Realization of laser textured brass surface via temperature tuning for surface wettability transition

-

Abstract

Superhydrophobic surfaces have attracted extensive interests and researches into their fundamentals and potential applications. Laser texturing provides the convenience to fabricate the hierarchical micro/nanostructures for superhydrophobicity. However, after laser texturing, long wettability transition time from superhydrophilicity to superhydrophobicity is a barrier to mass production and practical industrial applications. External stimuli have been applied to change the surface composition and/or the surface morphology to reduce wettability transition time. Herein, by temperature tuning, wettability transition of laser textured brass surfaces is investigated. Scanning electron microscopy and surface contact angle measurement are employed to characterize the surface morphology and wettability behavior of the textured brass surfaces. By low-temperature heating (100 ℃~150 ℃), partial deoxidation of the top CuO layer occurs to form hydrophobic Cu2O. Therefore, superhydrophobicity without any chemical coating and surface modification could be achieved in a short time. Furthermore, after low-temperature heating, the low adhesive force between the water droplet and the sample surface is demonstrated for the laser textured brass surface. This study provides a simple method to fabricate the micro/nanostructure surfaces with controllable wettability for the potential applications.

-

Key words:

- ettability transition /

- temperature tuning /

- laser texturing /

- superhydrophobic surface /

- contact angle

-

Overview

Abstract: Superhydrophobic surfaces have attracted extensive interest and research into their fundamentals and potential applications, including self-cleaning, anti-icing, anti-corrosion, reduction of drag, oil/water separation, biomedical devices and microfluidic manipulation. Laser texturing provides a facile and promising method to makesuperhydrophobic metallic surfaces. However, immediately after laser texturing, the metallic surface becomes hydrophilic or superhydrophilic. It takes several weeks to months to achieve wettability transition from superhydrophilicityto superhydrophobicity under ambient conditions. This poses a barrier to mass production and industrial applications.Therefore, external stimuli have been applied to change the surface composition and/or the surface morphology toinfluence wettability transition. Among these methods, temperature tuning has attracted special attention due to itsadvantage of being a simple and controllable process.

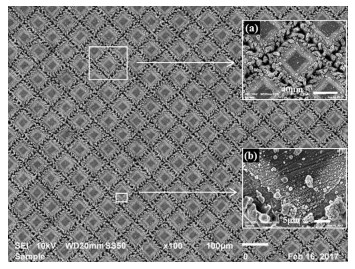

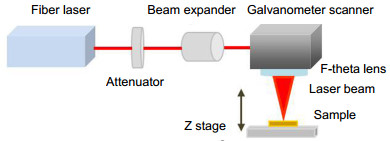

A nanosecond pulsed fiber laser is employed to fabricate the micro/nanostructures on the as-prepared brass samplesurfaces. The surface morphology of the laser textured samples is then characterized by a field-emission scanningelectron microscope. A uniform distribution of periodic micro-scale grid patterns on the brass substrate can be clearlyobserved in Fig. 1, which is beneficial to uniform superhydrophobic properties in all directions with trapped air.

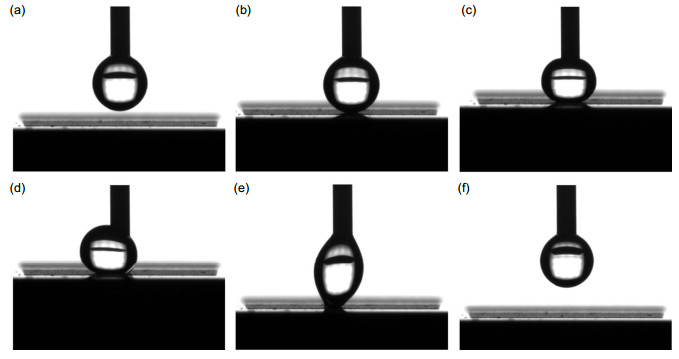

After the laser ablation, a post-processing by temperature tuning is carried out to investigate the influence of temperature on wettability behavior of the laser textured brass surfaces. After temperature tuning, the evolution fromsuperhydrophilic to hydrophobic or superhydrophobic state of laser textured surfaces is evaluated by measuring staticcontact angle (CA) with a CA analyzer using the sessile drop technique. Time taken to reach the CA of 135 ° is 14, 18,9, 9, 24, 17 and 17 days for temperature tuning at -16 ℃ , 25 ℃ , 100 ℃ , 150 ℃ , 200 ℃ , 250 ℃ and 300 ℃ , respectively.By low-temperature heating (100 ℃ ~150 ℃ ), partial deoxidation of the top CuO layer occurs faster, resulting in theformation of hydrophobic Cu2O. It demonstrates that applying low-temperature heating could greatly speed up therate of wettability transition of brass surfaces subjected to the laser texturing. After 100 ℃ temperature heating, thesample surface achieves superhydrophobicity with the CA of 150.2 ° after 18 days. Furthermore, for the laser texturedbrass surface after 100 ℃ temperature heating, a contacting experiment is carried out. The experimental results indicate the superhydrophobic performance of the laser textured surface and the low adhesive force between the dropletand the surface.

-

-

Table 1. Processing parameters of laser texturing.

Parameters Values Pass 1 Laser fluence/(J/cm2) 4.5 Speed/(mm/s) 5 Scan spacing/pm 75 -

参考文献

[1] Liu Hongliang, Zhang Pengchao, Liu Mingjie, et al. Organogel-based thin films for self-cleaning on various surfaces[J]. Advanced Materials, 2013, 25(32): 4477–4481. doi: 10.1002/adma.v25.32

[2] Ou Junfei, Hu Weihua, Xue Mingshan, et al. One-step solution immersion process to fabricate superhydrophobic surfaces on light alloys[J]. ACS Applied Materials & Interfaces, 2013, 5(20): 9867–9871.

[3] Davis A, Yeong Y H, Steele A, et al. Superhydrophobic nanocomposite surface topography and ice adhesion[J]. ACS Applied Materials & Interfaces, 2014, 6(12): 9272–9279. http://cn.bing.com/academic/profile?id=1b5751e99be940d0f7dee5bc50db6675&encoded=0&v=paper_preview&mkt=zh-cn

[4] Lv Jianyong, Song Yanlin, Jiang Lei, et al. Bio-inspired strategies for anti-icing[J]. ACS Nano, 2014, 8(4): 3152–3169. doi: 10.1021/nn406522n

[5] Qing Yongquan, Yang Chuanning, Yu Nannan, et al. Superhydrophobic TiO2/polyvinylidene fluoride composite surface with reversible wettability switching and corrosion resistance[J]. Chemical Engineering Journal, 2016, 290: 37–44. doi: 10.1016/j.cej.2016.01.013

[6] Dong Hongyu, Cheng Mengjiao, Zhang Yajun, et al. Extraordinary drag-reducing effect of a superhydrophobic coating on a macroscopic model ship at high speed[J]. Journal of Materials Chemistry A, 2013, 1(19): 5886–5891. doi: 10.1039/c3ta10225d

[7] Liu Na, Cao Yingze, Lin Xin, et al. A facile solvent-manipulated mesh for reversible oil/water separation[J]. ACS Applied Materials & Interfaces, 2014, 6(15): 12821–12826. https://pubs.acs.org/doi/abs/10.1021/am502809h?journalCode=aamick

[8] Wang Fajun, Lei Sheng, Xue Mingshan, et al. In situ separation and collection of oil from water surface via a novel superoleophilic and superhydrophobic oil containment boom[J]. Langmuir, 2014, 30(5): 1281–1289. doi: 10.1021/la403778e

[9] Wang Fajun, Lei Sheng, Xue Mingshan, et al. Superhydrophobic and superoleophilic miniature device for the collection of oils from water surfaces[J]. The Journal of Physical Chemistry C, 2014, 118(12): 6344–6351. doi: 10.1021/jp500359v

[10] Li Jian, Li Dianming, Yang Yaoxia, et al. A prewetting induced underwater superoleophobic or underoil (super) hydrophobic waste potato residue-coated mesh for selective efficient oil/water separation[J].Green Chemistry, 2016, 18(2): 541–549. doi: 10.1039/C5GC01818H

[11] Darmanin T, Guittard F. Recent advances in the potential applications of bioinspired superhydrophobic materials[J]. Journal of Materials Chemistry A, 2014, 2(39): 16319–16359. doi: 10.1039/C4TA02071E

[12] Simpson J T, Hunter S R, Aytug T. Superhydrophobic materials and coatings: a review[J].Reports on Progress in Physics, 2015, 78(8): 086501. doi: 10.1088/0034-4885/78/8/086501

[13] Ganesh V A, Raut H K, Nair A S, et al. A review on self-cleaning coatings[J]. Journal of Materials Chemistry, 2011, 21(41): 16304–16322. doi: 10.1039/c1jm12523k

[14] He Tian, Wang Yuanchao, Zhang Yijian, et al. Super-hydrophobic surface treatment as corrosion protection for aluminum in seawater[J]. Corrosion Science, 2009, 51(8): 1757–1761. doi: 10.1016/j.corsci.2009.04.027

[15] Chen Zhi, Hao Limei, Chen Anqi, et al. A rapid one-step process for fabrication of superhydrophobic surface by electrodeposition method[J]. Electrochimica Acta, 2012, 59: 168–171. doi: 10.1016/j.electacta.2011.10.045

[16] Zhang Dengying, Yu Weixing, Hao Dongliang, et al. Functional nanostructured surfaces in hybrid sol–gel glass in large area for antireflective and super-hydrophobic purposes[J]. Journal of Materials Chemistry, 2012, 22(33): 17328–17331. doi: 10.1039/c2jm33557c

[17] Huang Zhongbing, Zhu Ying, Zhang Jihua, et al. Stable biomimetic superhydrophobicity and magnetization film with Cu-ferrite nanorods[J]. The Journal of Physical Chemistry C, 2007, 111(18): 6821–6825. doi: 10.1021/jp0678554

[18] Wang Zhiwei, Zhu Liqun, Li Weiping, et al. Rapid reversible superhydrophobicity-to-superhydrophilicity transition on alternating current etched brass[J]. ACS Applied Materials & Interfaces, 2013, 5(11): 4808–4814. http://pubs.acs.org/doi/pdf/10.1021/am400299f

[19] Liu Lijun, Xu Feiyan, Ma Lin. Facile fabrication of a superhydrophobic Cu surface via a selective etching of high-energy facets[J]. The Journal of Physical Chemistry C, 2012, 116(35): 18722–18727. doi: 10.1021/jp302794p

[20] Yang Y L, Hsu C C, Chang T L, et al. Study on wetting properties of periodical nanopatterns by a combinative technique of photolithography and laser interference lithography[J]. Applied Surface Science, 2010, 256(11): 3683–3687. doi: 10.1016/j.apsusc.2010.01.006

[21] Sun Qingfeng, Lu Yun, Liu Yixing. Growth of hydrophobic TiO2 on wood surface using a hydrothermal method[J]. Journal of Materials Science, 2011, 46(24): 7706–7712. doi: 10.1007/s10853-011-5750-y

[22] Broderick A H, Manna U, Lynn D M. Covalent layer-by-layer assembly of water-permeable and water-impermeable polymer multilayers on highly water-soluble and water-sensitive substrates[J]. Chemistry of Materials, 2012, 24(10): 1786–1795. doi: 10.1021/cm300307g

[23] Zhai Lei, Cebeci F , Cohen R E, et al. Stable superhydrophobic coatings from polyelectrolyte multilayers[J]. Nano Letters, 2004, 4(7): 1349–1353. doi: 10.1021/nl049463j

[24] Moradi S, Kamal S, Englezos P, et al. Femtosecond laser irradiation of metallic surfaces: effects of laser parameters on superhydrophobicity[J].Nanotechnology, 2013, 24(41): 415302. doi: 10.1088/0957-4484/24/41/415302

[25] Jagdheesh R, Pathiraj B, Karatay E, et al. Laser-induced nanoscale superhydrophobic structures on metal surfaces[J]. Langmuir, 2011, 27(13): 8464–8469. doi: 10.1021/la2011088

[26] Tang M, Shim V, Pan Z Y, et al. Laser ablation of metal substrates for super-hydrophobic effect[J]. Journal of Laser Micro/Nanoengineering, 2011, 6(1): 6–9. https://www.researchgate.net/publication/270226136_Laser_Ablation_of_Metal_Substrates_for_Super-hydrophobic_Effect

[27] Bizi-Bandoki P, Valette S, Audouard E, et al. Time dependency of the hydrophilicity and hydrophobicity of metallic alloys subjected to femtosecond laser irradiations[J]. Applied Surface Science, 2013, 273: 399–407. doi: 10.1016/j.apsusc.2013.02.054

[28] Sun Wei, Zhou Shuxue, You Bo, et al. A facile method for the fabrication of superhydrophobic films with multiresponsive and reversibly tunable wettability[J]. Journal of Materials Chemistry A, 2013, 1(9): 3146–3154. doi: 10.1039/c2ta01293f

[29] Liang Weitao, Zhu Liqun, Li Weiping, et al. Facile fabrication of a flower-like CuO/Cu(OH)2 nanorod film with tunable wetting transition and excellent stability[J]. RSC Advances, 2015, 5(48): 38100–38110. doi: 10.1039/C5RA04359J

[30] Wang Rong, Hashimoto K, Fujishima A, et al. Light-induced amphiphilic surfaces[J]. Nature, 1997, 388(6641): 431–432. doi: 10.1038/41233

[31] Naghdi S, Jaleh B, Shahbazi N. Reversible wettability conversion of electrodeposited graphene oxide/titania nanocomposite coating: investigation of surface structures[J]. Applied Surface Science, 2016, 368: 409–416. doi: 10.1016/j.apsusc.2016.01.193

[32] Ngo C V, Chun D M. Fast wettability transition from hydrophilic to superhydrophobic laser-textured stainless steel surfaces under low-temperature annealing[J]. Applied Surface Science, 2017, 409: 232–240. doi: 10.1016/j.apsusc.2017.03.038

[33] Erbil H Y, Demirel A L, Avcı Y, et al. Transformation of a simple plastic into a superhydrophobic surface[J]. Science, 2003, 299(5611): 1377–1380. doi: 10.1126/science.1078365

[34] Chang Fengming, Cheng Shaoliang, Hong S J, et al. Superhydrophilicity to superhydrophobicity transition of CuO nanowire films[J]. Applied Physics Letters, 2010, 96(11): 114101. doi: 10.1063/1.3360847

[35] Ta D V, Dunn A, Wasley T J, et al. Nanosecond laser textured superhydrophobic metallic surfaces and their chemical sensing applications[J]. Applied Surface Science, 2015, 357: 248–254. doi: 10.1016/j.apsusc.2015.09.027

[36] Tang Mingkai, Huang Xingjiu, Guo Zheng, et al. Fabrication of robust and stable superhydrophobic surface by a convenient, low-cost and efficient laser marking approach[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2015, 484: 449–456. https://www.researchgate.net/publication/282939581_Fabrication_of_robust_and_stable_superhydrophobic_surface_by_a_convenient_low-cost_and_efficient_laser_marking_approach

[37] Guo Zheng, Chen Xing, Li Jie, et al. ZnO/CuO hetero-hierarchical nanotrees array: hydrothermal preparation and self-cleaning properties[J]. Langmuir, 2011, 27(10): 6193–6200. doi: 10.1021/la104979x

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: