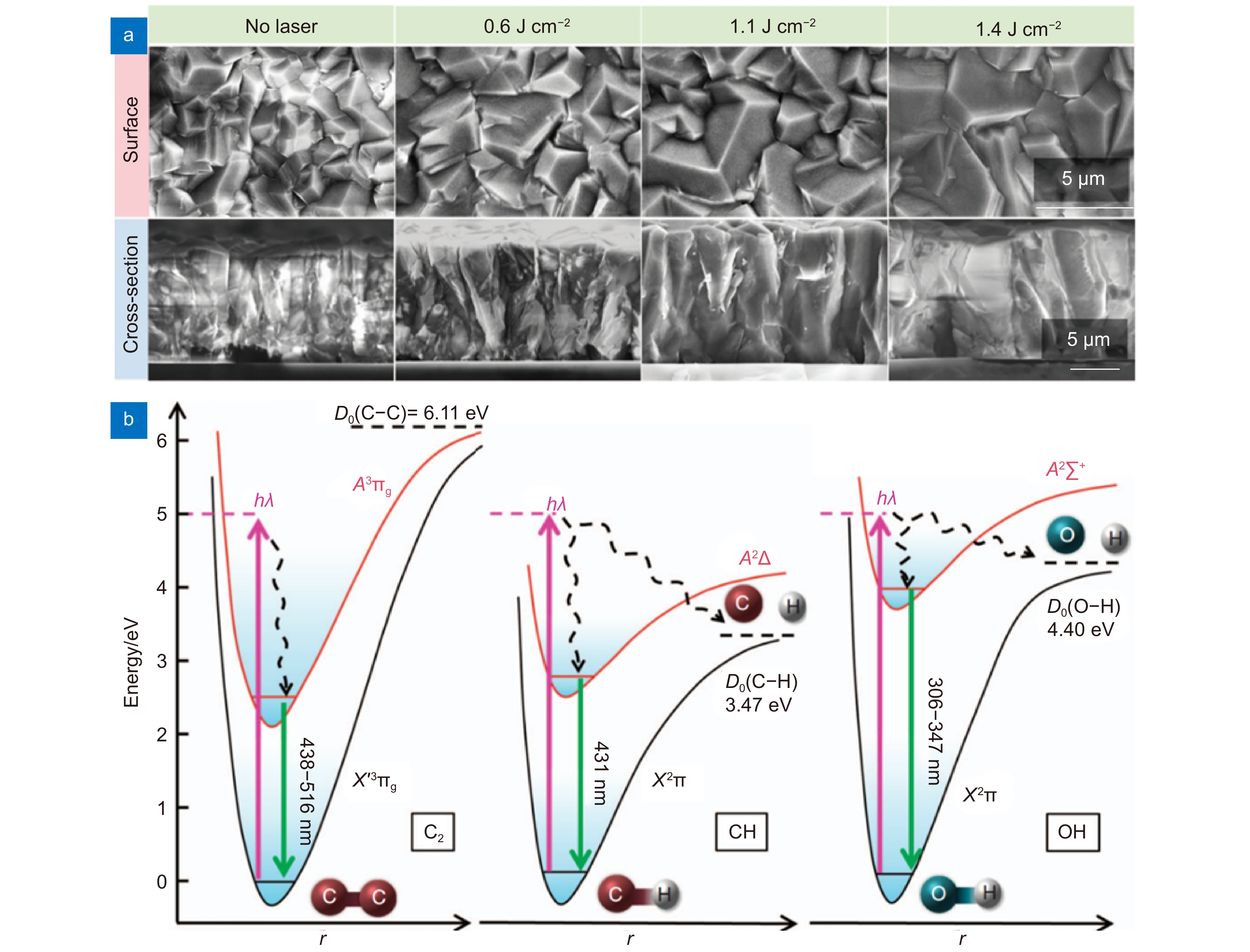

图 6 使用传统CVD于1173 K制备的HfO2薄膜(a)表面和(b)横截面扫描电镜图像,使用热解LCVD于1203 K和1383 K制备的HfO2薄膜(c), (e)表面和(d), (f)横截面扫描电镜图像,(c), (e) 沉积温度对(g)常规CVD和(h)热解CVD制备的HfO2薄膜沉积速率、微晶尺寸、以及形态演化的影响[71]

Figure 6. (a) Surface and (b) cross-sectional SEM images of HfO2 films prepared using conventional CVD at 1173 K, (c), (e) surface and the corresponding (d), (f) cross-sectional SEM images of (c), (d) HfO2 films prepared at 1203 K and (e), (f) HfO2 films prepared at 1383 K by pyrolysis CVD, effect of deposition temperature on deposition rate, crystallite size, and morphological evolution in HfO2 films prepared using (g) conventional CVD and (h) pyrolysis CVD[71]

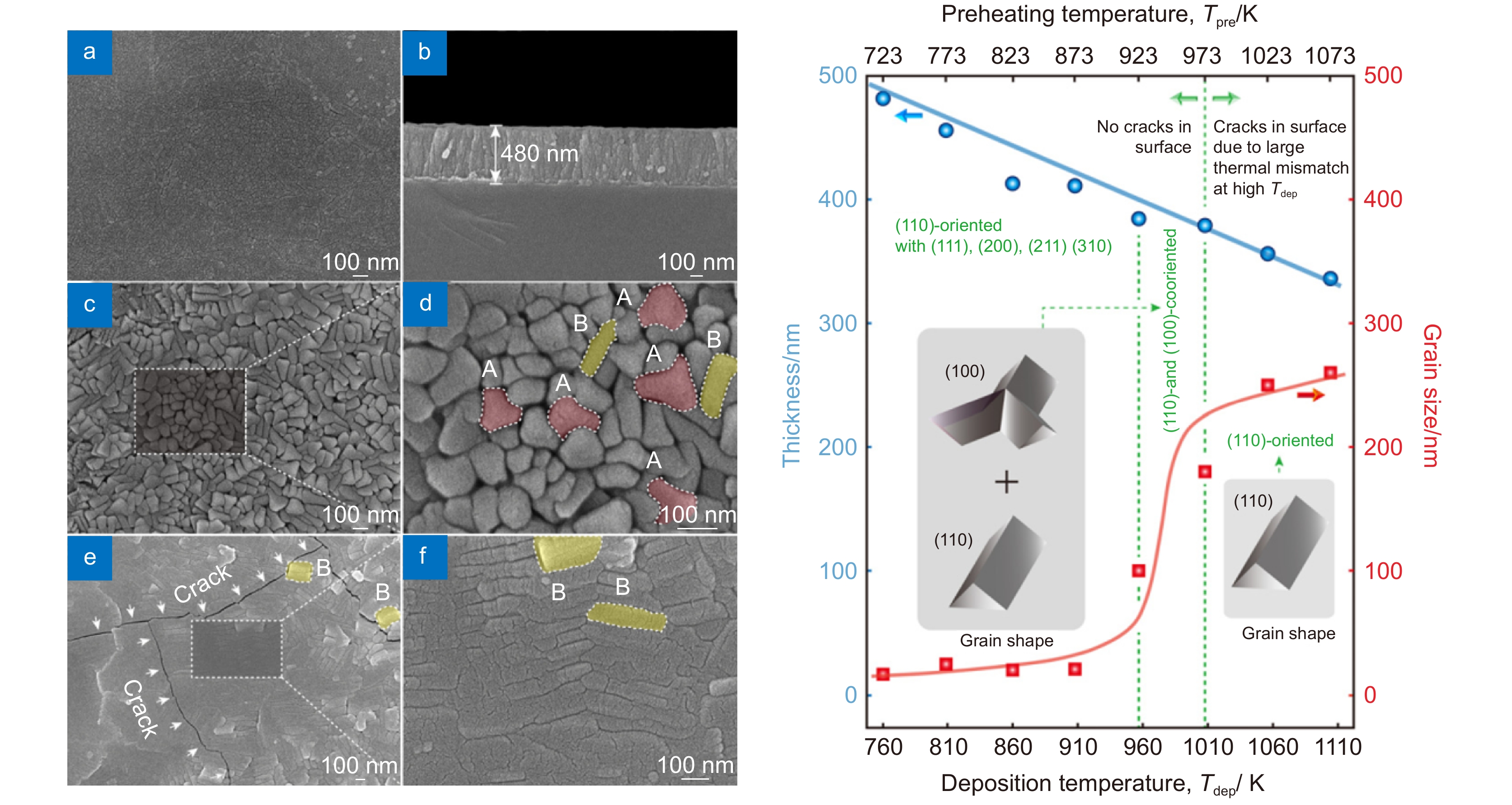

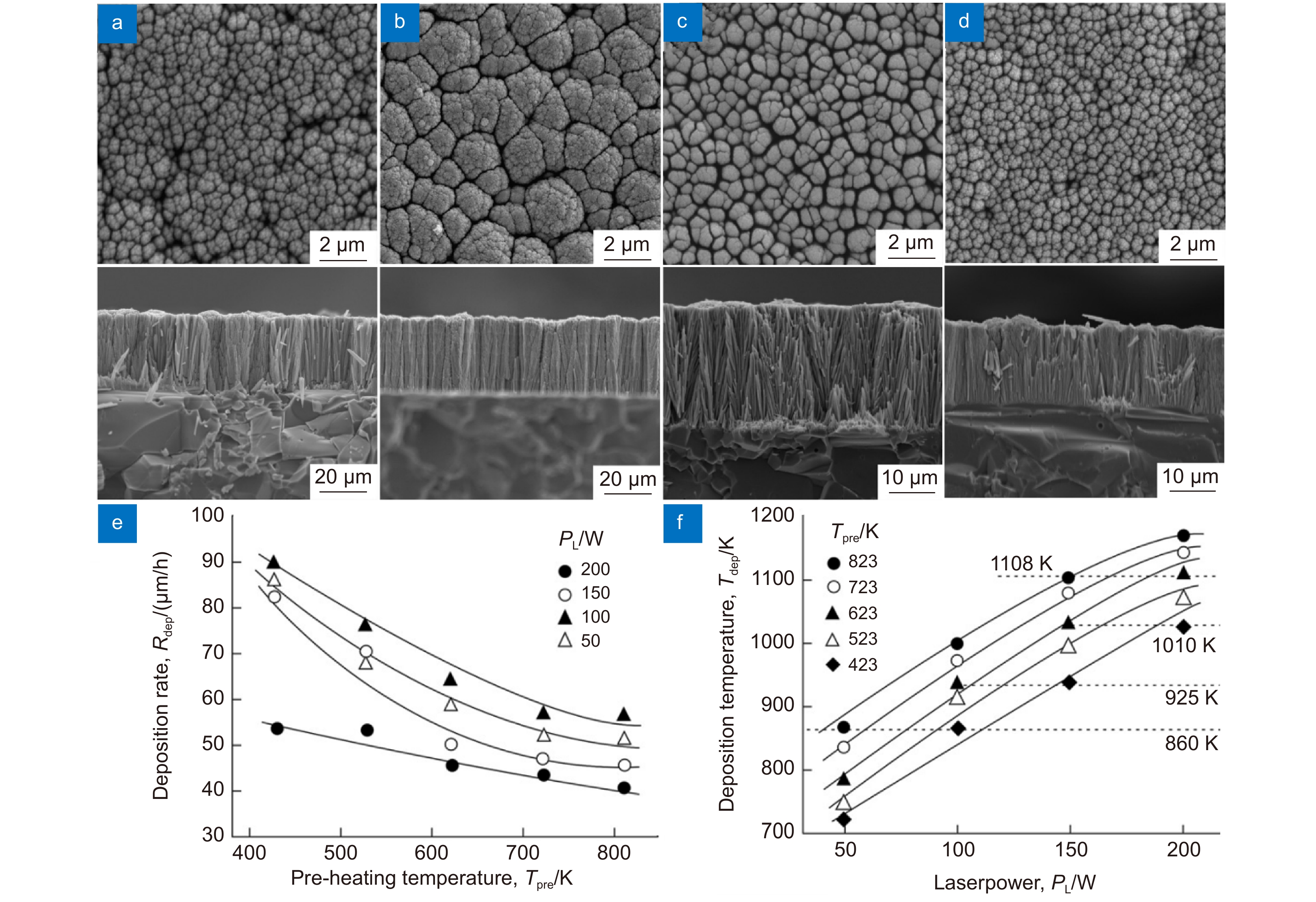

图 7 激光功率150 W,沉积温度分别在760 K (a, b)、957 K (c, d)和1104 K (e, f)时在石英玻璃上制备的SrTiO3薄膜表面和横截面SEM图像;(g) 沉积温度对SrTiO3薄膜厚度、晶粒尺寸、晶粒形状和择优取向的影响[128]

Figure 7. Surface and cross‐sectional SEM images of the SrTiO3 films prepared at 760 K (a, b) , 957 K (c, d) and 1104 K (e, f) with a laser power of 150 W, respectively; (g) Influences of the deposition temperature on thickness, grains size, grains shape, and preferred orientation of the SrTiO3 films[128]

图 8 在1523 K和400 Pa下沉积的具有类纳米森林结构的3C-SiC/石墨烯复合薄膜的(a),(b)TEM形貌(c)原子构型,具有稳定框架和连续电子路径的3C-SiC/石墨烯复合薄膜的(d)示意图与(e)循环性能测试图[136]

Figure 8. (a), (b) TEM observations and (c) atomic configuration of the nanoforest-like 3C-SiC/graphene composite films deposited at 1523 K and 400 Pa, (d) schematic illustration and (e) cycling performance of 3C-SiC/graphene nanoforest composite films with stable framework and continuous electron pathways[136]

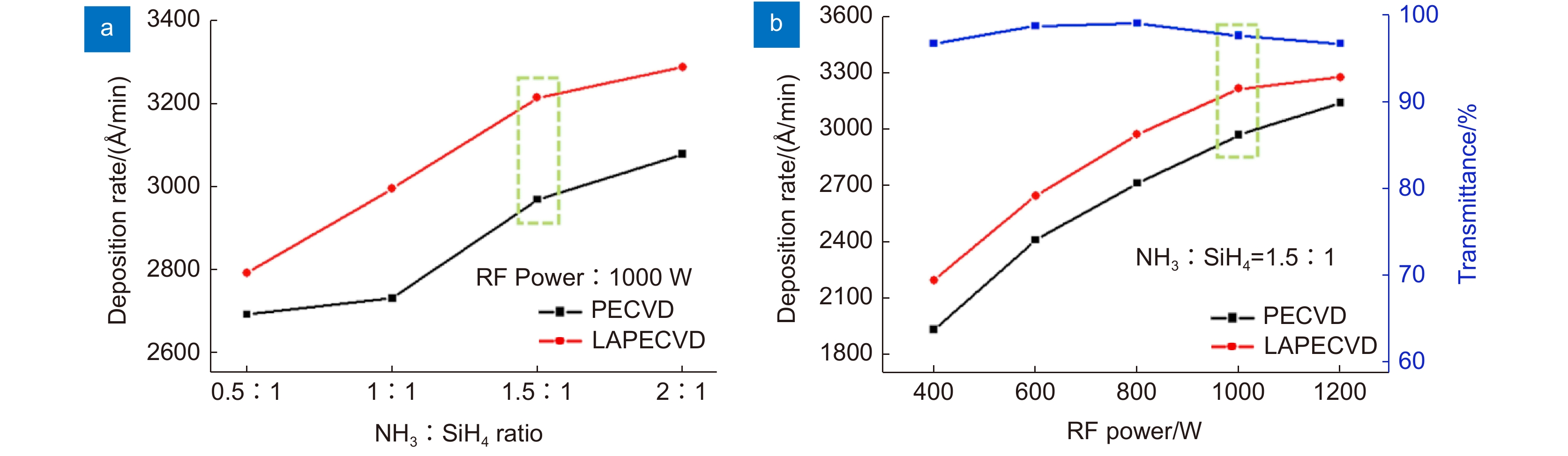

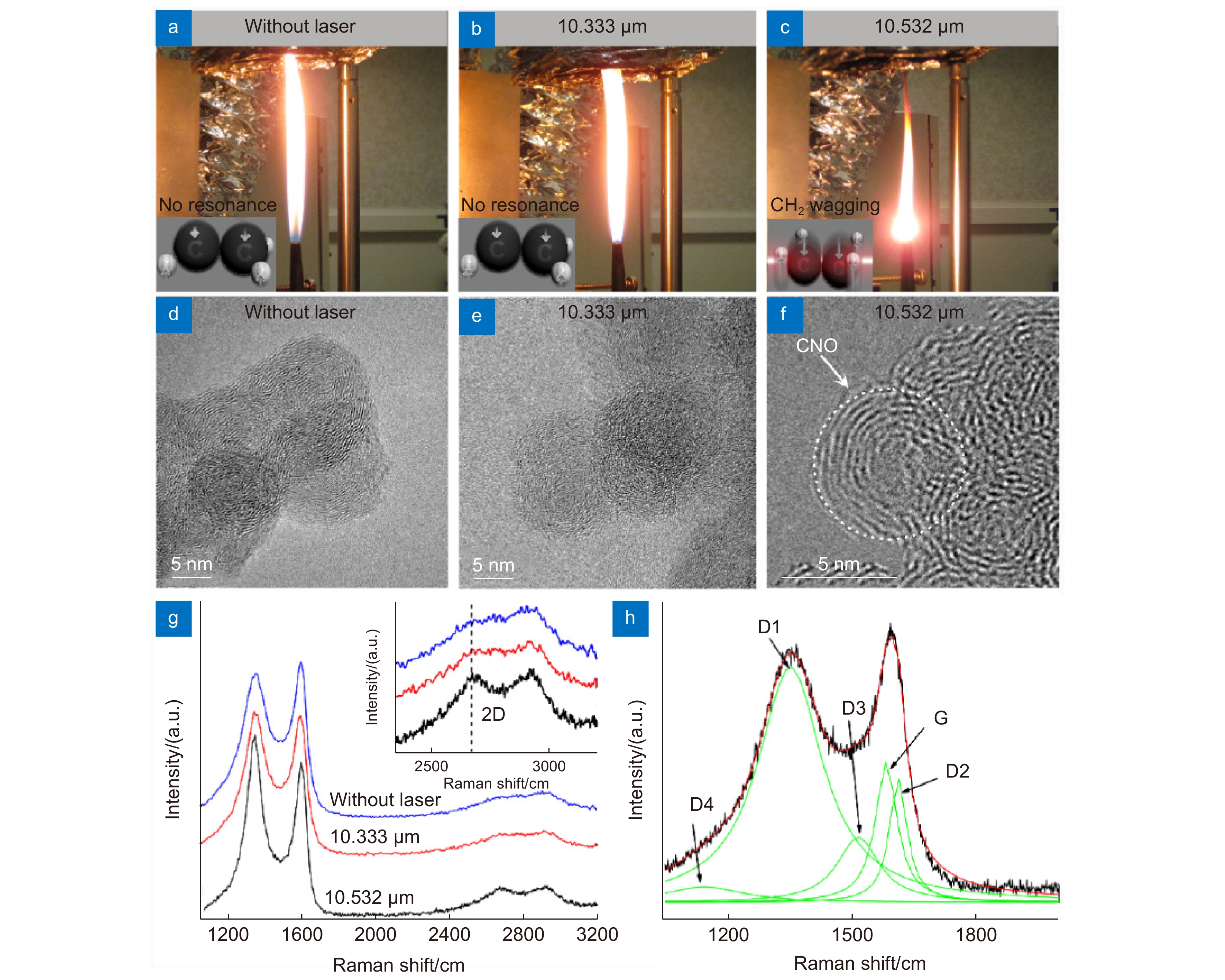

图 18 (a) CO2激光辅助燃烧化学气相沉积实验装置与不同激光激励下NH3/C2H2/O2火焰的(b)发射光谱和(c)质谱分析所得到的火焰中离化基团的相对摩尔分数[181];(d) C2H4/C2H2/O2火焰的光学图像[184]

Figure 18. (a) Experimental setup for the CO2 laser-assisted CCVD and (b) optical emission spectra and (c) mole fractions of the species of NH3/C2H2/O2 flames under different laser excitations measured using mass spectrometer[181]; (d) Optical images of C2H4/C2H2/O2 flames[184]

表 1 各类化学气相沉积技术对比

Table 1. Comparison of various CVD techniques

技术类别 优点 缺点 MOCVD 大面积制备,高沉积精度 设备成本高,材料要求苛刻,沉积速度慢 PCVD 较低沉积温度,较快沉积速度,设备维护简单 反应过程复杂难以控制 HFCVD 大面积制备,适用于复杂形貌,操作系统简单 沉积速度慢 CCVD 大气环境下制备 沉积速度慢 LCVD 可局部制备,高沉积精度/效率/质量,成膜材料种类广泛 设备成本高,操作略复杂 表 2 常见LCVD光源

Table 2. Commonly used laser sources for LCVD

表 3 最近热解LCVD薄膜制备研究工作

Table 3. Recent reports of thin film deposition using pyrolysis LCVD

年 材料 基体 光源 沉积参数 温度/(°C) 速率/(μm/h) 2021[28] SmBa2Cu3O7-δ LaAlO3 波长808 nm半导体连续激光器 780 8.76 2020[71] HfO2 AlN 波长976 nm半导体连续激光器 600~1300 67 2020[72] BCN SiO2 波长1064 nm Nd:YAG连续激光器 1100 18.4 2020[73] ZrCN C Nd:YAG连续激光器 1100~1180 40 2020[74] SrTiO3 MgAl2O4 波长1064 nm Nd:YAG连续激光器 900 20 2020[75] Y-doped BaZrO3 AlN 波长1064 nm Nd:YAG连续激光器 645.1~656.3 2.67 2020[76] β-Yb2Si2O7, X1/X2-Yb2SiO5 AlN 波长808 nm半导体连续激光器 750~1100 114~423、353~943 2019[77] LaPO4 Al2O3 波长1064 nm Nd:YAG连续激光器 802~847 58.6 2019[78] SiBCN Graphite 波长1064 nm Nd:YAG连续激光器 1210~1410 1620 表 4 最近光解LCVD制备薄膜的工作总结

Table 4. Reports of thin film deposition using photolysis LCVD recently

年 材料 基体 光源 沉积参数 温度/(°C) 速率/(μm/h) 2020[141] 金刚石 Si 波长532 nm超高斯分布连续激光器 700~900 0.38 2019[47] W TFT-LCD 波长351 nm脉宽45 ns Nd:YAG脉冲激光器 > 450 - 2018[59] 金刚石 WC 波长193 nm脉宽15 ns ArF、波长248 nm脉宽20 ns KrF准分子激光器 2177 11、10.3 2018[142] β-SiC β-SiC 波长808 nm InGaAlAs半导体激光器 1067~1257 50 2018[143] Si3N4 Si/PET 波长193 nm ArF

准分子激光器100 0.93 2017[144] Ni U 波长248 nm KrF

准分子激光器165~200 - 2011[145] Cr2O3 Al2O3 波长248 nm脉宽30 ns KrF准分子激光器 室温 360 -

参考文献

[1] Moore C A, Yu Z Q, Thompson L R, et al. Laser and electron beam assisted processing[M]//Seshan K. Handbook of Thin Film Deposition Processes and Techniques: Principles, Methods, Equipment and Applicatios. Norwich: William Andrew Publishing, 2001: 349–379.

[2] Mazumder J, Kar A. Theory and Application of Laser Chemical Vapor Deposition[M]. New York: Plenum Press, 1995.

[3] Tan S T, Chen B J, Sun X W, et al. Blueshift of optical band gap in ZnO thin films grown by metal-organic chemical-vapor deposition[J]. J Appl Phys, 2005, 98(1): 013505. doi: 10.1063/1.1940137

[4] Chhowalla M, Teo K B K, Ducati C, et al. Growth process conditions of vertically aligned carbon nanotubes using plasma enhanced chemical vapor deposition[J]. J Appl Phys, 2001, 90(10): 5308−5317. doi: 10.1063/1.1410322

[5] Hawaldar R, Merino P, Correia M R, et al. Large-area high-throughput synthesis of monolayer graphene sheet by Hot Filament Thermal Chemical Vapor Deposition[J]. Sci Rep, 2012, 2: 682. doi: 10.1038/srep00682

[6] Liu Y, Koep E, Liu M L. Highly sensitive and fast-responding SnO2 sensor fabricated by combustion chemical vapor deposition[J]. Chem Mater, 2005, 17(15): 3997−4000. doi: 10.1021/cm050451o

[7] Goto T. A review: structural oxide coatings by laser chemical vapor deposition[J]. J Wuhan Univ Technol-Mater Sci Ed, 2016, 31(1): 1−5. doi: 10.1007/s11595-016-1319-6

[8] 刘丽, 韦建军, 吴卫东, 等. 激光诱导化学气相沉积(LCVD)制膜技术[C]//2011中国功能材料科技与产业高层论坛论文集(第三卷), 2011: 232–235.

Liu L, Wei J J, Wu W D, et al. Technology of thin films by LCVD[C]//Proceedings of 2011 China Functional Materials Technology and Industry Forum, 2011: 232–235.

[9] 孙克, 赵岩, 张彩碚. 脉冲Nd: YAG激光诱导化学沉积金属Ag和Au[J]. 应用激光, 2002, 22(1): 15−18. doi: 10.3969/j.issn.1000-372X.2002.01.005

Sun K, Zhao Y, Zhang C B. Pulsed Nd: YAG laser induced chemical deposition of Ag and Au[J]. Appl Laser, 2002, 22(1): 15−18. doi: 10.3969/j.issn.1000-372X.2002.01.005

[10] Park B S, Malshe A P, Muyshondt A, et al. The effects of substrate properties on metal coatings from liquid medium by reactive laser deposition[J]. Surf Coat Technol, 1999, 115(2-3): 201−207. doi: 10.1016/S0257-8972(99)00245-5

[11] Chen Q J, Allen S D. Laser direct writing of aluminum conductor lines from a liquid phase precursor[J]. MRS Online Proc Lib, 1995, 397(1): 637−642.

[12] Armstrong J V, Burk A A Jr, Coey J M D, et al. Wavelength control of iron/nickel composition in laser induced chemical vapor deposited films[J]. Appl Phys Lett, 1987, 50(18): 1231−1233. doi: 10.1063/1.97918

[13] Ehrlich D J, Osgood R M Jr, Deutsch T F. Spatially delineated growth of metal films via photochemical prenucleation[J]. Appl Phys Lett, 1981, 38(11): 946−948. doi: 10.1063/1.92192

[14] Popovici D, Piyakis K, Sacher E, et al. Terraced copper growth deposited onto teflon AF1600 by the excimer laser irradiation of Cu(hfac)Tmvs[J]. MRS Online Proc Lib, 1995, 397(1): 643−648.

[15] Okoshi M, Toyoda K, Murahara M. Open air fabrication process of Cu thin films on Teflon surface using ArF excimer laser irradiation[J]. MRS Online Proc Lib, 1995, 397(1): 655−660.

[16] Allen S D, Tringubo A B. Laser chemical vapor deposition of selected area Fe And W films[J]. J Appl Phys, 1983, 54(3): 1641−1643. doi: 10.1063/1.332154

[17] Liu Z Z, Xu Q F, Sun Q Y, et al. Effect of hydrogen flow on microtwins in 3C-SiC epitaxial films by laser chemical vapor deposition[J]. Thin Solid Films, 2019, 678: 8−15. doi: 10.1016/j.tsf.2019.03.036

[18] Xu Q F, Deng Z, Sun Q Y, et al. Electrically conducting graphene/SiC(111) composite coatings by laser chemical vapor deposition[J]. Carbon, 2018, 139: 76−84. doi: 10.1016/j.carbon.2018.06.038

[19] Zhu P P, Xu Q F, Chen R Y, et al. Structural study of β-SiC(001) films on Si(001) by laser chemical vapor deposition[J]. J Am Ceram Soc, 2017, 100(4): 1634−1641. doi: 10.1111/jace.14672

[20] Xu Q F, Zhu P P, Sun Q Y, et al. Elimination of double position domains (DPDs) in epitaxial 〈111〉-3C-SiC on Si(111) by laser CVD[J]. Appl Surf Sci, 2017, 426: 662−666. doi: 10.1016/j.apsusc.2017.07.239

[21] Cheng H, Tu R, Zhang S, et al. Preparation of highly Oriented β-SiC bulks by halide laser chemical vapor deposition[J]. J Eur Ceram Soc, 2017, 37(2): 509−515. doi: 10.1016/j.jeurceramsoc.2016.09.017

[22] Zhang S, Xu Q F, Tu R, et al. Growth mechanism and defects of <111>-oriented β-SiC films deposited by laser chemical vapor deposition[J]. J Am Ceram Soc, 2015, 98(1): 236−241. doi: 10.1111/jace.13248

[23] Zhang S, Tu R, Goto T. High-speed epitaxial growth of β-SiC film on Si(111) single crystal by laser chemical vapor deposition[J]. J Am Ceram Soc, 2012, 95(9): 2782−2784. doi: 10.1111/j.1551-2916.2012.05354.x

[24] Wan Z F, Chen X, Gu M. Laser scribed graphene for supercapacitors[J]. Opto-Electron Adv, 2021, 4(7): 200079. doi: 10.29026/oea.2021.200079

[25] 张鸿俭, 冯钟潮, 张鹤. TiN类薄膜的激光化学气相沉积[J]. 兵器材料科学与工程, 1999, 22(1): 41−44. doi: 10.3969/j.issn.1004-244X.1999.01.010

Zhang H J, Feng Z C, Zhang H. Preparing films of titanium carbide and nitride on titanium alloy by lcvd[J]. Ordnance Mater Sci Eng, 1999, 22(1): 41−44. doi: 10.3969/j.issn.1004-244X.1999.01.010

[26] 涂溶, 胡璇, 章嵩, 等. 碳化硼薄膜制备技术研究进展[J]. 现代技术陶瓷, 2018, 39(6): 417−431.

Tu R, Hu X, Zhang S, et al. Preparation methods of boron carbide thin films[J]. Adv Ceram, 2018, 39(6): 417−431.

[27] Thirugnanam P, Xiong W, Mahjouri-Samani M, et al. Rapid growth of m-plane oriented gallium nitride nanoplates on silicon substrate using laser-assisted metal organic chemical vapor deposition[J]. Cryst Growth Des, 2013, 13(7): 3171−3176. doi: 10.1021/cg400541e

[28] Wang T, Tu R, Zhang C L, et al. Influence of oxygen partial pressure on SmBa2Cu3O7-δ film deposited by laser chemical vapor deposition[J]. J Asian Ceram Soc, 2021, 9(1): 197−207. doi: 10.1080/21870764.2020.1860434

[29] Goto T, Kimura T. High-speed oxide coating by laser chemical vapor deposition and their nano-structure[J]. Thin Solid Films, 2006, 515(1): 46−52. doi: 10.1016/j.tsf.2005.12.022

[30] Chi C, Katsui H, Goto T. Preparation of Na-β-alumina films by laser chemical vapor deposition[J]. Surf Coat Technol, 2015, 276: 534−538. doi: 10.1016/j.surfcoat.2015.06.019

[31] Zhang C G, Fan Y, Zhao J L, et al. Corrosion resistance of non-stoichiometric gadolinium zirconate fabricated by laser-enhanced chemical vapor deposition[J]. J Adv Ceram, 2021, 10(3): 520−528. doi: 10.1007/s40145-020-0454-x

[32] Yang G, Wang D J, Zhang C, et al. Fabrication of gadolinium zirconate films by laser CVD[J]. Ceram Int, 2019, 45(4): 4926−4933. doi: 10.1016/j.ceramint.2018.11.192

[33] Wang D J, Liu Y C, Zhu C H, et al. Preparation of lanthanum zirconate films With a widely controllable La/Zr ratio by LCVD[J]. Ceram Int, 2018, 44(9): 10621−10627. doi: 10.1016/j.ceramint.2018.03.088

[34] Yang G, Mao X X, Wang D J, et al. Fabrication of columnar structured lanthanum zirconate films by laser CVD[J]. J Am Ceram Soc, 2017, 100(9): 4232−4239. doi: 10.1111/jace.14923

[35] Duty C, Jean D, Lackey W J. Laser chemical vapour deposition: materials, modelling, and process control[J]. Int Mater Rev, 2001, 46(6): 271−287. doi: 10.1179/095066001771048727

[36] 张魁武. 激光化学气相沉积(连载之一)[J]. 金属热处理, 2007, 32(6): 118−126. doi: 10.3969/j.issn.0254-6051.2007.06.033

Zhang K W. Laser chemical vapour deposition (LCVD) (Ⅰ)[J]. Heat Treat Met, 2007, 32(6): 118−126. doi: 10.3969/j.issn.0254-6051.2007.06.033

[37] 刘江龙, 邹至荣. 激光化学气相沉积薄膜材料技术的研究进展[J]. 材料导报, 1991, 5(10): 20−26.

Liu J L, Zou J L. Research progress of laser chemical vapor deposition thin film material technology[J]. Mater Rep, 1991, 5(10): 20−26.

[38] Dittrich S, Barcikowski S, Gökce B. Plasma and nanoparticle shielding during pulsed laser ablation in liquids cause ablation efficiency decrease[J]. Opto-Electron Adv, 2021, 4(1): 200072. doi: 10.29026/oea.2021.200072

[39] Zhang C Y, Zhou W, Geng D, et al. Laser direct writing and characterizations of flexible piezoresistive sensors with microstructures[J]. Opto-Electron Adv, 2021, 4(4): 200061.

[40] Graus P, Möller T B, Leiderer P, et al. Direct laser interference patterning of nonvolatile magnetic nanostructures in Fe60Al40 alloy via disorder-induced ferromagnetism[J]. Opto-Electron Adv, 2020, 3(1): 190027.

[41] Fan L, Constantin L, Wu Z P, et al. Laser vibrational excitation of radicals to prevent crystallinity degradation caused by boron doping in diamond[J]. Sci Adv, 2021, 7(4): eabc7547. doi: 10.1126/sciadv.abc7547

[42] Xu L F, Ito A, Goto T. High-speed deposition of tetragonal-ZrO2-dispersed SiO2 nanocomposite films by laser chemical vapor deposition[J]. Mater Lett, 2015, 154: 85−89. doi: 10.1016/j.matlet.2015.04.065

[43] Kadokura H, Ito A, Kimura T, et al. Moderate temperature and high-speed synthesis Of α-Al2O3 films by laser chemical vapor deposition using Nd: YAG laser[J]. Surf Coat Technol, 2010, 204(14): 2302−2306. doi: 10.1016/j.surfcoat.2009.12.029

[44] Ito A, Kadokura H, Kimura T, et al. Texture and orientation characteristics of α-Al2O3 films prepared by laser chemical vapor deposition using Nd: YAG laser[J]. J Alloys Compd, 2010, 489(2): 469−474. doi: 10.1016/j.jallcom.2009.09.088

[45] Fan L S, Xiong W, Jiang L J, et al. Fabrication of graphene patterns directly on SiO2/Si substrates using laser-induced chemical vapor deposition[J]. ICALEO, 2014, 2014: 1215−1219.

[46] Zhang G F, Buck V. Diamond films synthesized by pulsed-laser assisted hot-filament CVD At 0.2 mbar pressure[J]. Adv Eng Mater, 2001, 3(1-2): 81−84. doi: 10.1002/1527-2648(200101)3:1/2<81::AID-ADEM81>3.0.CO;2-K

[47] 张伟, 陈小英, 马永生, 等. 激光化学气相沉积法在TFT-LCD电路缺陷维修中的应用[J]. 液晶与显示, 2019, 34(8): 755−763. doi: 10.3788/YJYXS20193408.0755

Zhang W, Chen X Y, Ma Y S, et al. Application of laser chemical vapor deposition in repairing TFT-LCD circuit defects[J]. Chin J Liq Cryst Displays, 2019, 34(8): 755−763. doi: 10.3788/YJYXS20193408.0755

[48] Banerji N, Serra J, Serra C, et al. Comparison of modifications induced by ArF excimer laser irradiation on silicon nitride films deposited by different LCVD methods[J]. Surf Coat Technol, 1998, 100–101: 393−397.

[49] Morjan I, Soare I, Alexandrescu R, et al. Carbon nanotubes growth from C2H2 and C2H4/NH3 by catalytic LCVD on supported iron-carbon nanocomposites[J]. Phys E:Low-Dimens Syst Nanostruct, 2007, 37(1-2): 26−33. doi: 10.1016/j.physe.2006.10.009

[50] Fan L S, Zhou Y S, Wang M M, et al. Seed-free deposition of large-area adhesive diamond films on copper surfaces processed and patterned by femtosecond lasers[J]. Thin Solid Films, 2017, 636: 499−505. doi: 10.1016/j.tsf.2017.06.058

[51] Molian P A, Waschek A. CO2 laser deposition of diamond thin films on electronic materials[J]. J Mater Sci, 1993, 28(7): 1733−1737. doi: 10.1007/BF00595739

[52] Oliveira M N, do Rego A M B, Conde O. XPS investigation of BxNyCz coatings deposited by laser assisted chemical vapour desposition[J]. Surf Coat Technol, 1998, 100–101: 398−403.

[53] Golgir H R, Gao Y, Zhou Y S, et al. Effect of laser-assisted resonant excitation on the growth of GaN films[C]//Proceedings of the 33nd International Congress on Applications of Lasers and Electro-Optics (ICALEO), 2014.

[54] Golgir H R, Gao Y, Zhou Y S, et al. Low-temperature growth of crystalline gallium nitride films using vibrational excitation of ammonia molecules in laser-assisted metalorganic chemical vapor deposition[J]. Cryst Growth Des, 2014, 14(12): 6248−6253. doi: 10.1021/cg500862b

[55] Longtin R, Fauteux C, Pegna J, et al. Micromechanical testing of carbon fibers deposited by low-pressure laser-assisted chemical vapor deposition[J]. Carbon, 2004, 42(14): 2905−2913. doi: 10.1016/j.carbon.2004.06.039

[56] Lindstam M, Boman M, Carlsson J O. Area selective laser chemical vapor deposition of diamond and graphite[J]. Appl Surf Sci, 1997, 109–110: 462−466.

[57] Maxwell J L, Boman M, Springer R W, et al. Process-structure map for diamond-like carbon fibers from ethene at hyperbaric pressures[J]. Adv Funct Mater, 2005, 15(7): 1077−1087. doi: 10.1002/adfm.200400252

[58] Gao M, Ito A, Goto T. Preparation of γ-Al2O3 films by laser chemical vapor deposition[J]. Appl Surf Sci, 2015, 340: 160−165. doi: 10.1016/j.apsusc.2015.02.196

[59] Constantin L, Fan L S, Azina C, et al. Effects of laser photolysis of hydrocarbons at 193 and 248 nm on chemical vapor deposition of diamond films[J]. Cryst Growth Des, 2018, 18(4): 2458−2466. doi: 10.1021/acs.cgd.8b00084

[60] 周政卓, 曾永健, 邱明新, 等. 激光诱导化学反应合成硫化铅、氧化铅薄膜[J]. 应用激光, 1985, 5(6): 254−256.

Zhou Z Z, Zeng Y J, Qiu M X, et al. Lead sulphide and lead oxide films synthesised by laser induced chemical reaction[J]. Appl Laser, 1985, 5(6): 254−256.

[61] Fan L S, Constantin L, Li D W, et al. Ultraviolet laser photolysis of hydrocarbons for nondiamond carbon suppression in chemical vapor deposition of diamond films[J]. Light:Sci Appl, 2018, 7: 17177. doi: 10.1038/lsa.2017.177

[62] Crunteanu A, Cireasa R, Alexandrescu R, et al. Influence of the surface treatment of the substrate in the LCVD of CNx films[J]. Surf Coat Technol, 1998, 100–101: 173−179.

[63] Liu L, Deng L M, Fan L S, et al. Time-resolved resonance fluorescence spectroscopy for study of chemical reactions in laser-induced plasmas[J]. Opt Express, 2017, 25(22): 27000−27007. doi: 10.1364/OE.25.027000

[64] 徐捷, 吕新明, 楼祺洪. 准分子激光诱导沉积锰和钨薄膜[J]. 中国激光, 1992, 19(5): 357−362. doi: 10.3321/j.issn:0258-7025.1992.05.009

Xu J, Lü X M, Lou Q H. Excimer laser-induced deposition of manganese and tungsten thin film[J]. Chin J Lasers, 1992, 19(5): 357−362. doi: 10.3321/j.issn:0258-7025.1992.05.009

[65] 强游. 激光化学气相沉积[J]. 真空与低温, 1987(1): 44−49.

Qiang Y. Laser chemical vapor deposition[J]. Vac Cryog, 1987(1): 44−49.

[66] van de Burgt Y. Laser-assisted growth of carbon nanotubes-a review[J]. J Laser Appl, 2014, 26(3): 032001. doi: 10.2351/1.4869257

[67] Conde O, Silvestre A J. Laser-assisted deposition of thin films from photoexcited vapour phases[J]. Appl Phys A, 2004, 79(3): 489−497. doi: 10.1007/s00339-004-2566-5

[68] Nelson L S, Richardson N L. Formation of thin rods of pyrolytic carbon by heating With a focused carbon dioxide laser[J]. Mater Res Bull, 1972, 7(9): 971−976. doi: 10.1016/0025-5408(72)90087-6

[69] Chizari S, Shaw L A, Behera D, et al. Current challenges and potential directions towards precision microscale additive manufacturing-Part III: energy induced deposition and hybrid electrochemical processes[J]. Precis Eng, 2021, 68: 174−186. doi: 10.1016/j.precisioneng.2020.12.013

[70] Spreafico C, Russo D, Degl'Innocenti R. Laser pyrolysis in papers and patents[J]. J Intell Manuf, 2022, 33(2): 353−385. doi: 10.1007/s10845-021-01809-9

[71] Matsumoto S, Kaneda Y, Ito A. Highly self-oriented growth of (020) and (002) monoclinic HfO2 thick films using laser chemical vapor deposition[J]. Ceram Int, 2020, 46(2): 1810−1815. doi: 10.1016/j.ceramint.2019.09.156

[72] Katsui H, Harada K, Kondo N, et al. Preparation of boron carbon oxynitride phosphor film via laser chemical vapor deposition and annealing[J]. Surf Coat Technol, 2020, 394: 125851. doi: 10.1016/j.surfcoat.2020.125851

[73] Katsui H, Harada K, Kondo N, et al. Preparation of zirconium carbonitride by laser chemical vapor deposition using alkyl-amide precursor As a single source[J]. J Ceram Soc Jpn, 2020, 128(11): 855−862. doi: 10.2109/jcersj2.20081

[74] Chen J C, Ito A, Goto T. High-speed epitaxial growth of SrTiO3 transparent thick films composed of close-packed nanocolumns using laser chemical vapor deposition[J]. Vacuum, 2020, 177: 109424. doi: 10.1016/j.vacuum.2020.109424

[75] Sakai T, Kato T, Katsui H, et al. Preparation of Y-doped BaZrO3 thin film electrolyte by laser chemical vapor deposition[J]. Mater Today Commun, 2020, 24: 101184. doi: 10.1016/j.mtcomm.2020.101184

[76] Ito A, Sekiyama M, Hara T, et al. Self-oriented growth Of β-Yb2Si2O7 and X1/X2-Yb2SiO5 coatings using laser chemical vapor deposition[J]. Ceram Int, 2020, 46(7): 9548−9553. doi: 10.1016/j.ceramint.2019.12.217

[77] Katsui H, Kondo N. Preferred orientations and microstructures of lanthanum phosphate films prepared via laser chemical vapor deposition[J]. J Cryst Growth, 2019, 519: 46−53. doi: 10.1016/j.jcrysgro.2019.05.005

[78] Merenkov I S, Katsui H, Khomyakov M N, et al. Extraordinary synergetic effect of precursors in laser CVD deposition of SiBCN films[J]. J Eur Ceram Soc, 2019, 39(16): 5123−5131. doi: 10.1016/j.jeurceramsoc.2019.08.006

[79] Bäuerle D. Laser processing and chemistry [M]. Springer Science & Business Media, 2011.

[80] Uesugi F, Morishige Y, Shinzawa T, et al. Low resistivity contact formation for Lsi interconnection with short-pulse-laser induced Mo CVD[J]. MRS Online Proc Lib, 1987, 101(1): 61−65.

[81] Jeong K, Lee J, Byun I, et al. Pulsed laser chemical vapor deposition of a mixture of W, WO2, and WO3 from W(CO)6 at atmospheric pressure[J]. Thin Solid Films, 2017, 626: 145−153. doi: 10.1016/j.tsf.2017.02.043

[82] Jeong K, Lee J, Byun I, et al. Synthesis of highly conductive cobalt thin films by LCVD at atmospheric pressure[J]. Mater Sci Semicond Process, 2017, 68: 245−251. doi: 10.1016/j.mssp.2017.06.032

[83] Stuke M, Mueller K, Mueller T, et al. Laser-direct-write creation of three-dimensional OREST microcages for contact-free trapping, handling and transfer of small polarizable neutral objects in solution[J]. Appl Phys A, 2005, 81(5): 915−922. doi: 10.1007/s00339-005-3280-7

[84] Ten J S, Sparkes M, O'Neill W. Femtosecond laser-induced chemical vapor deposition of tungsten quasi-periodic structures on silicon substrates[J]. J Laser Appl, 2018, 30(3): 032606. doi: 10.2351/1.5040637

[85] Ning B, Xia T, Tong Z X, et al. Experimental and numerical studies of tungsten line growth in laser chemical vapor deposition[J]. Int J Heat Mass Transf, 2019, 140: 564−578. doi: 10.1016/j.ijheatmasstransfer.2019.06.001

[86] Westberg H, Boman M, Norekrans A S, et al. Carbon growth by thermal laser-assisted chemical vapour deposition[J]. Thin Solid Films, 1992, 215(2): 126−133. doi: 10.1016/0040-6090(92)90426-C

[87] Longtin R, Fauteux C, Coronel E, et al. Nanoindentation of carbon microfibers deposited by laser-assisted chemical vapor deposition[J]. Appl Phys A, 2004, 79(3): 573−577. doi: 10.1007/s00339-003-2449-1

[88] Fauteux C, Longtin R, Pegna J, et al. Raman characterization of laser grown carbon microfibers as a function of experimental parameters[J]. Thin Solid Films, 2004, 453–454: 606−610.

[89] Fauteux C, Longtin R, Pegna J, et al. Microstructure and growth mechanism of laser grown carbon microrods As a function of experimental parameters[J]. J Appl Phys, 2004, 95(5): 2737−2743. doi: 10.1063/1.1641954

[90] Park J B, Xiong W, Xie Z Q, et al. Transparent interconnections formed by rapid single-step fabrication of graphene patterns[J]. Appl Phys Lett, 2011, 99(5): 053103. doi: 10.1063/1.3622660

[91] Park J B, Xiong W, Gao Y, et al. Fast growth of graphene patterns by laser direct writing[J]. Appl Phys Lett, 2011, 98(12): 123109. doi: 10.1063/1.3569720

[92] Um J W, Kim S Y, Lee B H, et al. Direct writing of graphite thin film by laser-assisted chemical vapor deposition[J]. Carbon, 2020, 169: 163−171. doi: 10.1016/j.carbon.2020.07.035

[93] Lin Z, Huang T, Ye X H, et al. Thinning of large-area graphene film from multilayer to bilayer with a low-power CO2 laser[J]. Nanotechnology, 2013, 24(27): 275302. doi: 10.1088/0957-4484/24/27/275302

[94] Tu R, Liang Y, Zhang C, et al. Fast synthesis of high-quality large-area graphene by laser CVD[J]. Appl Surf Sci, 2018, 445: 204−210. doi: 10.1016/j.apsusc.2018.03.184

[95] Ristić G S, Trtica M S, Miljanić S Š. Diamond synthesis by lasers: recent progress[J]. Quim Nova, 2012, 35(7): 1417−1422.

[96] Tóth Z, Mechler Á, Heszler P. Local laser-assisted chemical vapor deposition of diamond[J]. Appl Surf Sci, 2000, 168(1-4): 5−8. doi: 10.1016/S0169-4332(00)00563-8

[97] Zhang S, Xu Q F, Tu R, et al. High-speed preparation of <111>- and <110>-oriented β-SiC films by laser chemical vapor deposition[J]. J Am Ceram Soc, 2014, 97(3): 952−958. doi: 10.1111/jace.12706

[98] Li B, Li Q, Katsui H, et al. Effect of the vacuum degree on the orientation and the microstructure Of β-SiC films prepared by laser chemical vapour deposition[J]. Mater Lett, 2016, 182: 81−84. doi: 10.1016/j.matlet.2016.06.091

[99] Li Y, Katsui H, Goto T. Highly (111)-oriented SiC films on glassy carbon prepared by laser chemical vapor deposition[J]. J Korean Ceram Soc, 2016, 53(6): 647−651. doi: 10.4191/kcers.2016.53.6.647

[100] Xu Q F, Tu R, Sun Q Y, et al. Morphology controlling of <111>-3C-SiC films by HMDS flow rate in LCVD[J]. RSC Adv, 2019, 9(5): 2426−2430. doi: 10.1039/C8RA09509D

[101] Tu R, Hu Z Y, Xu Q F, et al. Epitaxial growth of 3C-SiC (111) on Si via laser CVD carbonization[J]. J Asian Ceram Soc, 2019, 7(3): 312−320. doi: 10.1080/21870764.2019.1631995

[102] Sun Q Y, Yang M J, Li J, et al. Heteroepitaxial growth of thick 3C-SiC (110) films by laser CVD[J]. J Am Ceram Soc, 2019, 102(8): 4480−4491. doi: 10.1111/jace.16297

[103] Sun Q Y, Zhu P P, Xu Q F, et al. High-speed heteroepitaxial growth of 3C-SiC (111) thick films on Si (110) by laser chemical vapor deposition[J]. J Am Ceram Soc, 2018, 101(3): 1048−1057. doi: 10.1111/jace.15260

[104] Zhu P P, Yang M J, Xu Q F, et al. Epitaxial growth of 3C-SiC on Si(111) and (001) by laser CVD[J]. J Am Ceram Soc, 2018, 101(9): 3850−3856. doi: 10.1111/jace.15557

[105] Goto T, Banal R, Kimura T. Morphology and preferred orientation of Y2O3 film prepared by high-speed laser CVD[J]. Surf Coat Technol, 2007, 201(12): 5776−5781. doi: 10.1016/j.surfcoat.2006.10.023

[106] Zhao P, Su S, Wang Y, et al. High-speed preparation of highly (100)-oriented CeO2 film by laser chemical vapor deposition[J]. J Am Ceram Soc, 2016, 99(9): 3104−3110. doi: 10.1111/jace.14279

[107] Kimura T. Development of electrospray laser chemical vapour deposition for homogenous alumina coatings[J]. J Wuhan Univ Technol-Mater Sci Ed, 2016, 31(1): 11−14. doi: 10.1007/s11595-016-1321-z

[108] Ito A. Chemical vapor deposition of highly oriented ceramic coatings In a high-intensity laser irradiation[J]. J Ceram Soc Jpn, 2021, 129(11): 646−653. doi: 10.2109/jcersj2.21135

[109] Tu R, Huo G S, Kimura T, et al. Preparation of Magneli phases of Ti27O52 and Ti6O11 films by laser chemical vapor deposition[J]. Thin Solid Films, 2010, 518(23): 6927−6932. doi: 10.1016/j.tsf.2010.07.050

[110] Goto T. Thermal barrier coatings deposited by laser CVD[J]. Surf Coat Technol, 2005, 198(1-3): 367−371. doi: 10.1016/j.surfcoat.2004.10.084

[111] Suehiro S, Kimura T, Yokoe D, et al. Synthesis of Highly c-axis-oriented ZnO thin films using novel laser-enhanced electrospray CVD under atmospheric pressure[J]. CrystEngComm, 2017, 19(40): 5995−6001. doi: 10.1039/C7CE01333G

[112] Lange A P, Elhadj S, Matthews M J. Formation of nano-volcano structures during atmospheric, laser-driven chemical vapor deposition[J]. J Phys Chem C, 2020, 124(43): 23913−23922. doi: 10.1021/acs.jpcc.0c06551

[113] Sharma B, Sharma A. Enhanced surface dynamics and magnetic switching of α-Fe2O3 films prepared by laser assisted chemical vapor deposition[J]. Appl Surf Sci, 2021, 567: 150724. doi: 10.1016/j.apsusc.2021.150724

[114] Ito A, Endo J, Kimura T, et al. Eggshell- and fur-like microstructures of yttrium silicate film prepared by laser chemical vapor deposition[J]. Mater Chem Phys, 2011, 125(1-2): 242−246. doi: 10.1016/j.matchemphys.2010.09.014

[115] Tu R, Kimura T, Goto T. Rapid synthesis of yttria-partially-stabilized zirconia films by metal-organic chemical vapor deposition[J]. Mater Trans, 2002, 43(9): 2354−2356. doi: 10.2320/matertrans.43.2354

[116] Ito A, Joo H S, Kim T S, et al. Synthesis of pseudobrookite titanium oxynitride Ti3-δO4N films by laser chemical vapor deposition[J]. Vacuum, 2015, 116: 121−123. doi: 10.1016/j.vacuum.2015.03.015

[117] Ito A, Nishigaki S, Goto T. A feather-like structure of β-Al2TiO5 film prepared by laser chemical vapor deposition[J]. J Eur Ceram Soc, 2015, 35(7): 2195−2199. doi: 10.1016/j.jeurceramsoc.2015.01.027

[118] Chi C, Katsui H, Goto T. Preparation of Na-Al-O films by laser chemical vapor deposition[J]. Mater Chem Phys, 2015, 160: 456−460. doi: 10.1016/j.matchemphys.2015.05.024

[119] Huerta-Flores A M, Chen J C, Torres-Martínez L M, et al. Laser assisted chemical vapor deposition of nanostructured NaTaO3 and SrTiO3 thin films for efficient photocatalytic hydrogen evolution[J]. Fuel, 2017, 197: 174−185. doi: 10.1016/j.fuel.2017.02.016

[120] Huerta-Flores A M, Chen J C, Ito A, et al. High-speed deposition of oriented orthorhombic NaTaO3 films using laser chemical vapor deposition[J]. Mater Lett, 2016, 184: 257−260. doi: 10.1016/j.matlet.2016.08.083

[121] Chi C, Katsui H, Tu R, et al. Oriented growth and electrical property of LiAl5O8 film by laser chemical vapor deposition[J]. J Ceram Soc Jpn, 2016, 124(1): 111−115. doi: 10.2109/jcersj2.15220

[122] Yu S, Tu R, Goto T. Preparation of SiOC nanocomposite films by laser chemical vapor deposition[J]. J Eur Ceram Soc, 2016, 36(3): 403−409. doi: 10.1016/j.jeurceramsoc.2015.10.029

[123] Chen J C, Ito A, Goto T. High-speed deposition of highly (001)-oriented SrCO3 films prepared using laser chemical vapor deposition[J]. Ceram Int, 2015, 41(9): 11810−11814. doi: 10.1016/j.ceramint.2015.05.149

[124] Yang X J, Guo D Y. Preparation of (511)-oriented BaTi2O5 thick film on Pt/MgO(111) substrate by laser chemical vapor deposition[J]. Sens Mater, 2021, 33(7): 2531−2535.

[125] Chang J Y, Qi Y H, Zhao H Y, et al. Laser chemical vapor deposition of Lu2O3: Eu scintillation film[J]. Mater Res Express, 2019, 6(8): 086437. doi: 10.1088/2053-1591/ab2000

[126] Chen J C, Ito A, Goto T. High-speed epitaxial growth of (110) SrTiO3 films on (110) MgAl2O4 substrates using laser chemical vapour deposition[J]. Mater Today:Proc, 2017, 4(11): 11461−11464. doi: 10.1016/j.matpr.2017.09.029

[127] Chen J C, Ito A, Goto T. High-speed epitaxial growth of SrTiO3 films on MgO substrates by laser chemical vapor deposition[J]. Ceram Int, 2016, 42(8): 9981−9987. doi: 10.1016/j.ceramint.2016.03.100

[128] Zhao P, Zhang Q, Wu W, et al. Preparation of (110)-oriented SrTiO3 film on quartz glass by laser chemical vapor deposition[J]. J Am Ceram Soc, 2019, 102(4): 2135−2142. doi: 10.1111/jace.16009

[129] Zhao P, Su S, Wang Y, et al. Investigation on influence of deposition rate of YBa2Cu3O7-δ superconducting film prepared on Hastelloy C276 substrate by spray atomizing and coprecipitating laser chemical vapor deposition[J]. Thin Solid Films, 2016, 599: 179−186. doi: 10.1016/j.tsf.2016.01.003

[130] Zhao P, Ito A, Goto T. Effects of film thickness on the electrical properties of YBa2Cu3O7-δ films grown On a multilayer-coated Hastelloy C276 tape by laser CVD[J]. J Electroceram, 2015, 34(2-3): 137−141. doi: 10.1007/s10832-014-9962-9

[131] Zhao P, Wang Y, Huang Z L, et al. Influence of laser power on orientation, microstructure and electrical performance of YBa2Cu3O7-x film prepared on (001) SrTiO3 single crystal substrate by spray atomizing and coprecipitating laser chemical vapor deposition[J]. Ceram Int, 2015, 41(3): 3624−3630. doi: 10.1016/j.ceramint.2014.11.027

[132] Tu R, Wang K D, Wang T, et al. Structural study of epitaxial NdBa2Cu3O7-x films by laser chemical vapor deposition[J]. RSC Adv, 2018, 8(35): 19811−19817. doi: 10.1039/C8RA02758G

[133] Wang T, Wang K T, Tu R, et al. Thickness dependence of structure and superconductivity of the SmBa2Cu3O7 film by laser CVD[J]. RSC Adv, 2017, 7(89): 56166−56172. doi: 10.1039/C7RA12096F

[134] Loho C, Djenadic R, Bruns M, et al. Garnet-type Li7La3Zr2O12 solid electrolyte thin films grown by CO2-laser assisted CVD for all-solid-state batteries[J]. J Electrochem Soc, 2017, 164(1): A6131−A6139. doi: 10.1149/2.0201701jes

[135] Loho C, Djenadic R, Mund P, et al. On processing-structure-property relations and high ionic conductivity in garnet-type Li5La3Ta2O12 solid electrolyte thin films grown by CO2-laser assisted CVD[J]. Solid State Ionics, 2017, 313: 32−44. doi: 10.1016/j.ssi.2017.11.005

[136] Sun Q Y, Tu R, Xu Q F, et al. Nanoforest of 3C-SiC/graphene by laser chemical vapor deposition with high electrochemical performance[J]. J Power Sources, 2019, 444: 227308. doi: 10.1016/j.jpowsour.2019.227308

[137] Guo H, Yang X Y, Xu Q F, et al. Epitaxial growth and electrical performance of graphene/3C-SiC films by laser CVD[J]. J Alloys Compd, 2020, 826: 154198. doi: 10.1016/j.jallcom.2020.154198

[138] Yu S, Tu R, Ito A, et al. SiC-SiO2 nanocomposite films prepared by laser CVD using tetraethyl orthosilicate and acetylene as precursors[J]. Mater Lett, 2010, 64(20): 2151−2154. doi: 10.1016/j.matlet.2010.07.022

[139] Honda A, Kimura T, Ito A, et al. Rh-nanoparticle-dispersed ZrO2 films prepared by laser chemical vapor deposition[J]. Surf Coat Technol, 2012, 206(11-12): 3006−3010. doi: 10.1016/j.surfcoat.2011.12.038

[140] Ito A, You Y, Ichikawa T, et al. Preparation of Al2O3-ZrO2 nanocomposite films by laser chemical vapour deposition[J]. J Eur Ceram Soc, 2014, 34(1): 155−159. doi: 10.1016/j.jeurceramsoc.2013.07.025

[141] Yang M J, Bai S N, Xu Q F, et al. Mechanical properties of high-crystalline diamond films grown via laser MPCVD[J]. Diam Relat Mater, 2020, 109: 108094. doi: 10.1016/j.diamond.2020.108094

[142] Xu Q F, Zhu P P, Sun Q Y, et al. Fast preparation of (111)-oriented β-SiC films without carbon formation by laser chemical vapor deposition from hexamethyldisilane without H2[J]. J Am Ceram Soc, 2018, 101(4): 1471−1478. doi: 10.1111/jace.15315

[143] Kuk S, Nam H K, Wang Z, et al. Effect of laser beam dimension on laser-assisted chemical vapor deposition of silicon nitride thin films[J]. J Nanosci Nanotechnol, 2018, 18(10): 7085−7089. doi: 10.1166/jnn.2018.15727

[144] 张永彬, 陈志磊, 宾韧, 等. 铀上激光辅助化学气相沉积镍薄膜研究[J]. 原子能科学技术, 2017, 51(3): 411−417. doi: 10.7538/yzk.2017.51.03.0411

Zhang Y B, Chen Z L, Bin R, et al. Study on nickel film on uranium by laser assisted chemical vapor deposition[J]. At Energy Sci Technol, 2017, 51(3): 411−417. doi: 10.7538/yzk.2017.51.03.0411

[145] Sousa P M, Silvestre A J, Conde O. Cr2O3 thin films grown at room temperature by low pressure laser chemical vapour deposition[J]. Thin Solid Films, 2011, 519(11): 3653−3657. doi: 10.1016/j.tsf.2011.01.382

[146] 马兴孝, 孔繁敖. 激光化学[M]. 合肥: 中国科学技术大学出版社, 1990.

Ma X X, Kong F A. Laser Chemistry[M]. Hefei: University of Science and Technology of China Press, 1990.

[147] Ten J S, Sparkes M, O'Neill W. High speed, mask-less, laser controlled deposition of microscale tungsten tracks using 405 nm wavelength diode laser[J]. Proc SPIE, 2017, 10091: 100910C.

[148] Park J B, Kim C J, Shin P E, et al. Hybrid LCVD of micro-metallic lines for TFT-LCD circuit repair[J]. Appl Surf Sci, 2006, 253(2): 1029−1035. doi: 10.1016/j.apsusc.2006.06.054

[149] Mukaida M, Osato K, Watanabe A, et al. Densification of Ta2O5 film prepared by KrF excimer laser CVD[J]. Thin Solid Films, 1993, 232(2): 180−184. doi: 10.1016/0040-6090(93)90006-B

[150] Sousa P M, Silvestre A J, Popovici N, et al. Morphological and structural characterization of CrO2/Cr2O3 films grown by laser-CVD[J]. Appl Surf Sci, 2005, 247(1-4): 423−428. doi: 10.1016/j.apsusc.2005.01.061

[151] Sousa P M, Silvestre A J, Popovici N, et al. KrF laser CVD of chromium oxide by photodissociation of Cr(CO)6[J]. Materials Science Forum, 2004, 455–456: 20−24.

[152] Meng Q G, Witte R J, Gong Y J, et al. Thin film deposition and photodissociation mechanisms for lanthanide oxide production from tris(2, 2, 6, 6-tetramethyl-3, 5-heptanedionato)Ln(III) in Laser-Assisted MOCVD[J]. Chem Mater, 2010, 22(22): 6056−6064. doi: 10.1021/cm101283k

[153] Chen J C, Meng Q G, May P S, et al. Time-dependent excited-state molecular dynamics of photodissociation of lanthanide complexes for laser-assisted metal-organic chemical vapour deposition[J]. Mol Phys, 2014, 112(3-4): 508−517. doi: 10.1080/00268976.2013.845310

[154] Mulenko S A, Izvekov A V, Petrov Y N, et al. Laser photodeposition of thin semiconductor films from iron carbonyl vapors[J]. Appl Surf Sci, 2005, 248(1-4): 475−478. doi: 10.1016/j.apsusc.2005.03.067

[155] 戴国瑞, 姜喜兰, 南金, 等. 激光CVD制备SnO2薄膜的结构及其反应机理研究[J]. 半导体学报, 1998, 19(6): 427−430. doi: 10.3321/j.issn:0253-4177.1998.06.006

Dai G R, Jiang X L, Nan J, et al. Study of structure and reaction Mechanism of SnO2: thin films prepared by excimer laser-assisted CVD[J]. Chin J Semicond, 1998, 19(6): 427−430. doi: 10.3321/j.issn:0253-4177.1998.06.006

[156] Tsuji M, Sakumoto M, Itoh N, et al. SiO2 film growth by ArF laser photolysis of SiH4/N2O mixtures[J]. Appl Surf Sci, 1991, 51(3-4): 171−176. doi: 10.1016/0169-4332(91)90399-5

[157] Kitahama K, Hirata K, Nakamatsu H, et al. Synthesis of diamond by laser-induced chemical vapor deposition[J]. Appl Phys Lett, 1986, 49(11): 634−635. doi: 10.1063/1.97063

[158] Goto Y, Yagi T, Nagai H. Synthesis of diamond films by laser-induced chemical vapor deposition[J]. MRS Online Proc Lib, 1988, 129(1): 213−217.

[159] Rebello J H D, Straub D L, Subramaniam V V. Diamond growth from a Co/CH4 mixture by laser excitation of Co: laser excited chemical vapor deposition[J]. J Appl Phys, 1992, 72(3): 1133−1136. doi: 10.1063/1.351790

[160] López E, Chiussi S, Kosch U, et al. Compositional, structural and optical properties of Si-Rich a-SiC: H thin films deposited by ArF-LCVD[J]. Appl Surf Sci, 2005, 248(1-4): 113−117. doi: 10.1016/j.apsusc.2005.03.011

[161] López E, Chiussi S, Kosch U, et al. A growth rate, structure and surface morphology study of Si1-x-yGexCy films deposited by ArF-LCVD in tilted geometry[J]. Vacuum, 2008, 82(12): 1525−1528. doi: 10.1016/j.vacuum.2008.03.018

[162] Chiussi S, López E, Serra J, et al. Influence of laser fluence in ArF-excimer laser assisted crystallisation Of a-SiGe: H films[J]. Appl Surf Sci, 2003, 208–209: 358−363.

[163] López E, Chiussi S, González P, et al. Influence of the substrate temperature on the structure of Ge containing thin films produced by ArF laser induced chemical vapour deposition[J]. Appl Surf Sci, 2005, 248(1-4): 108−112. doi: 10.1016/j.apsusc.2005.03.091

[164] López E, Chiussi S, Serra C, et al. ArF-excimer laser induced chemical vapour deposition of amorphous hydrogenated SiGeC films[J]. Appl Surf Sci, 2003, 208–209: 682−687.

[165] Kafizas A, Carmalt C J, Parkin I P. CVD and precursor chemistry of transition metal nitrides[J]. Coord Chem Rev, 2013, 257(13-14): 2073−2119. doi: 10.1016/j.ccr.2012.12.004

[166] Ishihara S, Hanabusa M. Laser-assisted chemical vapor deposition of titanium nitride films[J]. J Appl Phys, 1998, 84(1): 596−599. doi: 10.1063/1.368086

[167] Gong Y S, Tu R, Goto T. Effect of NH3 on the preparation of TiNx films by laser CVD using tetrakis-diethylamido-titanium[J]. J Alloys Compd, 2009, 485(1-2): 451−455. doi: 10.1016/j.jallcom.2009.05.137

[168] Gong Y S, Tu R, Goto T. Laser chemical vapor deposition of titanium nitride films with tetrakis (diethylamido) titanium and ammonia system[J]. Surf Coat Technol, 2010, 204(14): 2111−2117. doi: 10.1016/j.surfcoat.2009.10.042

[169] Gong Y S, Zhou W, Tu R, et al. Preparation of stoichiometric TiNx films by laser CVD with metalorganic precursor[J]. Adv Mater Res, 2011, 239–242: 318−321.

[170] Kuk S, Park J, Zhang T, et al. Low temperature deposition of inorganic thin films by ultraviolet laser-assisted chemical vapor deposition[J]. Nanosci Nanotechnol Lett, 2016, 8(7): 586−591. doi: 10.1166/nnl.2016.2229

[171] Kuk S, Park J, Zhang T, et al. Low temperature deposition of inorganic films by excimer laser assisted chemical vapor deposition[J]. Proc SPIE, 2017, 10091: 1009105.

[172] An K, Lee H N, Cho K H, et al. Role of a 193 nm ArF excimer laser in laser-assisted plasma-enhanced chemical vapor deposition of SiNx for low temperature thin film encapsulation[J]. Micromachines, 2020, 11(1): 88. doi: 10.3390/mi11010088

[173] An K, Lee H N, Cho K H, et al. Two-step fabrication of thin film encapsulation using laser assisted chemical vapor deposition and laser assisted plasma enhanced chemical vapor deposition for long-lifetime organic light emitting diodes[J]. Org Electron, 2021, 91: 106078. doi: 10.1016/j.orgel.2021.106078

[174] Kim K H, Kim K S, Ji Y J, et al. Silicon nitride deposited by laser assisted plasma enhanced chemical vapor deposition for next generation organic electronic devices[J]. Appl Surf Sci, 2021, 541: 148313. doi: 10.1016/j.apsusc.2020.148313

[175] Zhou B, Li X, Tansley T L, et al. Growth mechanisms in excimer laser photolytic deposition of gallium nitride at 500°C[J]. J Cryst Growth, 1996, 160(3-4): 201−206. doi: 10.1016/0022-0248(95)00602-8

[176] Golgir H R, Li D W, Keramatnejad K, et al. Fast growth of gan epilayers via laser-assisted metal-organic chemical vapor deposition for ultraviolet photodetector applications[J]. ACS Appl Mater Interfaces, 2017, 9(25): 21539−21547. doi: 10.1021/acsami.7b03554

[177] Golgir H R, Zhou Y S, Li D W, et al. Resonant and nonresonant vibrational excitation of ammonia molecules in the growth of gallium nitride using laser-assisted metal organic chemical vapour deposition[J]. J Appl Phys, 2016, 120(10): 105303. doi: 10.1063/1.4962426

[178] Gao Y, Zhou Y S, Park J B, et al. Resonant excitation of precursor molecules in improving the particle crystallinity, growth rate and optical limiting performance of carbon nano-onions[J]. Nanotechnology, 2011, 22(16): 165604. doi: 10.1088/0957-4484/22/16/165604

[179] Xie Z Q, Zhou Y S, He X N, et al. Fast growth of diamond crystals in open air by combustion synthesis with resonant laser energy coupling[J]. Cryst Growth Des, 2010, 10(4): 1762−1766. doi: 10.1021/cg9014515

[180] Xie Z Q, He X N, Hu W, et al. Excitations of precursor molecules by different laser powers in laser-assisted growth of diamond films[J]. Cryst Growth Des, 2010, 10(11): 4928−4933. doi: 10.1021/cg1010083

[181] Fan L S, Xie Z Q, Park J B, et al. Synthesis of nitrogen-doped diamond films using vibrational excitation of ammonia molecules in laser-assisted combustion flames[J]. J Laser Appl, 2012, 24(2): 022001. doi: 10.2351/1.3685299

[182] Fan L S, Zhou Y S, Wang M X, et al. Resonant vibrational excitation of ethylene molecules in laser-assisted diamond deposition[J]. Laser Phys Lett, 2014, 11(7): 076002. doi: 10.1088/1612-2011/11/7/076002

[183] Fan L S, Zhou Y S, Wang M X, et al. Mass spectrometric investigation of the roles of several chemical intermediates in diamond synthesis[J]. RSC Adv, 2015, 5(7): 4822−4830. doi: 10.1039/C4RA09058F

[184] Zhou Y S, Fan L S, Xie Z Q, et al. Laser-assisted vibrational control of precursor molecules in diamond synthesis[J]. Curr Opin Solid State Mater Sci, 2015, 19(2): 107−114. doi: 10.1016/j.cossms.2014.10.003

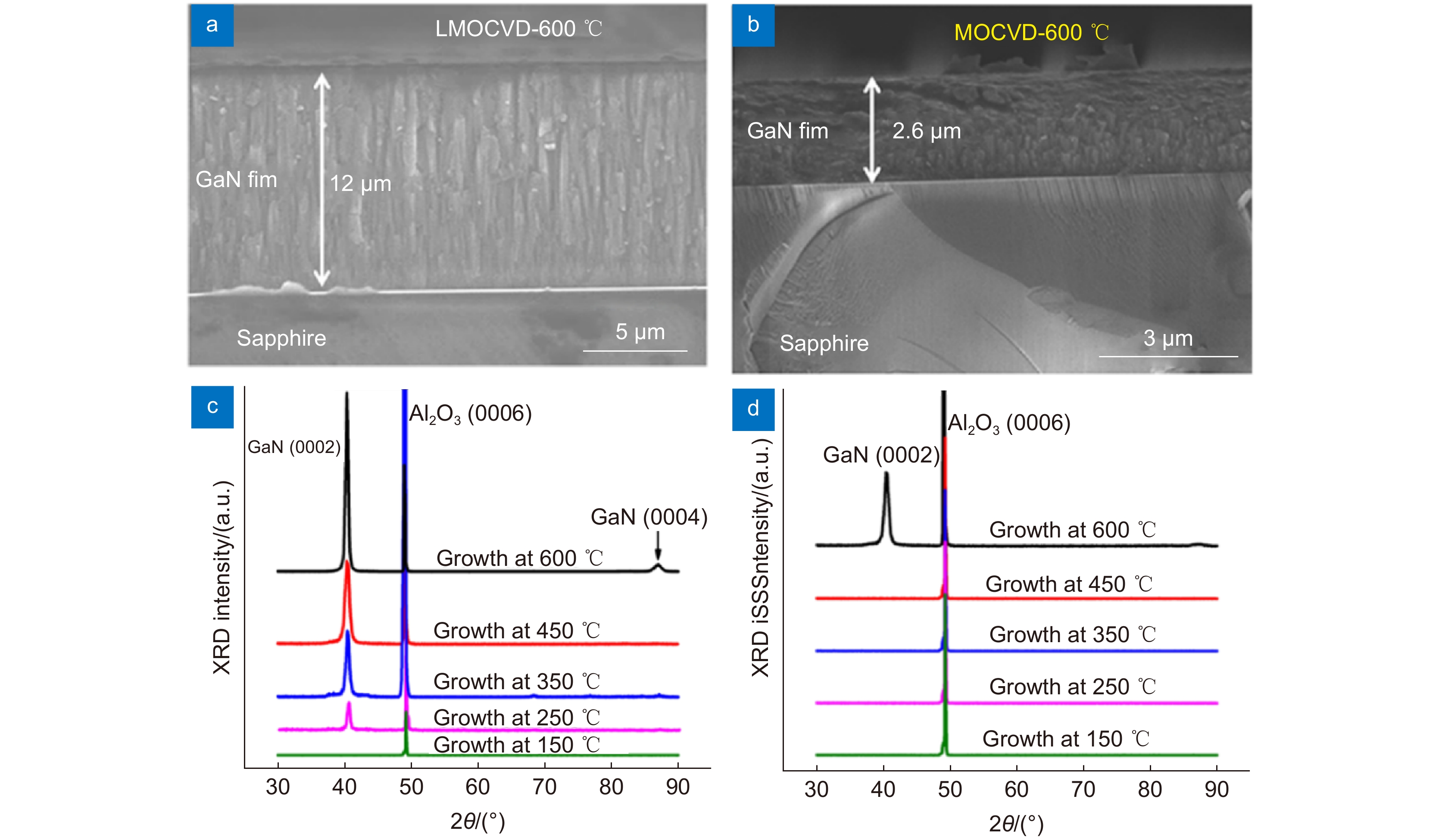

[185] Zhang Y X, Chen Z Y, Zhang K T, et al. Laser-assisted metal-organic chemical vapor deposition of gallium nitride[J]. Phys Status Solidi (RRL)-Rapid Res Lett, 2021, 15(6): 2100202. doi: 10.1002/pssr.202100202

[186] Papanikolaou A, Tserevelakis G J, Melessanaki K, et al. Development of a hybrid photoacoustic and optical monitoring system for the study of laser ablation processes upon the removal of encrustation from stonework[J]. Opto-Electron Adv, 2020, 3(2): 190037.

[187] Jean D, Duty C, Johnson R, et al. Carbon fiber growth kinetics and thermodynamics using temperature controlled LCVD[J]. Carbon, 2002, 40(9): 1435−1445. doi: 10.1016/S0008-6223(01)00307-4

[188] Prieske M, Müller S, Woizeschke P. Interaction of methane concentration and deposition temperature in atmospheric laser based CVD diamond deposition on hard metal[J]. Coatings, 2019, 9(9): 537. doi: 10.3390/coatings9090537

[189] Chen X, Azer M N, Egland K M, et al. Laser chemical vapor deposition of titanium nitride and process diagnostics with laser induced fluorescence spectroscopy[M]//Mazumder J, Conde O, Villar R, et al. Laser Processing: Surface Treatment and Film Deposition. Dordrecht: Springer, 1996: 693–701.

[190] Landström L, Kokavecz J, Lu J, et al. Characterization and modeling of tungsten nanoparticles generated by laser-assisted chemical vapor deposition[J]. J Appl Phys, 2004, 95(8): 4408−4414. doi: 10.1063/1.1667596

[191] Maxwell J L, Pegna J, Messia D V. Real-time volumetric growth rate measurements and feedback control of three-dimensional laser chemical vapor deposition[J]. Appl Phys A, 1998, 67(3): 323−329. doi: 10.1007/s003390050778

[192] Iida Y, Yeung E S. Acoustic monitoring of carbon film formation by laser-induced chemical vapor deposition[J]. Appl Spectrosc, 1993, 47(4): 523−527. doi: 10.1366/0003702934335010

[193] Guss G M, Sridharan A K, Elhadj S, et al. Nanoscale surface tracking of laser material processing using phase shifting diffraction interferometry[J]. Opt Express, 2014, 22(12): 14493−14504. doi: 10.1364/OE.22.014493

[194] Landström L, Lu J, Heszler P. Size-distribution and emission spectroscopy of W nanoparticles generated by laser-assisted CVD for different WF6/H2/Ar mixtures[J]. J Phys Chem B, 2003, 107(42): 11615−11621. doi: 10.1021/jp0343077

[195] Mahjouri M, Zhou Y S, Xiong W, et al. Growth of self-aligned single-walled carbon nanotubes by laser-assisted chemical vapor deposition[J]. Proc SPIE, 2008, 6880: 68800P. doi: 10.1117/12.762171

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: