-

摘要

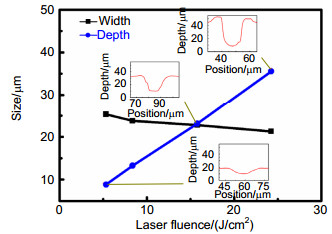

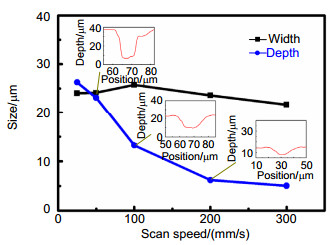

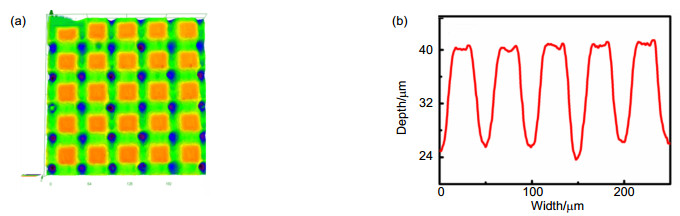

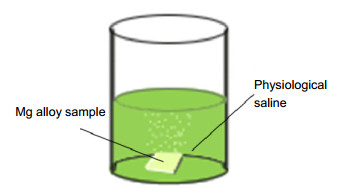

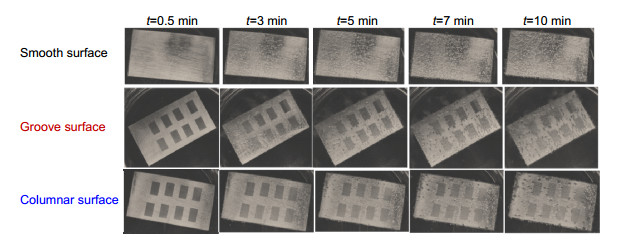

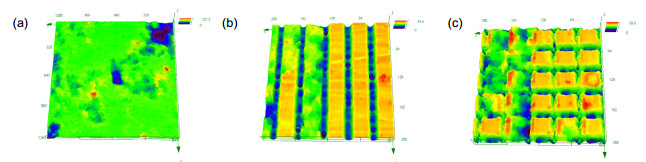

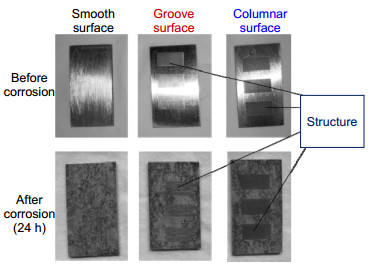

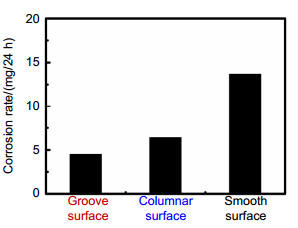

采用波长为515 nm的飞秒绿激光对AZ31镁合金进行实验研究,计算镁合金激光烧蚀阈值与烧蚀速率,研究镁合金的激光加工机理,对比分析AZ31镁合金有无表面微结构对其腐蚀速率的影响。结果表明:镁合金的激光烧蚀阈值为1.46 J/cm2,在能量密度为8.36 J/cm2时烧蚀速率为0.68 μm/pulse;随着能量密度的增大烧蚀速率增大,在能量密度为8.36 J/cm2,脉冲数为1000时可以加工出高质量的小孔。镁合金的腐蚀速率方面,微槽结构小于微柱结构,微柱结构小于光滑表面,拥有微结构表面的镁合金在24 h内的腐蚀速率约为光滑表面的1/3~1/2。

Abstract

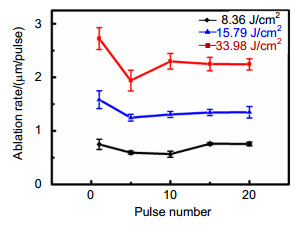

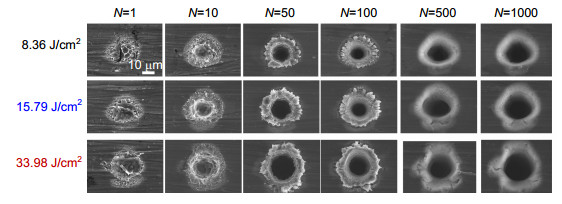

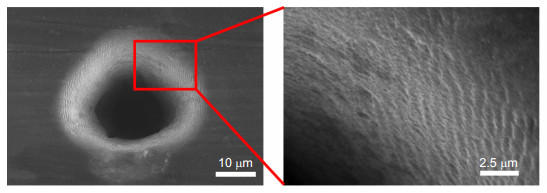

In this paper, a femtosecond green laser with wavelength of 515 nm was used to process the AZ31 magnesium alloy. The laser ablation threshold and ablation rate of Mg alloy were calculated. The mechanism of femtosecond green laser process was determined. The effects of surface microstructures on corrosion rate of AZ31 magnesium alloy was compared and analyzed. The results show that the laser ablation threshold of AZ31 magnesium alloy is 1.46 J/cm2, the ablation rate is 0.68 μm/pulse in the laser fluence of 8.36 J/cm2, the ablation rate increases with the laser fluence increasing. The high-quality holes can be fabricated with the laser fluence of 8.36 J/cm2 and the pulse number of 1000. In terms of the corrosion rate of magnesium alloy, the groove structure is less than that of the columnar structure and less than that of the smooth surface, among which the corrosion rate on the microstructural surface is about 1/3~1/2 of that on the smooth surface in 24 hours.

-

Key words:

- femtosecond laser /

- Mg alloy /

- structure /

- corrosion rate

-

Overview

Overview:AZ31 magnesium alloy is a highly potential material in the field of implanted medical devices due to its biodegradable absorbability, mechanical compatibility and good biocompatibility. However, Mg alloy has relatively active chemical properties, low melting point, high thermal conductivity and big coefficient of thermal expansion, which result in poor processing performance. Therefore, the traditional mechanical processing method would not be able to meet the demand. Laser processing has the advantages of non-contact and high precision, among which the green laser is very suitable for the processing of magnesium alloys, so their application fields can be broadened. With the characteristics of short pulse width, low heat-affected zone, high peak power and processing accuracy, ultrafast laser is widely used in many fields, such as micro-nano structure processing and functional surface processing. Moreover, femtosecond green laser having shorter wavelength and better absorption for magnesium alloys contributes to the trend that it would be more suitable for the processing. In this paper, a femtosecond green laser with wavelength of 515 nm was applied to process the AZ31 magnesium alloy. The laser ablation threshold of Mg alloy and its ablation rate were calculated. By analyzing and comparing the SEM micrograph of different laser fluences, the mechanism of femtosecond green laser process has been illustrated. The effects of Mg alloy with or without microstructure on its corrosion rates in physiological saline were analyzed subsequently.

The results show the laser ablation threshold of AZ31 magnesium alloy is 1.46 J/cm2, the ablation rate is 0.68 μm/pulse in the laser fluence of 8.36 J/cm2, the ablation rate is 1.37 μm/pulse with the laser fluence of 15.79 J/cm2, the ablation rate is 2.29 μm/pulse with the laser fluence of 33.98 J/cm2. In conclusion, the ablation rate increases with the laser fluence increasing. The high-quality holes can be fabricated with the laser fluence of 8.36 J/cm2 and the pulse number of 1000. When the number of pulses is less than 100, the ablation mechanism of the Mg alloy was mainly controlled by phase explosion, while the number of pulse reach 500 the ablation mechanism of composites transfer from phase explosion to thermal evaporation. In terms of the corrosion rate of magnesium alloy, the groove structure is less than that of the columnar structure and less than that of the smooth surface, among which the corrosion rate on the microstructural surface is about 1/3~1/2 of that on the smooth surface in 24 hours, the reason is Mg(OH)2 precipitation film was formed in the microstructures, which could prevent the corrosion of microstructures.

-

-

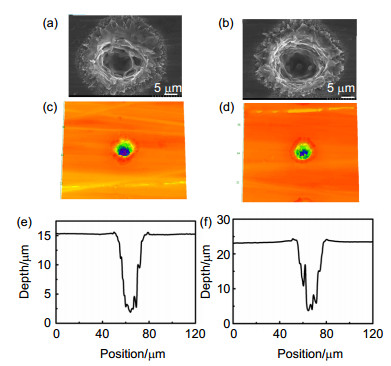

图 4 能量密度为15.79 J/cm2时激光加工的镁合金表面图。(a),(b)脉冲数为10、15的扫描电镜图;(c),(d)相应的三维表面形貌;(e),(f)相应的横截面

Figure 4. Mg alloy surface after femtosecond laser processing, the laser fluence was 15.79 J/cm2 in all cases. (a), (b) SEM images of Mg alloy surface with the pulse number of 10 and 15; (c), (d) Corresponding 3D surface topography; (e), (f) Corre-sponding cross-sectional surface profile

表 1 镁合金化学成份及室温下的热物理性能参数

Table 1. The chemical composition and thermos-physical parameters of magnesium alloy at room temperature

Thermophysical

parametersDensity/

(g·cm-3)

1.74Specific heat capacity/

(kJ·kg-1·K-1)

0.871Thermal conductivity/

(W·m-1·K-1)

153.66Melting/Boiling

point/K

923/1380Thermal expansion

coefficient/K

25.0×10-6Composition Mg Al Zn Mn Ni Fe Cu Si Content/% 95 3.5 1.10 0.32 0.001 0.03 0.01 0.08 -

参考文献

[1] Han H S, Kim Y Y, Kim Y C, et al. Bone formation within the vicinity of biodegradable magnesium alloy implant in a rat femur model[J]. Metals and Materials International, 2012, 18(2): 243-247. doi: 10.1007/s12540-012-2007-5

[2] Witte F, Reifenrath J, Müller P P, et al. Cartilage repair on magnesium scaffolds used as a subchondral bone replacement[J]. Materialwissenschaft Und Werkstofftechnik, 2006, 37(6): 504-508. doi: 10.1002/mawe.200600027

[3] Wong H M, Yeung K W K, Lam K O, et al. A biodegradable polymer-based coating to control the performance of magnesium alloy orthopaedic implants[J]. Biomaterials, 2010, 31(8): 2084-2096. doi: 10.1016/j.biomaterials.2009.11.111

[4] 李杰, 张会臣. MB8镁合金超疏水表面的制备和润湿性[J].材料研究学报, 2012, 26(3): 240-246. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201202682583

Li J, Zhang H C. Preparation and wetting behavior of superhydrophobic surface on MB8 magnesium alloy[J]. Chinese Journal of Materials Research, 2012, 26(3): 240-246. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201202682583

[5] Guan Y C, Zhou W, Li Z L, et al. Effect of processing environment on laser-induced darkening evolution in magnesium alloy[J]. Optics and Lasers in Engineering, 2014, 52: 35-40. doi: 10.1016/j.optlaseng.2013.07.018

[6] Guan Y C, Zhou W, Zheng H Y, et al. Darkening effect on AZ31B magnesium alloy surface induced by nanosecond pulse Nd:YAG laser[J]. Applied Surface Science, 2013, 280: 462-466. doi: 10.1016/j.apsusc.2013.05.011

[7] Guan Y C, Zhou W, Li Z L, et al. Femtosecond laser-induced ripple structures on magnesium[J]. Applied Physics A, 2014, 115(1): 13-18. doi: 10.1007/s00339-013-7927-5

[8] Shi H X, Cui Z Q, Wang W X, et al. Blackening of magnesium alloy using femtosecond laser[J]. Applied Optics, 2015, 54(25): 7766-7772. doi: 10.1364/AO.54.007766

[9] Demir A G, Previtali B. Dross-free submerged laser cutting of AZ31 Mg alloy for biodegradable stents[J]. Journal of Laser Applications, 2016, 28(3): 032001. http://cn.bing.com/academic/profile?id=604252a78afae374d4300208d0c32916&encoded=0&v=paper_preview&mkt=zh-cn

[10] 杨焕, 曹宇, 李峰平, 等.激光制备超疏水表面研究进展[J].光电工程, 2017, 44(12): 1160-1168. doi: 10.3969/j.issn.1003-501X.2017.12.003

Yang H, Cao Y, Li F P, et al. Research progress in superhydrophobic surfaces fabricated by laser[J]. Opto-Electronic Engineering, 2017, 44(12): 1160-1168. doi: 10.3969/j.issn.1003-501X.2017.12.003

[11] 龙江游, 吴颖超, 龚鼎为, 等.飞秒激光制备超疏水铜表面及其抗结冰性能[J].中国激光, 2015, 42(7): 0706002. http://d.old.wanfangdata.com.cn/Conference/9541410

Long J Y, Wu Y C, Gong D W, et al. Femtosecond laser fabricated superhydrophobic copper surfaces and their anti-icing properties[J]. Chinese Journal of Lasers, 2015, 42(7): 0706002. http://d.old.wanfangdata.com.cn/Conference/9541410

[12] 龙江游, 范培迅, 龚鼎为, 等.超快激光制备具有特殊浸润性的仿生表面[J].中国激光, 2016, 43(8): 0800001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjg201608001

Long J Y, Fan P X, Gong D W, et al. Ultrafast laser fabricated bio-inspired surfaces with special wettability[J]. Chinese Journal of Lasers, 2016, 43(8): 0800001. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgjg201608001

[13] Stenzel E, Gogoll S, Sils J, et al. Laser damage of alkaline-earth fluorides at 248 nm and the influence of polishing grades[J]. Applied Surface Science, 1997, 109-110: 162-167. doi: 10.1016/S0169-4332(96)00653-8

[14] Bonse J, Wrobel J M, Krüger J, et al. Ultrashort-pulse laser ablation of indium phosphide in air[J]. Applied Physics A, 2001, 72(1): 89-94. doi: 10.1007/s003390000596

[15] Li F, Chen X G, Lin W H, et al. Nanosecond laser ablation of Al-Si coating on boron steel[J]. Surface and Coatings Technology, 2017, 319: 129-135. doi: 10.1016/j.surfcoat.2017.03.038

[16] 杨强, 季凌飞, 徐博, 等.皮秒激光微制造As2Se3玻璃红外增透性表面[J].光电工程, 2017, 44(12): 1200-1209. doi: 10.3969/j.issn.1003-501X.2017.12.008

Yang Q, Ji L F, Xu B, et al. Picosecond laser microfabrication of infrared antireflective functional surface on As2Se3 glass[J]. Opto-Electronic Engineering, 2017, 44(12): 1200-1209. doi: 10.3969/j.issn.1003-501X.2017.12.008

[17] K nig J, Nolte S, Tünnermann A. Plasma evolution during metal ablation with ultrashort laser pulses[J]. Optics Express, 2005, 13(26): 10597-10607. doi: 10.1364/OPEX.13.010597

[18] 曾荣昌, 崔蓝月, 柯伟.医用镁合金:成分、组织及腐蚀[J].金属学报, 2018, 54(9): 1215-1235. http://d.old.wanfangdata.com.cn/Periodical/xyjsclygc200807023

Zeng R C, Cui L Y, Ke W. Biomedical magnesium alloys: composition, microstructure and corrosion[J]. Acta Metallurgica Sinica, 2018, 54(9): 1215-1235. http://d.old.wanfangdata.com.cn/Periodical/xyjsclygc200807023

[19] 余琨, 雷路, 陈良建, 等.新型镁合金在生理体液环境下腐蚀行为评价[J].金属功能材料, 2011, 18(2): 32-36. http://d.old.wanfangdata.com.cn/Periodical/jsgncl201102008

Yu K, Lei L, Chen L J, et al. Corrosion behavior of magnesium alloy in the biological environment[J]. Metallic Functional Materials, 2011, 18(2): 32-36. http://d.old.wanfangdata.com.cn/Periodical/jsgncl201102008

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: