Effect of water-guided laser machining technology on micro-morphology of 316L stainless steel

-

摘要

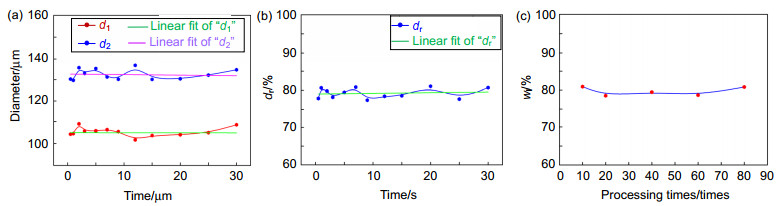

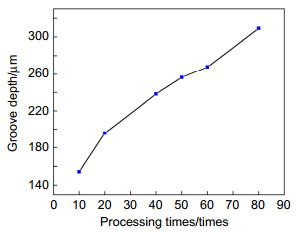

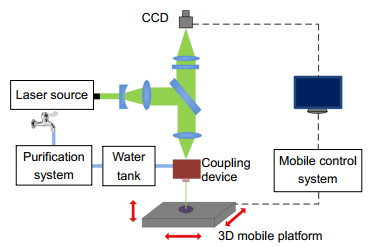

水导激光加工是一项利用水光纤将激光引导到材料加工表面的新颖加工技术,具有几乎无微裂纹、热影响区小、无污染、重熔层少、加工精度高和光束平行等优点。为研究不同水导激光加工工艺参数对微观形貌的影响,探索水导激光与物质的相互作用机理。本文采用自主研发的水导激光加工系统对316L不锈钢薄片试件进行切槽和打孔实验;使用Zeiss Vert.A1金相显微镜观察加工试件的二维形貌;使用Leica DVM6超景深显微镜和Bruke Contour Elite I白光干涉仪观察试件的三维微观形貌。实验结果表明:无论是对试件进行切槽还是打孔实验,均会在加工区域产生一定宽度的沉积层,且沉积层的大小不随加工时间和加工次数变化,其宽度约为13.5 µm;通过观察试件加工区域的二维形貌,发现打孔试件的dr和切槽试件的wl也不随加工试件和加工次数变化;通过观察切槽试件加工区域的三维形貌,其截面呈倒梯形。

Abstract

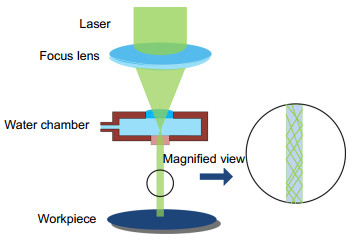

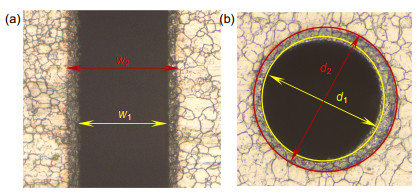

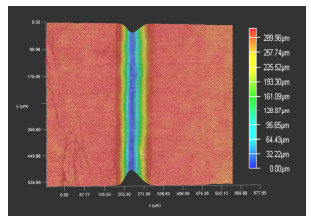

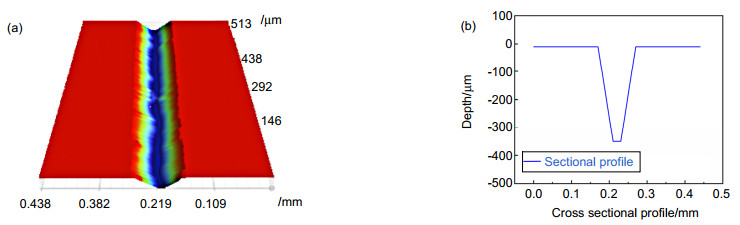

Water-jet guided laser (WJGL) machining is a novel processing technology using water beam fibers to guide the laser to machine the work-piece surface. This processing technology has the advantage of almost no micro-cracks, small heat-affected zone, pollution-free, less recast layer, high processing accuracy, parallel cuffing, etc. This work aims to investigate the effect of different WGLM parameters on the micro-morphology of materials and the mechanism between lasers and materials. The experiments for slotting and grooving 316L stainless steel thin samples were used by the WGLM system developed by our research group in this work. The 2D micro-topography after experiments were tested by the Zeiss Vert.A1 metalloscope, and the 3D micro-topography of samples after experiments were tested by the Leica DVM6 optical microscope with the large depth of field & Bruke Contour Elite I white-light interferometer. Experimental results show that a certain width deposition layer can be occurred in the machining region, and the width of deposition layers does not change with the parameter of the machining time and the number of machining times. From the 2D micro-topography of samples, it can be found that the 'dr' of slotting samples and the 'wl' of grooving samples also do not change with the machining parameters. From the 3D micro-topography of grooving samples, it can be found that the cross-section shape is inverted trapezoid.

-

Key words:

- water-jet guided laser machining /

- 316L stainless steel /

- grooving /

- slotting /

- micro-morphology

-

Overview

Overview:With the increasing of the thrust & thrust weight ratio of aircraft engines, the operating temperature of aero-engine hot components can be reached above 1400 K. In order to ensure the normal working of blades at an extremely high temperature environment, the ceramic/metal gradient thermal barrier coatings and design of gas film cooling holes are selected in general. However, the process for gas film cooling holes of aero-engines has encountered a major challenge due to its complex material structures. Laser machining (LM) and electrical discharge machining (EDM) are usually used for machining gas film cooling holes. The LM technology utilizes the laser thermal effect, so this method has disadvantages of thick molten layer, micro-cracks, laser ablation, etc. Thus, the EDM is selected because it can reduce the thickness of the molten layer. However, EDM cannot guarantee the processing accuracy and the recrystallization would be occurred during the processing, which will affect the serve life of aircraft engines. In addition, the EDM is only applicable to metallic materials. In recent years, ceramic materials have been widely used in the aerospace field. The above two methods are unable to meet processing requirements gradually. Water-guided laser machining (WGLM) is a novel method by using water beam fibers to guide the laser to machine the work-piece surface, which can solve these problems. It has been widely applied in the precise machining field of aerospace, bio-medical, micro-electromechanical, and so on, due to advantages of almost no micro-cracks, small heat-affected zone, pollution-free, less recast layer, high processing accuracy, parallel cuffing, etc. This work aims to investigate the effect of different WGLM parameters on the micro-morphology of materials and the mechanism between lasers and materials. The experiments for slotting and grooving 316L stainless steel thin samples were used by the WGLM system developed by our research group. The 2D micro-topography after experiments were tested by the Zeiss Vert. A1 metalloscope, and the 3D micro-topography of samples after experiments were tested by the Leica DVM6 optical microscope with the large depth of field & Bruke Contour Elite I white-light interferometer. Experimental results show that a certain width deposition layer can be occurred in the machining region, and the width of deposition layer does not change with the parameter of the machining time and the number of machining times. From the 2D micro-topography of the machining region of samples, it can be found that the 'dr' of slotting samples and the 'wl' of grooving samples also do not change with the machining parameters. From the 3D micro-topography of the machining region of grooving samples, it can be found that the cross-section shape is inverted trapezoid.

-

-

表 1 316L不锈钢主要化学成分

Table 1. Main chemical composition of the 316L stainless steel

Chemical composition Content% C ≤0.03 Si ≤1.00 Mn ≤2.00 S ≤0.03 P ≤0.04 Cr 16~18 Ni 10~14 Mo 2~3 表 2 316L不锈钢的热物理性能参数

Table 2. Physical property parameters of the 316L stainless steel

Physical property parameters Value Yield strength/MPa ≥175 Density/(g.cm-3) 7.98 Thermal conductivity/(W·m-1·K-1) 15.1 Hardness/HRB ≤90 Specific heat capacity/(J·g-1·K-1) 0.502 Thermal expansion coefficient/(℃) 17.3×10-6 表 3 水导激光加工系统的技术参数

Table 3. Technical parameters of the water-jet guided laser system

Technical parameters Value Laser energy/W 21 Laser wavelength/nm 532 Laser frequency/kHz 32.7 Water pressure/MPa 5 Nozzle diameter/µm 100 Cutting speed/(mm·s-1) 1 Water beam length at the cutting position/mm 15 -

参考文献

[1] 王祯, 杨泽南, 张朕, 等.单晶涡轮叶片气膜孔加工技术及其发展[J].特种铸造及有色合金, 2019, 39(8): 838–842. http://www.cqvip.com/QK/95567X/201908/84909090504849574856484857.html

Wang Z, Yang Z N, Zhang Z, et al. Progress in film hole processing method for single crystal turbine blades of aeroengine[J]. Special Casting & Nonferrous Alloys, 2019, 39(8): 838–842. http://www.cqvip.com/QK/95567X/201908/84909090504849574856484857.html

[2] 焦悦, 贺斌, 李朋, 等.大深径比微孔加工技术及其发展[J].航空科学技术, 2018, 29(3): 1–7. http://d.wanfangdata.com.cn/periodical/hkkxjs201803002

Jiao Y, He B, Li P, et al. Development of micro-holes machining with high-aspect ratio[J]. Aeronautical Science & Technology, 2018, 29(3): 1–7. http://d.wanfangdata.com.cn/periodical/hkkxjs201803002

[3] 连峰, 张会臣.钛合金的电火花加工技术及最新研究进展[J].现代制造工程, 2012(2): 18–23. http://www.cqvip.com/QK/93345A/20122/40872199.html

Lian F, Zhang H C. Technology and development of Ti alloy machined by EDM[J]. Modern Manufacturing Engineering, 2012(2): 18–23. http://www.cqvip.com/QK/93345A/20122/40872199.html

[4] Sheng P, Chryssolouris G. Investigation of acoustic sensing for laser machining processes Part 2: laser grooving and cutting[J]. Journal of Materials Processing Technology, 1994, 43(2–4): 145–163. doi: 10.1016/0924-0136(94)90018-3

[5] 陈聪, 高明, 顾云泽, 等.光纤激光切割铝合金薄板工艺特性研究[J].中国激光, 2014, 41(6): 0603004. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201406014.htm

Chen C, Gao M, Gu Y Z, et al. Study on fiber laser cutting of aluminum alloy sheet[J]. Chinese Journal of Lasers, 2014, 41(6): 0603004. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201406014.htm

[6] Weiss L, Aillerie M, Tazibt A, et al. Surface oxidation and phase transformation of the stainless steel by hybrid laser-waterjet impact[J]. Materials Research Express, 2014, 1(3): 036501. doi: 10.1088/2053-1591/1/3/036501

[7] 孙博宇, 乔红超, 赵吉宾, 等.水导激光切割技术研究现状[J].光电工程, 2017, 44(11): 1039–1044. doi: 10.3969/j.issn.1003-501X.2017.11.001

Sun B Y, Qiao H C, Zhao J B, et al. Current status of water-jet guided laser cutting technology[J]. Opto-Electronic Engineering, 2017, 44(11): 1039‒1044. doi: 10.3969/j.issn.1003-501X.2017.11.001

[8] Li C Q, Yang L J, Wang Y. A research on surface morphology of cutting of titanium sheet with water-jet guided laser and conventional laser[J]. Applied Mechanics and Materials, 2011, 120: 366–370. doi: 10.4028/www.scientific.net/AMM.120.366

[9] Li C Q, Yang L J, Wang Y. Experimental study on water-jet guided laser machining magnesium alloy[J]. Materials Science Forum, 2012, 723: 476–480. doi: 10.4028/www.scientific.net/MSF.723.476

[10] Li L, Wang Y, Yang L J, et al. Experimental research on water-jet guided laser processing[J]. Proceedings of SPIE, 2007, 6595: 659525. http://spie.org/Publications/Proceedings/Paper/10.1117/12.726482

[11] 孙冬, 王军华, 韩福柱.单晶硅水导/水辅助激光切割加工对比研究[J].应用激光, 2016, 36(6): 723–727. http://d.wanfangdata.com.cn/periodical/yyjg201606014

Sun D, Wang J H, Han F Z. Contrastive study of water jet guided laser and water jet assisted laser cutting of monocrystalline silicon[J]. Applied Laser, 2016, 36(6): 723–727. http://d.wanfangdata.com.cn/periodical/yyjg201606014

[12] Rashed C A A, Romoli L, Tantussi F, et al. Water jet guided laser as an alternative to EDM for micro-drilling of fuel injector nozzles: a comparison of machined surfaces[J]. Journal of Manufacturing Processes, 2013, 15(4): 524–532. doi: 10.1016/j.jmapro.2013.08.002

[13] 邹云, 桑振宽, 李大磊, 等. 304不锈钢水射流强化工艺的多目标优化设计[J].表面技术, 2018, 47(2): 25–29. http://www.cqvip.com/QK/93576X/20182/674644783.html

Zou Y, Sang Z K, Li D L, et al. Multi-objective optimal design of enhancing technology for 304 stainless steel by water jet peening[J]. Surface Technology, 2018, 47(2): 25–29. http://www.cqvip.com/QK/93576X/20182/674644783.html

[14] 蒋可静, 王梁, 张群莉, 等. 316L不锈钢激光瞬时退火软化工艺研究[J].表面技术, 2019, 48(2): 10–16. http://www.cqvip.com/QK/93576X/201902/7001291705.html

Jiang K J, Wang L, Zhang Q L, et al. Laser annealing and softening process of 316L stainless steel[J]. Surface Technology, 2019, 48(2): 10–16. http://www.cqvip.com/QK/93576X/201902/7001291705.html

[15] Perrottet D, Housh R, Richerzhagen B, et al. Heat damage-free laser-microjet cutting achieves highest die fracture strength[J]. Proceedings of SPIE, 2005, 5713: 285–292. doi: 10.1117/12.586710

[16] Porter J A, Louhisalmi Y A, Karjalainen J A, et al. Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence[J]. The International Journal of Advanced Manufacturing Technology, 2007, 33(9–10): 961–967. doi: 10.1007/s00170-006-0521-7

[17] 魏美容.空化对毛细管水射流稳定性的影响研究[D].武汉: 华中科技大学, 2018: 3–4.

Wei M R. Investigation on the stability of capillary waterjet influenced by cavitation[D]. Wuhan: Huazhong University of Science and Technology, 2018: 3–4.

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: