-

摘要

随着蓝光半导体激光器的发展和应用范围的拓宽,利用合束技术来获得高亮度的蓝光光源已经成为研究的热点。为了获取高亮度的蓝光输出,本文应用光学设计软件进行模拟仿真,将48只波长为450 nm、输出功率为3.5 W的单管半导体激光器通过快慢轴准直和空间合束,聚焦耦合进105 μm/0.22NA的光纤中,可获得功率为144.7 W、亮度为11 MW/(cm2·str)的蓝光输出,耦合效率为93.78%,整体系统的光-光转换效率为86.13%。

Abstract

With the development and application of blue semiconductor lasers, it has become a research hotspot to obtain high brightness blue light source by beam combining technology. In order to obtain high brightness blue light output, 48 single tube semiconductor lasers with wavelength of 450 nm and output power of 3.5 W are focused and coupled into 105 μm/0.22 NA fiber by fast slow axis collimation and spatial beam combination. The blue light with power of 144.7 W and brightness of 11 MW/(cm2·str) is obtained. The coupling efficiency is 93.78%, and the optical to optical conversion efficiency of the whole system is 86.13%.

-

Key words:

- blue light /

- high brightness /

- fiber coupling /

- beam combining technology

-

Overview

Overview: Blue laser diodes (LDs) having the advantages of compact construction, long operating lifetime, and short-wavelength are extremely attractive for many applications, such as laser display, material processing, etc. To date, it has become one of the favorable lasers in welding copper-based alloy materials because the blue light absorption rate is 5~12 times greater than that of the near-infrared light for such materials. However, the highest output power of commercialized blue LDs is only 5 W. It cannot be used directly in laser welding unless the needed high-power output can be achieved by combining hundreds of such blue LDs. In 2020, NUBURU, an American company, showed 1500 Watts of blue laser output from a 100 μm core, NA=0.22 fiber for the first time. It is the highest level of output brightness of blue diode lasers so far in the world. Some achievements have also been made in China in recent years, and BWT Corporation has developed a blue laser with an output power of 500 W from a 400 μm core fiber with a 0.22 NA. However, the output brightness of laser seems to be insufficient for laser welding.

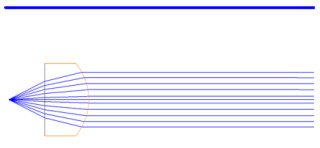

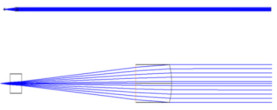

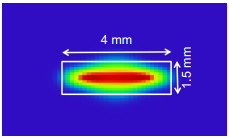

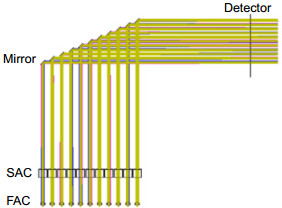

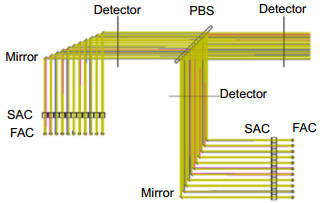

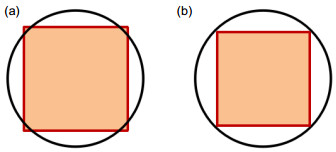

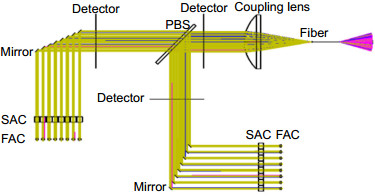

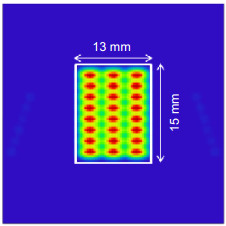

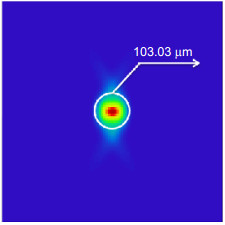

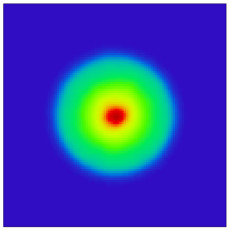

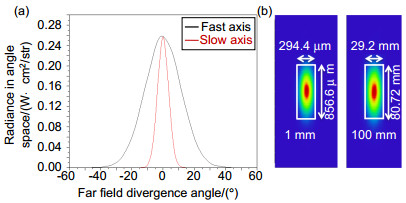

In this paper, we designed a high brightness blue LD module by using optical design software ZEMAX, where 48 blue LDs with 3.5 W output power were combined into a beam and efficiently coupled into a fiber with 105 μm core, 0.22 NA. Because of the large divergences, collimation was implemented before beam combination. The fast and slow axis collimating lenses with effective focal lengths of 1.65 mm and 16 mm are used. After that, the spot size of the fast and slow axis is 1.5 mm×4 mm, and the divergence half-angle is 0.043°×0.06°. Multiple such beams were spatially combined. To further improve the output power without deteriorating the beam quality, the polarization beam combining technology was used to double the output power. By theoretical analysis of fiber coupling conditions, four arrays constituted by combined beams, which are 6×3, 7×3, 8×3, and 9×3 arranged in fast and slow axis, are obtained. The output power and coupling efficiency of these four arrays are 108.97 W/94.18%, 126.83 W/93.93%, 144.7 W/93.78%, and 157.91 W/91%. The combination of 6×3 completely meets the fiber coupling conditions, and the focused light spot completely falls into the fiber core. But the latter three arrays cannot fully meet the fiber coupling conditions, and the focused light spot cannot entirely fall into the fiber core. If we regarded the coupling loss of 6×3 array as a reference, and the relative losses of the arrays of 7×3, 8×3 and 9×3 are 0.27%, 0.42%, and 3.38%, respectively. It can be seen that the 8×3 array is a better choice because the coupling loss only increases by 0.42%, but the output power increases by 32.7% compared with the 6×3 array. The output brightness is calculated to be 11 MW/(cm2·str). The total optical to optical conversion efficiency is 86.13%. As a result, the output power is further improved by slightly increasing the coupling loss, which provides a technical reference for making high brightness fiber-coupled LD modules in the future.

-

-

表 1 蓝光LD的主要参数

Table 1. The main parameters of blue LDs

Parameter Symbol Type Center wavelength/nm λd 450 Half angle divergence of fast axis/(°) θfast 22.5 Half divergence angle of slow axis/(°) θslow 7 Light-emitting size of fast axis/µm Dfast 1 Light-emitting size of slow axis/µm Dslow 30 Output power/W P 3.5 表 2 准直前后快慢轴的光束参数

Table 2. The beam parameters of fast and slow axis before and after collimation

D/mm θ/mrad BPP/(mm·mrad) Before fast axis collimation 0.001 392.699 0.196 After fast axis collimation 1.5 0.75 0.563 Before slow axis collimation 0.03 122.173 1.833 After slow axis collimation 4 1.047 2.09 表 3 快轴单管数量变化时耦合输出参数对比

Table 3. The comparison of various parameters for the number of LDs in the fast axis

m×n The output power of optical fiber coupling/W Coupling efficiency/% Relative loss/% 6×3 108.97 94.18 0 7×3 126.83 93.93 0.27 8×3 144.7 93.78 0.42 9×3 157.91 91 3.38 -

参考文献

[1] 曹宇轩, 舒世立, 孙方圆, 等. 中红外半导体激光器合束技术研究进展(特邀)[J]. 红外与激光工程, 2018, 47(10): 1003002. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201810002.htm

Cao Y X, Shu S L, Sun F Y, et al. Development of beam combining technology in mid-infrared semiconductor lasers(invited)[J]. Infrared Laser Eng, 2018, 47(10): 1003002. https://www.cnki.com.cn/Article/CJFDTOTAL-HWYJ201810002.htm

[2] Li X H, Liu X M, Gong Y K, et al. A novel erbium/ytterbium co-doped distributed feedback fiber laser with single-polarization and unidirectional output[J]. Laser Phys Lett, 2010, 7(1): 55-59. doi: 10.1002/lapl.200910100

[3] Li X H, Wang Y S, Zhao W, et al. All-fiber dissipative solitons evolution in a compact passively Yb-doped mode-locked fiber laser[J]. J Lightwave Technol, 2012, 30(15): 2502-2507. doi: 10.1109/JLT.2012.2201210

[4] Li X H, Wang Y G, Wang Y S, et al. Yb-doped passively mode-locked fiber laser based on a single wall carbon nanotubes wallpaper absorber[J]. Opt Laser Technol, 2013, 47: 144-147. doi: 10.1016/j.optlastec.2012.08.010

[5] 周睿. 高功率连续运转全固态蓝光、红光激光器研究[D]. 天津: 天津大学, 2006.

Zhou R. High-power continuous-wave all-solid-state blue and red laser[D]. Tianjin: Tianjin University, 2006.

[6] 高伟男, 许祖彦, 毕勇, 等. 激光显示技术发展的现状和趋势[J]. 中国工程科学, 2020, 22(3): 85-91. https://www.cnki.com.cn/Article/CJFDTOTAL-GCKX202003014.htm

Gao W N, Xu Z Y, Bi Y, et al. Present development and tendency of laser display technology[J]. Strateg Study CAE, 2020, 22(3): 85-91. https://www.cnki.com.cn/Article/CJFDTOTAL-GCKX202003014.htm

[7] Grupp M, Reinermann N. Copper welding with high-brightness fiber lasers: process stabilization by high dynamic beam deflection[J]. Laser Technik J, 2017, 14(3): 25-29. doi: 10.1002/latj.201700014

[8] Keller C. Processing of highly reflective materials: Improving metal cutting with high power fiber lasers by examination of backreflected light[J]. Laser Technik J, 2017, 14(4): 30-33. doi: 10.1002/latj.201700024

[9] König H, Lell A, Stojetz B, et al. Blue 450nm high power semiconductor continuous wave laser bars exceeding rollover output power of 80W[J]. Proc SPIE, 2018, 10514: 1051402. http://adsabs.harvard.edu/abs/2018SPIE10514E..02K

[10] Sa M S, Finuf M, Fritz R, et al. Blue laser diode (450 nm) systems for welding copper[J]. Proc SPIE, 2018, 10514: 1051407. http://www.researchgate.net/publication/323270555_Blue_laser_diode_450_nm_system_for_welding_copper

[11] Feve J P, Finuf M, Fritz R, et al. Scalable blue laser system architecture[J]. Proc SPIE, 2020, 11262: 112620P. http://www.researchgate.net/publication/339638075_Scalable_blue_laser_system_architecture

[12] [13] Zhao P F, Wang Z N, Yu H J, et al. 12-W continuous-wave green output from a 200-μm fiber-coupled diode laser based on TO-Can packaged emitters[J]. Appl Opt, 2018, 57(9): 2263-2267. doi: 10.1364/AO.57.002263

[14] Wu Y L, Dong Z Y, Chen Y Q, et al. Beam shaping for kilowatt fiber-coupled diode lasers by using one-step beam cutting-rotating of prisms[J]. Appl Opt, 2016, 55(34): 9769-9773. doi: 10.1364/AO.55.009769

[15] Unger A, Köhler B, Biesenbach J. High-power visible spectrum diode lasers for display and medical applications: beam sources with tailored beam quality and spectral characteristics[J]. Proc SPIE, 2014, 8965: 896513. http://proceedings.spiedigitallibrary.org/mobile/proceeding.aspx?articleid=1846047

[16] Balck A, Baumann M, Malchus J, et al. 700 W blue fiber-coupled diode-laser emitting at 450 nm[J]. Proc SPIE, 2018, 10514: 1051403. http://adsabs.harvard.edu/abs/2018SPIE10514E..03B

[17] Baumann M, Balck A, Malchus J, et al. 1000 W blue fiber-coupled diode-laser emitting at 450 nm[J]. Proc SPIE, 2019, 10900: 1090005. http://www.researchgate.net/publication/331513674_1000_W_blue_fiber-coupled_diode-laser_emitting_at_450_nm

[18] Chin R H, Dogan M, Fulghum S, et al. 1kW fiber-coupled pump-module at 976nm with 50% efficiency[J]. Opt Express, 2017, 25(15): 17695-17700. doi: 10.1364/OE.25.017695

[19] 刘翠翠, 王鑫, 井红旗, 等. 三波长合束单管激光器光纤耦合模块设计[J]. 发光学报, 2018, 39(3): 337-342. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201803012.htm

Liu C C, Wang X, Jing H Q, et al. Design of fiber-coupled laser diode module based on three-wavelengths multiplexing by ZEMAX[J]. Chin J Lumin, 2018, 39(3): 337-342. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201803012.htm

[20] Kaifuchi Y, Yamagata Y, Nogawa R, et al. Ultimate high power operation of 9xx-nm single emitter broad stripe laser diodes[J]. Proc SPIE, 2017, 10086: 100860D. http://spie.org/Publications/Proceedings/Paper/10.1117/12.2251145

[21] Price K, Karlsen S, Leisher P, et al. High-brightness fiber-coupled pump laser development[J]. Proc SPIE, 2010, 7583: 758308. doi: 10.1117/12.842102

[22] Wang Z L, Drovs S, Segref A, et al. Fiber coupled diode laser beam parameter product calculation and rules for optimized design[J]. Proc SPIE, 2011, 7918: 791809. doi: 10.1117/12.875386

[23] Pierer J, Lützelschwab M, Grossmann S, et al. Automated assembly processes of high power single emitter diode lasers for 100W in 105 μm/NA 0.15 fiber module[J]. Proc SPIE, 2011, 7918: 79180I. http://www.researchgate.net/publication/252499324_Automated_assembly_processes_of_high_power_single_emitter_diode_lasers_for_100W_in_105_mm_NA_015_fiber_module

[24] 李枫, 耿超, 黄冠, 等. 基于光纤耦合的光纤激光阵列像差探测[J]. 光电工程, 2018, 45(4): 78-89. doi: 10.12086/oee.2018.170691

Li F, Geng C, Huang G, et al. Wavefront sensing based on fiber coupling of the fiber laser array[J]. Opto-Electron Eng, 2018, 45(4): 78-89. doi: 10.12086/oee.2018.170691

[25] Zediker M S, Fritz R D, Finuf M J, et al. Laser welding components for electric vehicles with a high-power blue laser system[J]. J Laser Appl, 2020, 32(2): 022038. doi: 10.2351/7.0000054

[26] Feve J P, Finuf M, Fritz R, et al. Scalable blue laser system architecture[J]. Proc SPIE, 2020, 11262: 112620P. http://www.researchgate.net/publication/339638075_Scalable_blue_laser_system_architecture

[27] 朱洪波, 郝明明, 刘云, 等. 808nm高亮度半导体激光器光纤耦合器件[J]. 光学精密工程, 2012, 20(8): 1684-1690. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201208006.htm

Zhu H B, Hao M M, Liu Y, et al. 808 nm high brightness module of fiber coupled diode laser[J]. Opt Precision Eng, 2012, 20(8): 1684-1690. https://www.cnki.com.cn/Article/CJFDTOTAL-GXJM201208006.htm

[28] 张志军. 大功率半导体激光器合束技术及应用研究[D]. 长春: 中国科学院大学, 2013.

Zhang Z J. Research on high-power semiconductor laser beam combiner technology and application[D]. Changchun: University of Chinese Academy of Sciences, 2013.

[29] 周泽鹏, 薄报学, 高欣, 等. 基于ZEMAX高功率半导体激光器光纤耦合设计[J]. 发光学报, 2013, 34(9): 1208-1212. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201309026.htm

Zhou Z P, Bo B X, Gao X, et al. Fiber coupling design of high power semiconductor laser based on ZEMAX[J]. Chin J Lumin, 2013, 34(9): 1208-1212. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201309026.htm

[30] 虞天成. 单管半导体激光器光纤耦合技术研究[D]. 苏州: 苏州大学, 2015.

Yu T C. Design of fiber coupling of single emitters diode laser[D]. Suzhou: Soochow University, 2015.

[31] 王智宁. 高亮度半导体绿光激光器单管合束及光纤耦合的研究[D]. 长春: 长春理工大学, 2018.

Wang Z N. Research on single emitter beam combination and fiber coupling of high-brightness semiconductor green laser[D]. Changchun: Changchun University of Science and Technology, 2018.

[32] 周闯. 绿光半导体激光器单管合束及光纤耦合技术研究[D]. 西安: 西安电子科技大学, 2019.

Zhou C. Research on green single emitter diode laser combination and fiber coupling technology[D]. Xi'an: Xidian University, 2019.

[33] Pierer J, Lützelschwab M, Grossmann S, et al. Automated assembly processes of high power single emitter diode lasers for 100W in 105 μm/NA 0.15 fiber module[J]. Proc SIPE, 2011, 7918: 79180I. http://www.researchgate.net/publication/252499324_Automated_assembly_processes_of_high_power_single_emitter_diode_lasers_for_100W_in_105_mm_NA_015_fiber_module

[34] 朱洪波, 刘云, 郝明明, 等. 高效率半导体激光器光纤耦合模块[J]. 发光学报, 2011, 32(11): 1147-1151. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201111013.htm

Zhu H B, Liu Y, Hao M M, et al. High efficiency module of fiber coupled diode laser[J]. Chin J Lumin, 2011, 32(11): 1147-1151. https://www.cnki.com.cn/Article/CJFDTOTAL-FGXB201111013.htm

[35] Unger A, Küster M, Köhler B, et al. High-power fiber-coupled 100W visible spectrum diode lasers for display applications[J]. Proc SPIE, 2013, 8605: 86050K. doi: 10.1117/12.2001837

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: