Research progress of ultrafast laser industrial applications based on filamentation

-

摘要

激光成丝是超快激光在透明介质传输中的一种非线性光学现象,来源于光克尔效应引起的激光光束自聚焦与弱电离产生的等离子体散焦之间的动态平衡,对其超长传输物理特征非衍射性的调控在研发新一代超快激光材料加工技术上具有至关重要的作用。本文面向激光制造现代工程应用的发展需求,对基于光丝效应的激光高精加工研究现状进行了调研和总结,从激光成丝物理现象、基本机制和特征优势出发,介绍了超快激光在气、液及固体不同介质中光丝引导加工工艺的研发进展,对技术发展中的问题和前景进行了思考与分析。

Abstract

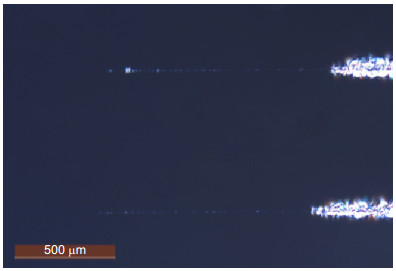

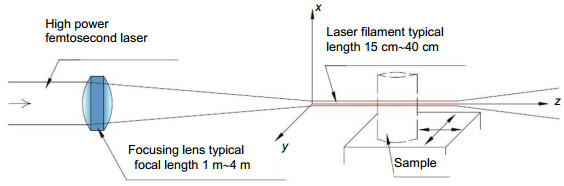

Ultrafast laser filamentation is an attractive nonlinear phenomenon as a consequence of dynamic balance between Kerr self-focusing and defocusing effect in the electron plasma generated through the ionization process. Achieving the regulation of the non-diffractive ultra-long transmission will play an important role in the development of novel ultrafast laser material processing technology. In this paper, the investigation on the research of ultrafast laser industrial application based on filamentation was introduced. From the physical feature, basic mechanism and characteristic advantages of filamentation effects, the representative research achievements on the laser applications of filamentary propagation induced by gas, liquid and solid different media were presented. The development problem and prospect of the technique were also considered and discussed.

-

Key words:

- ultrafast laser /

- filamentation /

- transparent material /

- laser material processing

-

Overview

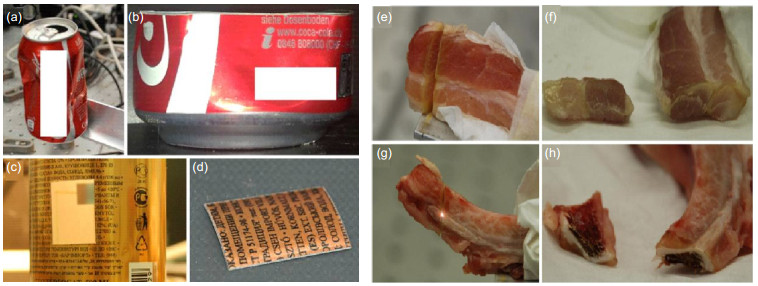

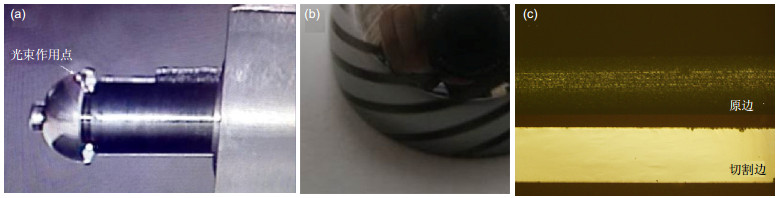

The research progress of ultrafast laser industrial application based on filamentation effect is introduced. Ultrafast laser filamentation is an attractive nonlinear phenomenon as a consequence of dynamic balance between Kerr self-focusing and defocusing effect in the electron plasma generated through the ionization process. It has been observed for various laser wavelengths from the ultraviolet to the infrared domain and for the pulse durations from several tenth of femtosecond to picosecond. The optical intensity in the filamentary volume can become high enough to induce permanent structural modifications which can be utilized in material processing with high precision and some special features. The basic characteristics and the theoretical modes of the filament propagation were described briefly for better understanding the effect. However, the main emphasis of the paper is on the laser industrial application from filamentation effect which is found as a promising and exploring research field in recent years. To achieve non-diffractive ultra-long transmission of filament propagation will play an important role in the development of the novel ultrafast laser material processing technology. From the physical feature, basic mechanism and characteristic advantages of filamentation effects, the representative research achievements on the laser applications of filamentation induced in gas, liquid and solid different media were presented. It is demonstrated that laser filamentation induced in gas provides high intensity plasma strings of micrometric diameters and lengths of tens of centimeters which can achieve remotely drilling, cutting and milling of metals, biological materials, ceramics and single crystal (sapphire). Complex 3D shapes can be machined without any adjustment of the technique because the processing is carried out under defocusing condition. Micromachining techniques of cutting and welding by water acting as a medium for filament formation were introduced afterwards. Filament formation in water leads to decrease of the focal spot diameter and increases of fluence and axial focal length, which is capable of drilling holes in thick soda-lime and hardened glasses, even for complex –shape fabrication. Filament formation at the interface of two glass samples was also used for welding applications. By varying repetition rate, scanning speed and focal position optimal conditions, strong glass welding via filamentation were obtained. The development problem and prospect of the technique were also considered and discussed. Ultrafast laser processing using filamentation must be a versatile technique in the future industrial material machining because the material modification is initiated by nonlinear absorption with the advantages which is quite different from common ablation.

-

-

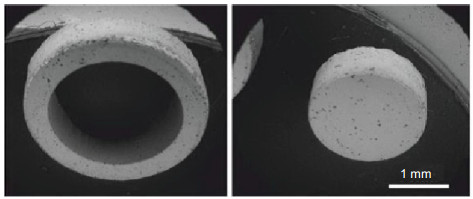

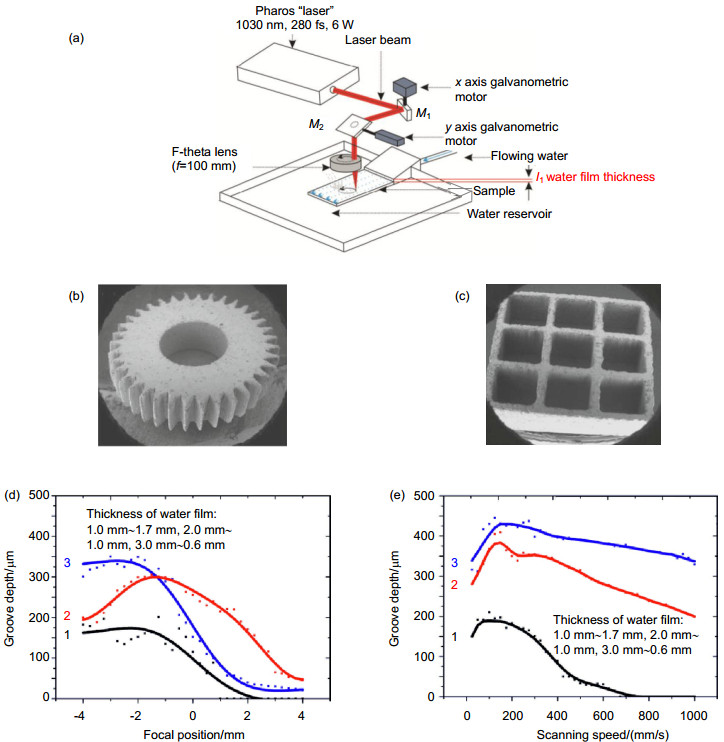

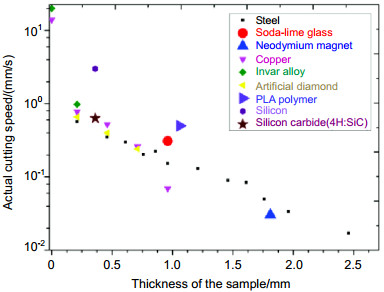

图 8 超快激光水介光丝切割实验[38, 39]. (a)实验装置架构图. (b),(c) 1 mm厚钠-钙玻璃复杂切割件SEM图. (d), (e)水膜厚度、激光工艺参数分析.

Figure 8. Cutting process of ultra-fast laser filamentation in water[38, 39]. (a) Experimental set-up. (b), (c) Complex shape soda-lime glass cut samples. (d), (e) Thickness of water layer, laser parameters versus groove depth.

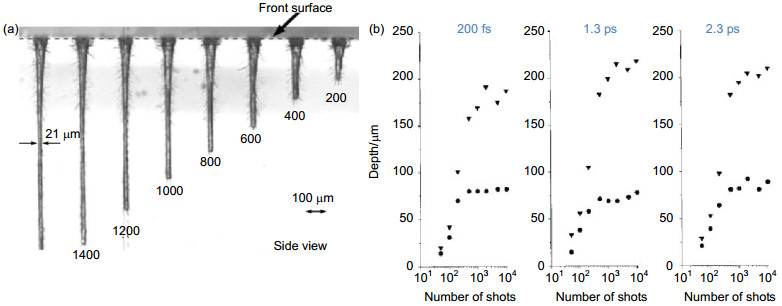

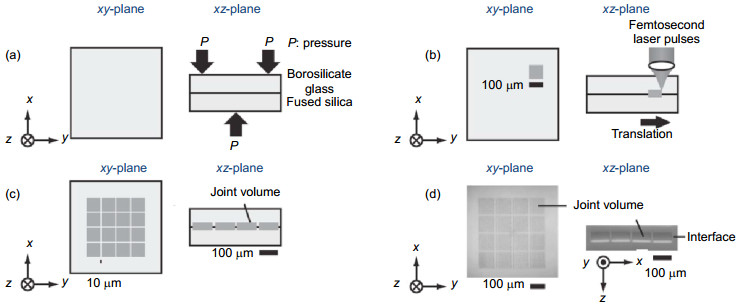

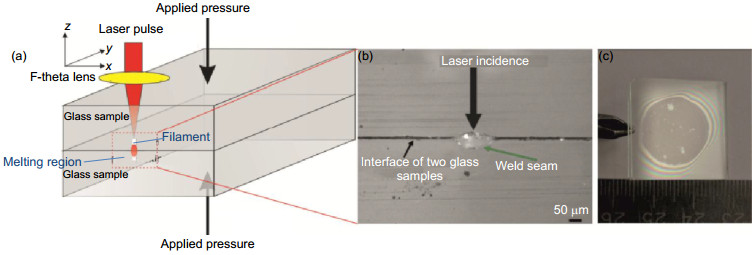

图 11 固体介质成丝微连接示意图[44]. (a)将一个样品放在另一个样品上并加压. (b)飞秒脉冲激光聚焦于界面并平移样品. (c)样品连接. (d)飞秒激光辐照后样品俯视(xy平面)和侧视(xz平面)显微图.

Figure 11. Schematic diagrams of laser joining process of filamentation in solid media[44]. (a) Place one sample on another and press together. (b) Focus femtosecond laser pulses at the interface and translate the samples. (c) Join the samples. (d) Photomicrographs of top view (xy plane) and side view (yz plane) after femtosecond laser joining.

-

参考文献

[1] 程亚.超快激光微纳加工:原理、技术与应用[M].北京:科学出版社, 2016.

[2] Dausinger S, Hügel H, Konov V I. Micromachining with ultrashort laser pulses: From basic understanding to technical applications[J]. Proceedings of SPIE, 2003, 5147: 106–115. https://www.spiedigitallibrary.org/conference-proceedings-of-spie/5147/1/Micromachining-with-ultrashort-laser-pulses--from-basic-understanding-to/10.1117/12.537496.full

[3] Gattass R R, Mazur E. Femtosecond laser micromachining in transparent materials[J]. Nature Photonics, 2008, 2(4): 219–225. doi: 10.1038/nphoton.2008.47 http://cn.bing.com/academic/profile?id=f65ba9d3cafe3af705bc4969fff8f697&encoded=0&v=paper_preview&mkt=zh-cn

[4] Cheng g, Rudenko A, D'Amico C, et al. Embedded nanogratings in bulk fused silica under non-diffractive Bessel ultrafast laser irradiation[J]. Applied Physics Letters, 2017, 110(26): 261901. doi: 10.1063/1.4987139 https://aip.scitation.org/doi/10.1063/1.4987139

[5] Bhuyan M K, Velpula P K, Colombier J P, et al. Single-shot high aspect ratio bulk nanostructuring of fused silica using chirp-controlled ultrafast laser Bessel beams[J]. Applied Physics Letters, 2014, 104(2): 021107. doi: 10.1063/1.4861899 http://cn.bing.com/academic/profile?id=c948836035d76a212e2d0794d033c810&encoded=0&v=paper_preview&mkt=zh-cn

[6] Butkus S, Paipulas D, Sirutkaitis R, et al. Rapid cutting and drilling of transparent materials via femtosecond laser filamentation[J]. Journal of Laser Micro/Nano Engineering, 2014, 9(3): 213–220. http://www.jlps.gr.jp/jlmn/upload/7e752110807cf37e6624bdf3a0a4da1e.pdf

[7] Sudrie L, Franco M, Prade B, et al. Study of damage in fused silica induced by ultra-short IR laser pulses[J]. Optics Communications, 2001, 191(3–6): 333–339. doi: 10.1016/S0030-4018(01)01152-X http://cn.bing.com/academic/profile?id=75faa6f4d569825f3ba3e6dde293ed1c&encoded=0&v=paper_preview&mkt=zh-cn

[8] Tan Dezhi, Sharafudeen K N, Yue Yuanzheng, et al. Femtosecond laser induced phenomena in transparent solid materials: Fundamentals and applications[J]. Progress in Materials Science, 2016, 76: 154–228. doi: 10.1016/j.pmatsci.2015.09.002 https://www.sciencedirect.com/science/article/pii/S0079642515000924

[9] De Aldana J R V, Moreno P, Roso L. Ultrafast lasers: A new frontier for optical materials processing[J]. Optical Materials, 2012, 34(3): 572–578. doi: 10.1016/j.optmat.2011.05.002 http://www.doc88.com/p-3961242353526.html

[10] 何飞, 廖洋, 程亚.利用飞秒激光直写实现透明介电材料中三维微纳结构的制备与集成[J].物理学进展, 2012, 32(2): 98–113. http://edu.wanfangdata.com.cn/Periodical/Detail/wlxjz201202002

He Fei, Liao Yang, Cheng Ya. Fabrication and integration of three-dimensional micro/nano-structures inside dielectric materials using femtosecond laser direct writing[J]. Progress in Physics, 2012, 32(2): 98–113. http://edu.wanfangdata.com.cn/Periodical/Detail/wlxjz201202002

[11] 李焱, 蒋红兵, 杨宏, 等.透明材料飞秒激光三维微制备[J].量子电子学报, 2004, 21(2): 188–193. http://doi.wanfangdata.com.cn/10.3969/j.issn.1007-5461.2004.02.009

Li Yan, Jiang Hongbing, Yang Hong, et al. Three-dimensional microfabrication in transparent materials with femtosecond laser pulses[J]. Chinese Journal of Quantum Electronics, 2004, 21(2): 188–193. http://doi.wanfangdata.com.cn/10.3969/j.issn.1007-5461.2004.02.009

[12] 夏博, 姜澜, 王素梅, 等.飞秒激光微孔加工[J].中国激光, 2013, 40(2): 0201001. https://www.wenkuxiazai.com/doc/588b6652ed630b1c59eeb5e5.html

Xia Bo, Jiang Lan, Wang Sumei, et al. Femtosecond laser drilling of micro-holes[J]. Chinese Journal of Lasers, 2013, 40(2): 0201001. https://www.wenkuxiazai.com/doc/588b6652ed630b1c59eeb5e5.html

[13] Li Helong, Chu Wei, Xu Huailiang, et al. Simultaneous identification of multi-combustion-intermediates of alkanol-air flames by femtosecond filament excitation for combustion sensing[J]. Scientific Reports, 2016, 6: 27340. doi: 10.1038/srep27340 http://cn.bing.com/academic/profile?id=9e18b71bd65543c0a80895d8b95191cf&encoded=0&v=paper_preview&mkt=zh-cn

[14] Davis K M, Miura K, Sugimoto N, et al. Writing waveguides in glass with a femtosecond laser[J]. Optics Letters, 1996, 21(21): 1729–1731. doi: 10.1364/OL.21.001729 http://cn.bing.com/academic/profile?id=e877a3f700c96cf2b06836f1776eb5a0&encoded=0&v=paper_preview&mkt=zh-cn

[15] Kovachev L M, Georgieva D A. The long range filament stability: balance between non-paraxial diffraction and third-order nonlinearity[J]. Proceedings of SPIE, 2013, 8770: 87701G. doi: 10.1117/12.2013663 https://www.spiedigitallibrary.org/conference-proceedings-of-spie/8770/1/The-long-range-filament-stability--balance-between-non-paraxial/10.1117/12.2013663.short?SSO=1

[16] Daigle J F, Kosareva O, Panov N, et al. A simple method to significantly increase filaments' length and ionization density[J]. Applied Physics B, 2009, 94(2): 249–257. doi: 10.1007/s00340-008-3270-5 http://cn.bing.com/academic/profile?id=3fabf6b189441d49629c5afce3b28d48&encoded=0&v=paper_preview&mkt=zh-cn

[17] Couairon A, Mysyrowicz A. Femtosecond filamentation in transparent media[J]. Physics Reports, 2007, 441(2–4): 47–189. doi: 10.1016/j.physrep.2006.12.005 http://cn.bing.com/academic/profile?id=61e193ead8ed87cf3ca0755a6acf5183&encoded=0&v=paper_preview&mkt=zh-cn

[18] Zergioti I, Kyrkis K D, Papazoglou D G, et al. Structural modifications in fused silica induced by ultraviolet fs laser filaments[J]. Applied Surface Science, 2007, 253(19): 7865–7868. doi: 10.1016/j.apsusc.2007.02.095 http://cn.bing.com/academic/profile?id=22d5dcb7927ec85ace4f4367401bc118&encoded=0&v=paper_preview&mkt=zh-cn

[19] Hosseini S A, Herman P R. Method of material processing by laser filamentation: WO/2012/006736 Kind Code: A3[P]. 2012-01-19.

[20] 盛政明.强场激光物理研究前沿[M].上海:上海交通大学出版社, 2014.

Sheng Zhengming. Advances in high field laser physics[M]. Shanghai: Shanghai Jiao Tong University Press, 2014.

[21] Braun A, Korn G, Liu X, et al. Self-channeling of high-peak-power femtosecond laser pulses in air[J]. Optics Letters, 1995, 20(1): 73–75. doi: 10.1364/OL.20.000073 http://cn.bing.com/academic/profile?id=4554b0735b87185c0fadd14c08ec3956&encoded=0&v=paper_preview&mkt=zh-cn

[22] Brodeur A, Chien C Y, Ilkov F A, et al. Moving focus in the propagation of ultrashort laser pulses in air[J]. Optics Letters, 1997, 22(5): 304–306. doi: 10.1364/OL.22.000304 http://cn.bing.com/academic/profile?id=8246ad29bcc68aba7a3f002828299cf6&encoded=0&v=paper_preview&mkt=zh-cn

[23] Mlejnek M, Wright E M, Moloney J V. Dynamic spatial replenishment of femtosecond pulses propagating in air[J]. Optics Letters, 1998, 23(5): 382–384. doi: 10.1364/OL.23.000382 http://cn.bing.com/academic/profile?id=e6c7212a62bcecc908f0d0965375fb35&encoded=0&v=paper_preview&mkt=zh-cn

[24] Ashkenasi D, Kaszemeikat T, Mueller N, et al. Machining of glass and quartz using nanosecond and picosecond laser pulses[J]. Proceedings of SPIE, 2012, 8243: 82430M. doi: 10.1117/12.907740 https://www.researchgate.net/publication/258711392_Machining_of_Glass_and_Quartz_using_Nanosecond_and_Picosecond_Laser_Pulses

[25] Du Keming, Brüning S, Gillner A. High-power picosecond laser with 400W average power for large scale applications[J]. Proceedings of SPIE, 2012, 8244: 82440P. doi: 10.1117/12.915676 https://www.spiedigitallibrary.org/redirect/proceedings/proceeding?doi=10.1117/12.915676

[26] Zvorykin V D, Ionin A A, Levchenko A O, et al. Effects of picosecond terawatt UV laser beam filamentation and a repetitive pulse train on creation of prolonged plasma channels in atmospheric air[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 2013, 309: 218–222. doi: 10.1016/j.nimb.2013.02.030 https://www.researchgate.net/publication/273874353_Effects_of_picosecond_terawatt_UV_laser_beam_filamentation_and_a_repetitive_pulse_train_on_creation_of_prolonged_plasma_channels_in_atmospheric_air

[27] Tzortzakis S, Lamouroux B, Chiron A, et al. Femtosecond and picosecond ultraviolet laser filaments in air: experiments and simulations[J]. Optics Communications, 2001, 197(1–3): 131–143. doi: 10.1016/S0030-4018(01)01443-2 http://cn.bing.com/academic/profile?id=6901a9c735ce36ddb975fbba239b5fad&encoded=0&v=paper_preview&mkt=zh-cn

[28] 倪洁蕾, 程亚.飞秒激光成丝若干新效应研究进展[J].深圳大学学报理工版, 2014, 31(1): 1–15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=szdxxb201401001

Ni Jielei, Cheng Ya. Several new phenomena in femtosecond laser filamentation[J]. Journal of Shenzhen University Science and Engineering, 2014, 31(1): 1–15. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=szdxxb201401001

[29] Ju Jingjing, Liu Jiansheng, Wang Cheng, et al. Effects of initial humidity and temperature on laser-filamentation-induced condensation and snow formation[J]. Applied Physics B, 2013, 110(3): 375–380. doi: 10.1007/s00340-012-5265-5 http://cn.bing.com/academic/profile?id=8b985e6ac916495d8381af6697601909&encoded=0&v=paper_preview&mkt=zh-cn

[30] 林尊琪, 陈卫标, 楼祺洪, 等.我国近期激光前沿若干重要进展评述[J].中国科学:技术科学, 2013, 43(9): 961–978. https://www.wenkuxiazai.com/doc/a93a225e10a6f524cdbf8512.html

Lin Zunqi, Chen Weibiao, Lou Qihong, et al. Review on the recent progress of laser frontiers in China[J]. Science China Technological Science, 2013, 56(7): 1571–1588. https://www.wenkuxiazai.com/doc/a93a225e10a6f524cdbf8512.html

[31] Ju Jingjing, Liu Jiansheng, Wang Cheng, et al. Laser-filamentation-induced condensation and snow formation in a cloud chamber[J]. Optics Letters, 2012, 37(7): 1214–1216. doi: 10.1364/OL.37.001214 http://cn.bing.com/academic/profile?id=483a96969b23bdccda7c636c5029c39d&encoded=0&v=paper_preview&mkt=zh-cn

[32] Kiselev D, Woeste L, Wolf J P. Filament-induced laser machining (FILM)[J]. Applied Physics B, 2010, 100(3): 515–520. doi: 10.1007/s00340-010-4102-y https://www.researchgate.net/publication/226113410_Filament-induced_laser_machining_FILM

[33] 北京工业大学. 一种激光三维精细曲面铣削的方法: 中国, CN201610218392. 8[P]. 2016-08-17.

University Beijing Technology. Three-dimensional laser precise curved surface milling method: China, CN201610218392. 8[P]. 2016-08-17.

http://www.wanfangdata.com.cn/details/detail.do?_type=patent&id=CN201610218392.8 [34] 燕天阳, 季凌飞, Li Lin, 等.蓝宝石亚微米级精细切面化学辅助皮秒激光成丝切割研究[J].中国激光, 2017, 44(10): 1002002. http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201710009.htm

Yan Tianyang, Ji Lingfei, Li Lin, et al. High precision processing of sapphire with submicron cut-surface Roughness by chemical-assisted picosecond laser[J]. Chinese Journal of Lasers, 2017, 44(10): 1002002. http://www.cnki.com.cn/Article/CJFDTOTAL-JJZZ201710009.htm

[35] 罗芬-新纳技术公司. 激光成丝在透明材料中非烧蚀光声压缩加工的方法和装置: 中国, CN201410379877. 6[P]. 2015-02-11.

Rofin Sinar Technologies Inc. Method and apparatus for non-ablative and/or photo acoustic compression machining a transparent target: China, CN201410379877. 6[P]. 2015-02-11.

[36] 罗芬-新纳技术公司. 用于在透明材料内执行激光成丝的系统: 中国, CN201410380104. X[P]. 2015-02-11.

Rofin Sinar Technologies Inc. System for performing laser filamentation within transparent materials: China, CN201410380104. X[P]. 2015-02-11.

[37] 罗芬-新纳技术公司. 用于在透明材料内执行激光成丝的方法和设备: 中国, CN201410380147. 8[P]. 2015-02-11.

Rofin Sinar Technologies Inc. Method and device for performing laser filamentation within transparent materials: China, CN201410380147. 8[P]. 2015-02-11.

[38] Butkus S, GaiŽauskas E, Paipulas D, et al. Rapid microfabrication of transparent materials using filamented femtosecond laser pulses[J]. Applied Physics A, 114(1): 81–90. doi: 10.1007/s00339-013-8108-2 http://cn.bing.com/academic/profile?id=4cbf2e441581348529cacd249e8c45d6&encoded=0&v=paper_preview&mkt=zh-cn

[39] Butkus S, Paipulas D, Viburys Ž, et al. Rapid microfabrication of transparent materials using a filamented beam of the IR femtosecond laser[J]. Proceedings of SPIE, 2014, 8972: 897216. doi: 10.1117/12.2038231 http://cn.bing.com/academic/profile?id=cc0b841e96e4e598f9c57b1e9df2e463&encoded=0&v=paper_preview&mkt=zh-cn

[40] Butkus S, Alesenkov A, Paipulas D, et al. Micromachining of transparent, semiconducting and metallic substrates using femtosecond laser beams[J]. Journal of Laser Micro/ Nanoengineering, 2016, 11(1): 81–86. https://www.researchgate.net/publication/296477591_Micromachining_of_Transparent_Semiconducting_and_Metallic_Substrates_Using_Femtosecond_Laser_Beams

[41] Liu Jun, Chen Xiaowei, Liu Jiansheng, et al. Spectrum reshaping and pulse self-compression in normally dispersive media with negatively chirped femtosecond pulses[J]. Optics Express, 2006, 14(2): 979–987. doi: 10.1364/OPEX.14.000979 http://cn.bing.com/academic/profile?id=dc58f2824374fa79e6950cc434c56ea4&encoded=0&v=paper_preview&mkt=zh-cn

[42] 冯柳宾, 鲁欣, 刘晓龙, 等.飞秒激光离焦抽运熔融石英产生超连续白光的实验研究[J].物理学报, 2012, 16(17): 174206–1–6. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_wlxb201217037

Feng Liubin, Lu Xin, Liu Xiaolong, et al. Off-focus generation of strong super-continuum emission in fused silica using high power femtosecond laser pulses[J]. Acta Physics Sinica, 2012, 16(17): 174206–1–6. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_wlxb201217037

[43] Varel H, Ashkenasi D, Rosenfeld A, et al. Micromachining of quartz with ultrashort laser pulses[J]. Applied Physics A, 1997, 65(4–5): 367–373. doi: 10.1007/s003390050593 http://cn.bing.com/academic/profile?id=101cad4ee99517443b345f08dc72dc35&encoded=0&v=paper_preview&mkt=zh-cn

[44] Watanabe W, Tamaki T, Itoh K. Filamentation in laser microprocessing and microwelding[J]. Proceedings of SPIE, 2007, 6733: 67332F. doi: 10.1117/12.753150 http://cn.bing.com/academic/profile?id=651a68bf16a78e1e0f1320c6368bbe7f&encoded=0&v=paper_preview&mkt=zh-cn

[45] Watanabe W, Onda S, Tamaki T, et al. Space-selective laser joining of dissimilar transparent materials using femtosecond laser pulses[J]. Applied Physics Letters, 2006, 89(2): 021106. doi: 10.1063/1.2221393 http://cn.bing.com/academic/profile?id=a23a3d494c85b3a6bc71db73489ac9f8&encoded=0&v=paper_preview&mkt=zh-cn

[46] Tamaki T, Watanabe W, Itoh K. Laser micro-welding of transparent materials by a localized heat accumulation effect using a femtosecond fiber laser at 1558 nm[J]. Optics Express, 2006, 14(22): 10460–10468. doi: 10.1364/OE.14.010460 http://cn.bing.com/academic/profile?id=fbf1ef8a4b96385e1dbaa13348b90590&encoded=0&v=paper_preview&mkt=zh-cn

[47] Yoshino F, Zhang Haibin, Arai A. Ultrashort pulse laser processing of transparent materials[J]. Journal of Laser Micro/Nanoengineering, 2009, 4(3): 212–217. http://cn.bing.com/academic/profile?id=f6b1d5e915b827d727c691e6a7490464&encoded=0&v=paper_preview&mkt=zh-cn

[48] Courvoisier F, Stoian R, Couairon A. Ultrafast laser micro-and nano-processing with nondiffracting and curved beams: invited paper for the section: hot topics in ultrafast lasers[J]. Optics & Laser Technology, 2016, 80: 125–137. https://www.sciencedirect.com/science/article/pii/S0030399215303923

[49] Juodkazis S, Mizeikis V, GaiŽauskas E, et al. Studies of femtosecond pulse filamentation in glasses[J]. Proceedings of SPIE, 2006, 6053: 60530R. http://cn.bing.com/academic/profile?id=a864000fa8f3bbcb29af78c1eddcb899&encoded=0&v=paper_preview&mkt=zh-cn

[50] 高慧, 赵佳宇, 刘伟伟.超快激光成丝现象的多丝控制[J].光学精密工程, 2013, 21(3): 598–607. http://www.opticsjournal.net/abstract.htm?id=OJ130408000196DaGcJf

Gao Hui, Zhao Jiayu, Liu Weiwei. Control of multiple filamentation induced by ultrafast laser pulses[J]. Optics and Precision Engineering, 2013, 21(3): 598–607. http://www.opticsjournal.net/abstract.htm?id=OJ130408000196DaGcJf

[51] Plat K, von Witzendorff P, Suttmann O, et al. Process strategy for drilling of chemically strengthened glass with picosecond laser radiation[J]. Journal of Laser Applications, 2016, 28(2): 022201. doi: 10.2351/1.4944508 https://lia.scitation.org/doi/10.2351/1.4944508

[52] Galinis J, Tamošauskas G, Gražulevičiũtè I, et al. Filamentation and supercontinuum generation in solid-state dielectric media with picosecond laser pulses[J]. Physical Review A, 2015, 92(3): 033857. doi: 10.1103/PhysRevA.92.033857 http://adsabs.harvard.edu/abs/2015PhRvA..92c3857G

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: