-

摘要:

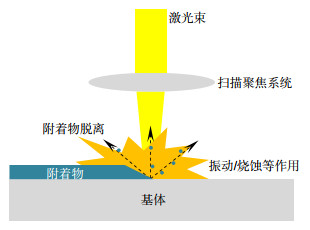

激光清洗是利用激光高能量特点去除基体表面附着物的表面工程技术,逐渐在微电子、模具、建筑和航空航天等领域示范应用。石化作为国民经济的支柱产业,却鲜有激光清洗技术应用的报道。本文介绍了石化领域清洗需求和技术现状,发现现有技术不能完全满足石化行业发展新要求,综述了近年来国内外激光清洗技术的发展,其为激光清洗在石化领域的应用提供了理论基础和思路参考,分析了激光清洗技术在石化领域的应用场合,并浅析了具体的研究方向及应用前景。

Abstract:Laser cleaning is a surface engineering technology which uses the high-energy characteristic of laser to remove attachments on the substrate. It has been gradually promoted in the fields of microelectronics, mould, building, aerospace, and so on. However, as a pillar industry of national economy, there are rare reports on the application of laser cleaning technology in petrochemical industry. In this paper, the cleaning needs and technology status of petrochemical industry are introduced, the existing technology cannot fully meet the new requirements of petrochemical industry development. The development of laser cleaning technology both at home and abroad in recent years is reviewed, the work has provided a theoretical basis and ideal reference for the application of laser cleaning in the petrochemical field. And the application occasions of laser cleaning technology in petrochemical field are analyzed. In addition, the specific research directions and application prospect are pointed out.

-

Key words:

- laser cleaning technology /

- petrochemical field /

- application occasion

-

Overview:Laser cleaning is a surface engineering technology that uses the high-energy characteristic of laser to remove attachments on the substrate. It was first applied in the field of microelectronics. Because of its green environmental protection, high efficiency, high precision, and wide application range, it has been gradually promoted in the fields of mould, building, ship, aerospace, high-speed railway, and so on. It is regarded as the most potential cleaning technology in the 21st century. As a pillar industry of national economy, there are rare reports on the application of laser cleaning technology in petrochemical industry. During the operation of petrochemical equipment, many kinds of dirt (such as atmospheric dirt, water scale and the dirt generated by chemical reaction) are deposited, and defects (such as wear and corrosion) may be generated in critical areas and parts of the equipment. Whether it is dirt removal or surface cleaning before defect detection, cleaning technology is needed. Petrochemical industry now commonly uses chemical cleaning technology and physical cleaning technology. Chemical cleaning technology produces waste liquid and waste water, which will cause the problem of environmental protection. The physical cleaning technology includes traditional poking, brushing, grinding, shoveling and so on, which is highly labor intensive and inefficient. Later, PIG cleaning technology and jet cleaning technology (such as sandblast cleaning, shot peening cleaning, dry ice cleaning, and high-pressure water jet cleaning) are developed. The former is only applicable to the internal cleaning of pipes and equipment, and the latter may cause accidental mechanical damage and wear to the cleaned objects. In addition, ultrasonic cleaning technology is harmful to human health due to its noise pollution, and drying process is needed after the cleaning. The demand of cleaning technology has become increasingly urged in modern petrochemical industry, the cleaning costs should be reduced and cleaning efficiency, and the quality should be improved. Moreover, the cleaning technology must be environmentally friendly. Obviously, chemical cleaning technology and traditional physical cleaning technology cannot fully meet these new requirements. Hence, it is necessary to explore and introduce new green cleaning technology, such as laser cleaning technology. In recent years, the work of mechanism research, experimental verification, process optimization, and practical applications conducted by domestic and foreign colleges, enterprises and research institutes has provided a theoretical basis and ideal reference for the application of laser cleaning in the petrochemical field. In this paper, the cleaning needs and technology status of petrochemical industry and the development of laser cleaning technology are introduced, and the application occasions of laser cleaning technology in petrochemical field are analyzed. In addition, the specific research directions and application prospect are pointed out.

-

-

-

[1] 史兴宽, 徐传义, 王健.超光滑基底表面污染微粒的激光清洗技术[J].中国机械工程, 2000, 11(10): 1138–1141. http://www.cnki.com.cn/article/cjfdtotal-zgjx200010019.htm

Shi X K, Xu C Y, Wang J. Research on mechanism of laser-assisted cleaning micron contaminate particulates on substrate with supersmooth surface[J]. China Mechanical Engineering, 2000, 11(10): 1138–1141. http://www.cnki.com.cn/article/cjfdtotal-zgjx200010019.htm

[2] 周桂莲, 吴俊飞, 陈建国, 等.激光技术应用于模具清洗[J].橡塑技术与装备, 2002, 28(9): 13–15. http://www.cnki.com.cn/Article/CJFDTotal-XJJZ200209006.htm

Zhou G L, Wu J F, Chen J G, et al. Laser technology applied for moulding cleaning[J]. China Rubber/Plastics Technology and Equipment, 2002, 28(9): 13–15. http://www.cnki.com.cn/Article/CJFDTotal-XJJZ200209006.htm

[3] 张自豪, 余晓畅, 王英, 等.脉冲YAG激光清洗轮胎模具的实验研究[J].激光技术, 2018, 42(1): 127–130. http://www.cqvip.com/QK/92283X/201801/74717483504849564849485053.html

Zhang Z H, Yu X C, Wang Y, et al. Experimental study about cleaning of tire molds with pulse YAG laser[J]. Laser Technology, 2018, 42(1): 127–130. http://www.cqvip.com/QK/92283X/201801/74717483504849564849485053.html

[4] 张秉坚, 铁景沪, 刘嘉玮.古建筑与石质文物的清洗技术[J].清洗世界, 2004, 20(5): 25–28. http://www.cnki.com.cn/Article/CJFDTotal-HXQX200405005.htm

Zhang B J, Tie J H, Liu J W. Cleaning technique for ancient architecture and stone relics[J]. Cleaning World, 2004, 20(5): 25–28. http://www.cnki.com.cn/Article/CJFDTotal-HXQX200405005.htm

[5] 叶亚云, 齐扬, 秦朗, 等.激光清除石质文物表面污染物[J].中国激光, 2013, 40(9): 0903005. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201309015.htm

Ye Y Y, Qi Y, Qin L, et al. Laser cleaning of contaminations on the surface of stone relics[J]. Chinese Journal of Lasers, 2013, 40(9): 0903005. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ201309015.htm

[6] 解宇飞, 刘洪伟, 胡永祥.船舶板材激光除锈工艺参数确定方法研究[J].中国激光, 2016, 43(4): 0403008. http://www.cqvip.com/QK/95389X/201604/668641538.html

Xie Y F, Liu H W, Hu Y X. Determining process parameters for laser derusting of ship steel plates[J]. Chinese Journal of Lasers, 2016, 43(4): 0403008. http://www.cqvip.com/QK/95389X/201604/668641538.html

[7] 刘洪伟, 周毅鸣.船用板材激光除锈应用技术[J].造船技术, 2016(6): 87–93. http://d.wanfangdata.com.cn/Periodical/zcjs201606016

Liu H W, Zhou Y M. Technology and application of optical fiber laser derusting of ship steel plates[J]. Marine Technology, 2016(6): 87–93. http://d.wanfangdata.com.cn/Periodical/zcjs201606016

[8] 靳森, 王静轩, 袁晓东, 等.飞机金属蒙皮以及复合材料表面激光除漆技术[J].航空制造技术, 2018, 61(17): 63–70. http://d.wanfangdata.com.cn/periodical/hkgyjs201817009

Jin S, Wang J X, Yuan X D, et al. Laser paint removal technology for aircraft metal skin and composite materials[J]. Aeronautical Manufacturing Technology, 2018, 61(17): 63–70. http://d.wanfangdata.com.cn/periodical/hkgyjs201817009

[9] 李帅, 李野, 李磐, 等.基于高功率光纤激光器的清漆剥离实验研究[J].红外与激光工程, 2017, 46(S1): S106008. http://d.old.wanfangdata.com.cn/Periodical_hwyjggc2017z1008.aspx

Li S, Li Y, Li P, et al. Study on the varnish stripping experiment based on the high power fiber laser[J]. Infrared and Laser Engineering, 2017, 46(S1): S106008. http://d.old.wanfangdata.com.cn/Periodical_hwyjggc2017z1008.aspx

[10] 王懿峰.浅谈石油化工设备的离线清洗[J].清洗世界, 2018, 34(8): 16–19. http://www.cnki.com.cn/Article/CJFDTotal-HXQX201808006.htm

Wang Y F. Discussion on off-line cleaning of petrochemical equipment[J]. Cleaning World, 2018, 34(8): 16–19. http://www.cnki.com.cn/Article/CJFDTotal-HXQX201808006.htm

[11] 靳兆文.石化设备清洗技术进展[J].化工设备与管道, 2008, 45(4): 62–64. http://d.wanfangdata.com.cn/Periodical/hgsbygd200804016

Jin Z W. Development of petrochemical equipment cleaning technology[J]. Process Equipment & Piping, 2008, 45(4): 62–64. http://d.wanfangdata.com.cn/Periodical/hgsbygd200804016

[12] Baidu contributors. Baidu image[EB/OL]. (2020-03). https://image.baidu.com.

[13] 周雅文, 徐宝财, 韩富.中国工业清洗技术应用现状与发展趋势[J].中国洗涤用品工业, 2010(1): 33–36. http://www.cnki.com.cn/Article/CJFDTotal-XDYP201001007.htm

Zhou Y W, Xu B C, Han F. Application status and developing trends of Chinese I & I cleaning technology[J]. China Cleaning Industry, 2010(1): 33–36. http://www.cnki.com.cn/Article/CJFDTotal-XDYP201001007.htm

[14] 周炳琨, 高以智, 陈倜嵘, 等.激光原理[M]. 7版.北京:国防工业出版社, 2014.

Zhou B K, Gao Y Z, Chen T R, et al. The Principle of Laser[M]. 7th ed. Beijing: National Defense Industry Press, 2014.

[15] Bedair S M, Smith Jr H P. Atomically clean surfaces by pulsed laser bombardment[J]. Journal of Applied Physics, 1969, 40(12): 4776–4781. doi: 10.1063/1.1657288

[16] Barone P, Stranges F, Barberio M, et al. Application of laser ablation to cleaning process of the corrosion chloride patina formed on bronze surfaces in air and marine water[J]. Journal of Physical Science and Application, 2013, 3(3): 135–140. http://www.cqvip.com/QK/71224X/201303/47176675.html

[17] 叶亚云, 袁晓东, 向霞, 等.激光冲击波清洗K9玻璃表面SiO2颗粒的研究[J].激光技术, 2011, 35(2): 245–248. http://d.wanfangdata.com.cn/Periodical/jgjs201102028

Ye Y Y, Yuan X D, Xiang X, et al. Clearance of SiO2 particles on K9 glass surfaces by means of laser shockwave[J]. Laser Technology, 2011, 35(2): 245–248. http://d.wanfangdata.com.cn/Periodical/jgjs201102028

[18] 宋峰, 刘淑静, 邹万芳, 等.蒸气式激光清洗[J].清洗世界, 2005, 21(9): 27–29, 34. http://d.wanfangdata.com.cn/Periodical/hxqx200509007

Song F, Liu S J, Zou W F, et al. Steam laser cleaning[J]. Cleaning World, 2005, 21(9): 27–29, 34. http://d.wanfangdata.com.cn/Periodical/hxqx200509007

[19] 雷正龙, 田泽, 陈彦宾.工业领域的激光清洗技术[J].激光与光电子学进展, 2018, 55(3): 030005. http://www.cnki.com.cn/Article/CJFDTotal-JGDJ201803005.htm

Lei Z L, Tian Z, Chen Y B. Laser cleaning technology in industrial fields[J]. Laser & Optoelectronics Progress, 2018, 55(3): 030005. http://www.cnki.com.cn/Article/CJFDTotal-JGDJ201803005.htm

[20] Mateo M P, Ctvrtnickova T, Fernandez E, et al. Laser cleaning of varnishes and contaminants on brass[J]. Applied Surface Science, 2009, 255(10): 5579–5583. doi: 10.1016/j.apsusc.2008.08.034

[21] Striova J, Salvadori B, Fontana R, et al. Optical and spectroscopic tools for evaluating Er:YAG laser removal of shellac varnish[J]. Studies in Conservation, 2015, 60(S1): S91–S96. http://www.tandfonline.com/doi/full/10.1179/0039363015Z.000000000213

[22] Senesi G S, Allegretta I, Porfido C, et al. Application of micro X-ray fluorescence and micro computed tomography to the study of laser cleaning efficiency on limestone monuments covered by black crusts[J]. Talanta, 2018, 178: 419–425. doi: 10.1016/j.talanta.2017.09.048

[23] Gemeda B T, Lahoz R, Caldeira A T, et al. Efficacy of laser cleaning in the removal of biological patina on the volcanic scoria of the rock-hewn churches of Lalibela, Ethiopia[J]. Environmental Earth Sciences, 2018, 77(2): 36. doi: 10.1007/s12665-017-7223-3

[24] Genna S, Lambiase F, Leone C. Effect of laser cleaning in Laser Assisted Joining of CFRP and PC sheets[J]. Composites Part B: Engineering, 2018, 145: 206–214. doi: 10.1016/j.compositesb.2018.03.032

[25] Maffini A, Uccello A, Dellasega D, et al. Laser cleaning of diagnostic mirrors from tungsten–oxygen tokamak-like contaminants[J]. Nuclear Fusion, 2016, 56(8): 086008. doi: 10.1088/0029-5515/56/8/086008

[26] Palomar T, Oujja M, Llorente I, et al. Evaluation of laser cleaning for the restoration of tarnished silver artifacts[J]. Applied Surface Science, 2016, 387: 118–127. doi: 10.1016/j.apsusc.2016.06.017

[27] 施曙东.脉冲激光除漆的理论模型、数值计算与应用研究[D].天津: 南开大学, 2012.

Shi S D. Researches on theoretical model, numerical simulation and application of painting removal by laser cleaning[D]. Tianjin: Nankai University, 2012.

http://cdmd.cnki.com.cn/Article/CDMD-10055-1013174824.htm [28] 鲜辉, 冯国英, 王绍朋.激光透过油漆层的理论分析及相关实验[J].四川大学学报(自然科学版), 2012, 49(5): 1036–1042. http://www.cnki.com.cn/Article/CJFDTotal-SCDX201205020.htm

Xian H, Feng G Y, Wang S P. Laser transmission model in paint and related experimental[J]. Journal of Sichuan University (Natural Science Edition), 2012, 49(5): 1036–1042. http://www.cnki.com.cn/Article/CJFDTotal-SCDX201205020.htm

[29] 刘彩飞, 冯国英, 邓国亮, 等.有限元法移动激光除漆的温度场分析与实验研究[J].激光技术, 2016, 40(2): 274–279. http://d.wanfangdata.com.cn/Periodical/jgjs201602026

Liu C F, Feng G Y, Deng G L, et al. Temperature field analysis and experiment study about paint irradiated by moving laser based on FEM[J]. Laser Technology, 2016, 40(2): 274–279. http://d.wanfangdata.com.cn/Periodical/jgjs201602026

[30] 陈康喜, 冯国英, 邓国亮, 等.基于发射光谱及成分分析的激光除漆机理研究[J].光谱学与光谱分析, 2016, 36(9): 2956–2960. http://d.wanfangdata.com.cn/Periodical/gpxygpfx201609044

Chen K X, Feng G Y, Deng G L, et al. Study on the mechanism of laser paint removal based on emission spectrum and composition analysis[J]. Spectroscopy and Spectral Analysis, 2016, 36(9): 2956–2960. http://d.wanfangdata.com.cn/Periodical/gpxygpfx201609044

[31] 陈林, 邓国亮, 冯国英, 等.基于LIBS及时间分辨特征峰的激光除漆机理研究[J].光谱学与光谱分析, 2018, 38(2): 367–371. http://d.old.wanfangdata.com.cn/Periodical/gpxygpfx201802007

Chen L, Deng G L, Feng G Y, et al. Study on the mechanism of laser paint removal based on LIBS and time resolved characteristic signal[J]. Spectroscopy and Spectral Analysis, 2018, 38(2): 367–371. http://d.old.wanfangdata.com.cn/Periodical/gpxygpfx201802007

[32] 宋峰, 邹万芳, 田彬, 等.一维热应力模型在调Q短脉冲激光除漆中的应用[J].中国激光, 2007, 34(11): 1577–1581. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ200711026.htm

Song F, Zou W F, Tian B, et al. Model of one-dimensional thermal stress applied in paint removal by Q-switched short pulse laser[J]. Chinese Journal of Lasers, 2007, 34(11): 1577–1581. http://www.cnki.com.cn/Article/CJFDTotal-JJZZ200711026.htm

[33] 田彬, 邹万芳, 何真, 等.脉冲Nd:YAG激光除漆实验[J].清洗世界, 2007, 23(10): 1–5. http://www.cqvip.com/Main/Detail.aspx?id=25666969

Tian B, Zou W F, He Z, et al. Paint removal experiment with pulsed Nd:YAG laser[J]. Cleaning World, 2007, 23(10): 1–5. http://www.cqvip.com/Main/Detail.aspx?id=25666969

[34] 胡太友, 乔红超, 陆莹, 等.激光除漆对Ti17合金表面组织性能的影响[J].表面技术, 2018, 47(3): 7–12. http://www.cnki.com.cn/Article/CJFDTotal-BMJS201803003.htm

Hu T Y, Qiao H C, Lu Y, et al. Effects of laser De-painting on microstructure and properties of Ti17 alloy[J]. Surface Technology, 2018, 47(3): 7–12. http://www.cnki.com.cn/Article/CJFDTotal-BMJS201803003.htm

[35] 郭为席, 胡乾午, 王泽敏, 等.高功率脉冲TEA CO2激光除漆的研究[J].光学与光电技术, 2006, 4(3): 32–35. http://www.cnki.com.cn/Article/CJFDTotal-GXGD200603009.htm

Guo W X, Hu Q W, Wang Z M, et al. Paint removal research on high power pulse TEA CO2 laser[J]. Optics & Optoelectronic Technology, 2006, 4(3): 32–35. http://www.cnki.com.cn/Article/CJFDTotal-GXGD200603009.htm

[36] 王泽敏, 曾晓雁, 黄维玲.脉冲激光除漆机理及工艺参数的研究[J].材料保护, 2000, 33(4): 21–22, 59. http://www.cqvip.com/QK/92398X/20004/4258395.html

Wang Z M, Zeng X Y, Huang W L. Parameters and mechanisms of palntcoat laser cleaning[J]. Materials Protection, 2000, 33(4): 21–22, 59. http://www.cqvip.com/QK/92398X/20004/4258395.html

[37] 王欢, 蔄诗洁, 刘丽飒, 等. LD泵浦声光调Q Nd:YAG激光扫描除锈机制[J].清洗世界, 2018, 34(5): 37–41. http://www.cqvip.com/QK/97451A/201805/675338454.html

Wang H, Man S J, Liu L S, et al. Mechanism of derusting by laser-diode pumped acousto-optic Q-switch Nd:YAG laser[J]. Cleaning World, 2018, 34(5): 37–41. http://www.cqvip.com/QK/97451A/201805/675338454.html

[38] 乔玉林, 赵吉鑫, 王思捷, 等.锈蚀表面的激光清洗及其元素组成分析[J].激光与红外, 2018, 48(3): 299–304. http://www.cnki.com.cn/Article/CJFDTotal-JGHW201803006.htm

Qiao Y L, Zhao J X, Wang S J, et al. Laser cleaning and elemental composition analysis of rusty surface[J]. Laser & Infrared, 2018, 48(3): 299–304. http://www.cnki.com.cn/Article/CJFDTotal-JGHW201803006.htm

[39] 宋桂飞, 李良春, 夏福君, 等.激光清洗技术在弹药修理中的应用探索试验研究[J].激光与红外, 2017, 47(1): 29–31. http://d.wanfangdata.com.cn/Periodical/jgyhw201701005

Song G F, Li L C, Xia F J, et al. Application study on laser washing technology in ammunition repair[J]. Laser & Infrared, 2017, 47(1): 29–31. http://d.wanfangdata.com.cn/Periodical/jgyhw201701005

[40] 王曼曼, 张心明, 丁蕴丰.手持式激光清洗系统的研制[J].新型工业化, 2017, 7(12): 1–6. http://d.wanfangdata.com.cn/periodical/xxgyh201712001

Wang M M, Zhang X M, Ding Y F. Development of hand held laser cleaning system[J]. New Industrialization Straregy, 2017, 7(12): 1–6. http://d.wanfangdata.com.cn/periodical/xxgyh201712001

[41] 齐扬, 周伟强, 陈静, 等.激光清洗云冈石窟文物表面污染物的试验研究[J].安全与环境工程, 2015, 22(2): 32–38. http://www.cqvip.com/QK/90959A/20152/664440657.html

Qi Y, Zhou W Q, Chen J, et al. Laser cleaning of contaminants on the surface of Yungang grottoes[J]. Safety and Environmental Engineering, 2015, 22(2): 32–38. http://www.cqvip.com/QK/90959A/20152/664440657.html

[42] 张晓彤, 张鹏宇, 杨晨, 等.激光清洗技术在一件鎏金青铜文物保护修复中的应用[J].文物保护与考古科学, 2013, 25(3): 98–103. http://d.wanfangdata.com.cn/Periodical/wwbhykgkx201303015

Zhang X T, Zhang P Y, Yang C, et al. Laser cleaning technology in the conservation of gilt bronze[J]. Sciences of Conservation and Archaeology, 2013, 25(3): 98–103. http://d.wanfangdata.com.cn/Periodical/wwbhykgkx201303015

[43] 张力程, 周浩.激光清洗技术在一件汉代彩绘女陶俑保护修复中的应用[J].文物保护与考古科学, 2017, 29(2): 67–75. http://d.wanfangdata.com.cn/Periodical/wwbhykgkx201702010

Zhang L C, Zhou H. Restoration of a polychrome female pottery figurine from Han Dynasty using laser cleaning techniques[J]. Sciences of Conservation and Archaeology, 2017, 29(2): 67–75. http://d.wanfangdata.com.cn/Periodical/wwbhykgkx201702010

[44] 韩红敏, 韩建平, 宋可为, 等.铝合金的一种激光表面处理方法[J].固体火箭技术, 2017, 40(6): 776–779. http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201706019.htm

Han H M, Han J P, Song K W, et al. A method of laser purge aluminum alloy[J]. Journal of Solid Rocket Technology, 2017, 40(6): 776–779. http://www.cnki.com.cn/Article/CJFDTotal-GTHJ201706019.htm

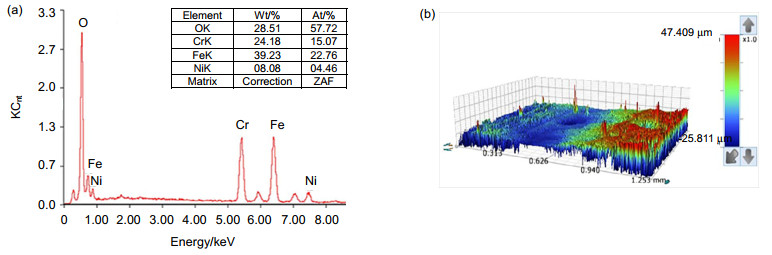

[45] 陈国星, 陆海峰, 赵滢, 等.激光功率对不锈钢表面清洗效果影响的研究[J].光电工程, 2017, 44(12): 1217–1224. doi: 10.3969/j.issn.1003-501X.2017.12.010

Chen G X, Lu H F, Zhao Y, et al. Effect of power on laser cleaning result of stainless steel surface[J]. Opto-Electronic Engineering, 2017, 44(12): 1217–1224. doi: 10.3969/j.issn.1003-501X.2017.12.010

[46] 刘伟嵬, 刘丽红, 章恒, 等.锂离子电池电极片的激光清洗理论与实验研究[J].清洗世界, 2016, 32(6): 17–23. http://qikan.cqvip.com/Qikan/Article/Detail?id=669413295

Liu W W, Liu L H, Zhang H, et al. Theoretical and experimental study on laser cleaning of cathode from lithium-ion batteries[J]. Cleaning World, 2016, 32(6): 17–23. http://qikan.cqvip.com/Qikan/Article/Detail?id=669413295

[47] 占小红, 范喜祥, 高川云, 等.脉冲激光清洗碳纤维增强树脂基复合材料表面研究[J].航空制造技术, 2017, 60(20): 38–42. http://d.old.wanfangdata.com.cn/Periodical_hkgyjs201720005.aspx

Zhan X H, Fan X X, Gao C Y, et al. Study on the surface of carbon fiber reinforced epoxy resin composites for pulse laser cleaning technology[J]. Aeronautical Manufacturing Technology, 2017, 60(20): 38–42. http://d.old.wanfangdata.com.cn/Periodical_hkgyjs201720005.aspx

[48] Yang G, Feng H X, Wang X L, et al. Research progress of plate heat exchanger[J]. Chemical Engineering & Equipment, 2019(5): 240–241, 74.

[49] 刘芸, 杨晓翔, 龚凌诸, 等. 基于模糊综合评价的锅炉汽包风险评估[J]. 石油化工设备, 2013, 42(3): 16–20. http://www.cqvip.com/QK/93632A/20131/44627517.html

Liu Y, Yang X X, Gong L Z, et al. Risk assessment for boiler drum on fuzzy comprehensive evaluation[J]. Petro-Chemical Equipment, 2013, 42(3): 16–20. http://www.cqvip.com/QK/93632A/20131/44627517.html

-

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: