-

摘要:

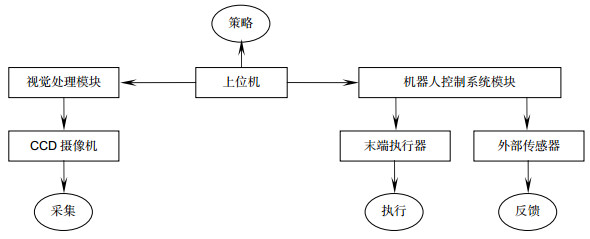

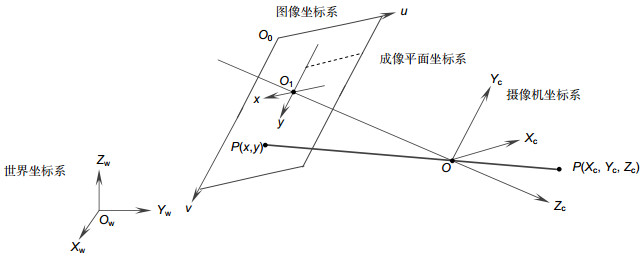

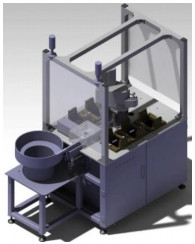

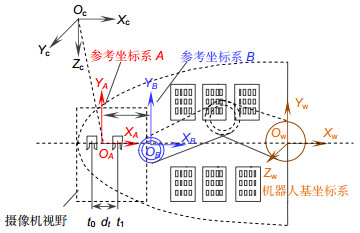

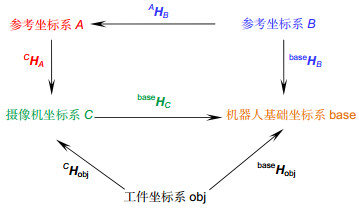

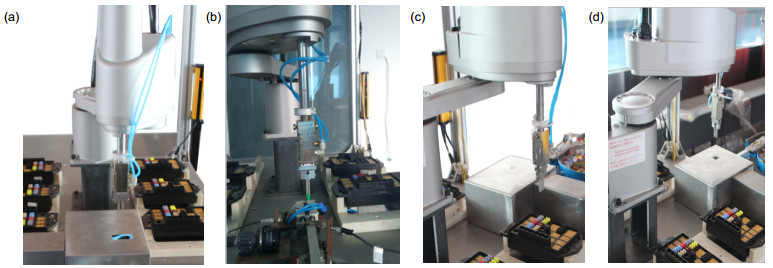

以SCARA机器人、机械夹爪、摄像机CCD为硬件基础,搭建了基于单目视觉的SCARA机器人自动识别和定位插件系统平台,并利用摄像机参数标定和建立的抓取系统参数化模型,将CCD摄像机获取的工件图像坐标信息转化为机器人坐标系下的抓取位置信息。本系统以Visual studio软件为开发平台,利用OpenCV视觉数据库函数进行颜色识别与定位算法开发,经测试,该视觉算法能够实现工件的颜色识别和获取工件的位置信息,并控制机器人夹爪进行目标工件的精确抓取,满足了一般工业生产中抓取工件实时性的要求。

Abstract:

Abstract:The system uses SCARA robot, mechanical jaw and camera CCD as the hardware foundation, building a SCARA robot automatic identification and positioning plug-in system platform based on monocular vision. The co-ordinate information of the workpiece image acquired by the CCD camera is transformed into the crawling position information in the robot coordinate system by using the parametric model of the crawler system calibration and establishment of the camera parameters. The system uses Visual Studio as the development platform, utilizing OpenCV visual database function for the secondary development of visual algorithms. The visual algorithm can realize the color recognition of the workpiece and obtain the position information of the workpiece, and control the robot jaws to grasp the target workpiece accurately, which meets the general industrial production in the grasp of real-time requirements of the workpiece.

-

Key words:

- SCARA robot /

- monocular vision /

- plug-in system /

- color recognition /

- positioning /

- precision crawl

-

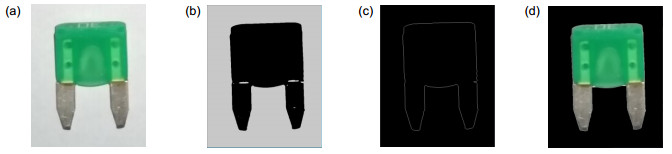

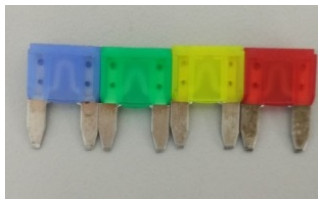

Abstract: The machine vision is introduced into the field of the plug-in robot system as a new type of sensor, and the function of the environment visual information (color, shape and attitude of the target workpiece) is realized by machine vision to achieve fast crawling and precise positioning. This method for the realization of fully automated plug, reduces the insertion error rate, improves the efficiency of plug-in workpiece, which is of great significance. The system uses SCARA robot, mechanical jaw and camera CCD as the hardware base, building a SCARA robot automatic identification and positioning plug-in system platform based on monocular vision, which mixed with a variety of colors of the insurance piece in a circular feeding tray. Under the vibration of the disk motor, the insurance piece is sent to the linear feeder in turn, and then the CCD camera is used to obtain the image information of the insurance piece, the contour shape and coordinate information are extracted from the image and the camera parameters are calibrated and parameterized model is established. The workpiece image coordinate information is transformed into the robot coordinate system under the crawl position information. The Visual Studio software is used as the development platform, and the visual recognition and positioning algorithm is developed by using the OpenCV visual database function. The visual algorithm prepares the image of the fuse piece, the image segmentation, the color recognition, the corner detection and the center point extraction. The center point of the workpiece is determined. Finally, the coordinates of the target point are obtained by calculating the scale ratio and the conversion of the coordinates. The visual algorithm can realize the color recognition of the workpiece and obtain the position information of the workpiece, and control the robot jaws to grasp the target workpiece accurately, which meets the general industrial production in the real-time requirements of the workpiece. In the field debugging, the visual algorithm can identify the color of the workpiece, get the workpiece coordinate information, and control the robot jaws for fast target positioning and accurate crawling. The results show that the system has high positioning accuracy, fastness and stability, and can meet the high precision and high reliability requirements of automatic plug-in inserts under robot operation. It can achieve a variety of colors and multi-station fully automated plug-in operations, without manual participation, reduces the number of recycling, improves the efficiency of the plug and has the advantages of high efficiency.

-

-

表 1 测试坐标点结果表.

Table 1. Test coordinate point results table.

角点/pixel 1 2 3 4 平均值 中心点 u 115 116 443 433 276.75 277.26 v 103 356 355 92 226.5 225.42 表 2 视觉定位实验分析.

Table 2. Experimental analysis of visual positioning.

序号 视觉定位位置/mm 末端实际位置/mm 颜色识别时间/ms 定位时间/ms 1 (41.39, 260.30, 100.06) (40.55, 259.43, 100.87) 20.3 133.7 2 (40.86, 258.23, 101.53) (41.02, 259.20, 100.96) 19.8 131.2 3 (41.53, 259.46, 100.56) (41.36, 260.12, 100.66) 19.4 132.6 4 (41.53, 259.46, 100.56) (41.59, 260.51, 100.42) 19.9 133.3. 5 (40.93, 260.13, 100.67) (41.06, 260.73, 100.68) 20.1 134.2 -

[1] 金桂根, 穆建军.视觉识别机器人在物流作业中的智能应用[J].制造业自动化, 2013, 35(11): 103–105. doi: 10.3969/j.issn.1009-0134.2013.11.31

Jin Guigen, Mu Jianjun. Material handling application of intel-lectual robot with vision system[J]. Manufacturing Automation, 2013, 35(11): 103–105. doi: 10.3969/j.issn.1009-0134.2013.11.31

[2] 倪鹤鹏, 刘亚男, 张承瑞, 等.基于机器视觉的Delta机器人分拣系统算法[J].机器人, 2016, 38(1): 49–55. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jqrr201601007&dbname=CJFD&dbcode=CJFQ

Ni Hepeng, Liu Ya'nan, Zhang Chengrui, et al. Sorting system algorithms based on machine vision for Delta robot[J]. Robot, 2016, 38(1): 49–55. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jqrr201601007&dbname=CJFD&dbcode=CJFQ

[3] 王永强, 孟然, 于德敏, 等.机器视觉玻壳产品在线分类识别系统研究[J].仪器仪表学报, 2005, 26(8增刊): 636–637, 645. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yqyb200508293

Wang Yongqiang, Meng Ran, Yu Demin, et al. A classification and recognition system research about the glass bulb products on-line by machine vision[J]. Chinese Journal of Scientific In-strument, 2005, 26(8 Suppl 1): 636–637, 645. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=yqyb200508293

[4] 原玉磊, 蒋理兴, 刘灵杰.罗德里格矩阵在坐标系转换中的应用[J].测绘科学, 2010, 35(2): 178–179, 119. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=chkx201002061

Yuan Yulei, Jiang Lixing, Liu Lingjie. Applications of Lodrigues matrix in coordinates transformation[J]. Science of Surveying and Mapping, 2010, 35(2): 178–179, 119. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=chkx201002061

[5] 凡良玉, 潘丰.基于视觉的接插件pin针正位度检测系统设计[J].江南大学学报(自然科学版), 2015, 14(6): 762–768. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jiangndxxb201506014

Fan Liangyu, Pan Feng. Detection system design for the pin's position of connectors using machine vision[J]. Journal of Jiangnan University (Natural Science Edition), 2015, 14(6): 762–768. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jiangndxxb201506014

[6] 金隼, 洪海涛.机器视觉检测在电子接插件制造工业中的应用[J].仪表技术与传感器, 2000(2): 13–16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ybjsycgq200002005

Jin Sun, Hong Haitao. The application of the inspection tech-nology based on machine vision in the electronic connectors mannfacturing industry[J]. Instrument Technique and Sensor, 2000(2): 13–16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ybjsycgq200002005

[7] 孙国栋, 张杨, 李萍, 等.电子接插件视觉检测系统设计与误差分析[J].仪表技术与传感器, 2015(8): 104–106, 110. http://www.cqvip.com/QK/94978X/201508/666107053.html

Sun Guodong, Zhang Yang, Li Ping, et al. Design of visual inspection system for electronic connectors and error analysis[J]. Instrument Technique and Sensor, 2015(8): 104–106, 110. http://www.cqvip.com/QK/94978X/201508/666107053.html

[8] 赵登步. 基于机器视觉的SCARA机器人快速定位控制系统的研究与开发[D]. 无锡: 江南大学, 2015.

Zhao Dengbu. Research and development of rapid position control system of SCARA robot based on machine vision[D]. Wuxi: Jiangnan University, 2015.

http://cdmd.cnki.com.cn/Article/CDMD-10295-1015429959.htm [9] Xu Liang, He Xiaomin, Li Xiuxi, et al. A machine-vision inspec-tion system for conveying attitudes of columnar objects in packing processes[J]. Measurement, 2016, 87: 255–273. doi: 10.1016/j.measurement.2016.02.048

[10] 黄震, 顾启民.高精度机器视觉插件系统的研究与应用[J].组合机床与自动化加工技术, 2014(10): 105–108. http://www.cnki.com.cn/Article/CJFDTOTAL-ZHJC201410029.htm

Huang Zhen, Gu Qimin. Research and application of high-precision plug-in system based on machine vision[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2014(10): 105–108. http://www.cnki.com.cn/Article/CJFDTOTAL-ZHJC201410029.htm

[11] 桂卫华, 阳春华, 徐德刚, 等.基于机器视觉的矿物浮选过程监控技术研究进展[J].自动化学报, 2013, 39(11): 1879–1888. http://www.cqvip.com/QK/90250X/201311/47539894.html

Gui Weihua, Yang Chunhua, Xu Degang, et al. Ma-chine-vision-based online measuring and controlling technologies for mineral flotation——a review[J]. Acta Automatica Sinica, 2013, 39(11): 1879–1888. http://www.cqvip.com/QK/90250X/201311/47539894.html

[12] 翟敬梅, 董鹏飞, 张铁.基于视觉引导的工业机器人定位抓取系统设计[J].机械设计与研究, 2014, 30(5): 45–49. http://www.docin.com/p-1269559281.html

Zhai Jingmei, Dong Pengfei, Zhang Tie. Positioning and grasping system design of industrial robot based on visual guidance[J]. Machine Design & Research, 2014, 30(5): 45–49. http://www.docin.com/p-1269559281.html

[13] 胡小平, 谢珂, 彭涛.一种新的双目固定式机器人三维视觉定位方法[J].光电工程, 2014, 41(8): 10–15. http://doi.wanfangdata.com.cn/10.3969/j.issn.1003-501X.2014.08.002

Hu Xiaoping, Xie Ke, Peng Tao. A new 3D visual positioning method of eye-to-hand stereovision of robot[J]. Opto-Electronic Engineering, 2014, 41(8): 10–15. http://doi.wanfangdata.com.cn/10.3969/j.issn.1003-501X.2014.08.002

[14] 解则晓, 陈文柱, 迟书凯, 等.基于结构光视觉引导的工业机器人定位系统[J].光学学报, 2016, 36(10): 1015001. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxxb201610041&dbname=CJFD&dbcode=CJFQ

Xie Zexiao, Chen Wenzhu, Chi Shukai, et al. Industrial robot positioning system based on the guidance of the structured-light vision[J]. Acta Optica Sinica, 2016, 36(10): 1015001. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gxxb201610041&dbname=CJFD&dbcode=CJFQ

[15] 张文增, 陈强, 孙振国, 等.弧焊机器人工件坐标系快速标定方法[J].焊接学报, 2005, 26(7): 1–4. http://www.docin.com/p-688053379.html

Zhang Wenzeng, Chen Qiang, Sun Zhenguo, et al. Quick calibration method of part coordinates for arc welding robot[J]. Transactions of the China Welding Institution, 2005, 26(7): 1–4. http://www.docin.com/p-688053379.html

[16] 李婷, 柳宁.基于机器视觉的圆定位技术研究[J].计算机工程与应用, 2012, 48(9): 153–156. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsjgcyyy201209044

Li Ting, Liu Ning. Study on circle locating technology based on machine vision[J]. Computer Engineering and Applications, 2012, 48(9): 153–156. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsjgcyyy201209044

[17] 王建文, 林劼.基于颜色直方图金字塔的图像自动标注方法[J].计算机工程, 2016, 42(6): 235–240. http://www.cnki.com.cn/Article/CJFDTotal-JSJC201606043.htm

Wang Jianwen, Liu Jie. Automatic image annotation method based on color histogram pyramid[J]. Computer Engineering, 2016, 42(6): 235–240. http://www.cnki.com.cn/Article/CJFDTotal-JSJC201606043.htm

[18] 黄风山, 秦亚敏, 任玉松.成捆圆钢机器人贴标系统图像识别方法[J].光电工程, 2016, 43(12): 168–174. doi: 10.3969/j.issn.1003-501X.2016.12.026

Huang Fengshan, Qin Yamin, Ren Yusong. The image recognition method on round bales robot labeling system[J]. Opto-Electronic Engineering, 2016, 43(12): 168–174. doi: 10.3969/j.issn.1003-501X.2016.12.026

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: