-

摘要

激光冲击强化是一种利用激光诱导等离子体冲击波来提高材料疲劳寿命的新型表面改性技术,具有强化效果显著、可控性强、适应性好等优点,对提高结构可靠性和部件疲劳强度、延长材料使用寿命具有重要作用。近年来,该技术受到了广泛重视,得到了快速发展。本文简要介绍了激光冲击强化技术的基本原理、特点与应用领域;总结了国内外激光冲击强化技术的发展状况与研究成果;并针对国内外激光冲击强化技术的现状,提出了一些现在需要解决的强化工艺问题;最后对激光冲击强化技术的应用前景进行了展望。

Abstract

Laser shock processing is a new type of surface modification technology that can improve the fatigue life of materials by using laser-induced plasma shock waves. It has the advantages of significant strengthening effect, strong controllability and good adaptability. Laser shock processing plays an important role in improving the structural reliability, the fatigue strength of parts and the service life of materials. In recent years, the technology has received widespread attention and developed rapidly. This paper briefly introduces the basic principle, characteristics and application fields of laser shock processing, and summarizes the development and research results of laser shock processing. In view of the current situation of laser shock processing at home and abroad, some problems of the technology that need to be solved now are put forward. Finally, the application prospect of laser shock processing is forecasted.

-

Key words:

- laser shock processing /

- plasma /

- shock waves /

- fatigue life /

- surface strengthen

-

Overview

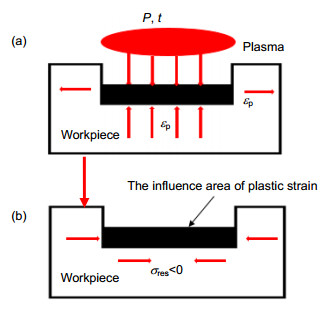

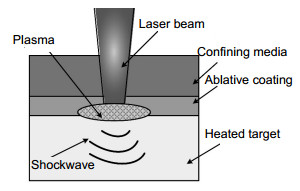

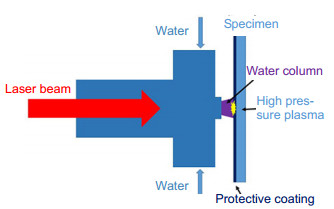

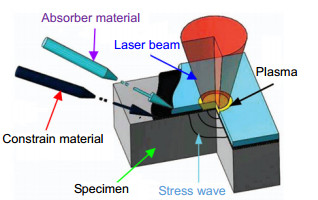

Overview: The fatigue properties of metal components are related to their surface integrity closely. In general, the components’ fatigue fracture, especially the high-cycle fatigue fracture is often due to the surface cracks, and the gradual expansion of the crack may leads to the overall destruction. In order to improve the structural reliability and extend the fatigue life without changing the properties of the matrix material, the surface strengthening technology has got more and more research and application internationally. Common surface strengthening techniques include shot peening, surface rolling, forging and extrusion, etc. Shot peening is a surface technology that uses the high-speed projectile to hit the material surface, which can produce Strain hardening layer and cause residual compressive stress in the surface. The compressive stress can cancel part of the working load (tensile stress), thereby enhancing the fatigue strength of the parts. Surface rolling can apply a certain amount of pressure to the surface of material by the rolling tools, and the local slight plastic deformation would occur in the surface of material, and improve the surface roughness and uniform the stress field distribution. Certainly, the technology of forging and the extrusion can introduce a certain amount of pressure in the surface of materials, and it can improve the mechanical properties and service life of materials too. With the development of high-end equipment such as aerospace, weapons, nuclear energy and transportation, the surface requirements of parts are becoming higher and higher. The traditional strengthening technique such as shot peening and surface rolling will difficult to meet the production requirements of high-performance equipment gradually. But the laser shock processing can solve these problems well. Laser shock processing is a new surface strengthening technology that can improve the fatigue life of materials by using laser-induced plasma shock waves. It has the advantages of significant strengthening effect, strong controllability and good adaptability. Laser shock processing plays an important role in improving the structural reliability, the fatigue strength of parts and the service life of materials. In recent years, laser shock processing has received widespread attention and developed rapidly. This paper briefly introduces the basic principle, characteristics and application fields of laser shock processing, and summarizes the development and research results of laser shock processing. In view of the current situation of laser shock processing at home and abroad, some problems of the technology that need to be solved now are put forward. Finally, the application prospect of laser shock processing is forecasted.

-

-

参考文献

[1] Alexander W O, Davies G J, Reynolds K A, et al. Essential Metallurgy for Engineers[M]. United Kingdom: Van Nostrand Reinhold, 1985.

[2] 曼森S S. 金属疲劳损伤: 机理、探测、预防和维修[M]. 陆索, 译. 北京: 国防工业出版社, 1976.

Manson S S. Metal Fatigue Damage[M]. Lu S, trans. Beijing: National Defense Industry Press, 1976.

[3] 徐滨士, 马世宁, 刘世参, 等.纳米表面工程[M].北京:中国化工出版社, 2000.

Xu B S, Ma S N, Liu S C, et al. Nano Surface Engineering[M]. Beijing: Chemical Industry Press, 2000.

[4] 李松夏, 乔红超, 赵吉宾, 等.激光冲击强化技术原理及研究发展[J].光电工程, 2017, 44(6): 569-576. http://www.oee.ac.cn/CN/abstract/abstract2014.shtml

Li S X, Qiao H C, Zhao J B, et al. Research and development of laser shock processing technology[J]. Opto-Electronic Engineering, 2017, 44(6): 569-576. http://www.oee.ac.cn/CN/abstract/abstract2014.shtml

[5] Singh G, Grandhi R V, Stargel D S. Modeling and parameter design of a laser shock peening process[J]. International Journal for Computational Methods in Engineering Science and Mechanics, 2011, 12(5): 233-253. doi: 10.1080/15502287.2010.542795

[6] 李应红.激光冲击强化理论与技术[M].北京:科学出版社, 2013.

Li Y H. Theory and Technology of Laser Shock Processing[M]. Beijing: Science Press, 2013.

[7] 李伟, 李应红, 何卫锋, 等.激光冲击强化技术的发展和应用[J].激光与光电子学进展, 2008, 45(12): 15-19. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jgdj200812029&dbname=CJFD&dbcode=CJFQ

Li W, Li Y H, He W F, et al. Development and application of Laser Shock Processing[J]. Laser & Optoelectronics Progress, 2008, 45(12): 15-19. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jgdj200812029&dbname=CJFD&dbcode=CJFQ

[8] 陆建, 倪晓武, 贺安之.激光与材料相互作用物理学[M].北京:机械工业出版社, 1996.

Lu J, Ni X W, He A Z. Laser and Material Interaction Physics[M]. Beijing: China Machine Press, 1996.

[9] Nalla R K, Altenberger I, Noster U, et al. On the influence of mechanical surface treatments—deep rolling and laser shock peening—on the fatigue behavior of Ti-6Al-4V at ambient and elevated temperatures[J]. Materials Science and Engineering: A, 2003, 355(1-2): 216-230. doi: 10.1016/S0921-5093(03)00069-8

[10] Pirri A N. Analytic solutions for laser-supported combustion wave ignition above surfaces[J]. AIAA Journal, 1977, 15(1): 83-91. doi: 10.2514/3.60605

[11] 邹世坤.激光冲击处理技术的最新发展[J].新技术新工艺, 2005(4): 44-46. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=xjxg200504018&dbname=CJFD&dbcode=CJFQ

Zou S K. The latest development of laser shock processing[J]. New Technology & New Process, 2005(44): 44-46. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=xjxg200504018&dbname=CJFD&dbcode=CJFQ

[12] Fabbro R, Peyre P, Berthe L, et al. Physics and applications of laser-shock processing[J]. Journal of Laser Applications, 1998, 10(6): 265-279. doi: 10.2351/1.521861

[13] 毕凤琴, 张春成, 李红翠, 等.激光冲击强化技术的发展及应用[J].兵器材料科学与工程, 2010, 33(1): 101-104. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bckg201001040&dbname=CJFD&dbcode=CJFQ

Bi F Q, Zhang C C, Li H C, et al. Development and application of laser shock processing[J]. Ordnance Material Science and Engineering, 2010, 33(1): 101-104. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bckg201001040&dbname=CJFD&dbcode=CJFQ

[14] 肖爱民, 杨继昌, 张永康.激光冲击强化原理及应用概述[J].电加工与模具, 2000(6): 7-10. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=djgu200006002&dbname=CJFD&dbcode=CJFQ

Xiao A M, Yang J C, Zhang Y K. Physical processes of Laser Shock processing and examples of application[J]. Electromachining & Mould, 2000(6): 7-10. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=djgu200006002&dbname=CJFD&dbcode=CJFQ

[15] 张宏, 邓琦林, 唐亚新, 等.激光冲击强化技术及其进展[J].航空工艺技术, 1997(1): 19-21. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj199701007&dbname=CJFD&dbcode=CJFQ

Zhang H, Deng Q L, Tang Y X, et al. Laser shock processing and its progress[J]. Aeronautical Manufacturing Technology, 1997(1): 19-21. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj199701007&dbname=CJFD&dbcode=CJFQ

[16] 丁阳喜, 周立志.激光表面处理技术的现状及发展[J].热加工工艺, 2007, 36(6): 69-72. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=sjgy200706023&dbname=CJFD&dbcode=CJFQ

Ding Y X, Zhou L Z. Status and development of laser surface treating[J]. Metal Hotworking Technology, 2007, 36(6): 69-72. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=sjgy200706023&dbname=CJFD&dbcode=CJFQ

[17] Montross C S, Wei T, Ye L, et al. Laser shock processing and its effects on microstructure and properties of metal alloys: a review[J]. International Journal of Fatigue, 2002, 24(10): 1021-1036. doi: 10.1016/S0142-1123(02)00022-1

[18] Askar'yan G A, Moroz E M. Pressure on evaporation of matter in a radiation beam[J]. Soviet Journal of Experimental and Theoretical Physics, 1963, 16: 1638-1639. http://adsabs.harvard.edu/abs/1963JETP...16.1638A

[19] 胡太友, 乔红超, 赵吉宾, 等.激光冲击强化设备的开发[J].光电工程, 2017, 44(7): 732-737. http://www.oee.ac.cn/CN/abstract/abstract2050.shtml

Hu T Y, Qiao H C, Zhao J B, et al. Development of laser shock peening equipment[J]. Opto-Electronic Engineering, 2017, 44(7): 732-737. http://www.oee.ac.cn/CN/abstract/abstract2050.shtml

[20] Fairand B P, Wilcox B A, Gallagher W J, et al. Laser shock-induced microstructural and mechanical property changes in 7075 aluminum[J]. Journal of Applied Physics, 1972, 43(9): 3893-3895. doi: 10.1063/1.1661837

[21] Fairand B P, Clauer A H. Laser generation of high‐amplitude stress waves in materials[J]. Journal of Applied Physics, 1979, 50(3): 1497-1502. doi: 10.1063/1.326137

[22] 高玉魁, 蒋聪盈.激光冲击强化研究现状与展望[J].航空制造技术, 2016(4): 16-20. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj201604003&dbname=CJFD&dbcode=CJFQ

Gao Y K, Jiang C Y. Review and prospect on laser shock peening[J]. Aeronautical Manufacturing Technology, 2016(4): 16-20. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj201604003&dbname=CJFD&dbcode=CJFQ

[23] Clauer A H, Fairand B P, Wilcox B A. Pulsed laser induced deformation in an Fe-3 Wt Pct Si alloy[J]. Metallurgical Transactions A, 1977, 8(1): 119-125. doi: 10.1007/BF02677273

[24] Universal Technology Corporation. High Cycle Fatigue (HCF) science and technology program 1997 annual report[R]. 1998.

[25] Universal Technology Corporation. High cycle fatigue science and technology program 1999 annual report[R]. Dayton, Oh: Universal Technology Corporation: Universal Technology Corporation, 2000.

[26] Universal Technology Corporation. High Cycle Fatigue (HCF) science and technology program 2000 annual report[R]. Dayton, Oh: Universal Technology Corporation, 2000.

[27] Universal Technology Corporation. High Cycle Fatigue (HCF) science and technology program, 2001 annual report[R]. Dayton, Oh: Universal Technology Corporation, 2002.

[28] Universal Technology Corporation. High Cycle Fatigue (HCF) Science and Technology Program 2002 Annual Report[R]. Dayton, Oh: Universal Technology Corporation, 2003.

[29] Bartsch T M. High Cycle Fatigue (HCF) science and technology program[M]//Nuclear Data in Science and Technology, International Atomic Energy Agency, 2002: 607-614.

[30] Peyre P, Fabbro R, Berthe L, et al. Laser shock processing of materials, physical processes involved and examples of applications[J]. Journal of Laser Applications, 1996, 8(3): 135-141. doi: 10.2351/1.4745414

[31] Zhang H, Yu C Y. Laser shock processing of 2024-T62 aluminum alloy[J]. Materials Science and Engineering: A, 1998, 257(2): 322-327. doi: 10.1016/S0921-5093(98)00793-X

[32] Ruschau J J, John R, Thompson S R, et al. Fatigue crack growth rate characteristics of laser shock peened Ti-6Al-4V[J]. Journal of Engineering Materials and Technology, 1999, 121(3): 321-329. doi: 10.1115/1.2812381

[33] Prevéy P S. The effect of cold work on the thermal stability of residual compression in surface enhanced IN718[C]// Proceedings of the 20th ASM Materials Solutions Conference & Exposition, 2000.

[34] See D W, Dulaney J L, Clauer A H, et al. The air force manufacturing technology laser peening initiative[J]. Surface Engineering, 2002, 18(1): 32-36. doi: 10.1179/026708401225001264

[35] Sano Y, Mukai N, Okazaki K, et al. Residual stress improvement in metal surface by underwater laser irradiation[J]. Nuclear Instruments and Methods in Physics Research Section B: Beam Interactions with Materials and Atoms, 1997, 121(1-4): 432-436. doi: 10.1016/S0168-583X(96)00551-4

[36] 乔红超, 赵吉宾, 陆莹.激光诱导冲击波应用技术研究现状[J].表面技术, 2016, 45(1): 1-6, 48. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmjs201601001&dbname=CJFD&dbcode=CJFQ

Qiao H C, Zhao J B, Lu Y. Current status of laser-induced shock wave application technology[J]. Surface Technology, 2006, 45(1): 1-6, 48. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmjs201601001&dbname=CJFD&dbcode=CJFQ

[37] Hashmi S, Batalha G F, Van Tyne C J, et al. Comprehensive Materials Processing[M]. Oxford: Elsevier, 2014.

[38] 苏纯, 周建忠, 孟宪凯, 等.温度辅助的激光冲击技术研究进展[J].表面技术, 2016, 45(10): 121-128. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmjs201610019&dbname=CJFD&dbcode=CJFQ

Su C, Zhou J Z, Meng X K, et al. Research progress of temperature-assisted laser shock technology[J]. Surface Technology, 2006, 45(10): 121-128. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmjs201610019&dbname=CJFD&dbcode=CJFQ

[39] Liao Y L, Ye C, Kim B J, et al. Nucleation of highly dense nanoscale precipitates based on warm laser shock peening[J]. Journal of Applied Physics, 2010, 108(6): 063518. doi: 10.1063/1.3481858

[40] Ye C, Liao Y L, Cheng G J. Warm laser shock peening driven nanostructures and their effects on fatigue performance in aluminum alloy 6160[J]. Advanced Engineering Materials, 2010, 12(4): 291-297. http://www.mendeley.com/research/warm-laser-shock-peening-driven-nanostructures-effects-fatigue-performance-aluminum-alloy-6160/

[41] Lin D, Suslov S, Ye C, et al. Laser assisted embedding of nanoparticles into metallic materials[J]. Applied Surface Science, 2012, 258(7): 2289-2296. doi: 10.1016/j.apsusc.2011.09.132

[42] Liao Y L, Suslov S, Ye C, et al. The mechanisms of thermal engineered laser shock peening for enhanced fatigue performance[J]. Acta Materialia, 2012, 60(13-14): 4997-5009. doi: 10.1016/j.actamat.2012.06.024

[43] Kalentics N, Boillat E, Peyre P, et al. Tailoring residual stress profile of Selective Laser Melted parts by Laser Shock Peening[J]. Additive Manufacturing, 2017, 16: 90-97. doi: 10.1016/j.addma.2017.05.008

[44] 刘志东, 杨怡生, 余承业.激光冲击强化改善金属疲劳特性的研究[J].航空工艺技术, 1992(5): 8-12. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj199205004&dbname=CJFD&dbcode=CJFQ

Liu Z D, Yang Y S, Yu C Y. Using laser shock processing to improve metal fatigue property[J]. Aeronautical Manufacturing Technology, 1992(5): 8-12. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=hkgj199205004&dbname=CJFD&dbcode=CJFQ

[45] 高建民.我国首台激光冲击强化装置问世[J].高技术通讯, 1996(9): 32. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gjsx609.010&dbname=CJFD&dbcode=CJFQ

Gao J M. Chinese first laser shock peening equipment is published[J]. High Technology Letters, 1996(6): 32. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=gjsx609.010&dbname=CJFD&dbcode=CJFQ

[46] 佚名.我国第一条激光冲击强化生产线建成[J].军民两用技术与产品, 2009(1): 29. http://www.cqvip.com/qk/92317A/200901/29204000.html

Anonymous. Chinese first laser shock peening production line is established[J]. Dual Use Technology & Products, 2009(1): 29. http://www.cqvip.com/qk/92317A/200901/29204000.html

[47] 乔红超, 高宇, 赵吉宾, 等.激光冲击强化技术的研究进展[J].中国有色金属学报, 2015, 25(7): 1744-1755. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=zyxz201507002&dbname=CJFD&dbcode=CJFQ

Qiao H C, Gao Y, Zhao J B, et al. Research process of laser peening technology[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1744-1755. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=zyxz201507002&dbname=CJFD&dbcode=CJFQ

[48] 中科院宁波材料技术与工程研究所.新一代激光冲击强化技术研究获得突破[J].表面工程与再制造, 2017, 17(1): 53. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmzx201701031&dbname=CJFD&dbcode=CJFQ

Ningbo Institute of Material Technology and Engineering, CAS. A new generation of laser shock peening technology get a breakthrough[J]. Surface Engineering & Remanufacturing, 2017, 17(1): 53. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=bmzx201701031&dbname=CJFD&dbcode=CJFQ

-

访问统计

E-mail Alert

E-mail Alert RSS

RSS

下载:

下载: