-

摘要

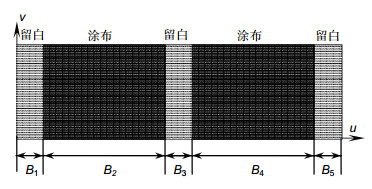

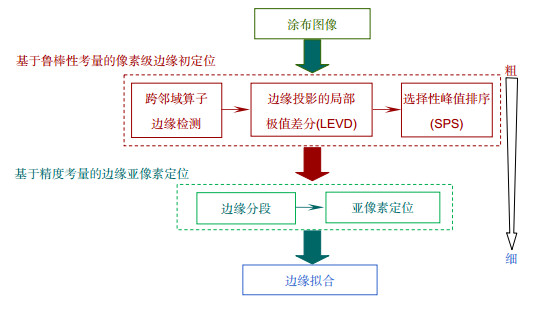

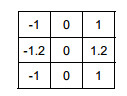

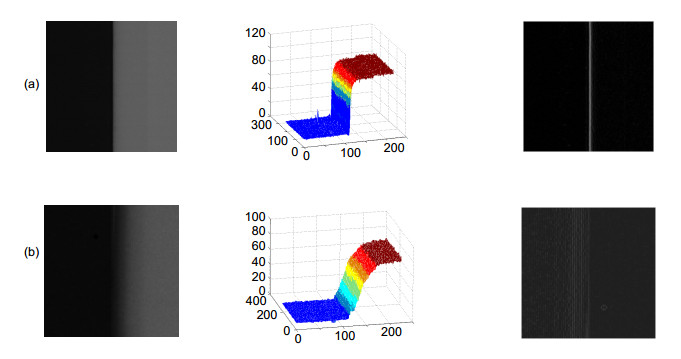

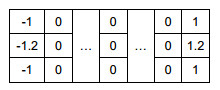

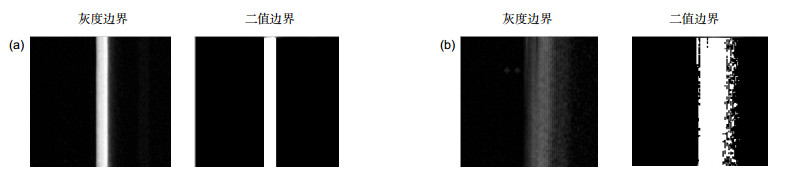

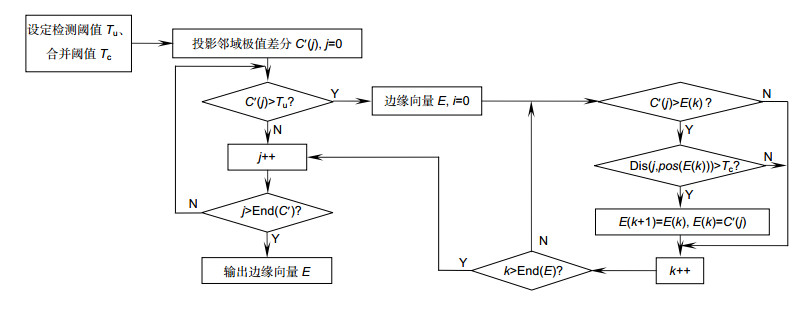

边缘定位是锂电池涂布测量的关键,但由于生产的震动和纠偏原因,边缘会出现虚化和卷边等现象。为了提高锂电池涂布在线检测的精度和鲁棒性,本文结合锂电池涂布生产的特点提出了边界渐进定位法,实现了边缘的快速准确检测。首先利用跨邻域方向边界检测算子进行初次边缘定位,以提高弱边界的检测能力;再利用局部极值差分算法配合选择性峰值排序获得边缘像素级定位,保证了边缘投影的保峰性和抗噪性,提高了边缘定位的效率;最后,基于分段三次样条边界插值和分段直线拟合方法,实现了边缘的亚像素高精度定位。实测结果表明,算法在直线型边缘上具有较强鲁棒性。

Abstract

Edge detection is a key step for the online vision measurement of lithium battery coating (LBC). However, as the vibration and rectification in LBC production, the virtualization and curling of edges could occur. In order to improve the accuracy and efficiency of on-line measurement of LBC, this paper proposed a staged edge location method according to the production characteristics of LBC, and achieved the swift and accurate detection of edges. Firstly, a cross neighborhood operator is used to detect the edge preliminarily to improve the ability of week edge detection. Then, local extreme values difference (LEVD) algorithm with selective peak sort algorithm is proposed to guarantee for the ability of edge-preserving and anti-noise of edge projection and to improve the efficiency of edge detection. Finally, piecewise cubic spline interpolation combined with segmented linear fitting method is provided to realize the sub-pixel location of the edge. The experimental results show the effectiveness of the method.

-

Key words:

- lithium battery coating /

- vision measurement /

- edge detection /

- oriented projection /

- linear fitting

-

Overview

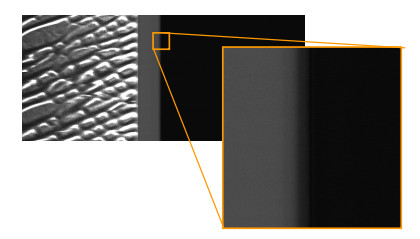

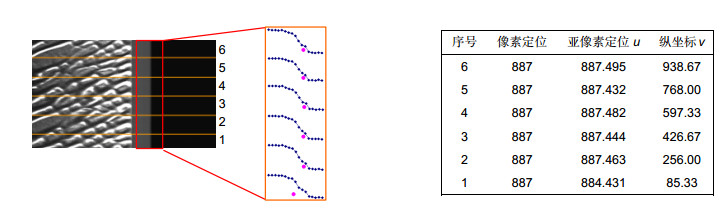

Overview: Lithium battery has been widely used in various industries. The coating quality is an important key that affects the performance of the battery. At present, the dimension of the coating of batteries in production mainly depends on manual sampling inspection with soft ruler, which is low-efficiency and has poor real-time performance. This paper focused on the study of the on-line vision dimension measurement technology of the lithium battery coating (LBC) in production, discussed the design of visual measurement system, and proposed a method of progressive location and segmental fitting of coating edges according to the characteristics of LBC production. As traditional boundary operators are noise-sensitivity and poor-robustness, this paper provided an across-neighborhood operator to detect the direction edges of coating. This operator has larger dimension and improved his sensitive to gradual edges. Then, a method of local extreme values difference (LEVD) was performed on the vertical projection of the boundary image. LEVD was operated in local neighborhood of each nonzero projection and search maximum and minimal projected value to mark edge projection, hence reducing the noise peak interference and obtaining a more accurate boundary projection curve. In order to obtain the boundary position, the peaks above a set threshold were fused according to the neighborhood judging rules and sorted by selective sorting algorithm (SPS) with the desired edge number, obtaining the initial location of coating boundary at u direction. In order to obtain more accurate edges of LBC, a segmented edge fitting method was proposed in this paper. First, an edge image was divided into several segments (6 parts in this paper) in the vertical direction, and a number of pixel values in the local range of the u points of the coarse boundary were taken along the gradient direction for each segment to form a boundary fitting vector. Then, the cubic spline curve fitting with the first boundary condition was used for each segment fitting vector. After that, the second derivative of the fitting curve was derived and equal to zero to find the maximum gradient point. Finally, the line fitting for each segment boundary point was done by means of oblique cutting to form the final accurate fitting boundary of LBC. Based on the proposed method, an online measurement system of LBC was developed and applied to the production practice. The field operation realized the high precision measurement with 0.2 pixel, and experimental results prove that the edge fitting method is robust, efficient and suitable for the production needs.

-

-

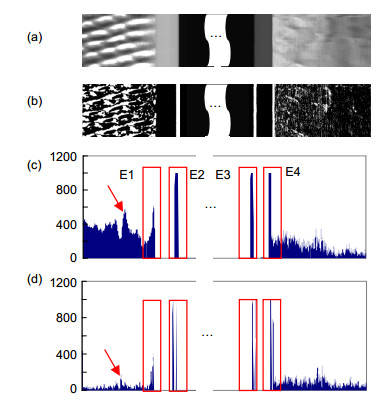

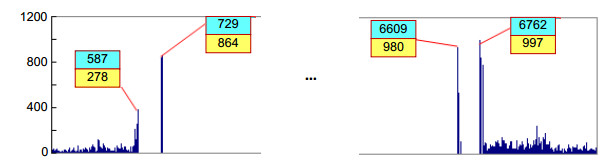

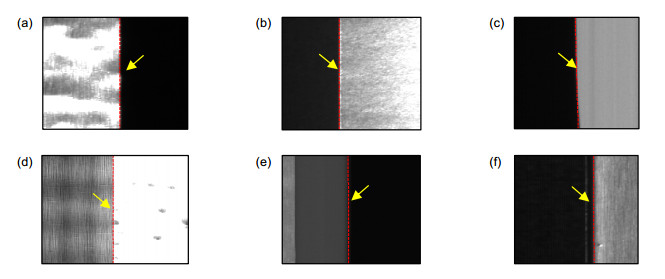

图 9 涂布边界的纵向投影及局部极值差分。图像宽度为8192,省略中间部分,箭头位置为干扰峰值。图像宽度为 8192,省略中间部分,箭头位置为干扰峰值。 (a) 原始图像; (b) 跨邻域边缘二值化; (c) 方向投影图; (d) 局部极值差分图

Figure 9. The vertical projection and local extreme value difference of LBC (middle LBC is omitted). (a) Original image; (b) Binary image of CNO; (c) Projection image; (d) Image of LEVD

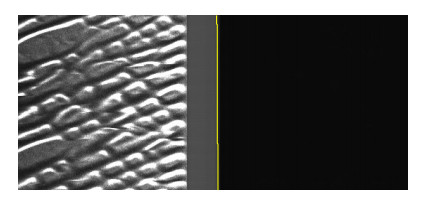

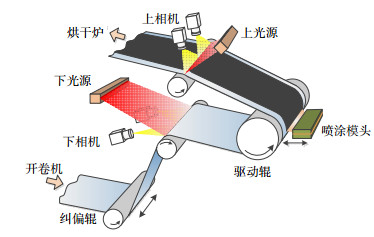

图 16 现场图像单边拟合结果(局部)。 (a) Our: 23 ms, Hough: 256 ms; (b) Our: 20 ms, Hough: 243 ms; (c) Our: 18 ms, Hough: 230 ms; (d) Our: 20 ms, Hough: 262 ms; (e) Our: 18 ms, Hough: 231 ms; (f) Our: 22 ms, Hough: 238 ms

Figure 16. The edge fitting results of site LBC image. (a) Our: 23 ms, Hough: 256 ms; (b) Our: 20 ms, Hough: 243 ms; (c) Our: 18 ms, Hough: 230 ms; (d) Our: 20 ms, Hough: 262 ms; (e) Our: 18 ms, Hough: 231 ms; (f) Our: 22 ms, Hough: 238 ms

表 1 边缘检测算法效率对比(8M图像)

Table 1. The efficiency comparison of edge detection algorithms (8M image)

Sobel 算子 跨邻域算子 时间/ms 145 38 表 2 排序算法效率对比(8192维,k=7,排序1000次)

Table 2. The efficiency comparison of sort algorithms (dimension of 8192, k=7, 1000 times)

快速排序算法[13] 本文 SPS 算法 时间/ms 242 111 -

参考文献

[1] Chen L, Shaw L L. Recent advances in lithium-sulfur batteries[J]. Journal of Power Sources, 2014, 267: 770–783. doi: 10.1016/j.jpowsour.2014.05.111

[2] Barghamadi M, Kapoor A, Wen C E. A review on Li-S batteries as a high efficiency rechargeable lithium battery[J]. Journal of the Electrochemical Society, 2013, 160(8): A1256–A1263. doi: 10.1149/2.096308jes

[3] 迟彩霞, 张双虎, 乔秀丽, 等.狭缝式涂布技术的研究进展[J].应用化工, 2016, 45(2): 360–363, 366. http://d.old.wanfangdata.com.cn/Periodical/sxhg201602040

Chi C X, Zhang S H, Qiao X L, et al. Research progress on slot-die coating technology[J]. Applied Chemical Industry, 2016, 45(2): 360–363, 366. http://d.old.wanfangdata.com.cn/Periodical/sxhg201602040

[4] 河北银隆新能源有限公司.一种锂离子电池浆料涂布尺寸测量装置: CN107957230A[P]. 2018-04-24.

Hebei Yinlong Energy LTD. A measurement device of lithiumion battery slurry coating: CN107957230A[P]. 2018-04-24.

[5] 谭文斌, 李醒飞, 刘超, 等.一种移动视觉测量系统的建模及标定方法[J].光电工程, 2014, 41(6): 1–6. doi: 10.3969/j.issn.1003-501X.2014.06.001

Tan W B, Li X F, Liu C, et al. A modeling and calibration method of portable vision metrology[J]. Opto-Electronic Engineering, 2014, 41(6): 1–6. doi: 10.3969/j.issn.1003-501X.2014.06.001

[6] 任志刚.动力锂离子电池电极材料在线厚度测量及生产中的应用[J].装备制造技术, 2010(10): 153–156. http://d.old.wanfangdata.com.cn/Periodical/zbzzjs201510048

Ren Z G. On-line thickness measurement for electrode materials and its application in EV Li-ion Battery manufacture[J]. Equipment Manufacturing Technology, 2010(10): 153–156. http://d.old.wanfangdata.com.cn/Periodical/zbzzjs201510048

[7] 胡玥红.基于机器视觉的锂电池极片缺陷检测研究[D].哈尔滨: 哈尔滨工业大学, 2015.

Hu Y H. Research on defect detection of lithium battery electrode based on machine vision[D]. Harbin: Harbin Institute of Technology, 2015.

[8] 张国海, 李艳玲, 柴颖, 等.锂电池极板表面缺陷CCD成像检测系统初步设计[C]//中国光学学会2010年光学大会论文集, 2010: 5.

Zhang G H, Li Y L, Chai Y, et al. Preliminary design of a CCD imaging system for defecting defect that in the surface of pole plate of lithium battery[C]//2010 Optical Conference Symposium, 2010: 5.

[9] 洪留荣.无需设定阈值的图像边缘检测[J].计算机应用, 2013, 33(8): 2330–2333. doi: 10.3969/j.issn.1001-3695.2013.08.022

Hong L R. Image edge detection without threshold[J]. Journal of Computer Applications, 2013, 33(8): 2330–2333. doi: 10.3969/j.issn.1001-3695.2013.08.022

[10] Sun Q C, Hou Y Q, Tan Q C. A subpixel edge detection method based on an arctangent edge model[J]. Optik, 2016, 127(14): 5702–5710. doi: 10.1016/j.ijleo.2016.03.058

[11] 马登极, 朱善安, 王长军.线阵CCD在高精度测径系统中的应用[J].计算机测量与控制, 2006, 14(2): 175–176, 185. http://d.old.wanfangdata.com.cn/Periodical/jsjzdclykz200602014

Ma D J, Zhu S N, Wang C J. Application of linear CCD in high precision diameter measuring system[J]. Computer Measurement & Control, 2006, 14(2): 175–176, 185. http://d.old.wanfangdata.com.cn/Periodical/jsjzdclykz200602014

[12] 蒋伟, 丁志全, 刘亚威.基于分数阶偏微分的图像边缘检测新模型[J].计算机应用, 2012, 32(10): 2848–2850, 2858. http://d.old.wanfangdata.com.cn/Periodical/jsjyy201210042

Jiang W, Ding Z Q, Liu Y W. New image edge detection model based on fractional-order partial differention[J]. Journal of Computer Applications, 2012, 32(10): 2848–2850, 2858. http://d.old.wanfangdata.com.cn/Periodical/jsjyy201210042

[13] 周建钦.超快速排序算法[J].计算机工程与应用, 2006, 42(29): 41–42, 86. doi: 10.3321/j.issn:1002-8331.2006.29.013

Zhou J Q. Super quick sort algorithm[J]. Computer Engineering and Applications, 2006, 42(29): 41–42, 86. doi: 10.3321/j.issn:1002-8331.2006.29.013

[14] Qu Y D, Cui C S, Chen S B, et al. A fast subpixel edge detection method using Sobel-Zernike moments operator[J]. Image and Vision Computing, 2005, 23(1): 11–17. doi: 10.1016/j.imavis.2004.07.003

[15] 吴晓. LED芯片粗精定位系统[J].红外与激光工程, 2013, 42(9): 2478–2484. doi: 10.3969/j.issn.1007-2276.2013.09.033

Wu X. LED chips coarse and fine locating system[J]. Infrared and Laser Engineering, 2013, 42(9): 2478–2484. doi: 10.3969/j.issn.1007-2276.2013.09.033

[16] 吕春峰, 任全会.基于Sobel黑片图像亚像素边缘检测算法研究[J].制造业自动化, 2013, 35(2): 34–36. doi: 10.3969/j.issn.1009-0134.2013.01(x).10

Lv C F, Ren Q H. The silicon sheet steel image sub-pixel edge detection algorithm research based on Sobel[J]. Manufacturing Automation, 2013, 35(2): 34–36. doi: 10.3969/j.issn.1009-0134.2013.01(x).10

[17] 孙秋成, 周亚洲, 宁闯, 等.基于三次样条插值的亚像素边缘检测方法[J].控制工程, 2014, 21(2): 290–293. doi: 10.3969/j.issn.1671-7848.2014.02.029

Sun Q C, Zhou Y Z, Ning C, et al. A sub-pixel edge detection method based on cubic spline interpolation[J]. Control Engineering of China, 2014, 21(2): 290–293. doi: 10.3969/j.issn.1671-7848.2014.02.029

[18] 李庆扬, 王能超, 易大义.数值分析[M]. 4版.北京:清华大学出版社, 2001: 51–57.

Li Q Y, Wang N C, Yi D Y. Numerical Analysis[M]. 4th ed. Beijing: Tsinghua University Press, 2001: 51–57.

[19] 刁燕, 吴晨柯, 罗华, 等.基于改进的概率Hough变换的直线检测优化算法[J].光学学报, 2018, 38(8): 0815016. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201808017

Diao Y, Wu C K, Luo H, et al. Line detection optimization algorithm based on improved probabilistic Hough transform[J]. Acta Optica Sinica, 2018, 38(8): 0815016. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gxxb201808017

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: