Three-dimensional shape measurement of composite surface based on defocused binary display and fringe projection

-

摘要:

由于复合表面物体中漫反射部分和镜面部分反射性质不同,受到相机景深的限制,镜面成像的正弦条纹发生离焦,从而引起相位误差。为了实现复合表面物体的高效、高精度测量,本文提出了一种离焦二值结合正弦条纹的复合表面三维形貌测量方法。首先,本文基于刃边法与二次模糊法对系统离焦程度进行分区标定,解决了由于相机倾斜放置导致参考面离焦程度不同的问题。然后,建立二值条纹相位误差模型,确定最佳条纹宽度和离焦量范围。最后,对轻微离焦区域的二值条纹进行离焦补偿,确保相机采集的条纹均在最佳离焦范围内。在此基础上进行三维形貌测量。实验结果表明,所提方法使镜面部分误差从原来的0.033 mm降至0.019 mm,提高了复合表面测量精度。

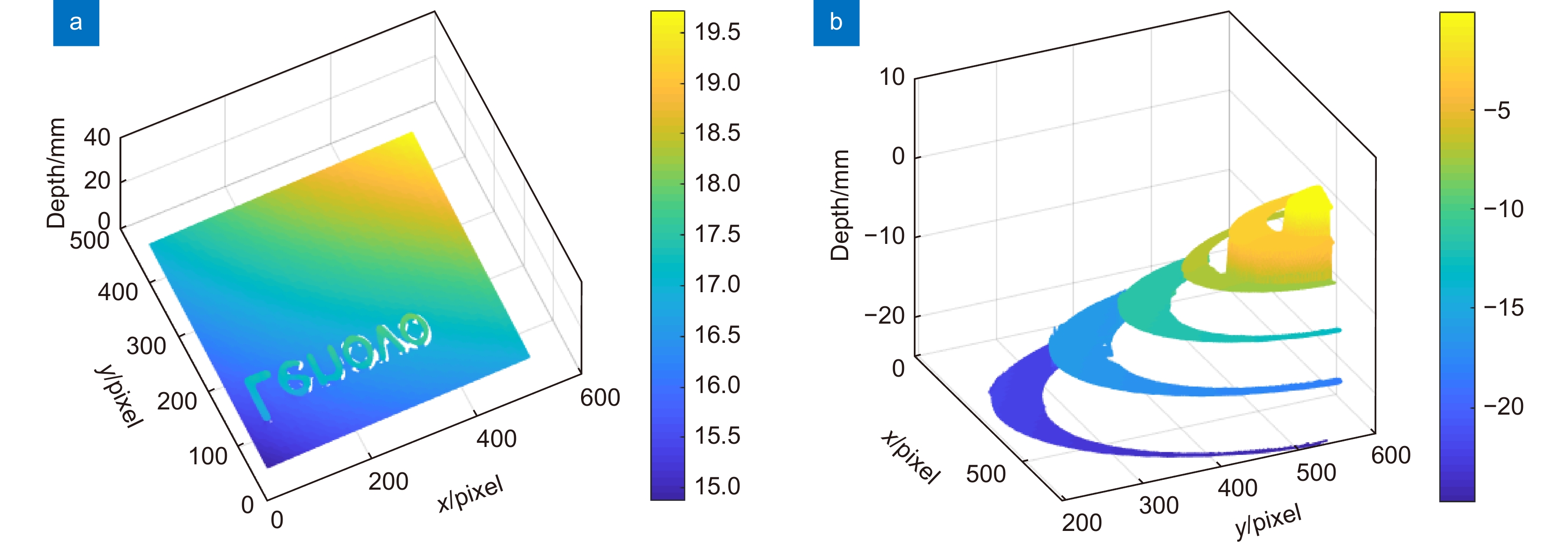

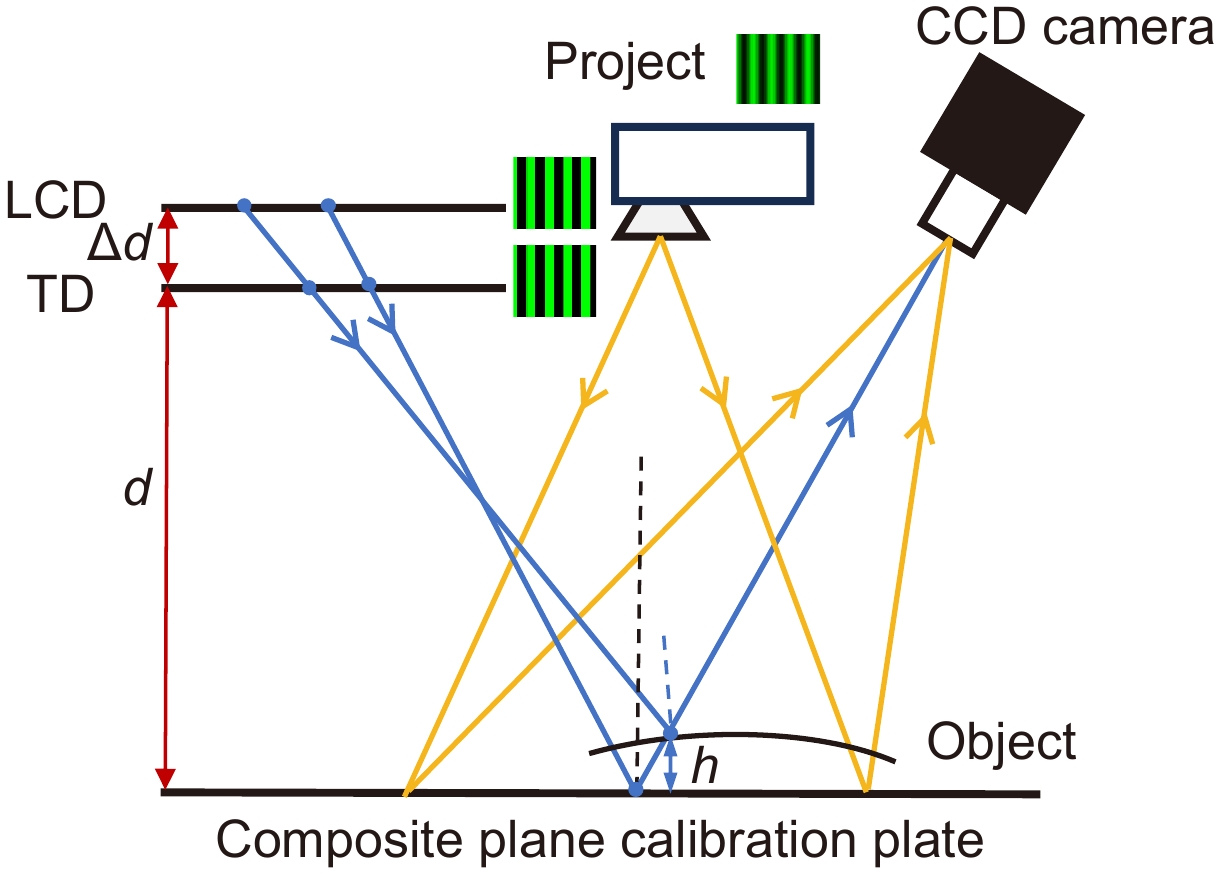

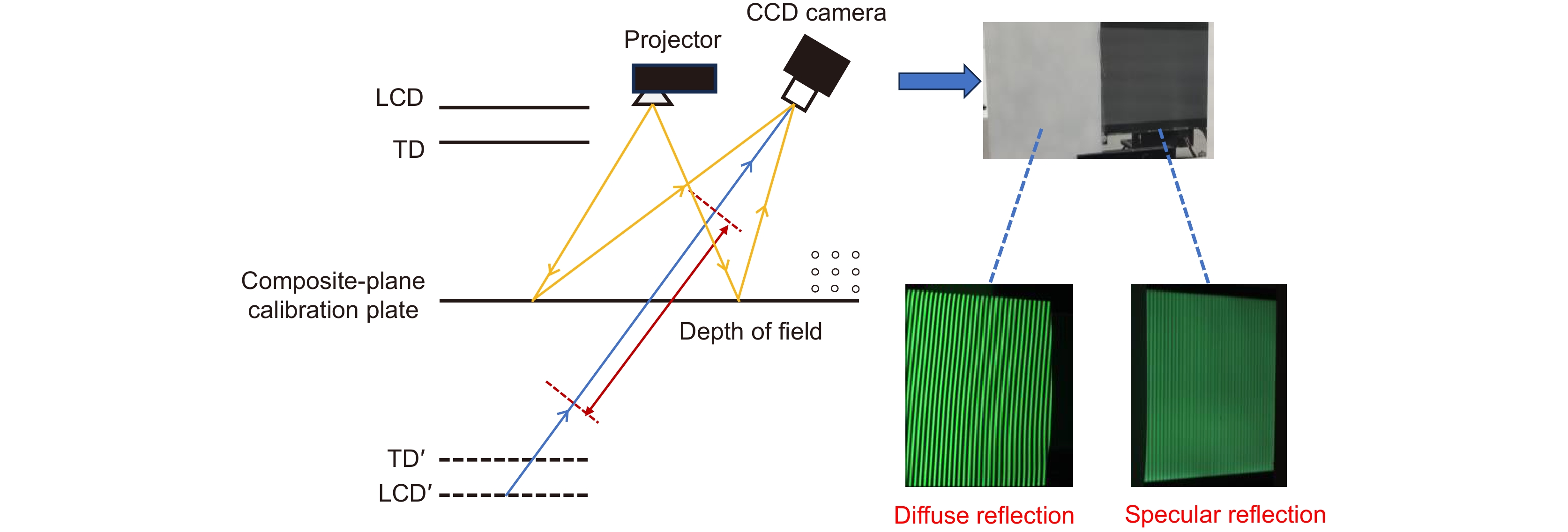

Abstract:Due to the different reflective properties of the diffuse and specular components in composite surface objects and the limitations imposed by the camera depth of field, defocusing of sinusoidal fringes occurs in specular imaging, leading to phase errors. To achieve the efficient and high-precision measurement of composite surface objects, this paper proposes a method for three-dimensional surface topography measurement by combining defocused binary patterns with sinusoidal fringes. Firstly, the paper partitions and calibrates the defocus level of the system based on the edge and second-order blur methods, addressing the issue of varying defocus levels of the reference surface due to the tilted placement of the camera. Then, a binary fringe phase error model is established to determine the optimal fringe width and the defocus range. Finally, defocus compensation is applied to the binary fringes in the slightly defocused region, ensuring that the captured fringes are within the optimal defocus range. Three-dimensional surface topography measurement is conducted based on this approach. Experimental results show that the proposed method reduces the error in the specular component from 0.033 mm to 0.019 mm, thereby improving the accuracy of composite surface measurement.

-

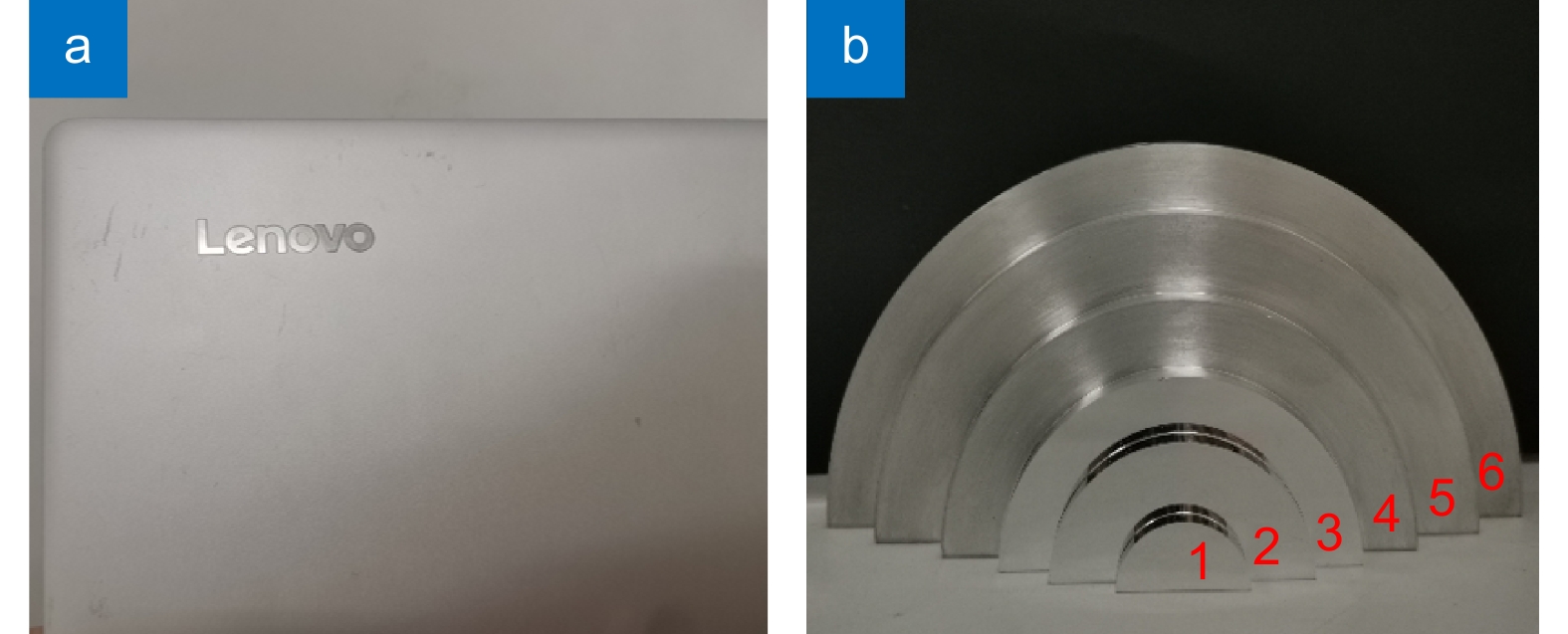

Overview: In the field of smart manufacturing, there is a growing need for the precise measurement of composite surface components exhibiting both specular and diffuse reflection characteristics. The construction of a measurement system based on fringe projection and phase-shifting deflectometry allows for the non-destructive and rapid acquisition of three-dimensional information for composite surface objects. However, the structured light by reflecting from the measured surface, exhibits different imaging positions, significantly increasing the difficulty in camera focusing and leading to defocusing blur issues, causing phase errors.

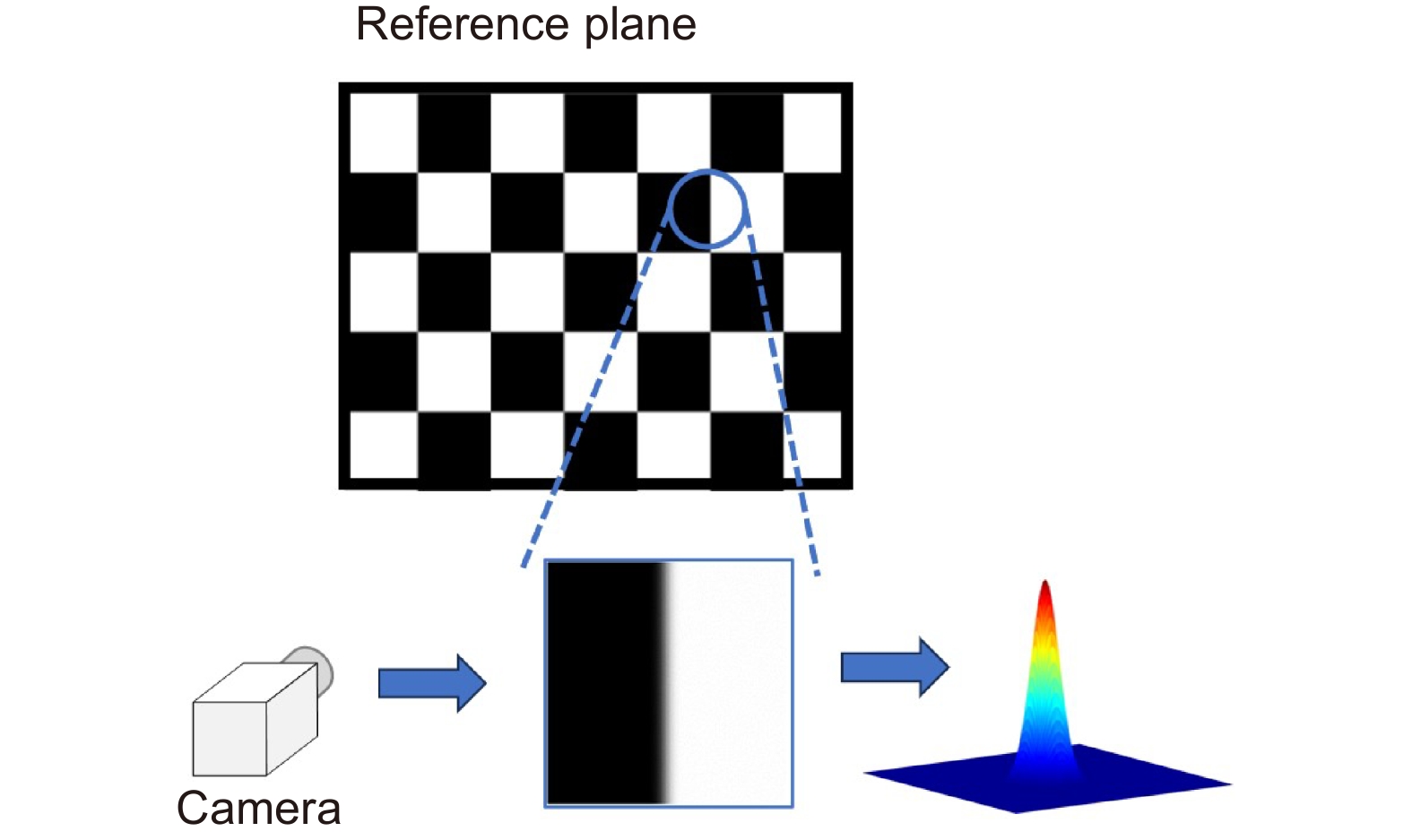

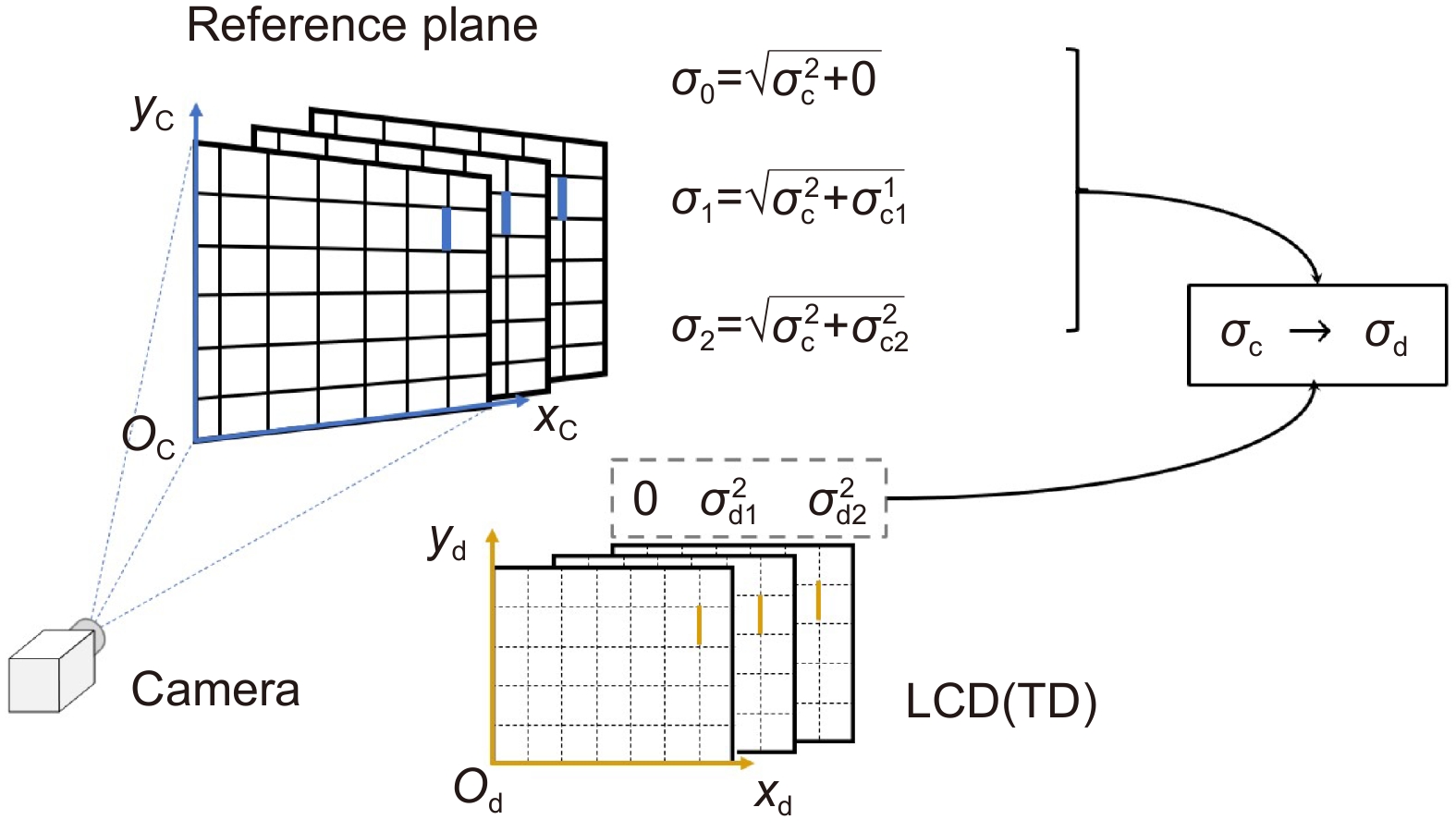

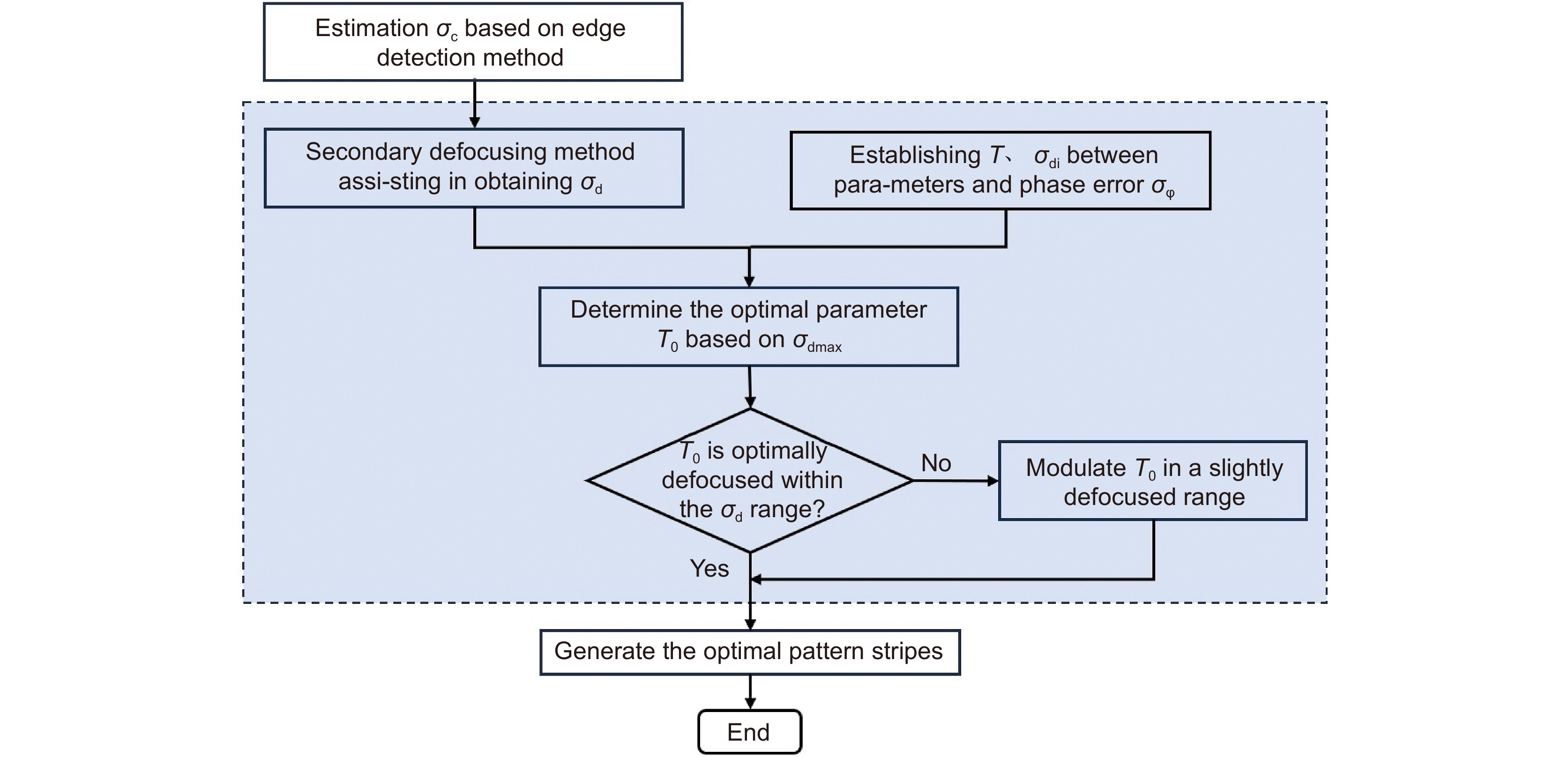

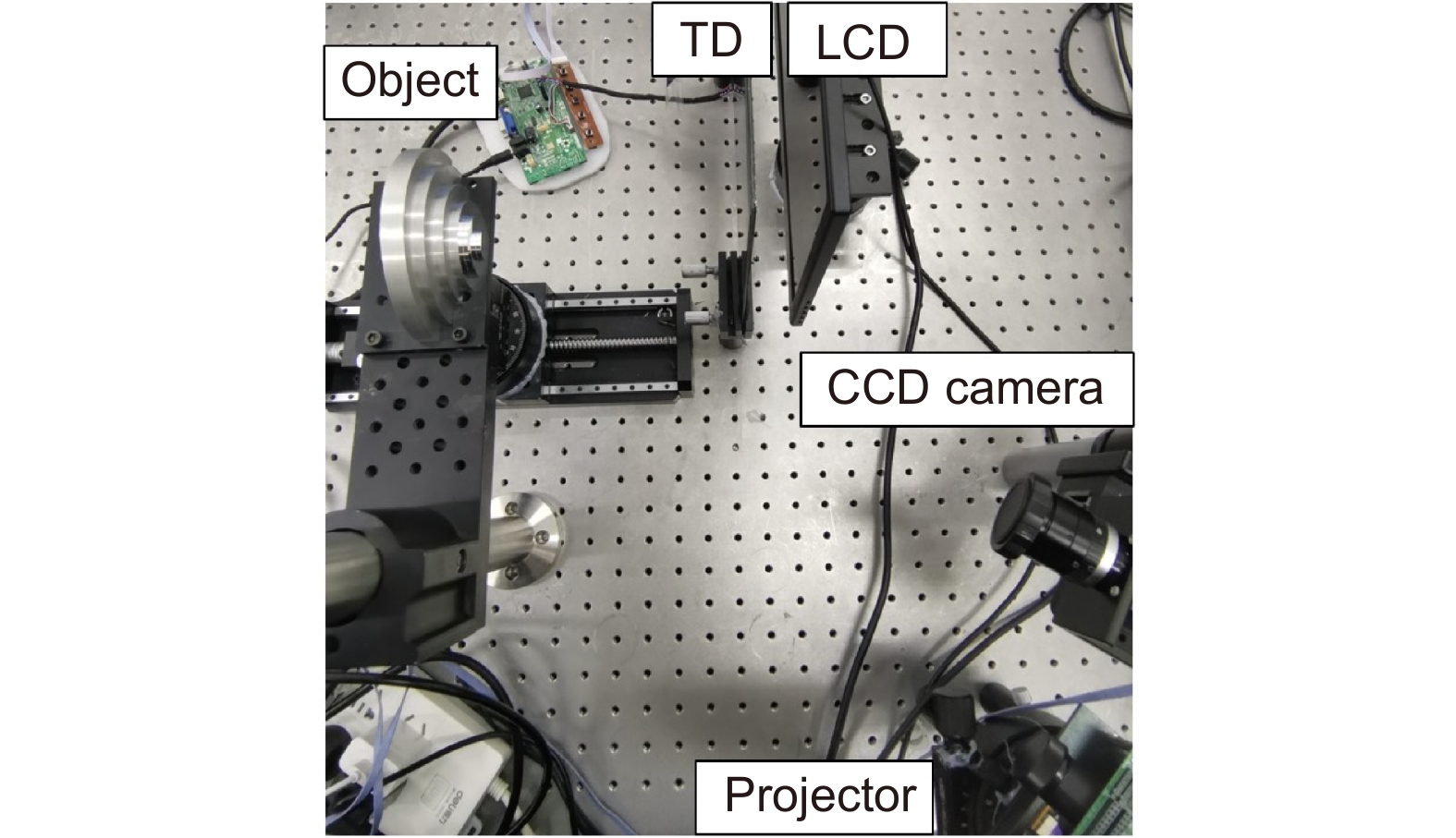

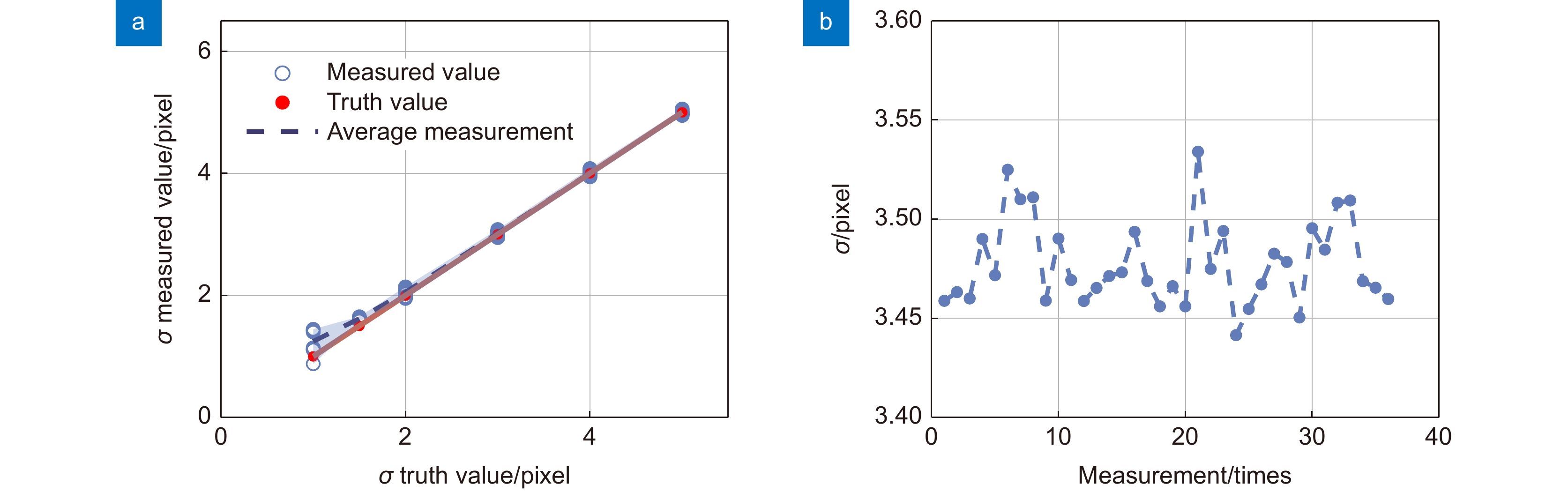

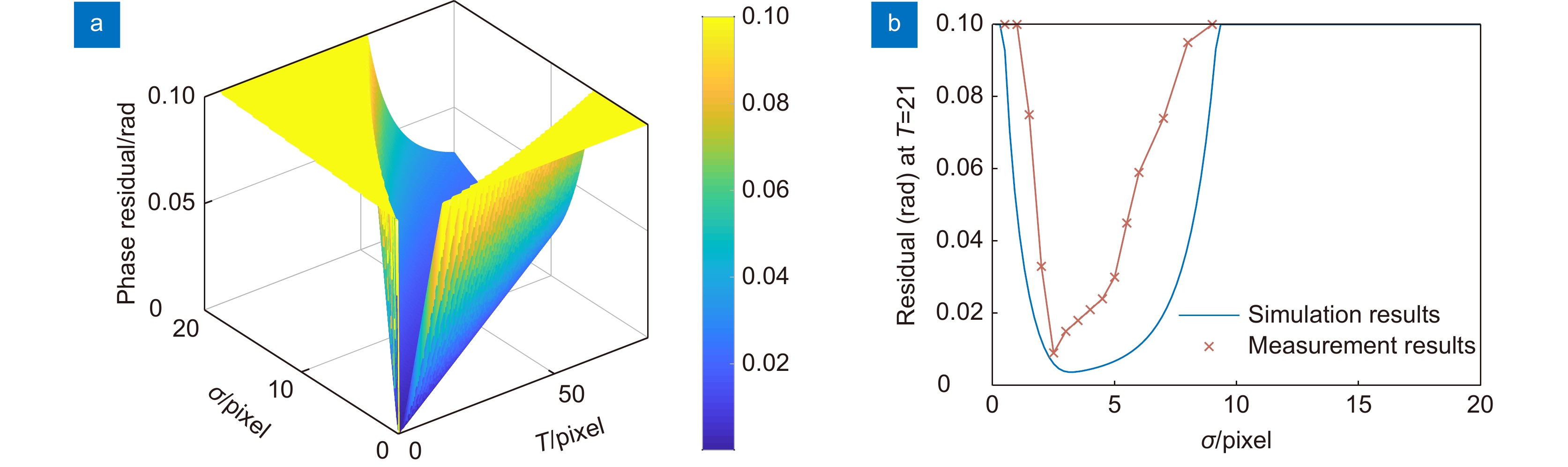

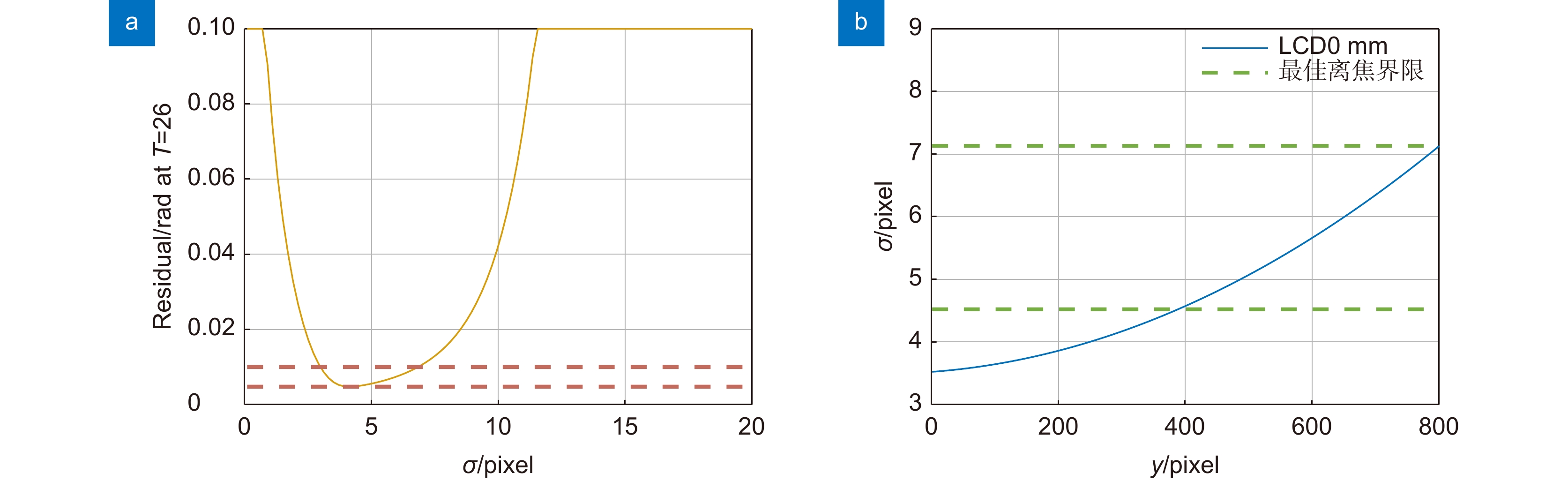

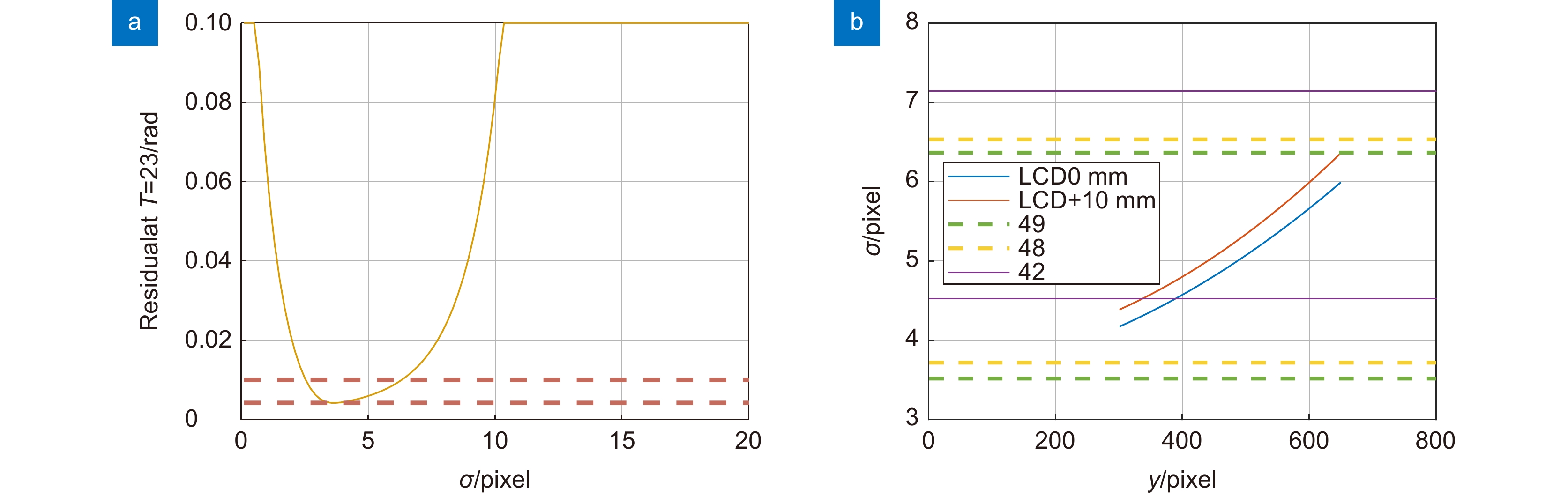

To expand the system measurement range and achieve the efficient and high-precision measurement of composite surface objects, this paper proposes a method for three-dimensional surface topography measurement by combining defocused binary patterns with sinusoidal fringes. Firstly, considering the varying defocus levels on the same plane due to the angle between the camera and the reference plane, the paper introduces a method combining the edge and second-order blur methods. It utilizes a chessboard pattern to accurately partition and quantify the defocus level, completing system defocus calibration. Secondly, based on the established model of optimal defocus, period, and phase error for binary fringes, and considering the actual blur level within the system measurement range, the paper selects the optimal width of binary fringes and the range of defocus, determining smooth regions with minimal phase error. Then, considering that the tilted placement of the camera may cause some regions of the fringes to deviate from sinusoidal behavior, slightly defocused fringes outside the smooth regions are pre-compensated with a Gaussian filter. This is done by calculating the parameters of the Gaussian function and convolving it with the fringes, ensuring that the deformed fringe patterns captured by the camera are within the optimal defocus range. This operation effectively suppresses high-order harmonics of binary fringes, expanding their applicability. Finally, appropriate binary fringes are displayed on two screens, and sinusoidal projection is displayed on the project, allowing the camera to capture clear sinusoidal and quasi-sinusoidal fringes. This method completes three-dimensional surface topography measurement for the composite surface.

The method employs the combination of the edge method and the second-order blur method for defocus assessment, achieving a measurement accuracy of 0.1 pixel or more and ensuring accurate measurement of full-field defocus in the dual-screen system. Experimental results show that the combination of binary and sinusoidal fringes proposed in this paper reduces errors in the specular part and the transition region between specular and diffuse components from 0.033 mm to 0.019 mm, enhancing the accuracy of composite surface measurement.

-

-

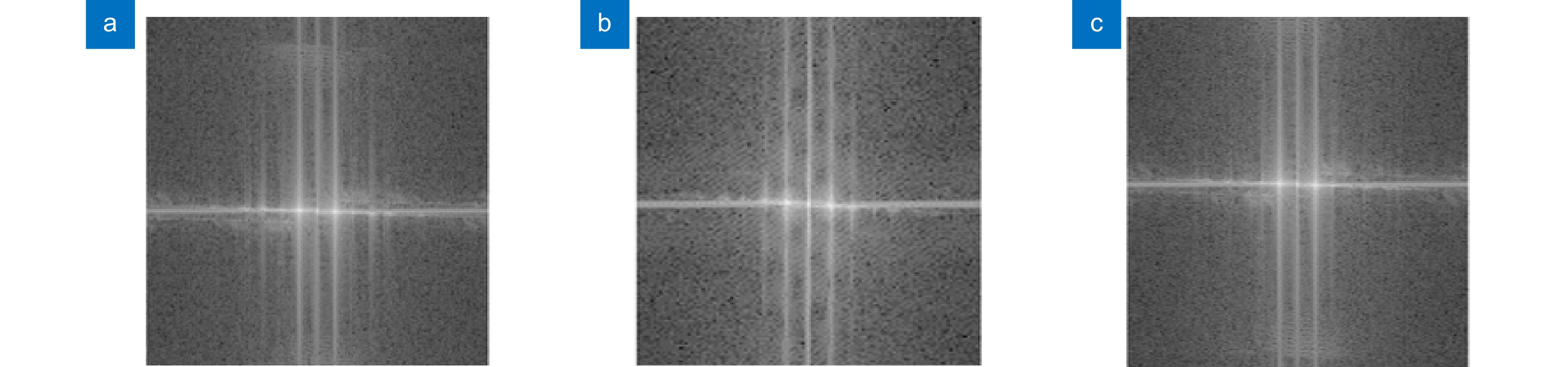

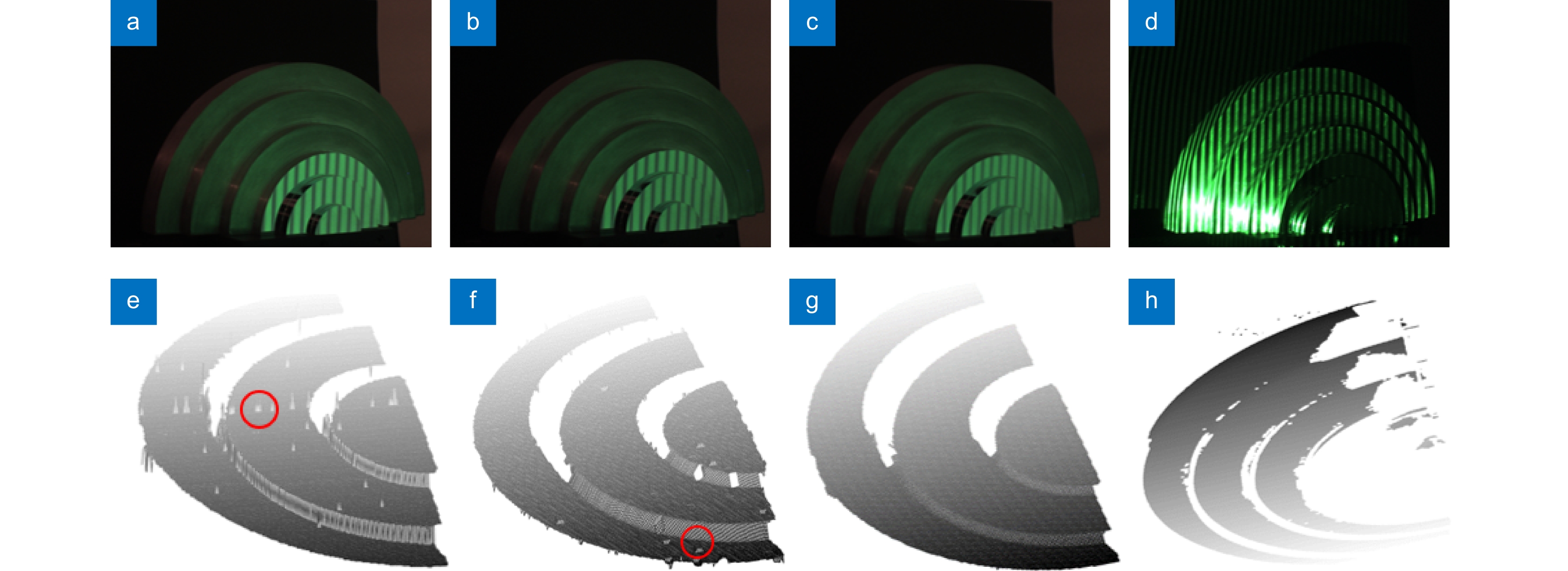

图 14 台阶相位展开及对比。(a)未调制的二值条纹图;(b)传统正弦条纹图;(c)调制后的二值条纹图;(d)正弦条纹图;(e)图(a)的绝对相位;(f)图(b)的绝对相位;(g)图(c)的绝对相位;(h)图(d)的绝对相位

Figure 14. Phase unwrapping and comparison of step. (a) Uncompensated binary fringes; (b) Sinusoidal fringes; (c) Compensated binary fringes; (d) Sinusoidal fringes; (e) Absolute phase of (a) ; (f) Absolute phase of (b) ; (g) Absolute phase of (c) ; (h) Absolute phase of (d)

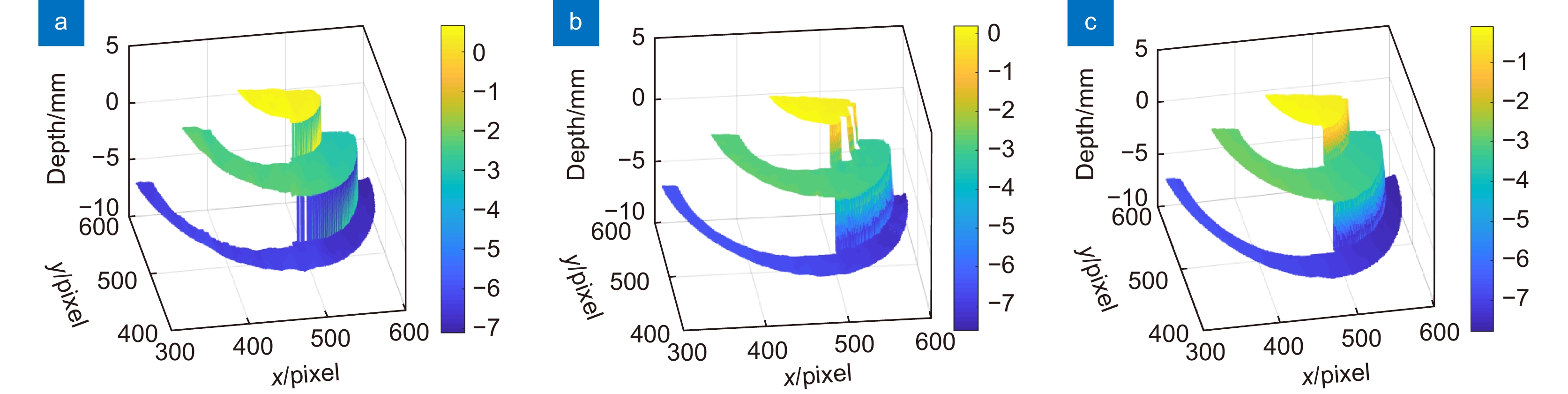

表 1 三维结果对比

Table 1. Comparison of three-dimensional results

Step

planeMeasured by

CMM /mmMeasured by

proposed value /mmAbsolute

error /mmBinary-sin

fringeSin fringe Binary-sin

fringeSin fringe 1-2 3.000 2.978 2.970 0.022 0.030 2-3 4.000 4.019 4.033 0.019 0.033 3-4 5.000 5.039 5.051 0.039 0.051 4-5 5.500 5.523 5.521 0.023 0.021 5-6 6.500 6.478 6.477 0.022 0.023 -

[1] Li Y X, Qian J M, Feng S J, et al. Deep-learning-enabled dual-frequency composite fringe projection profilometry for single-shot absolute 3D shape measurement[J]. Opto-Electron Adv, 2022, 5(5): 210021. doi: 10.29026/oea.2022.210021

[2] 王月敏, 张宗华, 高楠, 等. 基于全场条纹反射的镜面物体三维面形测量综述[J]. 光学 精密工程, 2018, 26(5): 1014−1027. doi: 10.3788/OPE.20182605.1014

Wang Y M, Zhang Z H, Gao N, et al. Review on three-dimensional surface measurements of specular objects based on full-field fringe reflection[J]. Opt Precis Eng, 2018, 26(5): 1014−1027. doi: 10.3788/OPE.20182605.1014

[3] 向卓龙, 张启灿, 吴周杰. 结构光投影三维面形测量及纹理贴图方法[J]. 光电工程, 2022, 49(12): 220169. doi: 10.12086/oee.2022.220169

Xiang Z L, Zhang Q C, Wu Z J. 3D shape measurement and texture mapping method based on structured light projection[J]. Opto-Electron Eng, 2022, 49(12): 220169. doi: 10.12086/oee.2022.220169

[4] Liu X H, Zhang Z H, Gao N, et al. 3D shape measurement of diffused/specular surface by combining fringe projection and direct phase measuring deflectometry[J]. Opt Express, 2020, 28(19): 27561−27574. doi: 10.1364/OE.402432

[5] 刘硕, 张宗华, 高楠, 等. 复合表面形貌测量中通道串扰和色差消除方法[J]. 光电工程, 2023, 50(4): 220340. doi: 10.12086/oee.2023.220340

Liu S, Zhang Z H, Gao N, et al. Elimination method of crosstalk and chromatic aberration between color channels for composite surface measurement[J]. Opto-Electron Eng, 2023, 50(4): 220340. doi: 10.12086/oee.2023.220340

[6] Zhang S. High-speed 3D shape measurement with structured light methods: a review[J]. Opt Lasers Eng, 2018, 106: 119−131. doi: 10.1016/j.optlaseng.2018.02.017

[7] 付莉娜, 杨静雯, 李雁玲, 等. 二值条纹离焦投影技术综述[J]. 激光与光电子学进展, 2022, 59(14): 1415011. doi: 10.3788/LOP202259.1415011

Fu L N, Yang J W, Li Y L, et al. Binary fringe defocused projection technology: a review[J]. Laser Optoelectron Prog, 2022, 59(14): 1415011. doi: 10.3788/LOP202259.1415011

[8] 邢生平, 蔡宁, 林斌. 基于蚁群相位抖动优化的高质量三维形貌测量[J]. 光电工程, 2021, 48(7): 210114. doi: 10.12086/oee.2021.210114

Xing S P, Cai N, Lin B. High-quality 3D shape measurement based on ant colony phase jitter optimization[J]. Opto-Electron Eng, 2021, 48(7): 210114. doi: 10.12086/oee.2021.210114

[9] Wang Y F, Zhao H J, Jiang H Z, et al. Defocusing parameter selection strategies based on PSF measurement for square-binary defocusing fringe projection profilometry[J]. Opt Express, 2018, 26(16): 20351−20367. doi: 10.1364/OE.26.020351

[10] Hu Y, Liu Z, Yang D Z, et al. Online fringe pitch selection for defocusing a binary square pattern projection phase-shifting method[J]. Opt Express, 2020, 28(21): 30710−30725. doi: 10.1364/OE.409046

[11] Zheng Y, Wang Y J, Li B W. Active shape from projection defocus profilometry[J]. Opt Lasers Eng, 2020, 134: 106277. doi: 10.1016/j.optlaseng.2020.106277

[12] Zheng Z J, Gao J, Zhang L Y, et al. A novel defocus-degree-based phase unwrapping and fusion algorithm for high-speed and large-depth-range 3D measurement[J]. IEEE Trans Ind Electron, 2023, 70(4): 4278−4288. doi: 10.1109/TIE.2022.3176265

[13] Shi Y Q, Chang C X, Liu X H, et al. Infrared phase measuring deflectometry by using defocused binary fringe[J]. Opt Lett, 2021, 46(13): 3091−3094. doi: 10.1364/OL.431044

[14] Rao G, Song L B, Zhang S, et al. Depth-driven variable-frequency sinusoidal fringe pattern for accuracy improvement in fringe projection profilometry[J]. Opt Express, 2018, 26(16): 19986−20008. doi: 10.1364/OE.26.019986

[15] 孟浩, 李博, 杨耀森. 基于刃边法的红外图像目标信息复原[J]. 激光与红外, 2020, 50(3): 374−379. doi: 10.3969/j.issn.1001-5078.2020.03.020

Meng H, Li B, Yang Y S. Restoration of infrared image target information based on edge method[J]. Laser Infrared, 2020, 50(3): 374−379. doi: 10.3969/j.issn.1001-5078.2020.03.020

[16] 田思恒, 黄永梅, 徐杨杰, 等. 利用离焦光斑的离轴望远镜失调校正方法研究[J]. 光电工程, 2023, 50(7): 230040. doi: 10.12086/oee.2023.230040

Tian S H, Huang Y M, Xu Y J, et al. Study of off-axis telescope misalignment correction method using out-of-focus spot[J]. Opto-Electron Eng, 2023, 50(7): 230040. doi: 10.12086/oee.2023.230040

[17] Li J L, Hassebrook L G, Guan C. Optimized two-frequency phase-measuring-profilometry light-sensor temporal-noise sensitivity[J]. J Opt Soc Am A, 2003, 20(1): 106−115. doi: 10.1364/JOSAA.20.000106

[18] Servin M, Padilla M, Garnica G. Statistical theory of digital interferometry: a tutorial with applications to fringe projection profilometry[J]. Opt Lasers Eng, 2022, 150: 106848. doi: 10.1016/j.optlaseng.2021.106848

[19] 肖月新, 张宗华, 刘硕, 等. 基于条纹投影和双屏投射显示的复合表面三维形貌测量方法[J]. 激光与光电子学进展, 2023, 60(3): 1006−4125.

Xiao Y X, Zhang Z H, Liu S, et al. Method for three-dimensional shape measurements of composite surface based on fringe proiection and dual-transparent display screens[J]. Laser Optoelectron Prog, 2023, 60(3): 1006−4125.

[20] Towers C E, Towers D P, Jones J D C. Absolute fringe order calculation using optimised multi-frequency selection in full-field profilometry[J]. Opt Lasers Eng, 2005, 43(7): 788−800. doi: 10.1016/j.optlaseng.2004.08.005

[21] 楚冬娅, 张广汇, 宋仁杰, 等. 先验知识辅助的条纹投影动态三维形貌测量[J]. 光电工程, 2022, 49(8): 210449. doi: 10.12086/oee.2022.210449

Chu D Y, Zhang G H, Song R J, et al. Priori knowledge assisted dynamic 3D shape measurement with fringe projection[J]. Opto-Electron Eng, 2022, 49(8): 210449. doi: 10.12086/oee.2022.210449

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: